Which Disc To Cut The Laminate Angle Grinder

Combined

Combination wheels combine dry and wet cutting capabilities. This nozzle is a cross between solid and segmented discs. In terms of cut quality, it is inferior to solid modifications, but wins in segmented ones. As for the time of continuous work, it requires breaks more often than segment, but less often than continuous.

It is forbidden to apply water cooling to the combination disc. It does not withstand temperature changes, it expands unevenly under the influence of liquid, which is fraught with rupture.

Getting rid of dust

One of the drawbacks of the angle grinder is the large amount of dust generated during the sawing process. Here are some “life hacks” to help reduce dust:

- DO NOT cut through the full thickness of the tiles. just make a small groove and then just break the tiles along the mowing line of the cut.

- Use wet cutting or water cooling to keep debris from flying.

- Get a vacuum cleaner designed for construction needs.

You can use a vacuum cleaner without an assistant. The masters propose to build an impromptu hood from a container and a vacuum cleaner:

- Cut off the top of the plastic canister.

- Cut a round hole in the side for the vacuum cleaner hose.

- Place workpiece and angle grinder over the container.

- Switch on the vacuum cleaner and cut over the hood.

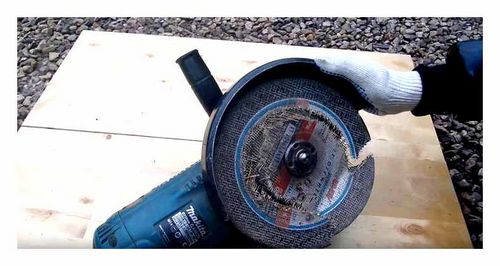

Segmented dry cutters

In segmented dry cutters, functional slots are provided along the perimeter, directed from the cutting edge to the center hole. Thanks to the radial cut, free expansion is provided. Heat the metal and more efficient heat dissipation by air cooling. This allows for a longer continuous rotation time. the segmented angle grinder can work for 1-1.5 minutes with a 20-second pause.

How to choose the right drive?

Depending on the disc modification, the angle grinder is capable of processing a wide variety of materials. metals, wood, porcelain stoneware, reinforced concrete, natural stone, etc.

Stone discs

Discs made of stone have only one clear advantage. affordable cost. But the disadvantages of this type of attachments are much more:

- Short service life;

- Fast wear;

- Large cutting thickness.

Since it is impossible to cut tiles with stone discs, a lot of dust is generated during the work. The nozzle creates a number of restrictions in processing. it is used mainly for making simple straight cuts. But for thinner and curly sawing, such discs are not suitable.

What determines the price of a circle?

Replaceable elements designed for processing hard materials, as a rule, are diamond-coated, which gives the cutting edge extra strength. It is the diamond coating that significantly increases the cost of nozzle wheels. But they are also the strongest and most durable, easily coping with difficult processing tasks.

Professional wheels for cutting with a diameter from 125 mm to 350 mm are also distinguished by a high cost. They are distinguished by their maximum durability, excellent spraying and cutting quality, even with regular use. Such attachments can be used to cut Not only tiles, but also marble, granite massifs and even reinforced concrete.

Tile cutting disc

Experienced tilers claim that the most convenient and efficient tile trimmer is an angle grinder, popularly referred to as an angle grinder. The main functional load in the unit falls on the replaceable cutting element, which acts as a disc of a given diameter and modification. How to choose the right disc for cutting tiles, what determines the price of the part, and how to work with the cutting tool correctly.

Fine work disc

For those tile elements where you need to achieve high accuracy and a certain cut configuration, it is recommended to choose a disc more carefully. It is better to use a circle of small thickness. about 1.5 mm. It will facilitate manipulation with an angle grinder, and will not make a wide cut and will NOT damage fragile tiles.

The result of the work largely depends on the cutting technique. To create oval shapes, the angle grinder makes short cuts tangentially to the outer contour, trying to cut off excess areas.

Steel wheels

Blades made of steel form a large product group, which includes wheels for dry and wet cutting, as well as combined models. Steel discs are very tough and durable, and diamond-coated makes them suitable for the hardest materials.

Diamond grit is applied by the manufacturer in three methods:

- Silver solder is the cheapest product suitable for household use. Potential service life is low due to the loss of strength of the solder when heated;

- Laser brazed. heavy-duty high-end wheels used on an industrial scale. They perfectly cope with the processing of workpieces of any strength;

- Geometric closure. diamond chips are embedded in the surface during the heating of the disc edge with electricity. They belong to the middle price segment, they serve for a long time, which makes it possible to recommend them for processing large volumes of tiles.

Cutting

After the concrete angle grinder is ready, you can start working:

-

First of all, you need a tent fishing line, along which the cut will be made.

It is better to fix wood blocks along the strip, which will make the cut strips even.

Note! Before starting work, it is necessary to protect the respiratory organs respirator.

In addition, other personal protective equipment should be used. glasses and gloves.

Here, perhaps, is the whole annotation on the implementation of this work.

Advantages and disadvantages of different cutting wheels

Abrasive discs are affordable, consistently available in a wide variety, and generally useful.

The drawback is rapid wear, accompanied by the emission of a sheaf of spark during operation.

It’s not enough that it’s dirty, you can also start a fire.

The processing of the alloy is accompanied by a corresponding smell, which does NOT fade for a long time. All this limits the use of the angle grinder in room criteria.

Diamond Wheels Actually “do not spark “when working, cutting the alloy is NOT accompanied by a powerful smell. There are two shortcomings:

- Diamond wheels are afraid of overheating, so pauses should be made during work. When using a non-segmented circle, liquid cooling is indispensable;

- The high cost often guides the buyer in favor of cheap abrasive discs.

How to choose a diamond blade for your angle grinder

When choosing a diamond blade, pay attention to the type. For which the disc is intended, on its size, bore diameter and disc rotation speed.

Alloy discs are the most popular angle grinder accessory. What will pay attention to when choosing?

Despite the fact that the real name “angle grinder” is an angle grinder (angle grinder), the main purpose of this popular tool is cutting in.

Everyone can imagine how much effort it took to cut an iron corner or a water pipe using an alloy hacksaw. Cutting disc mounted on an angle grinder will handle this job for a few seconds.

The angle grinder is a versatile tool that allows you to do the following main types of work:

- Cutting alloy, stone and the rest of the hard in;

- Grinding in all its forms, from sanding to mirror polishing;

- Peeling off paint, glue and corrosion.

For THESE works, different attachments (discs) are used.

Various attachments for angle grinder

The most popular are cutting discs. With their help, an angle grinder can be cut, molded or nesting In fact, at least there are such types of work that without the introduction of an angle grinder is unrealistic.

For example, they drank a square hole for ventilation in an iron garage door. Obviously, in addition to the specification for various types of processed surfaces, the discs have mechanical parameters.

Description of the technical features of the cutting wheel

The main indicator is the size of the disk. He describes the main abilities, in particular the depth of cut. But large diameter is NOT always a boon.

Firstly, to use it, you need the largest angle grinder.

At the same time, the most massive angle grinder is needed NOT only to ensure the rim diameter of the disc. To unwind a cutter 230 mm in diameter, motor power 0.75. 1 kW will not be enough.

Secondly, the huge dimensions need space. Agree, cutting off the rusted stud of the exhaust manifold under the bottom of your car is much easier using a small-sized angle grinder with a small disc diameter. Almost all home professionals DO NOT discard half-cut discs just for such “jewelry” work.

Another example of using a small diameter. Cutting reinforcement from a reinforced concrete wall when installing a switch or a block of automatic machines for electricity meters.

But spraying a corner of the “eighty” for the construction of a fence or a shed in the yard, it will turn out only with a disc of 150 mm.

Featured: variable speed angle grinder: power tool capabilities

Grinding and polishing models

For an angle grinder, a huge variety of consumables are produced, allowing grinding and polishing different surfaces.

By the type of coating used, discs are divided into:

- With sandpaper.

- Spongy.

- Felted.

- Cloth.

In addition to our own sanding coating, together with almost all replaceable ones, we need to use fine abrasive pastes.

Coarse grinding of the surface is done with fine abrasive grinding wheels.

Final polishing is carried out with a cloth or felt attachment.

Disk selection

When choosing a disc, it should be borne in mind that the segments can be attached to the canvas in 2 ways:

-

Solder with silver.

These blades are widely used for wet cutting.

In addition, when choosing a disc, you need to make sure that its diameter and mounting hole match the technical specifications of the angle grinder. Also, the principal moment is the highest speed. It is better that this indicator of the disc was higher, the highest rotational speed that an angle grinder can provide.

After all of the above characteristics are determined, you can choose the best type of tool, which will ensure the highest work efficiency.

segmented concrete angle grinder

Working principle of diamond cutting disc

Most diamond discs are used on angle grinders up to 12,000 rpm.

The greatest number of revolutions that the favorite wheels can withstand is 13,900 rpm, but there are not very many tools that can develop them when cutting.

Only the diamond itself is in contact with the surface to be processed. it protrudes above the surface of the rim and, when rotating, abrades into small dust. The multi-layer structure of the cutting edge ensures constant readiness of the disc for work. abraded or ejected diamonds are replaced by other diamonds, which are located in the lowest layer of the rim.

The durability of the wheel and the efficiency of its penetration depend on the size of the diamonds.

Large ones provide work efficiency, but wear quickly, small ones cut Extremely accurately, but slower, their service life is 25. 30% longer than in tools with large fractions of crystals.

Varieties of diamond discs

Diamond cutting discs have certain differences in design and manufacturing technology.

Design of cutting diamond discs

Structurally, a diamond disc is a metal circle with a cutting part and slots over the entire area, which promote heat dissipation and reduce deformation stresses. Diamonds are interspersed throughout the rim of the disc. They fit into a rim made of nickel, zinc, cobalt and tin alloys.

With a linear speed of movement up to 80 m / s and enormous frictional forces, the fastening must only be strong, which is achieved by using special technologies.

To ensure the retention of the cutting part under enormous weights, they can be secured using laser welding, sintering, galvanic method or soldering. Soldering is only used in discs for cutting with water-cooled machines.

The purpose of the disc is determined depending on the method of setting the diamond. Diamonds fixed by galvanic method are intended for working with soft types of natural stone, processed by laser welding and sintering, in particular segmented. for all types of hard in dry and “wet” method.

The holes and the slot are placed strictly symmetrically, the mass of diamonds is also balanced in diametrically opposite directions.

This eliminates vibration and “runout” of the blade and ensures even cutting. But it is possible to use circles for dry cutting only for performing a straight cut. with a curved mowing line of movement, the disc may NOT only lose diamonds, but also collapse. This kind of tool is extremely sensitive to lateral loads.

Damping slots. 2. Cutting layer. 3. Landing hole. 4. Metal disc.

How to cut slate. an overview of tools and cutting methods

Flat and corrugated slate sheets are widely used as roofing materials. During their installation, there is a need for cutting, which is a rather specific operation.

How can you cut slate from power tools

In addition to the angle grinder, a cutting machine equipped with a stone cutting disc can be used to cut slate. The preparatory procedure here is the same as in the case of an angle grinder: the letter is first marked, and then moistened. When working with a cut-off machine, it is important to avoid any shifts by running the disc exactly along the markings. It is usually not possible to cut the slate in one approach, therefore, after wetting, cut with water, the procedure is repeated again, due to which the cut deepens. As a rule, in order to comfortably break the slate, 3-4 such approaches are required.

For sawing wet slate, you can use a regular jigsaw, equipped with fine-toothed blades. In this case, the spindle is set to the low gear mode. When using this tool, it is important to be very careful to avoid any pressure on the slate, otherwise it will crumble. The use of a jigsaw is justified only in the case of small volumes of such work.

How to organize slate cutting

Slate is characterized by sufficient fragility, which is why very small asbestos fibers and particles are formed during the breaking or sawing of sheets. As you know, asbestos is a harmful substance that provokes the occurrence of cancer. So that cutting the material is NOT accompanied by its destruction, with the appearance of asbestos dust, you need to know what slate is cut with and use protective equipment.

Requirement for cutting slate sheets:

- Mandatory use of personal protective equipment. For the respiratory system, this is a respirator, for the eyes. special glasses for the skin. gloves and tight clothing. In addition, a lot of noise is generated during the operation of a cut-off electric tool: noise ear muffs will help from it.

- In order to reduce the amount of dust generated by an order of magnitude and make the slate not so fragile, the cut section is moistened with water before cutting. To do this, you can use wet rags or direct watering of the cut mowing line during operation.

- When working outdoors, it is important to find such a place that the resulting asbestos dust is blown away by the wind away from the operator.

- If the procedure is carried out indoors, there should be no one in it except workers. All doors must be tightly closed, taking measures to further seal them.

Mechanical tools

If slate cutting is carried out indoors, or a suitable power tool for work is not available, classical techniques come to the rescue than cutting slate.

In this case, a wet letter can be cut in the following ways:

- Hand saw. A tool with replaceable blades and fine teeth is suitable for this. It is necessary to stock up in advance with several such canvases, since in the course of work they rather quickly become dull and clogged with asbestos dust. It is recommended to avoid pressure when cutting, otherwise the fragile material may break.

- Manual cutter. In this case, it will take several times to deepen the cut along the applied markings. Between approaches it is necessary to wet the line and cut. When the cutter is 2/3 deeper than the plate thickness, it can break. To do this, a wooden plank is placed under the slate, cut along the mowing line: after pressing on the edges of the sheet, it will easily split into two parts.

- Hammer and roofing nail. For this, the line is carefully pierced with a nail in many places. It is advisable to make as many of these holes as possible. this will only contribute to the quality of the fault. When making holes in the direction longitudinal to the wave, the slate is turned in such a way that this wave passes below. After applying a series of holes, a wooden block or lath is placed under them: pressed on the edges of the sheet, they are broken. To facilitate this procedure, it is allowed to tap the break line with a hammer.

To implement this method, you will need special slate nails. The usual ones are distinguished by the presence of a special rod shape and a soft head, which allows avoiding splitting of sheets during driving. To speed up the process of equipping the slate with a series of holes, roofing nails are stuffed into the block. This kind of comb is usually used for constant work with slate letters.

How to cut slate with an angle grinder. What disc is cut

This procedure can be performed using two types of slate discs:

Disc for stone. In this case, NO Significant Efforts will be required. It is important to organize a constant supply of water with a thin stream to the point of contact between the angle grinder and the slate. In this way, the disc is cooled and dust is prevented. The easiest way to do this is to have a helper with a garden hose or cut-up plastic bottle next to it. When working alone, the water hose is secured in a convenient position for watering. Using an angle grinder and stone disc, it is best to cut along the slate wave. For convenience, before starting work, the letter is marked out and laid on a flat surface. If the cut is made near the edge of the sheet, a wide board is installed under it.

If it is necessary to cut in the direction transverse to the waves, the procedure is divided into two stages. First, an incision is made on the convex ridges. Then, turning the slate over, the procedure is repeated: it turns out that the ridges that were at the bottom are on top. If done correctly, the letter neatly splits in two. At the end of work, the tool should be thoroughly wiped off dust, especially its working part. The fact is that if the asbestos-cement layers become fossilized, it will be very difficult to remove them from the surface of the disc with an angle grinder on the slate. Use a soft dry cloth for cleaning.

Diamond wheel. Using an angle grinder with a diamond wheel, you can cut slate in any direction. For greater efficiency, it is pre-wetted, increasing the elasticity and pliability of the material. In addition, this will significantly reduce the amount of dust generated. If the cutting is carried out in winter, then the slate sheets can simply be laid on top of the snow: in this case, most of the asbestos dust will simply be absorbed into the snow cover.

Cutting flat slate at home

To separate flat slate sheets, any method of cutting corrugated slate can be adopted. However, it is most convenient to cut smooth slate with an angle grinder with a disc on a stone. For the procedure, a flat surface is selected on which the material is laid. it can be a simple wooden flooring, or a dense soil area. The main thing is that the lower base is not expensive, as it will be damaged during cutting. When cutting near the edge of the slate, it is advisable to put a wooden lath of the required length under it. Before cutting flat slate at home, you need to organize the water supply to the work site to reduce the amount of asbestos dust