What tiles to take for porcelain tile. Video Description

Features of the choice of tile cutter for porcelain tile

When working with porcelain tiles, there is always a need to cut off the excess part of the tile or cut a hole under the outlet or switch. And when creating a panel, using this material, you certainly can not do without a special “cut”. A tile for porcelain tile performs the functions of tile processing and contributes to the creation of spectacular mosaic surfaces from pieces of cladding, cut in a special way. The use of the device is due to the developed design design project.

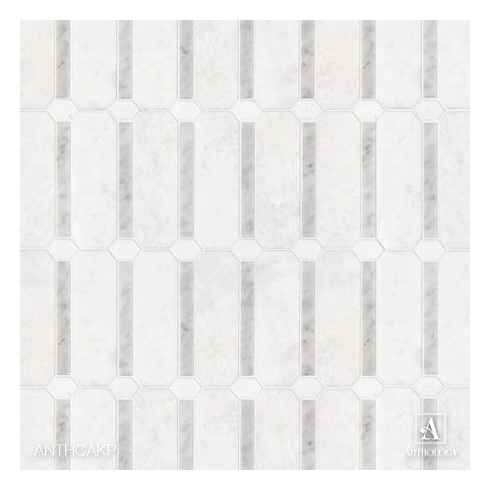

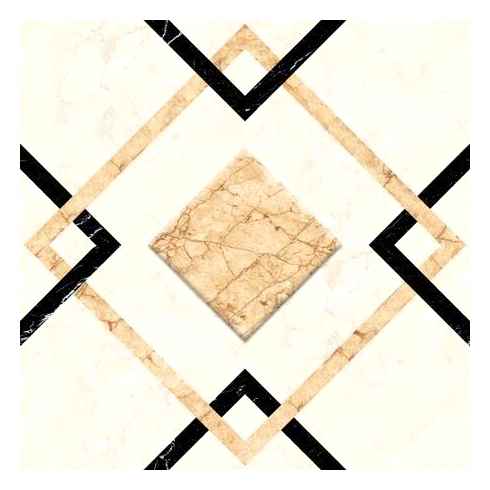

For example, when installing by the methods of straight or diagonal masonry, the tile cutting is used for direct cutting of the tiles, allowing to cut the material diagonally, cut off the excess plane, cut simple geometric shapes for decorating decorative elements.

Features of facing material

Crama border tiles in technical indicators are similar to natural stone. It is characterized by high strength, density and hardness. That is, unlike the glazed tiles, an inexpensive manual tile cutter, even from the rating, will not work to cut a porcelain tile. In the case of the latter, several nuances can be distinguished, which can adversely affect the planned work:

- The permissible thickness of porcelain tiles is 3-7 mm;

- The edges after the formation of a narrow strip have to be additionally polished;

- There is a probability of breaking the workpiece not on the intended line;

- The complexity of cutting the tiles diagonally;

- It is impossible to make cutouts on the entire plane.

Often, instead of a tile cutter for cutting porcelain tile, an angle grinding machine is used. But there are also disadvantages here. One of the main = formation of a large amount of dust. An alternative in both cases are electrical tiles. Let us consider in detail the principle of operation of the tools that are designed for cutting tiles.

Manual tile cutter

Such a tool is relevant to perform a small volume of facing work. He is in great demand among home masters who choose a tile cutter for short.Term use. This is justified by relatively low cost and simplicity of the device. Here the principle of operation is as follows:

- Markings are applied to the tile;

- The workpiece is laid on the platform of the tile cutter focusing on its longitudinal axis;

- With the help of a lever and carriage, the video rolls along the planned line;

- By the same mechanism, using the foot, pressing on the tile is carried out in order to break in the right place.

The principle of action is essentially similar to the work of glass cutter. A novice master can cope with such actions. The main thing is to choose the right tile, since not everyone is designed to cut high.Strength porcelain tile. If you need to additionally form a hole, then there are models with a second carriage that is equipped with a mechanism for rotating the crown.

By the type of device of the working part, three main types of tools are distinguished:

- Roller. Here, as a cutting element, a wheel of carbide steel acts as a cutting element.

- Bearing. Such a tile cut can work with tiles with a thickness of up to 15 mm. Bearings are located in the bushings that pass along the guides. Their function is to ensure smooth.

- Mechanical. This tile cutter is designed to work with tiles of various hardness.

Consider how to choose a manual tile cut in an inexpensive, but good: masters recommend paying attention to the following points:

It should be stiff and all.Metal, with reliably kept anti.Slip coating on the surface. There should also be rubberized pads from below, which will exclude the risk of floor damage. The thickness of the steel platform should be at least 3 mm, aluminum. From 5 mm.

The integrity and rigidity is also important here. For example, if a crossbar or tube to maintain a carriage is elastic, then it will be impossible to form a sufficiently deep groove to break out durable porcelain tiles in the right place.

This is an important point that is often overlooked by beginner builders. To obtain a qualitative result, it is necessary that the carriage moves smoothly with the same pressure along the entire length of the intended line. If the movement is intermittent, then the groove will turn out to be different depths. Because of this, the blanks break, as a rule, in pieces. Here it is impossible to predict on which side the tile will burst, since the paw exerts pressure on the sample on both sides of the strip the same.

One more point needs to be taken into account deciding which tiles of manual is better to choose. Most models are designed to work with tile samples in size up to 600 mm. There are options with a massive platform and additional supports on which you can lay a workpiece up to 1200 mm long. It is also important to pay attention to the permissible thickness of the facing material.

Electric tile cutter

Unlike manual tiles in electrical cutting elements, a metal disk is. For porcelain tiles, as a rule, circles are selected, the edges of which have diamond spraying. Thanks to him, tile cutting is carried out quickly and accurately.

Constructive performance of technology also differs. There is a small electric motor, which is mounted in a sealed box. Water is poured into the case for the duration of work. It plays the role of coolant for the disk, which allows you to cut the tile without a break to cool down the circle. Another option involves the implementation of dry cutting. There is a bed and frame, which acts as a guide for a mechanism with a circle.

When determining which tile cutter is better than manual or electric, you can pay attention to the advantages of the second that experienced craftsmen distinguish:

- The cutting process takes little time;

- It is possible to form strips with a width of less than 10 mm;

- The probability of obtaining defective segments is minimal;

- Due to the water cooler, a small amount of dust is released;

- There are models that allow you to cut the tile under a slope of 45 degrees.

Regarding the principle of operation, the equipment is divided into two types. In one cutting disc is fixed, so you have to move the tile yourself on the platform. In other tiles, the cut.Out circle shifts. Working such a technique is safer for the operator. In any case, the result is more dependent on the technical condition of the cutting disk and the cleanliness of the support for porcelain tiles of the site.

How to cut tiles with manual tile cutter?

Before you start using a manual tile, it is necessary to carry out a number of preparatory work that have a direct impact on the final result.

Preparation of tools for work

- Inspection of the product for any damage. View the video. There should be no curvature, Zazubrin. Otherwise you have to replace it with a new.

- Pay attention, cleaning the device, not forgetting to wipe the guides and the surface of the bed.

- All nuts and bolts need to be pulled up.

- Lubricate the carriage with oil if problems are observed with its movement.

Marking

To work at this stage, you will need a pencil/marker, with which you need to apply a fault line. In the future, the tool will need to be fixed so that the cutting element is located exactly above the drawn line.

Tile cutting technology

So, how to cut tiles with a tile cutter correctly? To obtain an even cut, follow the technology:

- For 1-1.5 hours, cover the tile with a wet cloth or soak in water. Thus, it will be possible to make ceramics more malleable and avoid its crushing.

- Tile fixation. There are models of tile cutters that have seizures. Take care of the immobility of the dick. If there is no such element, you need to support the material with one hand. The cutting element should be exactly over the future fault. If the dick is large, you can put something under its edges so that it does not stagger.

- The cutter should be at the very beginning, on the edge of the tile (where the line is drawn).

- In the process of cutting, make efforts so that later it is easier to break the dick into two parts.

Attention! If the furrow turned out to be shallow, you do not need to be repeatedly passed with a tile cutter. Otherwise, it is likely that the edges will begin to crumble and turn out to be inaccurate.

Fault

After cutting carefully, slowly, click on the lever. The tile should break through exactly along the line.

Round and curly cut

Often the question arises, than cutting ceramic tiles, if you need to not reduce its length/width/divide by diagonally or at an angle, and make a round hole.

For these purposes, a coronet drill or, otherwise, a diamond crown is best suited. This issue is considered here in more detail here. It is worth noting that the presence of a more rational version of drilling on a tile or separately, but for the sake of one hole, buy expensive drills on a tile and porcelain tile, of course, you should not. And

To work with the ballerinka, and for drilling it is advisable to tap the future center of the hole. Successfully removes the problem of vibration, work with tiles laid on 3 5 mm layer of water in a form coinciding with its dimensions.

The combination of several sawdust, straight and round will help to make a more complex neckline. If the transitions of the curve along which the incision is made is quite smoothed, or the broken line is used, it is convenient to use a grinder and an angle grinding machine with an appropriate disk.

Best manual/mechanical tiles

Irwin Duplex T005616

This mechanical tile cutter from IRWIN is able to cut ceramic tiles quite high quality. The working part was made of high strength metal. Its coating reliably protects the device from corrosion. The design of the device has a device for adjusting the angle of the saw.

- Rubber coating. Tiles during the cut will not slip;

- The handle has a convenient shape and a rubber lining. It is more comfortable to work;

- The presence of holes in the case will fasten the tool on a workbench or table.

- Easy to regulate;

- The metal design is made quite durable;

- Can be installed in a horizontal or vertical position;

- The service life is considerable, but with a neat circulation.

Bars 87590

A manual tool in the form of a monorail for processing porcelain tile and tile up to 60 cm long. When cutting the material, the cut depth is in the range of 5-14 mm. On the case there is a ruler and an angular (both metallic), with which you can mark a workpiece for a cut at an acute angle.

For a carriage and rail, very high.Quality material was used. The carriage is easily moved. For this it is used by as many as nine bearings, and four of them are adjustable.

MTX 87689

One of the latest MTX models or, as it is also called, is Matrix. It is quite interesting and even unusual in something.

Cleaning Tile : How to Clean Grout Haze on Porcelain Tiles

It’s easy to work with her. You only need a couple of minutes of observation of people. The force of pressing the workpiece can be adjusted. You only need to tighten the special bolts harder.

The maximum stability during cutting is provided by the handle with the lining, and the coating of the device will prevent sliding of the carriage during the holiday prevents a slippage of the carriage during operation.

Bed. From aluminum, which is considered durable and at the same time quite easy. The choice of this metal greatly affects the mobility of the entire tool.

FIT 16460

Professional tiles of manual type. The design allows you to handle any tile, starting with the softest and ending with hard tiles. Wall or floor. This is another question. This model has a fairly convenient handle. The perfect grip is provided.

A clip with diameter 2 is used as a cutting element.2 cm. It is sharp enough to cut the tiles.

It is worth noting the presence of an enhanced platform, which contributes to the greater smoothness and the accuracy of the cut.

- Simple design for use;

- Strong frame;

- Good cutting video;

- The carriage has a rather smooth move;

- Compactness.

Bosch PTC 640

Compact professional device for cutting facing tiles and marble, as well as granite and natural stone. Such a device can offer the user not only high strength, but also good performance.

The tool does work in two stages. Cutting and breaking. Bottom line. High.Quality finished material. The line can be found in the kit. It will make the cutting process more accurate.

- Quite a high.Quality assembly;

- High cut accuracy;

- Convenience of carrying;

- A sufficiently long service life;

- Simplicity of use;

- Easy and compactness.

Battipav Basic Plus 60

A universal model that is suitable not only to professionals, but also for an amateur. She receives “bronze”. Due to its design, the device can cut the usual and hardened (past two.Time firing) tiles for subsequent use. You can configure the angle of inclination up to 45 degrees.

As a cutting tool, this tile cutter is a video with a diameter of 1.5 cm, which, when pressed on the handle, is set in motion. It is made non.Slip to make it easier to work with it.

The kit has a square with which the quality of work with tiles increases.

- High strength materials;

- Convenience and simplicity;

- An intuitive process of cutting material;

- Long service life;

- A sharp cutting video.

Rubi Speed-62 n

“Silver” receives a universal manual tile cutter of RUBI. The model of the Speed series is widely used by professionals and lovers in cutting various types of ceramics. True, it is more often used to cut tiles and destroyed gres.

Steel guides with a chrome coating will provide an ideal vision of the marking line when cutting material. Side supports are made of slightly simpler material. Aluminum. They will provide a more accurate incision in relation to large.Large workpieces.

MONTOLIT MASTERPIUMA 63P3

“Gold” gets the manual tile of Montolit, which is used by professionals and fans for cutting ceramic tiles and ceramic border guards. This tool is also suitable for cutting glass mosaics and glazed ceramics.

The cutting device turned out to be extremely simple, and control is intuitively understandable. For all simplicity, the tile cutting offers the user a rather high accuracy and a greater depth of cutting of the material, the width of which reaches 630 mm.

The handle is specially made large so that the work is comfortable, comfortable and does not spend a lot of effort from a common person.

How To Set Out & Fix Down Large Floor Tiles. Tile Mountain

The case itself turned out to be not only durable, but also quite light, which makes the device more mobile. Rubber legs prevent the occurrence of problems with equipment stability.

In this model, you can see not only a rotary angler with fixation and degrees, a rotary graduated angler with fixation, but also a device, the purpose of which is to lubricate the rollers in the apparatus. It is also worth highlighting the support of large tiles on the sides, which is sometimes important.

Submersible saws or parquet

Today on the market you can find a large number of parking lots, but we recommend that you consider the machines with water supply to the cut zone. I drank these tiles clean, and the dust during operation is at least, the truth is a drawback. The “sludge” that appeared during work, you need to collect somewhere. Therefore, when working at the facility, you will also need a vacuum cleaner for such a parquet for wet cleaning.

Also, when choosing a saw, it is worth giving preference to a car with the possibility of saw at 45 degrees.

Tiles for a beginner

Teling cutters produced today are divided into amateur and professional. The first includes inexpensive modifications that are not able to withstand a long workload.

The best hand tiles

A selection of manual mechanical tiles, different in both price and characteristics that professionals and amateurs prefer preference to independent repair of the house.

Zubble 33193 80

A mechanical monorail tool that is suitable for both tile cutting and porcelain tile with a thickness of 5 to 16 mm, including at an angle. This is possible thanks to a cutting roller with a diameter of 22 mm and a landing hole of 6 mm.

Tool from the domestic manufacturer. The special form of the guide provides the stiffness of the structure necessary for cutting porcelain tile, and the presence of bearings in the design. Smooth and ease of the cutting stroke.It comes complete with a cover for carrying and storage.

Encor 3660

Mechanical dual.Roller model designed for cutting ceramic tiles. A cutting video with a diameter of 15 mm and a thickness of 1.5 mm with a 6 mm landing hole is able to make an incision in a tile up to 6 mm.

MONTOLIT MASTERPIUMA 63P3

Mechanical monorail tile cutter with two millimeter rulers and lateral stops.

Professional tool from Italian manufacturer.

Rubi Star 61

Mechanical dual.Ruble tile cutter with lateral supports. Designed for tiles. The presence of interchangeable rollers from 6 to 10 mm, as well as a winning roller 6 mm, allows you to achieve a quality result. Maximum cutting length. 630 mm.

Bieber 55521

Manual tiles made of high.Quality steel in the form of a pencil with a brokenter. Used for small cutting tiles. Suitable for both tiles and glass. Approximate price. 100 rubles.

An indispensable assistant to many finishes in terms of pruning “in place”.

Bars 87590

Mechanical monorail tile cutter with corner stops. A cutting video with a diameter of 22 mm with a 6 mm landing hole allows you to cut material up to 14 mm thick.

How to choose manual tile cutter

Когда человек разбирается в характеристиках плиткореза, ему проще подобрать инструмент для выполнения определенных задач. Manual models are characterized by a simple device. They consist of a bed, on which guide elements are securely fixed. A carriage with a cutter moves along them.

All manual tile cutters have a similar main device

Stanin

The element is a metal platform on which the working nodes are fixed. It should be reliable, not vibrate. Stanin’s stiffness indicates the first sign of good quality of the tool. If the base is vibrated during cutting, the tile will split.

The length of the platform

Carrying out manual tile cutters, this parameter is paid attention to first of all. It depends on the length of the bed, what size the tile can be cut. It is optimal not to save, but to acquire a long tool. On it you can cut small.Sized wall tiles and large floor tiles.

The smoothness of the carriage

Manual models come with and without bearings. The first tool is different in the smooth course of the carriage. The cut is even without gaps and double lines. The absence of bearings worsens the smoothness of the move. However, many owners buy such tiles due to budget value. You can only check it in work. A couple of tiles are cut for this. The carriage should slide well along the guides, and the workpiece breaks exactly along the cutting line.

Advice! It is better to fork out on an expensive hand.Made tool with bearings. In the future, he pays off, maybe he will come in handy for hired work.

Cutter

The cutting element of manual tile cutter is the video. It is made of carbide steel. Over time, it is blunting. You can’t sharpen the video. As it is wear, they just change it.

Additional elements

Manufacturers equip different models with rotary rulers, adjusting elements of adjustment according to the thickness of the cut material. All these functions improve the quality of the cut, but such tiles are expensive.

The video has an example of a manual tile cutter:

TOP-10 rating according to KP

This device belongs to the class of rail. Russian brand, however, make a tile cutter in China. Designed for cutting tiles, including large squares. The bed is made in a traditional form factor, made of aluminum alloy. This made it possible to slightly reduce the weight of the tool, but it is still heavy. Exceeds seven kilos. A special coating is applied to the rail, which increases the reliability of the clutch of the rail and the ball mechanism. Buyers of this tile cutter mark a reliable grip. On the handle there is a lining in the shape of a palm, due to which a confident grip is provided. Regarding the strength of the tile cutters nodes, we did not find any complaints in the process of preparing the review. The model has an I.Beam rail, which is a guide rail. The carriage clamps it on both sides and moves with a ball.Bearing.

Characteristics: The length of the supporting surface is 600 mm, weight 7.35 kg

TOP-15 of the best tile cutters: Rating 2021-2022 What kind of electric with water cooling

Today’s rating of the Bulgarians on our Tekhnik portal.TOP is the best way to quickly choose the right model.

For quick navigation, we divided the rating into categories:

Laying of ceramic tiles is not complete without the use of tile cutter.

This is a special tool with which the material can be cut evenly and give it almost any form.

Correctly selected tile cutter will not only facilitate the work, but will also last many years.

When selecting a tool, several criteria are taken into account. For example, for infrequent home use, a manual model is enough, and for professional purposes you will have to buy several types of tiles for cutting tiles of different lengths and thicknesses.

Attention is also paid to the power of the tool and its specialization, because for different types of tiles their tools are provided.

An article will help to buy a suitable tool that provides tips for choosing a device and a rating of the best tile cutters according to the 2021-2022 version in price/quality ratio.

Types of tiles: which preference to give?

Manual or electric tiles for porcelain tiles can be used for cutting. They have certain differences both in the design and, in the principle of working with the material. However, the question of which tiles to choose for porcelain tiles is always solved by the master that performs work on the surface cladding.

With the help of manual equipment, the tile is usually cut with a thickness of not more than 15 mm. Such material is usually used for wall cladding. Electric tiles can work with tiles of a larger thickness used to facing floor surfaces.

What else can be cut porcelain?

The use of tile cutter, manual or electric is not the only option to cut porcelain tiles. Trying to find how to saw porcelain tiles, do not forget about an ordinary grinder. No additional costs and preparation are required to perform such cutting.

True, the quality of cutting is much worse than when using a special tool, chips and irregularities appear on the edges, which, by the way, can be further fixed with grinding with the same grinder.

Sometimes, when laying porcelain tiles, there is a need for specific types of cutting, for example, when laying mosaic from porcelain tiles, using high thickness plates and cutting along a complex contour (curly cutting). In this case, you can resort to the help of special organizations providing services for cutting porcelain tiles. They use special equipment capable of carrying out hydro.Carbonated or laser cutting.

The services of such companies can be used if you need to cut off only a few pieces of tiles. But if you have a fairly large amount of work and the usual tile is laid, then it is best to buy a machine for cutting porcelain tiles, its price is quite affordable and makes up a small part compared to the total cost of performing cladding porcelain tiles.

For this, both a special tool is used. Tile cutters, manual and electric, as well as a regular grinder with a set of disks. If necessary, perform art cutting, you can contact an organization providing appropriate services.

What are the best tiles

Fubag FB 350. This electrical tiles has a pendulum type. Its carriage is mobile, not fixed.

- The manufacturer placed a saw disc from above.

- It is noteworthy that the working area can rotate 45 degrees.

- There is a pump in the kit with the device, thanks to which you can provide water cooling.

- Experts praised this tile cutter.

DIAM SPMAX-250/1.5

This tile cutter differs from the previous model with a weaker motor and a smaller disk diameter. Therefore, the depth of cut in the machine is 60 mm. Despite this, experts consider the tile cutter effective when cutting, since it is able to turn 45 degrees.

In addition to tiles, the master will be able to cut stone and porcelain tiles. And all this for an adequate price. The only negative. You need to regularly clean the pump and use only clean water for cooling.

Helmut FS230H

The manufacturer tried to make the design of the machine as convenient as possible. The tile cutter has comfortable handles and folding supports. Unlike previous models, a tile cutter from a German manufacturer weighs much less (55 kg), while he has a strong base.

The quality of the cut depends on the basis, since it does not allow it to spoil its vibrations.

- Sawed here is possible by 45 mm. If you turn the head by 45 degrees, then the cut depth is reduced by 5 mm.

- Due to the fact that such machines are produced in China, they have a low price than attract Russian users.

As in previous devices, there is a minus here. It consists in insufficient calibration of the device from the factory. Therefore, before starting to work, you need to calibrate the device.

Elitech PE 1000/92p

This machine was created for professionals. Its power is 1000 watts. Rotation speed. 2950 rpm. The manufacturer equipped the table with a rubber coating that does not allow tiles to slide during cutting.

There is also a convenient design: there are handles and wheels that can be folded. Here the maximum depth of drank less than previous machines and is 36 mm.

Those who have already managed to use the device note a weak paintwork. The drain is also inconveniently made here.

Dewalt DWC410

This device is very compact. Its weight is only 3 kg. T.To. This is a light model, it does not have a table, so the master will have to equip it himself.

- Water cooling is supplied through a tube.

- Despite the small dimensions, the motor here is very powerful (1300 W), and the speed speed is even higher than that of previous tiles.

- It is 13 thousand revolutions per minute.

- Drink depth can reach 34 mm.

Russian users emphasize that the device is effective, but using it is inconvenient.

Caliber PLE-200/1000

This is also a sufficiently mobile device, but its weight is already 12 kg. Immediately it is worth highlighting the lack of a too smooth table, which is why the tile will slide during cutting.

- Power 1000 W, drive rotation occurs at a speed of 3000 rpm.

- The device has built a special line, which allows you to make a cut as accurately as possible.

- The disk is also available for 45 degrees. Another drawback is a crooked table.

Makita CC301DWAE

This is a battery tile. Its weight is extremely small (1.8 kg). The device works from the battery 2Ah. The manufacturer also provides customers with charging, a spare battery, water tank and a diamond disk with a key.

- Here a very small depth of drank (about 26 mm). Also here, of course, there is no table.

- Over, the manufacturer did not provide for the presence of a pallet for cold water.

- It is impossible not to note the extremely small disk diameter (85 mm).

- And the working hours of batteries are very meager. It will be enough for cutting several tiles.

Helmut FS 200

Brand’s homeland-Germany, producing country-China.

The desktop is characterized by a large size, which allows you to cut the tile up to 72 cm. The depth of the cut. 3 cm.

The engine rotates 2950 times per minute, power 800 watts. There is a water cooling system.

There is an additional shelf to increase the workplace.

- The manufacturer gives a guarantee of 12 months;

- Economical;

- Takes up little space;

- Almost inaudible work;

- It copes with the stone.

Selection criteria. Appearance and compactness, or professional device

The acquisition of a tool is always a crucial moment in the life of the master, whether he is engaged in the repair of his own bathroom or constantly works with tiles. Titting cutter is a collective name for several types of tools, which can only cut the tiles in common. If this refers to a simple tile for kitchen cladding, you can do it easier to a tool. It will still be in the home pantry for most of the time. Professional tile cutter is capable of cutting porcelain tiles, clinker and even plates of natural stone. Granite and marble on his teeth, but he is not suitable for glass cutting. This is just a common misconception that is broken by many solid tools.

Thinking which tile cutter is better to buy, the amateur believes that they differ only in cost and variations of appearance. After all, in each device there is a bed, guiding a lever or handle, a carriage. Only in stationary options, additional functionality is even visually determined and auxiliary tools and mechanisms can be viewed.

The main classification

Analysis of consumer demand, a rating for the already coming, and the past part of the 2021 path, is composed of tools with a high sales rating. But on the top 10, far from the best product samples, but models that are in demand due to cost or unfair advertising can get on this basis. At the same time, you can find not much more expensive options that have undoubted advantages over the chosen customers. The proposals market is huge, diverse, but sometimes the purchase does not have the expected bonuses, or quickly breaks. All this is that the choice was made rash. Find out the nuances and subtleties, You can turn to expensive models from a brand manufacturer, having viewed the best rating, compiled according to information portals, which are given by tips and write professional consultants.

The main differentiation occurs according to the type of device, its dimensions or compactness, convenience of transportation or stationary installation.

Mobile and transference

Differ in size convenient for carrying or transportation. Sometimes there is a bed in the kit, but for the most part they can be installed on any hard surface, or even hold in the hands. The desktop tile cutting is different in demand, because some are quite suitable for both the amateur and the professional:

By mobile tile cutter, sometimes also means a carrier-pencil with a glass cutter and shoulder blades to break off a cut. Judging by a cost of 100 rubles, this is not the tool that is suitable for existing.

Tiles-tiles-only to perform non-standard recesses. It is good to have it in professional tools, but this is not the main device for multiple cutting.

Mini-springs, not exceeding 4 kg by weight, mechanical or electric-this is just a convenient hilt equipped with a cutting surface. The best manual tiles are determined by weight and convenience, duration of the cutting surface. But the optimal option is an electric stabbing cutter, which is able to quickly cut out the earthenica through the electric motor through. The best electric tile cut can replace the circular saw in manual version. In this case, you need to choose a model with water cooling, because without it the device quickly overheats. And the cost of such a device is sometimes at the level of a professional stationary.

Desktop

This is a real cutting machine, with a removable bed or fixed, with the upper or lower disk feed, for dry cutting, where air serves as a cooler, or water cooling. Fluid supply is carried out depending on the supply of disk. And such a stationary model with water cooling and high power is the best tile for porcelain tile. Because this is an optimal model that is suitable for prolonged performance of production processes, can cut a non.Standard thickness and parameters in length. Everything that is required for this is to monitor the level of water in a separate tank.

Tile Floor 101 | Step by Step How to Install Tile for the First Time

To decide on the choice of the model, you just need to know for what needs it is bought. If a small area is planned, you can use the handle. If partial repair, then there is enough pencil. For decoration of their own home, they usually purchase a stationary or desktop tile cutter, but not very large dimensions. It is better for a professional to immediately purchase a stationary tool. It is expensive, but quickly pays for itself, allowing you to freely produce a large amount of work and save time without spending special physical efforts.

This rating is compiled taking into account several important points at once. Including the presence of cooling and the test energy, weight and size, the ability to process a certain material or wide orientation, quality of manufacturing materials, simplicity or complexity with control. And only after all these criteria are determined, to choose by cost. The best models are almost autonomous. The operator only needs to monitor the cycle or do some actions without any.

Little tricks

All methods are not exhausted by these two ways. With their help, you can get an acceptable result of any sections at home. Round holes in the material are made by a conventional tool without special nuances: drill with solid.Melodious spraying, ballerinas, crowns. The only difference is that due to the hardness of the material, the cutting tool will fail faster.

To solve the tile laying problem, you can use the complex approach:

- The most easily tile is cut with a manual tile cutter. The main mass of tiles is recommended to cut it;

- Tiles with cut faces, closed with skirting boards or overlays. In this case, it will be enough to use manual tile cutter or grinder (in limited cases);

- There are little tiles with an accurate fitting. Adjust with grinding;

- Put all the whole tiles. Depending on the existing tool, fit the tiles that are closed with skirting boards and overlays. The remaining elements are accurately measured and mark on the tile. Either rent a professional tile cutter, or take it to the nearest construction company with such equipment and cut.

Advice! If you need repair masters, there is a very convenient service for their selection. Just send in the form below a detailed description of the works that need to be completed and offers will come to you with with from construction brigades and firms. You can see reviews about each of them and photographs with work examples. It does not oblige it for free. Good advertising is the most readable