Which mills for the cultivator is better. Corneumer “Tornado”

Is it necessary to sharpen the mills of the cultivator. What is a cultivator and why it is needed

First you need to figure out what the cultivator is, how it is arranged and what is needed for. So, this is a type of compact agricultural machinery designed for prerequisite soil preparation. It allows you to plow, loosen and hill the ground, as well as decorate the furrows and carry out harrowing. This unit allows you to greatly facilitate agricultural work in a summer cottage or personal plot.

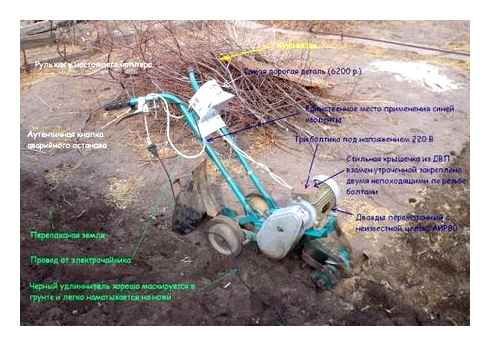

The motor.Cultivator is able to work where there is no access of full.Sized technique

Cultivators according to the type of mechanism are divided into groups:

- Mechanical manual. Used as additional equipment for more serious technology. They loosen the soil to a depth of not more than 5 cm and remove only weak, located on the surface, weeds;

- Electric. Light, maneuverable equipment that is used in limited land plots. The disadvantage is to work from an electric cord;

- Battery. This type of agricultural equipment is a combination of all the advantages of electrical counterparts with autonomy. They are heavier, but at the same time, mobile and safe;

- Gasoline. This technique is characterized by power, performance and greater weight. A good option for processing vast land plots.

A gasoline engine motor

Cultivators of any type consist of such basic elements as frame, control levers, engine, rotor, wheels and cultivation devices (cutters).

Factory cutters for a walk.Behind tractor (saber.Shaped) and cutters. Goose legs

The article was prepared with the information support of the leadership of the Mobile K plant. Publication is not advertising material and is intended solely for the aus of helping visitors to the online store of Production.

Many owners of garden plots are wondering which cutters are better for the walk.Behind tractor. To clarify this issue, we consider 2 types of structures that have become most widespread in Russia:

One. The saber.Shaped shape of a knife is a classic cultivator version.

The effectiveness of such geometry has been tested for decades. It should be noted that both domestic motoblocks (Neva, cascade, MKM-3, salute) and imported units, including the professional class (Barbieri, Goldoni, Meccanica Benassi), have sable-shaped knives design.

What are their advantages besides geometry? Of course, in the material and method of processing. In the presence of the necessary equipment, knives can be made of carbon high.Quality structural steel, which has high strength characteristics. Such steel is immune to welding, so a sign of high quality knives is the collapsible design of cultivators. To ensure a high complex of mechanical properties, thermal improvement and hardening of high frequency currents may also be used.

Recently, on the Internet, you can often find mills of the “Goose legs” type.

You can discuss for a long time on the purpose and functionality of this type of milling (struggle with weeds and t.P.), however, one simple fact is worth taking into account: the design of cultivators is welded, which indicates the brand of steel from which they are made. Steel 3 belongs to carbon steels of normal quality. It is perfectly welded, but the strength of such mills leaves much to be desired.

In case of serious loads (clay soil, virgin lands) there is a great risk of bending or breakdown of the cutter. Therefore, if you do not have a welding machine and a desire to spend time on repair and finalizing the finished product, the cutters “Goose legs” is far from the best choice.

Is it necessary to sharpen the mills on the walk.Behind tractor

Soilines are tools that are hidden themselves. In most cases, additionally sharpening the cutting surface is not advised: this often leads to a deterioration in the structure. For example, sharpening will be meaningless if they plan to loosen heavy soil by a machine with high performance and reinforced knives. In such a situation, you should not waste time on the procedure.

It is not difficult to make an adapter for a walk.Behind tractor with your own hands if you collect everything you need to work, to understand well.

It will be advisable to hide the blades if a very old mill has lost its sharpness. Also, he will subside cutting plates recommend before processing the site with a small light motor.Cultivator. However, in these cases, there is a danger of Rapid reproduction of weeds due to crushing their root system. The result of this procedure lasts only a couple of hours, and then it has to be repeated. To sharpen the blades, the part is removed from the walk.Behind tractor, remove the lumps of the earth from it and carefully pass with sandpaper on each edge in need of sharpening.

Motoboblock milling cutters

Manufacturers offer different options for soil cutting for a walk.Behind tractor. You can use one set of mills or purchase two different types of devices, changing them depending on the conditions of soil processing.

Some craftsmen prefer to use homemade products, which, with proper assembly, will be no worse than factory.

The main advantage of the independent creation of the Soofovses is that it can be adjusted to the specific features of the site.

Work by cutter on a walk.Behind tractor. How to install soil.Graze, types of tools and rules of work

Cultivation, or soil milling is the basic and one of the main processes that the motoblock performs. The essence of cultivation is to crumbling the soil and mixing it at a depth of 30-40 cm. The depth varies depending on the type and model of the walk.Behind tractor. The quality of the soil, controllability of the motor unit, application of the operator’s efforts, the load on the engine and the transmission depends on the correct operation of the cutter. Therefore, it is impossible to neglect the rules for selecting hinders and cultivation.

Freight work on the walk.Behind tractor Helps to fight weeds. The mill is also responsible for the structure of the processed soil: large or small Комментарии и мнения владельцев of the earth. Please note that such a tool can cope with very heavy and virgin soils, you just need to choose the right equipment.

Soilines are of various types and types, and can radically differ from each other. They differ in shape, design, as well as the number of knives and their location.

Conditionally, all tools can be divided into 2 large categories by the type of working body:

Sable.Shaped knives are often called a standard soilofreza, since this is the most common and popular option. Such a hitch often goes to the basic factory set of motor blocks and motors. Wide prevalence explains the versatility of the device: it can work with almost any type of soil. Saber.Shaped soil.Grade knives are made of very strong high.Quality carbon steel. In addition, such a milling cutter has a collapsible design, so the installation, maintenance and transportation of the tool is as simple as possible. The steel from which the knives are made is completely not susceptible to welding work. To improve the mechanical properties of the product, during production, the so.Called thermal cutter is used. Steel for strength is treated with high.Frequency currents.

Working with the “Goose legs” cutter is very effective when processing virgin or solid soils. Such a tool began to be used relatively recently. It manifests itself well when working on rocky ground. The continuous design of the soil.Grazes indicates its high reliability and strength. In the production of the “Goose legs” cutters, ordinary carbon steel is used, however, the advantage is that the tool can be welded and repair.

So, if you have to work with a cutter on heavy and complex soils, choose the type of “goose legs”. If the soil belongs to the simple ones, then you will be quite strong, reliable and durable saber.Shaped knives on the cutter.

Now let’s look at how to work with a cutter on a walk.Behind tractor. The process is simple, but requiring practice. At first it will seem to you that the motoblock is naughty, the depth of cultivation is insufficient, it is too hard to work. Believe in our experience. All this is temporary. A little patience and practical skills, and you will be delighted.

When working with the milling cutter, it is necessary to install a second.Block in the rear bracket. It needs to be fixed in the middle position. Well, then, working with the machine, you will adjust the final depth of adjustment. It will depend on the density and quality of the processed soil.

Pay attention to this question, since it is precisely on the correct adjustment of the snufftor that your convenience and the quality of the cultivated land will depend. Often there is a situation when a motorcycle block “grows on the spot” shows an insufficient depth of cultivation or you have to make significant efforts to work. It is the proper adjustment of the council that will solve such problems. Remember that neither crushing, nor pull, nor pushing, nor lean on a walk.Behind tractor. It will do all the work yourself, and you only must direct it and control it.

Well, after installing a coupon in the middle position (before starting cultivation), we will have a car and warm up the motor for several minutes. Now we turn on the first speed, add the speed, smoothly turn on the clutch and, without resting the snufftry against the ground, we will roll up the motorized car to the initial position for milling. Do not be afraid to roll the walk.Behind tractor on cutters. Nothing will happen to them, since they are intended for such situations.

Now we turn on the second speed, set maximum speed and smoothly turn on the clutch. Cutters will begin to enter and burst into the soil, and the walk.Behind tractor will follow them. Pay attention to the type and condition of the soil. If the soil is solid, then cultivation should be performed at first speed, at high engine speeds.

KUHN. OPTIMER L 9000. 12000 (Large-width Stubble Cultivators with discs)

To adjust the depth of loosening with a motor block, you need to slightly press the steering handle to the ground. So the coupon will go into the ground stronger and begin to slow down the course of the walk.Behind tractor. And at the same time, respectively, the depth of cultivation will increase. If you can’t achieve the desired depth, then lower the couch in the shoulder lower.

When loosening the soil on the “bayonet of shovels”, it is necessary to slowly swing the walk.Behind tractor to the sides. This will lead to the gear shift in depth and to the sides, and he will not fall into unprocessed soil.

We want to remind you that it is necessary to work with a flat back, and the hands should be at the level of the belt. So it will be convenient for you, you can work with a cutting cutter for a long time and will not be harmful to health.

Gradually, the work by the cutter on the walk.Behind tractor will become simple for you. You get used to this process, and it will pass easily and quickly. Then you can go, for example, from the side of the walk.Behind tractor, turning out its handles in order not to advance on already processed soil, or come up with other improvements for better and efficient cultivation of agricultural territories.

Which cultivator is better to buy

For professional use for the purpose of processing large fields, it is better to choose a gasoline type cultivator. If you need to prepare a summer cottage for sowing or put it in order after harvesting, it is quite possible to stop on an electric version. Those who plan to use this unit only episodically should think about purchasing a manual product.

The choice of a particular model depends on many factors:

- DAEWOO Power Products Dat 1800E is quite suitable for working with regularly plowed land.

- If you need to process some small area and do not touch the plants available on it, you can use the Hyundai T 2000E.

- For loosening the soil in the fields, it is worth buying Elitech KB 60N or Huter GMC-5.5.

- Patriot Mole 2 and Tarpan TMZ-MK-03 copes well with the cultivation of the Earth near the trees.

- In the personal plot will not be superfluous Caiman Trio 70 C3.

- If you plan to remove root crops with the help of a cultivator, it is better to choose a Husqvarna TF 230.

- The tornado corneum, a mord-mot-m and Gardena Combisystem, a spatula-moth shovel, copes with the removal of weeds.

The cultivator can be called good only in the case of convenient, safe and efficient use. Just such models are presented in this rating, which should facilitate the choice of a suitable option.

Is it possible to sharpen mills. Why you cannot sharpen saber mills for cultivators

In fact, everything is simple. Most domestic manufacturers purchase knives at the same factory in the Smolensk region, where knives are created from fake steel with the treatment of cutting edges of high frequency currents.

Please note that domestic cutters are always installed on the cultivator flange using bolts. This is due to the fact that fecal steel is poorly welcome to welding. So you can understand that many Chinese mills in welding are made of metal in quality, worse than domestic.

Sable mills that have seen soil kilometers

The process of creating such an edge is accompanied by the melting of the edge of the blade and its Rapid cooling. As a result, the blade of the knife under the increase will look uneven and resemble the saw.

When working in the ground and constant blows on the stones, reinforcement and so on, the carbide blade does not stupid, but crumbles. Forming deeper teeth “saw”. Therefore, many call such milling cutters to self.Shallowing.

Frankly, in my opinion, this term is not entirely fair. Rather, rolling knives is suitable.

Now to the issue of sharpening at home. You can sharpen motoblock mills with the help of a high.Temperature sharpening machine. If such a device does not lie in the garage, then do not take a file from the shelf !

Top 10 Best Tiller Cultivator

The file will remove the small teeth, making the knife even, which can lead to a large chip or a break of the knife with subsequent cultivation and getting into the stone.

If Zazubin appeared on the mill, just continue to work for her. See, after a while she will disappear herself.

I hope the article will come in handy. I ask you to like and subscribe to my channel ! It will be especially interesting for amateur gardeners who want to facilitate their work by mechanical assistants.

Interesting hitch ? Learn about other amazing devices for your garden assistant. Here are links to my articles:

Is it necessary to sharpen the mills on the walk.Behind tractor

There is no unequivocal answer to this question. The opinions of beginners and even experienced summer residents are contradictory. Some argue that sharpening significantly improves and accelerates the process of cultivating the soil. Others argue that there is no sense in this, since even the manufacturers of milling do not require this.

Having summarized the experience of one side and the other, among the arguments in favor of sharpening milling, the following should be distinguished:

- The sharpened cutting surfaces of the equipment penetrate the soil easier, accelerating the process of work.

- The first advantage should be reduced by the load on the power unit of the walk.Behind tractor, which extends its life and reduces fuel consumption.

- For light cultivators and with insufficiently high.Quality material knives, it becomes almost impossible to work with dumb mills. In this case, sharpening is actually the only way out.

The arguments of opponents of the sharpening of the milling plant are as follows:

- The acute cutting surface contributes to a strong grinding of weed vegetation, as a result of which the process of vegetative propagation is increasing repeatedly. From this point of view, preference is given to the process of winding weeds on a stupid mill.

- As a result of the effects of sharp knives, the meaning of the cultivation of the soil is lost, since the soil instead of loosening is simply cut and remains in large lumps.

- The process of sharpening the milling plants is quite time.Consuming, since in addition to the sharpening directly, the cutter must first be disassembled, and then correctly assembled. In this case, the severity of the cutting elements remains for a short time. After that, the procedure should be repeated again.

Comparison

The nozzle “Goose paws” is applicable for dense soil. It can be used on different modifications of motor cultivators due to the variability of the sleeve. It is easier to control these models in the process of work, but they are afraid of jerks and blows in the process of soil processing. Active analogues or factory products do not always cope with heavy soil. This is especially true for options with Chinese knives, where the quality of the metal leaves much to be desired. Not only will it be difficult for the user to keep the equipment in their hands, in addition, the load on the gearbox will significantly increase.

These cutters can be repaired by removing damaged elements and replacing them with new. In addition, there is a capture width latch here. At the request of the operator, you can put additional pairs of milling in a number.

If it is known in advance that the processing of complex soil is needed, here you will either have to select high.Quality mills of manufacturers of Ukraine and Poland, or look for other modifications.

As for the spiral milling mills, called the “virgin”, this design is whole, which is done specifically to increase its strength characteristics during operation. That is why it withstands heavy loads. The only thing the user may not like is the slowness of the work. However, it is understandable: it will not work to accelerate on virgin soil, no matter how I would like.

If you want to buy just this option of milling, it is important to take into account its other drawback. During cultivation, the Earth will be pushed from the center to the edges. A shallow furrow will form from this, which may further demand the alignment of the land. Otherwise, spiral cutters are considered more reliable devices in comparison with other analogues. They are strong, reliable and durable. If you need high.Quality soil processing in a complex area, they will become optimal to the gardener.

Cultivator Modifications

Comparison of milling plants awaits you in the next video.

It is forbidden to use any materials without our preliminary written consent.

Milling cutters for a cultivator (motor.Cultivator): How to do it with your own hands

It is enough to make cutters for a motor.Cultivator yourself, without resorting to large financial costs. As a rule, they are already present in a set of agricultural machinery, but far from always this attribute has a suitable width for processing. Do.It.Yourself equipment is a great way to get an inventory suitable in size. Let’s study the types of mills, features of their independent manufacture and installation on the cultivator.

The device is four bent knives. A “petal” fixed to the shaft. Most of them are directed: when assembly, it is necessary to take into account the direction of movement. Knives usually bend in both directions, except for those located at the edges of the shaft. There are models in which all the “petals” are bent only towards the gearbox: in this way, damage to plants during loosening is prevented. However, in this case, the width of the capture decreases.

Stamped steel elements are made. For the lightest devices, and from a steel strip, often forged. The last option is the most durable. As a rule, the milling cutter is a separate part, but there are models in which two soil and fiber are fixed on one shaft.

- Sharpened. “petal” easier enters the ground and does not allow adhesion to the soil. Accordingly, the load on the engine decreases and fuel consumption is reduced. On the other hand, sharp blades cut the roots of weeds, some of them remain in the ground and germinate again. Use sharpened cutters with great caution.

- With a semicircular edge. Safer, but when loosening they experience greater resistance, more often they get stuck. Weeds such an element removes more efficiently, as it does not cut, but wraps the root and pulls it out of the soil.

The diameter of the cutters for the cultivator determines the maximum depth of plowing. Relative is set by a sniff.

- On rivets. The element does not understand. This difficulty is not so much in storage as during transportation;

- On the bolts. A collapsible part. The photo shows a sample.

Welding is not used for connection. This reduces the strength of the product.

Equipment manufacturing. We study expert advice

Cutters for a motor cultivator do not differ in a complex design. Before starting independent creation of elements, you must carefully study store options. This will make it possible to take into account all the design features of the equipment and make effective inventory.

Before work, you need to make a drawing or use a ready.Made scheme. It will need to indicate the material of each of the parts, the sequence and the method of fastening.

After that, you need to prepare all the materials. If figured elements are used in the design, then it is better to immediately order them from the master.

When creating a milling cutter, special attention should be paid to the correct assembly. Try to avoid any deviations associated with the design, because any error can significantly reduce the effectiveness of milling. Over, the incorrectly collected inventory will pull the cultivator to the right or to the left.

An important factor is the location of the teeth. They must be installed exactly in the same position as in the design of store products.

Experts do not advise making mills, more than 50 cm in diameter. Equipment of this size can plunge into the soil by 26 cm, covering the strip, 1 meter wide. This is more than enough for high.Quality plowing.

Saber cutters in the form of a saber are considered safer and are not able to harm the operator when it falls on the design. The knives on them have a transverse location and are consistently immersed in the soil, without jerking.

To extend the life of homemade mills, it is necessary to adhere to the rules for using inventory. In the process of starting the cultivator engine, all knives should be located above the soil surface. After switching the motor with idle speeds, the blades should be slowly lowered and the soil plowed up.

Not knowing whether it is necessary to hide homemade mills, many newcomers make a lot of errors. It must be remembered that the more often the sharpening is performed, the better the result of soil processing will be, and the longer the knives will not succumb to corrosion.

Creating mills is a detailed algorithm for beginners

Having dealt with the secrets of independent manufacture, you can proceed directly to the creation of the structure. This will need:

- Several metal pipes, with a diameter of not more than 4.2 cm.;

- Sharp details that will play the role of knives;

- Bulgarian;

- Welding machine.

For the manufacture of knives, old automobile springs or spare parts from other equipment are suitable. The blades of the structure must be adjusted by suitable dimensions and bend in one direction.

Further, the blades are attached to the pipe from different sides by welding. If you have more time, you can sharpen the blades towards their alleged movement. The resulting design must be installed on the coupling of the cultivator.

After that, you need to check the operation of the equipment. If during operation you find deformation of knives or blades, then the cutters can be removed and leveled.

The design of the walk.Behind tractor

Before assembling the cutter begins, you need to figure out what the motor cultivator is and what is included in it. The upper part of the frame is usually welded. The fuel tank, engine are installed here. Fastening is carried out on brackets. The engine itself, or power unit, is equipped with a clutch and gearbox. Its power can be different, it all depends on the type and purpose of the motor.Cultivator.

Cutters are a scheme of 2 blocks, each has 12 separate mills. For each block, 3 separate nodes with 4 knives are used, which are mounted at an angle of 90 °. The position of the nodes has a displacement of 30 °. For the manufacture of one knife, a steel sheet is used, the thickness of which is 5 mm.

The stand is made of a metal corner 6340 mm. The knives are attached to the rack, the second end is welded to the flange to combine 4 knives into one structure. The whole mill is connected by bolts, washers, flanges. The design is reliable, it is able to withstand significant loads.

If it is planned to constant use of this equipment, then you need to prefer only factory options.

Factory cutters with saber.Shaped knives

Those who begin to use motoblocks ask the question: which knives are best to take? Types of motor cultivators can conditionally be combined into 2 large groups:

Sable.Shaped mills are as suitable for all types of work.

The saber.Shaped form of the milling plant is the most popular, it is precisely such schemes that are called standard. They are effective, the effectiveness of using this particular type has been proved for decades. Often the motor cultivators with which the cutters in the kit are in the set have a saber.Shaped shape.

It is as suitable for any type of work. The advantages that have saber.Shaped mills are obvious. The shape of the knives is optimal. They are suitable for performing various types of work. For the manufacture of knives, only carbon high.Quality steel is used, the strength of which is high.

Sable.Shaped mills have a collapsible design, which makes their installation and maintenance simple and effective. The steel from which the knives are made is completely not susceptible to welding work. To improve the mechanical properties of the product, the so.Called thermal tower is used during production. Steel for strength is treated with high.Frequency currents.

Factory cutters “Goose paws”

Not so long ago, mills began to be used for motoblocks, which were called “goose paws”. They have proven themselves well, are most often used to process solid and complex soils.

It is such cutters that are used when cultivation should be carried out in difficult conditions, on rocky soils. The design of the “goose legs” is made continuous, which provides the highest indicators of the strength of the equipment.

Mills are available in standard sizes:

- Knives width is 41 cm;

- The length of the knives is 38 cm;

- Structure height. 38 cm;

- The mass of the cutter is 16 kg;

- The permissible operating speed of a motor cultivator with such knives is 2-5 km/h.

What are the pluses of the “Goose legs” cutters, is it possible to install it on your own? It is convenient for soil processing, weed fighting. The remaining models will not be able to cope with work better.

For rocky and solid soils, the “Goose legs” cutters are simply indispensable. Of the advantages, it should be noted that the steel of cutters in this case is welded.

If necessary, you can carry out repairs at home, and not buy new knives, as it is costly.

The cutter of this type also has disadvantages. The main drawback is that ordinary carbon steel is used for manufacturing. The strength of the design itself is at a high level, but the material loses a little other varieties.

Such a milling cutter should be regularly inspected when work is carried out on clay soils, with the cultivation of virgin lands. Knizes knives can be curved or simply broken.

Magic Cultivator

However, the repair is not too complicated, a welding machine is usually used for a broken knife, after which the fracture is thoroughly polished.

When assembling the circuit, you should work together, since the weight of the design is significant. It is important not to confuse the direction of installation of knives on the axis. When assembling, sharpening should look towards the processed soil. To strengthen the cutter, use a lock, it is placed on the output axis.

Cutter assembly scheme

The photo 1 is well visible design, mill features. The scheme is simple, but before you start using the equipment, you should carefully familiarize yourself with it.

The design of the cutter includes elements such as:

- The rotor axis, which can have a different length (it can be one or divided into 2 parts, t. E. The mill will be collected from 2 parts);

- Short rotary axis;

- The so.Called finger equipped with a fixer;

- Right and left knives;

- Nuts, bolts, washers that are necessary for fastening the entire structure.

Direction of rotation. Counterclockwise. Soil mills of any type are self.Shaping tools, there is no need to use additional sharpening. You should not use sharpening without need, it can ruin the structure.

During the installation of cutters, difficulties may arise, such work is not recommended to carry out such work.

For assembly, special X-shaped goats made of wood are used, the height of which is about 50 cm. This allows you to quickly and easily put the wheels on the design.

Before assembling a walk.Behind tractor, you should carefully strengthen on a sashnik, and then tilt it by about 45 °. Bit goats are usually boards that are lost among themselves in the middle part in the X-shaped position, substituted under the existing steering handle. After that, the wheelchass wheel is removed, cutters of the selected size are placed.

Assembly of a cultivator cutter is the correct procedure

The manufacture of devices for a cultivator with your own hands makes it possible to fit the width, which will cover the design, to certain features of the existing site. Before gathering a cutter to a motorbike,

It will be necessary to prepare the following materials:

- A tube made of steel, with a diameter of about 4.2 cm;

- Metal spare parts that can be sharpened and further used for plowing soil;

- Welding device;

- Bulgarian.

For assembly of the device, springs from the old car or remains from another available technology will be consumed.

The further manufacturing algorithm is as follows:

- First, the details taken for plowing soils must be adjusted in size. In the future they will serve as blades for the cutter;

- Next, bend the blades in one specific direction;

- Then weld the finished blades to the pipe so that they are located from different sides of the existing axis;

- Sile the edges of the blades in the direction that will correspond to their movement;

- The freight made should be attached to the existing cultivator. The installation of the structure is carried out through the coupling mechanism of the unit:

- If you make additional mills to the already existing standard equipment of the motor.Cultivator, then you need to connect them not with the clutch device, but with the axis of standard mills. In this case, bolts are used for fastening.

After assembling the device, it will need to be tested. If necessary, uneven treatment of soil, the structure should be adjusted by setting its position in relation to the cultivator.

Block: 4/5 | Summer characters: 1598Source: https: // Sadovaja-tehnika.COM/Motokultivatory/Frezy-Na-Kultivator/

Types of cutters

The device is four bent knives. A “petal” fixed to the shaft. Most of them are directed: when assembly, it is necessary to take into account the direction of movement. Knives usually bend in both directions, except for those located at the edges of the shaft. There are models in which all the “petals” are bent only towards the gearbox: in this way, damage to plants during loosening is prevented. However, in this case, the width of the capture decreases.

Stamped steel elements are made. For the lightest devices, and from a steel strip, often forged. The last option is the most durable. As a rule, the milling cutter is a separate part, but there are models in which two soil and fiber are fixed on one shaft.

- Sharpened. “petal” easier enters the ground and does not allow adhesion to the soil. Accordingly, the load on the engine decreases and fuel consumption is reduced. On the other hand, sharp blades cut the roots of weeds, some of them remain in the ground and germinate again. Use sharpened cutters with great caution.

- With a semicircular edge. Safer, but when loosening they experience greater resistance, more often they get stuck. Weeds such an element removes more efficiently, as it does not cut, but wraps the root and pulls it out of the soil.

The diameter of the cutters for the cultivator determines the maximum depth of plowing. Relative is set by a sniff.

- On rivets. The element does not understand. This difficulty is not so much in storage as during transportation;

- On the bolts. A collapsible part. The photo shows a sample.

Welding is not used for connection. This reduces the strength of the product.

Pros and cons of cutters

To begin with, when selling, motoblocks usually come with cutters with removable saber.Shaped knives, consisting of several connecting sections. Such attaching equipment copes well with the processing of light sandy soils. But in the overgrown sites and virgin lands, factory cutters shows itself far from the best side. The motorcycle block goes unevenly and constantly jumps. Therefore, when processing the soil, you have to make serious efforts.

Perhaps therefore, people’s craftsmen began to invent other cutter designs. At the same time, some models were so successful that they went to industrial production.

“Goose paws”

This, first of all, is about a whole design consisting of a sleeve and knives welded to it with triangular tips. Such a cutter is called “goose legs”, and its choice directly depends on the shape (circle or hexagon) and the installation size of the motor block gearbox shaft.

Cutters of this type hold the direction well and are deepened into the soil with a heavy structure with minimal efforts of the operator. The main drawback of this design is a walk.Behind tractor equipped with “goose legs”:

Spiral cutter “virgin”

Another popular design that has become quite popular among motoblock owners. This option of hinged equipment consists of a sleeve, to which knives with sharp tips are welded in a spiral.

Experts say that such a milling cutter copes well with the depth of plowing and the loosening of the clay, heavy and even overgrown with grass soil. However, this design has serious shortcomings in the form of too slow work and deep ditch, which remains behind the walk.Behind tractor, since the cutters rake the soil from the middle to the edges. Therefore, after processing the site, it will have to carry out additional work on alignment of the soil.

How to sharpen a home.Made cutter correctly?

Manufacturers of motor cultivators supply equipment with already sharpened standard cutters on sale. However, what to do to a person who made mills for the existing cultivator on his own? In this case, it will be necessary to perform the independent sharpening of the cutting knives of the device.

To sharpen equipment, you will need a grinder equipped with a diamond circle with a diameter of 12.5 cm. Otherwise, you can use the grinding machine, but it will be difficult to use it in connection with the dimensions and the direction of bending of the knives. If the manufactured mills are equipped with small knives in size, then for their Rapid sharpening you can use fine.Grained sandpaper.

To sharpen the knives of a home.Made cutter for a cultivator, it is necessary strictly at an angle of 45 °. In this case, it is necessary to independently determine the side that deepens into the soil. It is not required to remove too much metal from the knife, 1-2 sharpening in one season is quite enough. In some cases, the frequency of sharpening knives can change. It all depends on the intensity of use and the type of soil processed.

With intensive work, the cultivator in wet weather will need to monitor the state of the milling. To exclude the formation of corrosion, they should be treated with a special anti.Corrosion compound, which can be found in almost any automobile spare parts store. It is also very important to try to exclude cutters on stones and other solid items. This will help extend the life of operation and reduce the need to sharpen the cutting knives of the device.