Which Side To Put The Chain On The Chainsaw

How to put the chain on a chainsaw correctly

When considering how to correctly put the chain on the chainsaw, it is worth noting that the modern version of the tool has a special setting wheel.

The chain is stretched

If the chain is used incorrectly or for a long time, it can be very stretched. This is due to the fact that the metal can deform over time. Too much wear becomes the reason why you have to purchase a new version, but it is possible to use the old one for a short period. Rapid stretching can be avoided only if the recommendations for use are followed. To carry out the work you need:

- A hammer.

- Vice.

- Welding machine.

- Beards.

- Pliers.

It is not difficult to put on an extended version, but there are quite a few problems with restoration, since the metal is characterized by increased strength. In this case, the main elements are fastened with rivets. The work is carried out as follows:

- The product is fastened in pieces.

- If the work is carried out when using a grinder, then there is a possibility that the surface will be damaged, since this tool is difficult to control.

- After crushing, rivets are knocked out. It does not need to be thrown away as it can be reused.

- Chain manufacturers do not supply spare parts that are required for service.

- You can make a rivet with your own hands, but the work is quite complicated.

- The product is divided into two parts. It should be borne in mind that the number of guides and the distance between them must remain unchanged.

When solving a problem with a long length, do not forget that too short a chain can no longer be pulled. In addition, it is not recommended to apply oil to the saw chain.

Why the chain flies find out the reasons

When considering how to install a chain on a chainsaw, you should also pay attention to what reasons lead to its collapse. There are three main reasons:

- Incorrect bus operation.

- Malfunction of the main elements.

- Poor drive sprocket retention.

- Strong chain elongation.

Each reason becomes the reason why quite a lot of difficulties arise with the use of a chainsaw.

How to put the chain on a chainsaw correctly

To perform a sufficiently large number of works, a chainsaw can be used. The main cutting element of such a tool is represented by a chain with different blades. Modern versions are characterized by the fact that they can be serviced independently. When cutting for a long time or if basic recommendations are not followed, the cutting edge wears out quickly. That is why it is necessary to remove and sharpen the chain, and then install it. This procedure is characterized by a fairly large number of features, which we will discuss in more detail below.

Bus problems

Today, the problem associated with an unreliable fixation of the tire is often encountered. It is characterized by the following features:

- The housing with the guide element is fixed with a bolt.

- The connection is ensured by two plates, one of which is located on the body, the second on that, which is designed to guide the chain at the time of operation.

- The drive sprocket and the tire support are protected by a special casing, which eliminates the possibility of damage to the main elements.

- When the locking bolts are loosened, the structural element in question begins to move and vibrate at the time of operation. This problem can be solved by tightening the fasteners.

Other defects simply cannot be solved. In most cases, defects become the reason why you have to purchase a tire and replace it.

How to put the chain on a chainsaw correctly: direction

When considering how to correctly put the chain on the chainsaw, we note that the modern version of the tool has a special setting wheel. Due to it, the procedure is greatly simplified. Among its features, we note the following points:

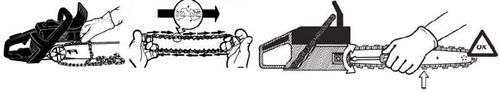

- Considering how to properly put the chain on the chainsaw, we note that first you need to prepare a flat surface. This eliminates the possibility of damage to the tool. After that, the main part of the tool, the bar and the chain are laid out separately.

- The next step is to remove the protection that protects the sprocket. In most cases, it is fixed with a conventional wing nut.

- On the tire, the sprocket turns to the right until it stops. It is in this position that the tool is installed.

- Then the chain is gradually superimposed on the fixing element. A fairly common question can be called which side this element is put on. Installation starts from the top, the chain is rotated so that the bar is on top. Such operations should only be carried out with thick gloves that can withstand the impact of the cutting edge. The cutter on the face should be facing forward.

- Both elements fit over the sprocket.

- The next step is to reattach the chain sprocket cover. It is important to make sure that the pins line up with the holes. Improper fixation may cause rattling or other problems.

- It is necessary to ensure that the guides fall into a special chute.

- The state of the chain is checked visually after its fixation.

The next step is to directly check to see if the chain has been over-tightened. To do this, release the chain brake and pull it along the mowing line of movement. The check is carried out exclusively with special gloves.

In general, we can say that the procedure under consideration is quite simple to execute and does not require special tools. However, not all chainsaws are as easy to maintain as stated above.

How to install a chainsaw cutter

After installing the chain, tighten it correctly and check the tension. Among the features of this moment, we note the following:

- Pulling too tight will cause excessive stress and the product may burst.

- Insufficient tension leads to chain wear and many other problems.

In general, we can say that there are practically no problems with fixing an unworn product.

How to properly put the chain and tire on the chainsaw: assembly

The procedure in question is quite simple. It is characterized by the following features:

- First, the chain brake is released.

- The tensioning screw is in close proximity to the tire.

- The next step is to pull the cutting element clockwise.

- If it is difficult to move the chain, then it is necessary to loosen the fixing screw.

Modern designs of chainsaws greatly simplify the conduct of such work. Therefore, you can do it yourself, even in the absence of special tools.

How to install a chainsaw cutter

After installing the chain, tighten it correctly and check the tension. Among the features of this moment, we note the following:

- Pulling too tight will cause excessive stress and the product may burst.

- Insufficient tension leads to chain wear and many other problems.

In general, we can say that there are practically no problems with fixing an unworn product.

How to put the chain on a chainsaw correctly

To perform a sufficiently large number of works, a chainsaw can be used. The main cutting element of such a tool is represented by a chain with different blades. Modern versions are characterized by the fact that they can be serviced independently. When cutting for a long time or if basic recommendations are not followed, the cutting edge wears out quickly. That is why it is necessary to remove and sharpen the chain, and then install it. This procedure is characterized by a fairly large number of features, which we will discuss in more detail below.

Poorly fixed drive sprocket

Quite widespread is the variant when the leading sprocket is poorly fixed. It often detaches itself during operation. The solution to this problem is carried out as follows:

- The protective cover of the engine and spark plugs are removed, after which the air filter is removed.

- The next step is to remove the spark plug, which requires a special wrench.

- A special plug allows you to fix the piston in the desired position.

- With a special key, the clutch plate is turned until the position of the piston, which should be located on top, changes.

Then you can fix the sprocket in the correct position and solve the problem in question. The specified information indicates that such work is quite problematic, it is often carried out by organizations servicing chainsaws.

Why the chain flies find out the reasons

When considering how to install a chain on a chainsaw, you should also pay attention to what reasons lead to its collapse. There are three main reasons:

- Incorrect bus operation.

- Malfunction of the main elements.

- Poor drive sprocket retention.

- Strong chain elongation.

Each reason becomes the reason why quite a lot of difficulties arise with the use of a chainsaw.

The chain is stretched

If the chain is used incorrectly or for a long time, it can be very stretched. This is due to the fact that the metal can deform over time. Too much wear becomes the reason why you have to purchase a new version, but it is possible to use the old one for a short period. Rapid stretching can be avoided only if the recommendations for use are followed. To carry out the work you need:

- A hammer.

- Vice.

- Welding machine.

- Beards.

- Pliers.

It is not difficult to put on an extended version, but there are quite a few problems with restoration, since the metal is characterized by increased strength. In this case, the main elements are fastened with rivets. The work is carried out as follows:

- The product is fastened in pieces.

- If the work is carried out when using a grinder, then there is a possibility that the surface will be damaged, since this tool is difficult to control.

- After crushing, rivets are knocked out. It does not need to be thrown away as it can be reused.

- Chain manufacturers do not supply spare parts that are required for service.

- You can make a rivet with your own hands, but the work is quite complicated.

- The product is divided into two parts. It should be borne in mind that the number of guides and the distance between them must remain unchanged.

When solving a problem with a long length, do not forget that too short a chain can no longer be pulled. In addition, it is not recommended to apply oil to the saw chain.

Step by step installation algorithm

Not all modern chainsaws are equipped with a setting wheel, which greatly simplifies the procedure for installing the saw blade. Systems with a setting wheel are generally a rarity among household chainsaws. Therefore, it is very important to know the technology and sequence of installing the chain on the chainsaw.

Key points to pay attention to:

- Prepare a level surface on which you will assemble the chain and bar. This will minimize the chance of damage to the chainsaw or loss of small parts. A tire is laid out on the prepared surface and a parallel chain next to it.

- Remove the sprocket protection, on modern chainsaws it is enough to unscrew the wing nut, on older models, you may need an appropriately sized spanner wrench.

- At the base of the guide bar, turn the sprocket all the way to the right. Only in this position is the chain installed.

- Then the chain is successively placed link by link on the fixing groove on the guide rail. Install the chain from the top of the guide, gradually turn it so that the bar is always on top, and the chain is on the bottom, this will allow it to always be taut and fit into the guide groove without problems. When doing this step, be sure to wear thick protective gloves, because your fingers will touch the cutting edge. Viewed from above, the cutter is always forward towards the end of the guide bar.

- Put both the bar and the chain on the drive sprocket.

- Secure the chain sprocket cover in place. Make sure all mounting pins line up with the holes. Incorrect installation with distortions or not completely can cause extraneous noise, rattling.

- Make sure that the guides go into the special mounting channel.

- After installation, check that the chain is secure on the chainsaw and on the bar. Everything should be securely fastened without play.

An important point is the degree of tension on the chain after installation. Setting the correct tension is easy and takes less than three minutes. First you need to loosen the nuts on the protective cover. Using the freely rotating adjusting screw, catch the correct tension so that the chain does not pull more than 3-5 mm from the edge of the guide bar.

It remains only to tighten the nuts and check the tension. If correction is necessary, adjust the tension again.

How to install the bar and chain on the chainsaw, see the following, which presents a clear algorithm of actions:

Chain direction and which side to wear

A chainsaw chain, if you look closely, has saw teeth pointing to one side. Therefore, the correct direction of the saw teeth on the guide bar is very easy to determine: if you place the chainsaw itself in the plane in which it is in operation, then the row of teeth located on top of the guide bar with sharp edges should be directed to the end of the bar. At the same time, the row of teeth, which is located at the bottom of the chainsaw, should point with sharp edges in the opposite direction, towards the drive sprocket.

How to install a chain on a chainsaw

The chainsaw chain is the element that is subjected to the greatest stress and overheating. From such influences, it can break, fly off the guide rail, or simply become dull from prolonged use. For timely maintenance or replacement with a new one, you need to know how to independently remove the saw chain from the chainsaw and reinstall it. The step-by-step algorithm of these operations will be shown below.

How to unravel a chainsaw chain

When removing an old chain or putting a new chain on the guide bar of the chainsaw, it can become tangled. It can also happen with careless transportation. When the chain is tangled, it folds into rings.

It is necessary to put the chainsaw chain on a horizontal surface and spin the rings in different directions, while pulling the blade in such a direction that the diameter of the rings increases. Sooner or later, the chain will unravel into its natural position.

There is another way you can rivet one link of the chain and straighten it, then connect it into a ring and rivet the riveted links back.

Chain tension

The chain of the chainsaw, together with the guide bar, during operation, experience the greatest stress, unlike other parts of the chainsaw. Over time, it lengthens in size due to boring gaps in the connecting links. This process occurs with absolutely any type of chain, therefore, when using a chainsaw, it is necessary to periodically monitor the correct tension of the chain and its wear.

The state of the chain depends on:

- The length of her life;

- Safety of felling or timber cutting;

- Internal combustion engine resource.

If the chain is overtightened, the efficiency of the sawing work decreases, and the motor and transmission are subjected to increased loads. The guide bar heats up a lot due to increased friction, the operating mode of the chainsaw goes into excessive consumption of the fuel mixture.

Why does the chain come off

Many, even the most experienced users of chainsaws, have come across in their lives a situation where the chain jumped off the guide bar during operation. The most common cause is insufficient chain tension or wear.

In 80% of cases, the stretched chain links slip from the teeth of the drive sprocket, and it flies out from the guide under the action of centrifugal force. Although sometimes the problem appears due to the incorrect position of the sprocket relative to the axis of rotation or a loose saw bar on the chainsaw.