Why the chain on a chainsaw does not tighten

Step-by-step guide: How to tension the chain on your chain saw correctly?

Regardless of chainsaw class, the chain slackens when exposed to intensive, regular use. This can be determined by the appearance of characteristic gaps in the joints of the links, changes in the sound of operation and an increase in vibration. You can tighten the tension of the saw unit yourself with a special mechanism. This avoids serious breakdowns and injuries while working with wood.

The chain performs two functions at the same time: it cuts wood and clamps the bar, preventing it from moving. Correct chain tensioning and correct positioning of the chain ensures proper use of the chain saw and avoids dangerous bodily injury. If the saw chain is not installed correctly, it can fly off while sawing and injure the operator. Even if it is slightly slack, it will gradually break the tire groove, causing the driven sprocket teeth to fail.

Excessive tensioning puts strain on the rotor and reduces the life of the saw. That’s why it is important to check tensioning at regular intervals and to re-tighten the tensioning mechanism on the housing if necessary.

Important! Sagging can be caused by worn components. Usually, it is a worn sprocket teeth, a broken outer edge of the bar groove.

How to Check Proper Tensioning?

Figure 1. How to check chain tension

To check quality of tensioning, pull back gently at middle of bar.

Allow no more than 2/3 of the length of the cutting link tails to come out.

The following signs are also an indication of the need for tensioning:

- Creaking and squealing in the area of the main drive sprocket;

- loosening of the safety mechanism, bar fasteners;

- jamming while sawing, increased vibration and noise.

The chainsaw has reduced productivity and operating time. Even when sawing soft types of wood the chain starts to jam in the groove, the rpm and smooth running are reduced.

Diagnosing and Caring Properly for a Chain Saw Chain

A chainsaw‘s productivity depends on a number of factors:

While the amount of tensioning affects the performance of the chainsaw, the sharpening of its teeth affects the rate of cutting

That’s why it’s important to pay special attention to the following points. If the teeth are well sharpened the cut is much more efficient, precise and safe

There are no specific guidelines on how often sharpening should be performed, but professional sawyers recommend that it be done several times a day. This is caused by the teeth dulling rather quickly through intensive sawing.

Most chain sharpening is measured very closely by the chainsaw‘s cutting performance. A tool also needs sharpening when the bar starts to run to the side. Another measure of sharpening is the condition of the shavings. As a rule, a properly sharpened cutter tends to produce very uniform chips. Shavings are rectangular or square in shape. In the case of a blunt chain, dust will predominate in the shavings, and the sawdust will resemble the shape of a needle from a simple hacksaw.

if you regularly check the tension in the chain and sharpen it in time, your chainsaw will last a long time. Cutting even very hard wood is not a problem.

If you are not experienced enough, it is advisable to have it checked by an expert. Professional sawyers know the chainsaw and its components when they first look at it. They will determine how worn it is, if the chain is too tight, and if the teeth are sharp.

Severe saw blade wear

A tire lasts much longer than a chain. This does not mean, however, that you can use it forever and not think about changing it. It’s common to change a guide bar after 2 or 3 worn chains. Before replacing a chainsaw guide bar, you need to assess its technical condition. If your chainsaw is equipped with a Chinese-made bar, it will wear out sooner than the chain. That’s why if you find a chain saw cutting wood crooked, you need to have the guide bar diagnosed.

To see if the tire is worn, you must remove it and inspect it. Wear is usually evident by shortening one of the beads. Sometimes it is very difficult to detect it visually, so it is necessary to use a caliper. A difference of a few tenths of a mm tells you that the guide bar needs to be replaced. There is also a simple way to check the wear on the guide bar with a straight edge. To do this, the rail is placed on a flat surface and an angle must be fixed to the side of the rail. If the upper and lower walls of the guide rail are in contact with the guide rail, that means the component is in good condition.

That’s interesting! The only way to extend the life of a chainsaw guide is to flip it over periodically. To do this, make sure you have the option on the tool and the markings on the headset will tell you that it is possible to check the guide bar.

Rapid tire wear can be caused by improperly functioning oil pump. If the oil supply is intermittently interrupted, there is correspondingly high friction and parts will wear out more quickly. If the lubricating mechanism works properly, it increases the service life not only of the chainsaw headset, but also of the complete tool.

Why does the chain come off the chainsaw or electric saw??

Owners of chain saws are occasionally faced with a common problem. the chain starts to come off the chainsaw or electric saw. Why this happens, we’ll cover later in this review.

There are only three main reasons why a chain comes off:

Let’s look at why this or that problem occurs:

If the chain stretches, starts to sag, slips off the tire

The reason is most likely in the wear of the component itself. The chain has a finite life and is the most rapidly wearing working element of a chainsaw or electric saw. The metal deforms due to stresses, so it not only blunts, but also becomes about 1 cm. longer than on a new tool. The easiest way is to change the part, i.e. to buy and install a new chain.

If there is a problem with the bar, it is in the place where it is attached

This reason is quite common: in the groove located between the outer plate installed on the chain headset and the inner plate located on the body of the gasoline or electric saw. The cover is usually bolted in place. This attachment is called the motor unit. The bar mount, like the drive sprocket, is covered with protective covers. When the fastener bolts loosen, the degree of vibration of the tire increases, it begins to move.

In the event that everything is okay with the tire, the tension is normal, as is the operation of the tool itself. If it is a loose guide bar that is causing the chain to stretch, reattach the guide bar and check the chain saw.

Trouble with the sprocket

If the drive sprocket is poorly fixed, the chainsaw chain will also need tensioning, because sag cannot be avoided. Secure the sprocket to the tire by removing the engine guard, spark plugs, and pulling out the air filter. In place of the spark plug, a stopper is installed, whose main task is to fix the piston. Then you can use a special wrench or a universal wrench for angle grinder to spin the clutch disk in the clockwise direction.

Make sure the piston is in its outermost position. if you look into the spark plug hole, the piston should be underneath.

Once the piston is locked in place, the drive sprocket can be clamped. Afterwards all the elements are assembled in the reverse order.

Block: 2/11 | Number of characters: 2342

Causes of chain failure

Like any part, a saw chain requires attention and proper maintenance. These words first and foremost apply to the break-in period of a chainsaw and its cutting attachments. You should, however, keep them in good working order for as long as you use them.

Main Causes of Chain Failure:

- Poor metal quality on low-end models;

- The operator’s operating style;

- Incorrect tension;

- Drive sprocket defective or excessively worn;

- Malfunctions in the automatic lubrication system;

- Bent, clogged or otherwise broken saw bar;

- Use of poor quality materials;

- Untimely sharpening of working edges;

- The level of operating stress on the chainsaw;

All of these can lead to rather unfortunate circumstances, and significant expenditures to buy new parts and repair the chainsaw:

- Deterioration of operating capabilities and productivity;

- Operator safety during sawing operations;

- Premature wear and tear of individual parts and of the chain saw as a whole;

Why the chain is flying, find the causes

If you’ve been wondering why the chain is flying off your chainsaw, then there are some problems in the mechanism. There are three main causes of this malfunction: a malfunctioning bar, an elongated chain, and a loose sprocket. We will discuss in detail each of the possible causes of failure.

Block: 3/12 | Number of characters: 348

Tensioning mechanisms

The chain must be tensioned correctly so that it can move freely on the bar by hand. A classic tensioner is used for tensioning, which is used in budget-priced machines. Such a tensioner is a threaded bolt and an adjusting component with a classic or lateral arrangement.

High-quality chainsaw models are equipped with adjusters that can be tensioned with a single movement of the lever or by turning the adjusting wheel. If a tensioner is used to tension the chain, the tightening torque is locked in place with a locknut. Otherwise, you can lock the chain tension by locking the bar in a given position with the cap. Both methods can be used to keep the product firmly in position.

Another option of adjusting screw location

Important to know! It is strictly forbidden to adjust the chain tension on the chainsaw when it is hot. The product must be cooled down, otherwise the procedure will be done incorrectly.

On how to properly tighten the chain of a chainsaw, it is necessary to learn in more detail, as this moment is very important, the performance of the tool and human safety depends on it.

Block: 3/5 | Number of characters: 1293

How to tension the chain

To check tension, first disengage the brake. Then pull chain back in the middle of the headset, normally the shanks should not protrude more than 2/3 of the way. It is recommended to spin it by hand. no jamming or too fast sliding is allowed. If necessary, tighten slackened, using the nut on the protective cap.

Figure 5. Checking chain tension

Checking the tension in the bar is an important process in any chainsaw. The job is easy to do on your own. Regular maintenance prevents injury and loss of performance, even with hardwood.

Block: 5/5 | Character count: 629

- Oregon. Produces saws, chains and accessories. Products of good quality and low price. Chains are equipped with tungsten carbide tines and anti-vibration protection.

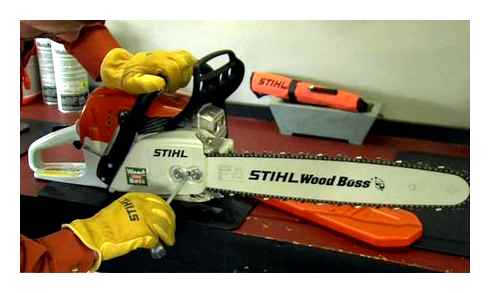

- STIHL. Professional woodworking saws. Their products are characterised by high resistance to cutting edge wear and elongation. Also features special grooves for high-performance lubrication.

- Carlton. High link durability due to special blasting technology.

- Vindsor. Innovative developments in the field of special refractory alloys of high strength and durability are used in production.

- Husqvarna. Only the best proven designs are used in production.

Important! Chain drive malfunctions are often caused not only by faulty bars and other major components, but also by poorly sharpened cutters.

- Tire defect. Wear on the threaded part of the mounting bolts causes vibration and loss of tension. Check the condition of the retainers at regular intervals and replace them if necessary.

- Chain stretching. Sooner or later the metal of the links will become structurally deformed and stretched to its limits. As a result, the chain can no longer be tightened. The chain needs to be completely replaced with a new one.

- Loose or uneven sprocket setting. Have the cause of the fault rectified by a specialist workshop. For fine tuning it is necessary to disassemble the chain block and remove many parts.

Synopsis! There are 3 major causes of chain stretching. inherently low quality metal alloy links, excessive chain tension and poor quality or poorly chosen lubrication.

What chainsaws are made of?

Depending on the intended use, that is, on the planned direction of sawing wood, chains for utility saws are divided directly into these types;

- longitudinal. the peculiarity of this type of headset is that when it is mounted and used on a garden tool, the performance of the latter increases almost 2 times;

- transversal. by installing a transversal headset with pobedite tips, the chainsaw operator can noticeably reduce the “aggressiveness” of the garden tool and reduce the load on the built-in factory motor, thereby making the engine’s vibration less noticeable.

Another important parameter for stable operation, according to which chains are constantly divided. is their pitch. Chainsaw chain pitch. this is the length of the gap between the three links.

On the market there are headsets with such pitch characteristics:

- 0,25 or 1/4″. these parts are used in single-handed household saws that are not very powerful. Most often, garden tools of this type are used for precise cutting of wood and short work in conditions of very limited space;

- 0,325 or 3/8″. Most chain saws are equipped with this type of set;

- 0.404 or 3/4″. carbide-tipped saw elements of this type have large dimensions. They are mounted exclusively on powerful professional garden tools that can be used for working on aerated concrete.

All available sawing parts are made with the assumption that the larger the size, the better the performance. Nevertheless, as the size of the sawing elements increases, so does the cutting width of the wood. To make the resistance of the material to be sawn less noticeable, you should only mount a large headset on saws with an impressive power reserve.

Quite often the manufacturers divide the saw elements according to the thickness of their shanks, which must necessarily coincide with the specified groove sizes of the standard bars of the garden tools. Following this rule will improve the security of the part on the bar as well as prevent the headset from slipping.

Another important parameter is the number of strings on the chain. The higher the number, the faster the gasoline saw will cut through hard wood or perform concrete work.

How to avoid chain stretching?

Before you decide what to do if the chain on your chainsaw breaks, it’s best to familiarize yourself with the main causes of breakage:

- The main reason is the poor quality of the product.

- It happens that the part overheats and is stretched because of the chainsaw itself. This is most often caused by wrong oil supply to the sprocket. Misalignment or a clogged oil inlet is possible.

Important! The chainsaw always needs adjustment and periodic maintenance. A worn sprocket can also cause stretching of the chain. If this happens, the guide lugs will slip, causing friction and heat to build up on the components

In this case the guide lugs slip, there is friction and heating of the parts

Sprocket wheels can also cause stretching of the chain. In this case the guide lugs slip, friction and heating of the parts takes place.

The principle of chain tensioning

The principle of chain tensioning is as follows:

- use the standard wrench that comes with the chainsaw to loosen the nuts on the cover;

- then a screwdriver is inserted into the special slot, rotary movements are performed and the chain is tensioned;

- the spanner should be turned slowly and carefully. after a couple of turns the degree of tension is checked manually and then if necessary a few turns are done again;

- when the chain is tightened enough, put the cap back on.

For work on hard materials, specialists use carbide chains made of tungsten carbide material. They are not made out of the whole wonite, but with a tungsten carbide facing. They are predominantly used for longitudinal bucking in concrete, aerated concrete and for bucking in very hard wood.

Carbide chain has a proper degree of durability, is much less blunt, but will cost 3-4 more than a standard. It is not possible to sharpen the pobedite chain at home, it requires special equipment.

How to Check a Chain Tension in a Chainsaw

To check if the chain is tensioned properly and needs tightening, look at these indicators:

- if it is tensioned correctly, the cutting quality is good, the bar quickly sinks into the material, cuts easily and does not bind in the wood;

- The bar does not get hot when you use it;

- both fine and coarse chips are produced during sawing.

The chain needs tightening if:

- the bar gets very hot;

- Quality of cut is reduced, cutting edge is uneven;

- increased fuel and oil consumption;

- Only fine chips are produced.

How to sharpen a chain cutter?

The Internet is now full of information on the subject. I also learned a lot, tried, experimented.

And in the end came to a conclusion, unless, of course, not to engage in professional chain sharpening, the best way on a domestic level, in my subjective opinion, is sharpening with the use of an ordinary semicircular file.

First of all it is not a big deal. just use a burr on the inner surface of the tooth.

The main thing. it is to do it in one direction, for example, from myself.

Secondly, it is not expensive at all. In short, 15 minutes of effort and the chain is ready to cut wood again.

As I touched the theme of wood I would like to share with you my experience in the process of preparation of firewood for winter.

How to Check the Chain Tension of a Chainsaw

To check if the chain is tightened well and doesn’t need tightening, pay attention to these indicators:

- If it is properly tensioned, the quality of cutting is good, the bar quickly sinks into the material, saws easily and without binding in the wood;

- the bar does not get hot during cutting;

- both fine and coarse chips are produced during sawing.

The chain should be retightened if:

- the bar gets very hot;

- sawing quality is reduced, the cutting edge is uneven;

- fuel and oil consumption increases;

- only small chips are formed.

STIHL MS 271 chainsaw

There are a lot of chainsaw chain models on sale these days. To begin with you need to know what size is right for your chainsaw, so you don’t make a mistake when buying. The second step is to install it correctly on the chain saw. This is a somewhat time consuming process, but if you know how to put on and adjust the chain on the saw bar yourself, then the good owner should not have any problems. We have tried to describe in detail how to install the sawblade on your chainsaw.

Hopefully after reading this article you will be able to do it right the first time. But to minimize problems with your chainsaw and chain in the future, remember the 3 basic rules:

- Replace the chain with a new one if it is worn or slack;

- If there is vibration and a bad cut when sawing. watch the chain tension on the chainsaw;

- Never use defective or repaired by dubious specialists saw blades, your health and the health of those who are nearby is much more important than small savings on the purchase of a new and reliable chain.

The chain is tensioned with the sprocket and the chain is stretched with the wrench nut

In order to tension properly, you need to know some simple mechanics and know how to use simple tools. On STIHL chain saws, tensioning is simple with the integrated chain tensioner. This method is as simple as possible and is very quick to tighten. To tighten or adjust the amount of slack in the chain, the manufacturer recommends you do the following:

- unscrew the sprocket cover with the wing nut;

- Turn the thumbwheel to find the right length of the chain and tension it as needed;

- close the sprocket cover again and the chain is firmly fixed on the bar.

If it is impossible to tension the chain of a chainsaw by the built-in mechanism, use the following tools (by the example of a Sparky electric saw):

- An angle grinder with a metal disk;

- Allen wrench, 5 mm in diameter;

- piece of wire;

- A wooden stick or a sturdy chip

- flat screwdriver.

After the electric saw de-energizing unscrew the screws with an allen key, remove the housing cover, unscrew the tensioning screw with a screwdriver and remove the stem-nut. The side of the screw that is adjacent to the body of the saw is ground with a disk. The saw is then assembled in reverse order. A splinter is needed to clean sawdust from the body.