Why is the mower not developing speed?

Cold engine

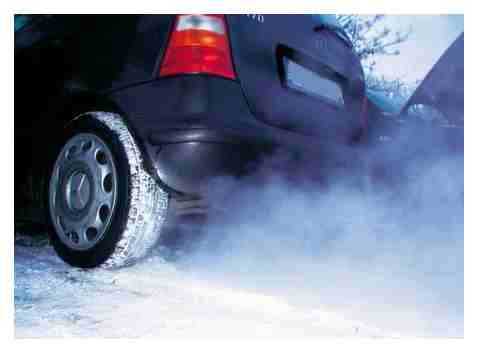

The dynamic characteristics of the power unit will not reach their maximum until the operating temperature of the coolant rises to a value of 90 ° C. A cold engine is unable to quickly develop speed, for this the air-fuel mixture in the combustion chamber must be warmed up. Otherwise, the engine will stall, twitch and detonate.

The main reasons for the lack of engine dynamics

A driver who constantly operates a car easily detects a deterioration in the dynamic characteristics of the engine, which manifests itself in sluggish acceleration, poor traction, increased fuel and oil consumption. These processes are often accompanied by the appearance of a bluish or black exhaust. Most often, this is due to the following reasons:

- Insufficient heating of the power unit.

- Poor quality of fuel used.

- Clogged air filter and air supply problems.

- Malfunctions of the gas distribution mechanism.

- Fuel supply system malfunctions.

- Sensor malfunction.

- Ignition system malfunctions.

- Weak compression in the cylinders.

- Incorrect operation of the vehicle ECU.

- Specific malfunctions of engines with a turbocharger or carburetor.

Dirty filters

Excessive clogging of the air filter reduces the amount of air that can pass through it into the combustion chambers, which causes the engine to decrease in power and its operation becomes uneven. A similar consequence causes a lack of fuel flow into the combustion chambers in the event of a malfunction of the fuel pump or difficulty in passing it along the highway or through fuel filters for various reasons.

ECU malfunctions

All processes of a modern car are controlled by an electronic unit that collects sensor readings and, on the basis of the program incorporated into it, regulates the operation of the engine. The operation of the ECU can be changed by adjusting different modes of operation depending on the required consumption and type of fuel used, vehicle operating conditions and other characteristics. Malfunctions in the electronic unit or its incorrect setting can lead to both a loss of power and the inability to operate the engine itself.

10 reasons why the engine is not picking up speed

When operating a car with a gasoline or diesel engine, sometimes a situation arises when the expected increase in revolutions does not occur when the accelerator pedal is depressed. A serviceable power unit should instantly respond to an increase in the combustible mixture in the combustion chambers with an increase in the crankshaft speed, but if this does not happen, you need to look for a malfunction. It can be caused by both fairly simple and easily fixed things, and serious breakdowns.

Piston group wear

With prolonged operation of the engine, the piston group naturally wear out, which causes a drop in the required compression in the cylinders and the power of the power unit. Excessive wear can occur when the piston rings are stuck due to improper engine operation, the use of poor quality fuel and oil.

Ignition system malfunctions

Most often, in the ignition system, malfunctions that reduce engine power relate to spark plugs, in which the gaps between the electrodes can be violated, carbon deposits have been deposited on them, or the insulator is damaged. Deterioration of spark quality or its absence is often the result of breakage, contact failure or integrity of high-voltage wires, ignition coil and distributor.

The engine is not picking up speed well. where to look for the problem?

The most unpleasant kind of problem is when something in the car is half broken. In such cases, troubleshooting becomes a complex task, reminiscent of catching fleas. A common example: the engine does not rev up after pressing the accelerator pedal. The car is driving, but it is not capable of accelerating to normal speed. the motor “sneezes” and stalls. If you decide to find the problem yourself, check out the full list of reasons causing inappropriate behavior of the power unit.

Ignition faults

In cases where, when you press the gas pedal, you hear a lumbago in the exhaust pipe or the engine starts to “triple” at idle, try to find a problem in the ignition system. Weak sparking at the spark plug electrodes leads to incomplete combustion of the air-fuel mixture and a loss of power in the power unit. The reasons for the malfunctioning of the system look like this:

- Problems with one or more high voltage coils.

- Leaky insulation of high voltage wires going from the coils to the candles.

- Due to the long service life, the candles themselves have worn out.

The trick of worn-out candles is that they give a normal spark during testing. But there is high pressure in the cylinders of the engine, at which the old candles die out. That is why the engine does not develop revs, and a sharp depression of the accelerator pedal causes a “failure”. It is necessary to check the candles on a special stand that creates a pressure of at least 20 bar.

You can diagnose a breakdown of a high-voltage wire or spark plug insulation in a dark garage. Open the hood, start the engine and watch it work. If you notice sparks on the “cradles”, put new parts.

A failure of the coil or a break in the high voltage wire is evidenced by the complete failure of one of the cylinders. Testing the wire is easy: swap it with the adjacent one and make sure the other cylinder stops working. This technique will not work with coils; special equipment is needed for diagnostics.

Motor problems

Critical wear of the cylinder-piston group of the power unit also leads to a decrease in power. There are other reasons why the engine revs poorly:

- burnout of a valve in one or more cylinders;

- lack of compression or its fall below the permissible level;

- incorrect adjustment of thermal clearances between valve stems and rocker arms;

- malfunctions of the timing belt or chain drive.

Most of these malfunctions are detected by measuring the compression. A burnt-out valve does not completely sit in the seat, which is why the pressure in this cylinder drops to 2-3 bar, and sometimes to zero. A general decrease in compression in all cylinders to a level of 9 bar and less indicates a “playful” piston rings.

Advice. Before announcing the verdict to the cylinder-piston group, it is worth checking the thermal clearances with a feeler gauge. If recently some “specialist” made an incorrect adjustment and clamped the valve, then the compression will also decrease.

Similar errors occur when replacing the timing chain or belt, when the marks are shifted by 1 tooth. The consequences are a violation of the valve timing and loss of power, plus unstable engine operation. A similar effect is encountered by careless drivers who do not follow their own car: from wear, the chain (belt) stretches strongly and jumps on the camshaft gear by 1 tooth.

Too high consumption of oil entering the combustion chambers through the valve seals also worsens the operating conditions of the power unit. From the inside, the walls of the chamber and the electrodes of the candles are covered with carbon deposits, and the piston rings coke and lie. A sure sign of a malfunction is a puff of gray smoke from the exhaust pipe.

Fuel system problems

If you encounter a problem with a drop in engine power, start looking for a malfunction from the fuel supply system. After all, if the engine does not respond to opening the throttle valve or starts to stall, it is logical to assume that it simply lacks fuel. Your actions:

- Remember when the fine filter was changed and check its condition. Clogged filter element does not allow enough gasoline to pass through, which is only enough for idling without load.

- A common reason is a fuel pump mesh clogged with dirt, located in the tank. Often, motorists ignore its replacement, installing only a new filter. To check the coarse mesh, you will have to disassemble the gas tank and pull out the pump.

- The pressure relief valve has failed, dumping excess fuel back into the tank. It is checked by measuring the pressure in the fuel rail through a special fitting.

- If you smell gasoline in the closed garage where the car is stored, walk along the entire fuel line, looking for leaks.

Note. A clogged filter is indicated by the prolonged noise of the fuel pump, audible after the ignition is turned on. The unit cannot raise the pressure in the line to normal and does not turn off for a long time.

serious problems are more difficult to detect. Both gasoline and diesel engines can suffer from malfunctioning or failure of injectors. Their performance is verified by removing and connecting to a power source. The sprayer must create an even, beautiful “torch”, otherwise it must be replaced.

The reason for the lack of fuel in a diesel engine is often the fuel pump, which creates high pressure in the system. When the parts of the unit are worn out, the pressure in the line drops below normal, and little diesel fuel is injected into the cylinders.

Together with the fuel filters, it will not hurt to check the air filter. Blow out the contaminated element, if you cannot immediately change.

Other problems

A modern car is equipped with an electronic control system for the power unit and flue gas neutralization. Since the technical condition of these systems directly affects the operation of the engine, power loss can occur for the following reasons:

- destruction and complete obstruction of the catalytic converter installed in the exhaust tract of a gasoline engine;

- a clogged diesel particulate filter has the same consequences. the exhaust gases have nowhere to go and the power unit “suffocates”;

- failure of one or more sensors associated with the electronic control unit.

Checking the patency of the catalytic converter and particulate filter is simple: unscrew the front flange of the device, opening the way for the exhaust gases, and start the engine. If its performance improves significantly, replace the catalyst with a new one or install a flame arrester.

When the lambda probe fails, the engine does not pick up speed at the command of the controller. Without “seeing” the amount of oxygen at the outlet, the electronic unit cannot properly prepare the air-fuel mixture, therefore it goes into emergency mode. The mixing of fuel with air occurs according to the established indicators, which reduces the engine power.

The transition to the emergency operation mode is accompanied by the inclusion of the Check Engine display on the dashboard. A malfunction occurs whenever one of the main sensors fails. the mass air flow sensor (in new cars. MAP), the lambda probe or the throttle position sensor. To check the performance of these devices, it is better to contact a competent auto electrician or to a service station.

Engine won’t rev or keep revving

The most common reasons why the engine is not picking up speed are:

- incorrect position of the choke lever or breakdown of its drive;

- dirty air filter;

- faulty manual accelerator control system.

At home, without special equipment and skills, you can only check:

- condition of the air filter;

- operation of the air damper drive lever (only on those models where the air damper position is manually adjusted);

- a manual accelerator control system, that is, a special lever on the folding handle and a cable connecting it to the carburetor.

Checking the condition of the air filter and flushing it is described in detail in the mower’s operating manual, and we examined the check of the throttle position regulator in the previous section.

To check the manual accelerator control system, you need to set the lever to a position where the engine speed will correspond to that required for mowing, then mark its position with a marker and, after waiting for them to decrease, compare the position of the lever relative to the mark.

If the lever matches the mark, then the problem is much more serious and you need to contact the service, if the lever has moved, then you need to replace it.

Some inexpensive Chinese devices are supplied with a factory defect, including an incompletely assembled air damper actuator or its incorrect adjustment.

If you know how to eliminate such defects, then you can do it yourself, if not, we recommend that you immediately contact the service center so that the mower can be repaired under warranty.

Many modern lawn mowers are equipped with automatic speed control, so they can only be diagnosed in a workshop.

Initial inspection

To establish the real cause of this defect, you must first carry out a complete visual inspection and make sure that the holes in the air filter or muffler are not clogged, there is gas in the tank, and the throttle lever and ignition switch are in the correct position.

If everything is in order with this, then it is necessary to perform pre-start work, including cleaning the air or fuel filters, described in detail in the operating instructions for the mower, and then try to start again.

After making sure that the engine still does not start, the mower is placed on the table and proceeds to a more detailed search for the reasons.

First, unscrew the spark plug and plug the plug hole tightly with your finger, then smoothly but quickly and strongly pull the recoil starter cable or press the electric start button.

The moving piston must create enough air pressure to push the pin through and out. If this does not happen, then the motor needs serious repairs, which are difficult to do at home, so it is better to take the mower to a specialized workshop.

After all, the reason that the piston does not move after the starter cable or the rotation of the electric starter shaft can be:

- breakdown of the starter, due to which it does not transfer rotational energy to the engine shaft;

- a sheared flywheel key that connects the flywheel and starter to the engine and also ensures the correct ignition angle.

To fix both faults, not only tools are needed, but also skill, so those who do not have the skill to repair any engines should not try to fix such problems on their own.

Engine speed drops and it stalls

If, when idling, the engine normally keeps even the forcibly raised high speed, but after the start of mowing, its speed drops sharply and it often stalls, then the reason may be as follows:

- the air damper drive is faulty or its lever is in the wrong position;

- clogged air filter;

- the candle is broken inside, therefore it gives a weak spark.

Perform the steps necessary to check these causes (we already talked about this in the previous sections) and, if the problem persists, contact a specialized workshop, because the motor needs professional diagnostics and repair.

To carry out such diagnostics and repairs, special equipment and skills are required that most users of gasoline lawn mowers do not have.

Most common problems

The most common faults are:

- the engine will not start;

- the motor stalls arbitrarily;

- the engine does not pick up speed or does not keep it;

- immediately after the start of mowing, the engine speed drops and it stalls or works intermittently;

- smokes heavily;

- goes badly;

- does not stop even after the operator releases the wheel drive lever;

- shakes violently;

- does not cut the grass well.

Cuts grass poorly

If after mowing the grass looks clumpy, then the reason for this is always the same. a dull knife, which must either be sharpened or replaced.

In this case, it is necessary to take into account the manufacturer’s recommendations, because not all knives can be sharpened, especially at home, so if it is recommended to change the knife in the operating instructions, then do not experiment.

An improperly sharpened knife quickly dulls and loses balance, which can lead not only to vibration, but also to rapid wear of the engine bearings. If the knife can be sharpened, then do it as described in the previous section.

The device does not drive well

The most common causes of such a malfunction are:

- incorrect adjustment of the wheel drive cable;

- clogged bushings or wheel bearings;

- Leaking lower oil seal of the engine crankshaft;

- poor quality or too large drive belt.

It is necessary to start the test by adjusting the wheel drive cable, this procedure is described in detail in the manual for the petrol lawn mower.

It is necessary to move the cable adjustment so that the drive engages with less pressure on the lever. If this does not help, it is necessary to return the cable to its original state, then prepare the mower for replacing the belt, all preparatory actions are also described in detail in the operating instructions.

To check the ease of rotation of the wheels, tilt the mower by raising the front and rear parts alternately, and also by hand checking the ease of rotation of the wheels.

If the drive wheels do not rotate tightly, then it is necessary to check the condition of the bushings by which they are connected to the mower body, possibly the bushings are clogged with grass. To cope with such a problem, it is necessary to remove the wheels, then pull the shaft out of the bushings and clean all the elements from adhering grass, a detailed description of this operation is in the operating instructions for the lawn mower.

To carry out the following steps, you need at least a minimum of locksmith and repair experience associated with any motorized equipment. If you do not have such experience or are not sure that you can handle it, it is better to entrust the performance of these works to a specialized workshop or service center.

After draining the oil and gasoline, the gasoline lawnmower is placed on the table, turning the muffler to the bottom or with the wheels towards the top.

Then remove the knife and belt guard (all these operations are described in detail in the operating instructions of the lawn mower) and check the tension of the latter, and also look for traces of oil.

If the belt is very stretched, then it must be replaced with a new one, this can be done independently, however, certain locksmith skills will be required.

If there are traces of oil, then it is advisable to deliver the device to a service center, because special equipment and certain skills are needed to repair it.

Incorrect ignition timing

It often happens that unlucky car owners, wondering why the engine does not develop speed, forget about the ignition moment, although it is he who plays the most important role in the operation of the power unit. Timely ignition of the fuel mixture in the combustion chambers depends on it. If the ignition timing is set incorrectly, you will never, by any means and methods, achieve the coordinated operation of all engine systems and mechanisms.

In injection power units, the corresponding sensors are responsible for the correct moment. Their job is to collect information and transfer it to an electronic control unit, which in turn regulates the angle. There are no such sensors in carburetor engines, so the ignition is set manually by scrolling the top of the ignition distributor.

Setting the correct angle yourself and without special equipment is not easy, although possible. At service stations, a special stroboscope is used for this, with the help of which the specialist determines the position of the mark on the crankshaft at a certain position of the distributor.

Cold engine

It would be wrong to demand full power from the power unit until its temperature reaches the operating indicator (90 0 C), especially when it comes to a carburetor-injected engine. A cold engine does not fully rev, even with the choke fully closed. The fuel mixture must be warmed up before entering the combustion chambers. Otherwise, the car will “jerk” and the engine will stall and detonate. So, if your car is equipped with a carburetor engine, do not rush to leave until it warms up.

Violation of valve timing

Violation of the valve timing usually occurs when the timing belt breaks or when it is replaced. Having made a mistake in the form of an offset of at least one “tooth” between the crankshaft gears and the gas distribution mechanism, you will get a real problem in the form of unstable engine operation, increased fuel consumption, colored exhaust and other troubles.

In order not to get into a similar situation, work on replacing the timing belt and repairing all elements associated with it should be carried out at service stations. Well, if this is not possible, then it is necessary to carefully check and recheck the correspondence of the marks on the timing gears, crankshaft and flywheel.

Malfunction symptoms

It is not difficult to determine that the engine is not developing the speed that it should develop, especially if you have driven a car before and you know its native characteristics. Those drivers who have encountered a similar problem in their practice know that a decrease in power is characterized by sluggish acceleration, loss of dynamics, traction, as well as engine overheating and increased fuel consumption. Sometimes these processes are accompanied by gray or even black exhaust.

Why the engine does not develop speed: possible causes and remedies

Reducing the number of engine revolutions significantly affects its power and traction. If suddenly your car has lost its former agility, you should think about its diagnosis, because such symptoms do not bode well.

In this article we will talk about why the engine does not develop rpm and what this may be due to. We will also look at the likely causes of the loss of power in the power unit and methods for their elimination.

Main reasons

There can be many reasons why the engine does not develop rpm. Here is a list of the most common ones:

- the power unit is not warmed up to operating temperature;

- low or, conversely, excessive fuel level in the float chamber;

- the accelerator pump is faulty;

- clogging of jets, carburetor channels;

- air leaks in the intake manifold;

- the ignition timing is incorrectly set;

- the valve timing is broken;

- the spark plug gaps are broken;

- clogged air or fuel filter;

- malfunction of mass air flow sensors, crankshaft position, throttle position, knock;

- insufficient compression in cylinders, etc.

As you can see, the list is quite extensive, although it cannot be called complete. Let’s consider in more detail the listed malfunctions.

Gaps between electrodes

The next reason why the engine is developing slowly or not developing at all, may be an incorrect gap between the electrodes of the spark plugs. I had a normal car with a normally working engine, but you didn’t like something, and you decided to change the candles, but did not read the manufacturer’s recommendations. An error in the gap of one tenth or one hundredth of a millimeter will certainly make negative adjustments to the operation of the engine. Depending on its increase or decrease, it may be difficult to start, loss of traction, decrease in power, excessive fuel consumption, etc.

When it comes to clearances, we cannot fail to mention two-stroke engines. For them, candles are one of the most important elements that ensure stable engine operation. So, if the two-stroke engine does not develop speed, the first step is to check the condition of the electrodes and the compliance of the gap with the recommended indicators.

Sensor malfunction

Compared to a carbureted one, an injection engine benefits from the fact that its operation is electronically controlled, and if any problems arise, the driver will know about them by an error signal on the control panel. He will only have to connect the tester and read the code to determine which of the nodes has failed. This happens thanks to electronic sensors that control the operation of the main systems and mechanisms. But they are not eternal either.

Reasons why the lawn mower does not develop momentum

There are five main reasons why the Stihl trimmer does not develop speed:

Little tricks

- If you are unable to tighten / loosen the adjusting screws properly, it may be that the spring is too thick and stiff. Then you can choose instead of her a more suitable.

- If your unit does not need pure gasoline, but its mixture with engine oil, strictly observe the proportions specified in the operating instructions. There is one little thing: the recommended ratio is 1: 25 (for all brands of oil) or 1: 50 (for “native” oils). Try the first ratio first. If, with such a recipe, oil drips appear on the motor, and a strong carbon deposit forms on the candle, reduce the proportion of oil by half. This usually helps to fade traces and reduce the amount of carbon deposits.

- To clean the spark plug electrodes from combustion products, you can use fine-grained “sandpaper”. Wipe them down with a dry cloth first and then gently sand them with sandpaper. If the space between the body of the device and the insulator is also clogged, a regular unbent paper clip can help clean it. To do this, briefly soak the candle in diesel fuel, and then scrape off the dirt. If the blockage is small, one procedure is sufficient. In case of heavy dirt, it is sometimes necessary to repeat it several times. After complete cleaning, the candle must be wiped dry from the remaining diesel fuel, and then it can be used as directed.

- Please note that foreign-made lawn mowers (gasoline, electric or battery) require a little more maintenance than domestic ones. In particular, many strongly recommend entrusting the adjustment of the carburetor of a two-stroke engine to professionals, especially if your purchase has not expired the warranty period.

- And finally, one more tip: follow all the manufacturer’s recommendations for the operation and maintenance of the device. This will prolong its smooth operation.

You will learn more about what to do if the petrol trimmer is not picking up speed.

The modern market offers a wide range of electric and fuel-powered trimmers from various manufacturers. The equipment may malfunction. For example, insufficient speed. Do not panic about this, since the problem of insufficient speed in lawn mowers, trimmers is quite common. There are several reasons for this.

How To Make Your Craftsman Hydrostatic Lawn Mower Go Faster with Taryl

How to start a Stihl lawn mower

The main steps for starting a Stihl lawn mower are:

- Before using the petrol trimmer, you should read the instructions and check the Stihl trimmer for the presence of each spare part. Then you can collect it.

- An important step is fuel preparation and refueling. You need to prepare the mixture in a measuring container. Gasoline and oil are poured into it in the specified ratio. Using a funnel, the mixture is poured into the fuel tank.

- When starting for the first time, turn on the ignition without opening the choke. Place the device on a flat and smooth surface for stability. Now. you need to sharply pull the cord 3 to 5 times. The air damper can be opened in any case: the engine has started or not.

The first start may require up to 15 jerks. After starting the engine, it is worth turning on idle to warm up. After a while, it is stopped with the Stop button.

Note! This instruction is universal, as in order to start the Stihl lawnmower, you need to follow the same steps.

In the case of starting an electric trimmer, everything is much simpler: you need to read the instructions and act in accordance with it. Instead of fuel, there is electricity. The appliance is powered by mains, so it is important to provide sufficient power to allow the trimmer to rev up.

Both the petrol and electric trimmer require a thorough inspection after each use.

By following the instructions, you can quickly fix any minor damage yourself. But sometimes it is not possible to start the unit with your own hands. In this case, it is better to seek professional help, especially if it relates to a problem with the engine and the development of rpm at the trimmer or lawn mower.

Any person who owns a summer cottage or land plot is well aware of the problems of dealing with excess vegetation. Now a trimmer has come to the rescue, which has successfully replaced the usual braid in this field. This unit is very convenient in operation, but it, like any mechanism, tends to fail due to difficult working conditions or incorrect operation. Situations when the trimmer does not pick up speed are quite common. To understand this problem, it is necessary to understand some aspects related to the operation of the apparatus.

Low quality fuels

The gas trimmer does not pick up speed in the case of poor quality fuel. It may stall or not start at all. To check the quality of the fuel, you need to inspect the spark plugs. They are the main indicators for problems with the combustion chamber.

In the presence of sediment formed on the candles, plaque, the old fuel is drained and another, high-quality.

It must be remembered that the trimmer or lawn mower must be filled with good quality gasoline and those brands of fuel that the manufacturer indicated in the technical passport of the device.

For your information! The candles should be thoroughly cleaned of plaque, and only after that they should be placed in the combustion chamber again.

Failure in the fuel circulation system

Lack of fuel circulation in the system can also be the reason why the device is not picking up speed. There are several options for why this happens:

- cracks in the hose, which causes air leaks;

- clogged fuel pump;

- clogged catalyst or muffler.

You can fix the problems yourself. For this you need:

- remove blockages from the fuel pump;

- renew hoses, pipes for fuel circulation;

- clean the muffler and the mesh on it;

- install a new catalyst.

Don’t worry if you have such problems. This does not mean at all that the unit is of poor quality. If the Patriot trimmer is not picking up speed, you can fix it yourself without going to the service.

Troubleshooting methods

The first three reasons are fairly easy to eliminate. If the matter is in the mixture, you need to pour out the old fuel from the tank, prepare a new emulsion from high-quality gasoline and engine oil (if your engine requires a mixture) and pour it into the fuel tank. If the trimmer is running on clean gasoline, it’s even easier.

In the second case, it is necessary to carefully free the trimmer parts from the wound grass.

If the filter is clogged, you can try rinsing it. If this procedure does not bring any effect, replace it with a new one.

The last reason a lawn mower doesn’t work properly will require a little more knowledge and skill from you.

To properly adjust the carburettor for lawn mowers, a specific procedure must be followed. First, clean the air filter thoroughly. The easiest way is to rinse it (it is advisable to douse the filter with water regularly after 9-10 hours of operation).

After that, in the diagram of your trimmer, which is in the instruction manual of the device, find the adjustment screws. There are usually three of them: the first is responsible for fuel supply, the second is for idling, and the third is designed to limit the number of maximum engine speed.

Next, turn on the unit and wait for the engine to warm up.

Tighten the first (fuel mixture) adjusting screw slowly. Catch the moment when the motor starts to stall and turn the propeller back 45 degrees. If you did not have time and the motor stalled, the screw should be turned 90 degrees. Open the throttle and watch the revs increase. Next, slowly unscrew the screw (each turn is the same 45 degrees) until the moment when, at full throttle, the engine begins to firmly give out maximum revolutions.

The second screw, as mentioned above, controls the engine idle speed. By loosening it, you decrease the number of revolutions, while twisting it, you increase it. The screw needs to be adjusted so that the motor runs reliably at low revs. For better starting, speed up the engine slightly. At the same time, make sure that the motor rotates several tens of times before starting the movement of the knives / line reel. If the engine starts poorly, tighten the screw a little.

After you have adjusted the first two screws, test the operation of the unit at maximum engine speed. If necessary, you can limit it (maximum). this will protect the motor from “boiling”. To do this, you need to tackle the third screw. Unscrew the locking nut until the adjusting screw can be safely turned. To increase the maximum number of revolutions, the screw must be loosened, to decrease. on the contrary, tighten. Fix the position of the screw with a nut. Test the motor again.

Check the position of the screws regularly. the high vibration levels of lawn mowers can cause them to move unintentionally.

Remember that carburetor adjustment is not a final procedure. During the operation of lawn mowers, you will most likely have to tinker with it more than once, because an unbalanced carburetor means both increased fuel consumption and a quick failure of the candles, not to mention a decrease in the power and performance of the device.

Carburetor

This mechanism is an important part of the petrol trimmer. In order for the carburetor to work properly, several conditions must be met:

- disassemble and clean it from time to time;

- adjust the idle speed according to the instructions;

- contact the wizard when adjusting.

In the event of a breakdown of this unit, you can do its repair yourself, but only if you have certain knowledge.

One of the reasons for poor carburetor performance is a loose cable. To eliminate the problem, you first need to disassemble the entire assembly, and then, after thoroughly washing all the parts, lubricate and tighten the cable, but not very much, so as not to stretch.

Important! Other malfunctions can also adversely affect the operation of the carburetor: failure of the inlet needle, deformation of the membrane, wear of the adjusting lever, contamination of the control cavity, wear of flaps.