Which way the angle grinder turns correctly

Yurb 15 Mar 2012

Sparks on yourself:

Igor Kozlov: If you saw with sparks from yourself, then ALL fragments FROM UNDER the protective casing will fly in your direction. At BOSCH I watched videos, there they specially sawed the disks and turned them on remotely in the camera with a cloth hung for clarity. When the “sparks on oneself” were spreading, all the fragments from under the casing flew forward and only a small part of the fragments flew down and towards the body of the angle grinder. I found this video about 8 years ago after hitting my leg with a disk. I sawed then “like everyone else” with sparks from myself.

Alexander Grebenkov: When clamping, sometimes the disk breaks out and rotates flying in the direction opposite to the direction of the sparks. If you are not a kamikaze, then the sparks should fly to you, specials will protect you from them. clothes and shoes, and nothing will protect you from a disc flying at you. The disc, rotating at high speed, cuts both clothes and shoes on its way.

Andrey Sysoev: When cutting metal, sparks should fly towards you. Because when you clamp the disc, the angle grinder will pull forward, away from you.

osminin.aleck: sparks should be flying towards you. You need to cut from yourself. The machine itself crawls on the metal and cuts even with its own weight

Evgeny Kuznetsov: To work with reverse rotation (sparks from yourself) you have to back up, which is not very good from the point of view of safety. I personally saw how the disk, when clamped in the metal, was torn from the angle grinder and it flew forward, and not into the worker (thanks to the correct forward rotation)

Andrey Novikov: If your hands come from one place, then of course the clothes burn out, but I, in my usual overalls (not with a spark, such as “Spring-N” from VS), cut, perhaps, hundreds of kilometers of reinforcement, but nothing burned, although I cut it for very rare exceptions, sparks “on yourself”.

Sergey Kalnin: I do not hire those who do not retrain to work “sparks for themselves”. The grinder gearbox can be installed new every week when cutting from yourself. Sparks all over the shop, by the evening half of the workers are at the eye. If you firmly hold the angle grinder and prevent it from hitting the body with the disc, the disc will most likely burst and fly to the neighbor’s head. Welders are not always teetotalers, they come with a bad head. If the angle grinder jerks forward or to the side, you can lean on it on the workbench or the floor without letting go. If the angle grinder jerks into the body, it often breaks it out of the hands, and if it doesn’t break it, you’ll fly your head or booty to the “stake”, the workpiece.

SERGEY EFREMOV: Several years ago I cut the 63rd corner with sparks from myself. Squeezed, jumped so that it knocked down. Fell. For three days I moved around the apartment with a stick. So let the sparks fly at me and not the instrument.

When cutting metal with an angle grinder, should sparks fly towards you or away from you? It turns out that this question gives rise to serious controversy, and there are many opinions, quite reasoned, which are at least worth listening to.

In the Комментарии и мнения владельцев to the publication, “In which direction should sparks fly from an angle grinder: towards yourself or away from yourself? ”Serious battles flared up. But, as you know, the truth is born in disputes, and many cognitive and curious opinions of experienced people were voiced that simply cannot be ignored. I would not want this experience to be wasted, so I decided to highlight the most interesting tips in a separate publication, noting the names of people who left Комментарии и мнения владельцев.

I divided opinions and arguments into two parts, sparks from myself, and sparks to myself, and let’s decide which option is more correct based on the Комментарии и мнения владельцев of visitors. Be sure to add our opinion in the Комментарии и мнения владельцев, it would be nice to be reasoned! But I ask you to be correct and not offend other commentators.

If you want, you can click on the author’s name and reply to his comment. Spelling and stylistics are preserved by the author’s.

Which way should the disc of the “angle grinder” rotate??

Usually the disc rotates counterclockwise (when viewed from the side of the disc), sparks fly forward, but recently, in a pipe warehouse, I saw that the cutter‘s disc rotates in the opposite direction, sparks fly under the feet. He has to cut a lot and every day. Therefore, the question arose. how is it right?

1 comment

I found 3 similar photos on the net (without bloody guts). But everywhere the angle grinder is set with sparks on itself, as luck would have it! But if you have a little logic, then you will understand where the dask should rotate so that the angle grinder is faster in your belly when you lose control.

Sparks from yourself. ease of work, whole pants.

I agree that sparks flying into the leg and hot metal particles flying into the boot do little to clean and even cut. It is especially offensive when, in a fit of construction passion, I wanted to cut something “a little” and forgot to change my synthetic pants. Thanks for your feedback! There is another advantage of this method. metal and abrasive particles hardly get inside the angle grinder. The insulation of the motor windings wears out less. the tool lasts longer. The effect is very extended in time, but it is there. Almost all angle grinders have at least two handle positions, so no prohibitions are laid down constructively. If you are interested, I am an adept of sparks on myself. An angle grinder is a very tricky tool. I am a strong guy, almost 100 kg in weight, but the angle grinder was also torn out of my hands. Once I made a vertical cut in a hard-to-reach place, the protective cover was removed. The car did not go from the exchange, but flew off perpendicular to the wall. that is, into my head. Fortunately, I was working in a gas mask, the blow fell on the intercom. Otherwise, the nose would have to be found in the dust. The viewing of video clips “the disc of an angle grinder is scattered” is excellent. Sometimes I revise them to maintain tone. It can be added that the spread of the disk by sparks from oneself can be safer than towards oneself (of course, when using a casing). On the other hand, I recently had to work with an angle grinder with sparks from myself. It was uncomfortable, unusual, and particles of stone and metal somehow got into my face ricochet, or something.

Now the promised advice:

Correct tool feed can reduce disc consumption of the angle grinder. When working with sparks on yourself. the cut must be done on your own. When working with sparks from yourself. the cut is done on yourself. The case is in the shape of the bottom edge. which is formed when cutting through metal. It is very sharp. When the disc is fed to it, the consumable experiences additional wear, each time hitting the sharp part (red).

Angle Grinder Safety

Safety when working with an angle grinder is extremely important when working with this tool. Of course, any tool requires careful attention, be it a jigsaw, a hammer drill or an electric screwdriver.

However, an angle grinder, or, as it is “scientifically” called, an angle grinder (angle grinder), requires this attitude doubly. Why ?

The angle grinder is the most traumatic power tool. The disk, mounted on the spindle, rotates at a speed of up to 13 thousand revolutions per minute. Circular blade protection, as, for example, with a circular saw, does not have a cut-off machine. If the disc is skewed, the tool can be pulled out of the hand, and the bounce path is impossible to predict. The circle can break into fragments, which scatter at speeds up to 360 km / h. long distances. All these factors make the angle grinder perhaps the most dangerous handheld power tool.

Why does it rip discs and how to avoid it? Sometimes, as mentioned above, the abrasive disc breaks into pieces during operation. As a rule, this happens so quickly that the worker notices the gap only after it has already occurred. over, the disc can rip off the spindle entirely (the middle breaks out), and it, like a flying saucer, rushes up !

Why this happens and how to avoid ruptured discs on grinders ?

A skewed blade in the cut is one of the most common causes of ripping blades. Most often, the worker himself inadvertently skews the tool, or clamps the disc in the metal (this can happen if you saw in the direction opposite to the direction of rotation, as well as if you cut for squeezing instead of breaking).

Unjustifiably long-term operation. In fact, discs for an angle grinder do not cost much, but some, in order to save a penny, work with them until there is practically one spindle left. In such cases, the discs also break.

Improper use. Grinding with cut-off wheels leads to their rapid thinning, as a result of which the strength of the bond is lost and the wheel is torn apart. Below you can see such a thinned circle:

Factory or acquired defect. chip, crack or break. In the process of work, the circles experience serious overloads, and in addition they noticeably heat up. Chips and cracks slowly creep to the sides and “spread” the disc. Therefore, it is strictly prohibited to work with such products.

Some “craftsmen” set it to 22 mm. discs for circular saws adapter flanges, so that it is possible to put such a disc on the spindle of an angle grinder, and then they begin to saw various pieces of wood.

So, if in the process of sawing at least a small knot or other non-uniform area accidentally comes across, then the tool can be pulled out of the hands, and it will fly to no one knows where. For example, in you. By the way, the disk does not stop rotating at a speed of 6-13 thousand revolutions per minute. Or the engine may still burn out, especially with a cheap angle grinder.

Dangers when sawing openings and grooving

When making cuts in concrete walls, reinforcement can get into the area of such a cut. If the disc is diamond, the angle grinder may break out of your hands. If the disc is abrasive, then it can break, and reinforcement particles can, heating up to 500 ° C, fly out of the cut zone directly at you at great speeds.

Before drilling in concrete, it is recommended to check the cutting area with a metal detector, if any. Also, unknown hidden wiring with current-carrying wires, as well as smeared junction boxes and old grooves, carry great dangers. Such things should also be excluded by ringing the walls with a non-contact probe or an electromagnetic radiation detector.

How I Make Straight Accurate Cuts With The Angle Grinder

Dangers from improper use of discs

If you cut tiles or granite ceramics with a disc for metal work, then part of the material will curl with shavings, which can fly in any direction at high speed. By the way, the temperature of such chips can reach 600 ° C or even more (literally “white heat”).

A similar situation will happen if you cut tiles at 11 thousand rpm (you need no more than 3 thousand revolutions to cut tiles). Sawing iron with a diamond blade on concrete can cause the angle grinder to tear out of your hands. Cutting aluminum with a disc over steel will damage this disc, and possibly damage the workpiece with the scattering of large torn chips. Etc.

Change circles and make any adjustments only with the plug disconnected. Until the plug is unplugged, nothing like this can be done. !

It is strongly recommended not to use the switch lock. this way the control over the rotation of the disc and in general over the instrument is maintained better.

Never use an angle grinder if the handles are greasy or slippery. They should be thoroughly cleaned of such contamination by 100% before work.

Sparks from the angle grinder are hot and may cause a fire. Therefore, there should be no flammable materials in the cutting area. The fact is that some “construction gurus” claim that they (sparks) are supposedly cold.

Video on this topic

WHICH SIDE TO INTERFERE TEA? I figured it out. What do you think about this? —————- LET’S COOK ON SOCIAL NETWORKS

Angle Grinder Disc Rotation Direction

I have been repairing power tools for eight years, during this time I have heard so many terrible first-hand stories from the owners that God forbid. Including about pieces of a disk in the neck. The last example: a man doesn’t take his instrument from repair for a long time, several months, when I call him on the phone, I don’t understand what he’s saying. Finally it appears: there is no voice, there is a terrible scar on the neck. He worked as an angle grinder without protection, then everything is clear. Saved by the fact that he worked in the immediate vicinity of the regional hospital, did not have time to bleed, everything was sewn up, but damaged the ligaments forever.

The disc is placed the way someone’s hands are sharpened.

Which way should the “angle grinder” disc rotate??

The disc on the left and, accordingly, the rotation towards oneself is a consequence of the fact that during work instinctively put the right hand forward, holding the gear knob with it. The same goes for shoveling. Whoever holds a shovel works as an angle grinder. Although with an effort of will, you can force yourself to change your hand. Because I work with my left hand forward (disc to the right, rotation away from myself), then, of course, I think this option is the only correct one: rolleyes :. Pros:

The sparks fly away without harming me or the angle grinder. When they work with sparks on themselves, they are sucked into the engine by the fan and over time all the windings begin to blush with pure uninsulated copper, as if someone rubbed it with sandpaper on purpose.

When biting, the angle grinder jumps out of the cut straight into my hands. You just have to always remember that you have a car with a power of several horsepower in your hands and hold these animals with a firm hand. According to the working conditions, of course, you have to turn the angle grinder, if you don’t get close to it in another way, but I always return to the usual option.

When working with an angle grinder, I try to avoid deep cuts. It is better to cut the corner in two steps, cut the shelves in turn. I cut the channel in three steps, first the core then the shelves. thus avoiding accidental pinching of the tool. A cut in thick metal sometimes has to be cut, deliberately widened by cutting in two steps, especially if the cutting zone is inconvenient and unintentional skewing of the disc is possible. I outline the cutting line in thick metal immediately and cut it by 5-7 mm, cutting the edges of the cut. when cutting, avoid cutting with a package; displacement of the stack is fraught with skewing of the lower layers. Two elements of spatial structures should not be cut when the disc cuts two elements spaced apart from each other at the same time; with a thin disc, the cuts of the comut turn out to be non-parallel (not coaxial).

The disk rotates around a fixed axis according to the law.

Determine the angular velocity, angular acceleration and rotational speed of the disk at time t = 2 s.

.

glad / s.

.

rad / s 2.

Since ω 0, ε 0, then the accelerated rotation.

rpm.

Date of publication: 2015-10-09; Read: 118 | Page copyright infringement

studopedia.org. Studopedia.Org. 2014-2018. (0.001 s)

In other words, how to “set up” an angle grinder correctly so that you can work with it simply, conveniently and safely!

Mansur Fattakhov: On “Interskol” the handle with the switch is turned over.

Mansur Fattakhov: I didn’t turn the knob with the button.

Vadim Rostov: It turns out somehow strange, if the power button is under your fingers (which is quite logical), then sparks fly away from you. If the sparks are on itself, then the power button looks up (into the palm) And then how to turn it on? The conclusion is obvious. sparks only from yourself!

Grinder Safety | How to Properly Use an Angle Grinder

Tsar of All Russia: sparks on itself, and when the disc scatters, it will also fly into fucking. Correctly sparks from yourself, and in order to make it convenient to saw and hold the angle grinder, the handle must be held with the left hand with another grip, and not as the author of the video shows

Rostislav Vodovrzov: Safely. When sparks, and with them the flying disc flies into your e @ alo, torso and legs. If you are nauseous and cannot hold a 230 angle grinder in your hands in case of a snack ……… At @ you for it, ram, you take it. You blah, “sparks on yourself” as if the sectarians are three-fingered and earless.

Nikolay Novikov: I must add that when cutting from yourself.

Igor 79: If the head is with brains, it doesn’t matter where the sparks fly!

Nikolay Yurassow: This is for lefties only

Alexander Kruglov.: From the factory everything was correct and the protective fence and the power button on the handle. At the beginning of the second minute, everything was turned inside out. Now you have to twist your hands as well.

Murat Balaev: why did they hang two Serbs, right above the work table, what do you use with them every day and why you need to install the cut-off wheel in an angle grinder, drawing from yourself?

PROvincial: sparks only along the body of the angle grinder AND THIS IS NOT DISCUSSED

Natalya Yurievna: I worked as an “angle grinder” for 30 years, in the nineties DAILY, later much less often, THIS WAY I CHOSE AND I. I tried both methods, there was no Internet yet, so I began to explore the WAY. With small bites on the disc, it is more difficult to hold the tool, and if it Bites WELL?

Working safely with an angle grinder

(There will be trouble). I will not insist on being right, BUT I WILL NEVER HOLD ON ANOTHER, N AND K O G D A.

lamplighter: Place the disc correctly.

Kremlin paws: Whoever says that sparks do not burn in the “away” position, let them try to saw off the stuck bolt under the bottom of the car. Or, try to imagine that you, a small angle grinder, saw a part. with one hand. In which case it will be safer for you: sparks on yourself or vice versa?

Alexey Salo: The crest should not use the Russian angle grinder.

Andrey Porokhnya: And if the disk breaks, it will fly at you, everything is simple

Sergey Ryabchikov: First you need to install the disc correctly. Printing should not be outward.

How to cut with an angle grinder: from yourself or to yourself?

To such “craftsmen” I would recommend to substitute your own hand for half a minute under the sheaf of sparks from the angle grinder. I assure you that in this case the theory of cold sparks will almost completely dissipate during this time, and perhaps even faster.

You need to cut in the direction of the “spark towards you”, from the far edge of the workpiece from the corner. However, for the reasons described above, it would be better to wear a leather apron, otherwise you will burn your pants. Of course, you should cut so that the flow of sparks is not directed to unprotected parts of the body, and even more so to the face.

In general, it is best to work with an angle grinder while wearing electric welder clothing or other thick, sturdy and fire-resistant clothing, and wear combat boots on your feet. It is reliable and convenient. Yes, never saw a metal profile with corners (especially profile pipes and channels) from the middle, only from the edge or from the corner. The corner can be turned over and cut from the middle (where the “shelves” converge), but at the same time you need to make sure that the cut zone will not be squeezed and the disc will not be squeezed.

Do not use a wire that is smaller than the angle grinder cable or is very long for an extension cord. This can result in a large loss of power and clamping of the disc. Similarly, do not cut with an angle grinder when it is powered by a diesel generator, and at this moment the electric welding process takes place.

Before starting work, turn on the machine and keep idling for half a minute. If you hear any abnormal sound, grinding, hissing, etc., turn off the instrument immediately and find out the source of the sound. Sometimes strong noises are emitted by almost torn pieces of paper and or petals of the petal disc, as well as damaged (broken) 1 mm. abrasive discs.

Never start the angle grinder again if the emergency lock is activated and the blade is jammed in the cut. It is very dangerous ! You should unplug the plug from the socket, carefully pull the blade out of the cut, replace it (as it is almost certainly damaged), test the tool and only then start working, ensuring the cut is released.

Do not under any circumstances allow people or animals to appear in the plane of rotation of the disc. Safety goggles and work gloves should always be worn (leather or any welding gloves are best).

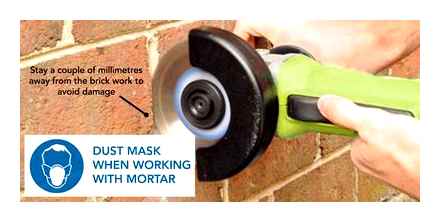

When processing concrete, stone, etc., it is also imperative to use dust protection equipment. Do not operate the angle grinder with additional handles and guards removed, and do not place unsuitable discs on it.

And, of course, you must always monitor the angle grinder so that the tool is fully functional, that there is a whole network cable, the brushes work normally, and so on. By the way, I recommend not to throw abrasive discs in bulk into a bag, but to carry them in a special box so that they do not get chipped or cracked.