Why the chainsaw saws the cause of the reason. What to do if gasoline does not enter the carburetor of the chainsaw?

Why is the chainsaw tire in a log

Modern gasoline chain saw consists of certain mechanisms, on the serviceability and coordinated work of which the productivity and effectiveness of the instrument when sawing different types of wood depends. Each of the saw nodes stands out by its own life, after which the tool must be repaired. You can do this yourself, having previously studied common breakdowns and methods of eliminating them with your own hands.

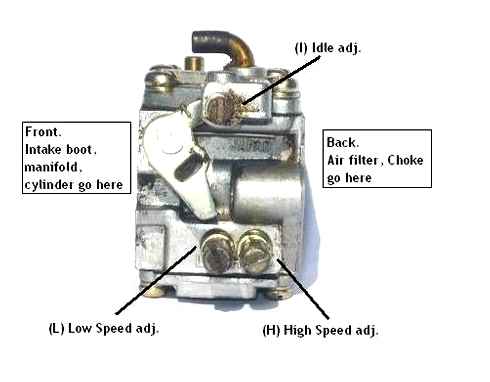

The carburetor is one of the most important elements of the chainsaw, the main function of which is to enrich the fuel with air and instant supply of the finished mixture into the cylinder of the power unit.

The following signs are said about the malfunctions of the carburetor:

- Problems with the launch of a gasoline saw. To turn on the motor it is required to make more efforts than usual;

- Unstable operation of the internal combustion engine in different modes. Interruptions in the rotation of the motor at idle, as well as when switching to low and high speeds are noticeable;

- A sharp increase in the volume of the consumed fuel. On average, the amount of fuel increases by 20-30%;

- Increasing the amount of released gas outlets-gas volumes increase by 50-60%, and evaporations acquire dark blue, brown or black color.

The adjustment of the chainsaw should be performed on a fully working and stable engine. Before starting the setup, it will be necessary to rinse or replace the filter, check the integrity of the fuel tubes, and also make sure that there are no burrs and other damage on the surface of the cylinder and other details of the power unit of the chainsaw.

Chainsaw Won’t Start. What To Look For & How To Fix. (Husqvarna Carburetor Cleaning)

In order to independently adjust the chain benzo tool in the device of its carburetor, steel spring.Loaded screws are provided. Their number and marking depend on the brand manufacturer of the chainsaw.

The order of adjustment of the fuel unit for most chainsaws looks almost the same.

The algorithm of actions should be like this:

- First, the saw needs to be drowned out and wait for the cooling of its internal combustion engine;

- After that, all the screws available in the device of its carburetor must be twisted along the clock of the clock until it stops;

- Then each of the screws must be turned on the fourth or fifth of the turnover in the opposite direction;

- Next, you need to configure the operation of the power unit at low speeds. For this, the corresponding screw will need to start slowly turning in different directions. As soon as the motor becomes as quietly and stable as possible, the screw needs to be left;

- To configure idle on a chainsaw, you need to pay attention to the chain. If it rotates on the tire, then it is necessary to find the position of the screw in which it will stand motionless;

- At the end, it remains to set up the work of the internal combustion engine at high speeds. To do this, it will be necessary to connect the tachometer to the motor cylinder and start the rotation of the corresponding screw until the indicators on the scale of the device and the instructions in the operating instructions will match. For example, if the guide to the saw indicates that its maximum turns should be 12500 rpm, then the same number should be indicated on the tachometer scale during adjustment.

To check the operation of the chainsaw after configuration, it is necessary to drown it out and wait for complete cooling of the motor. After that, you need to start the engine and start to smoothly squeeze the accelerator lever. If at the same time the power unit is smoothly gaining momentum, then the saw adjustment was performed correctly.

Why is a chainsaw crookedly sawing? There is a solution!

Many owners of the chainsaws know that when working with a tree whose diameter exceeds 30 centimeters, the sawing of the material is accompanied by a curvature of the tire, which seems to lead. The problem becomes obvious with an increase in the diameter of the barrel, when the operators use the “double cut” technique (make a cut from above, then they turn the barrel and make a second cut to finish the material to the end). If the chainsaw saws crookedly, the reason should be identified immediately.

How to fix the curvature of the tire with your own hands

The lost chain is pulled on a stationary machine, and the tire is removed and turned over. This technique helps for a while. If the tire has already been turned over, and it is curved on both sides, it will have to be aligned. This will be needed:

Remove the tire, put it with an edge on a flat surface. Put a square to her. If the tire deviates, then the ribs are curved. Turned over with the other side. If it is exactly, the problem is only in the first side. If it also deviates, both ribs need to be aligned.

- A disk is installed on the grinder.

- Clamp the grinder in a vice.

- They put a bar next to the tool, a sheet of chipboard (or any other material) is placed on it so that its surface is at the level of a food circle, and the end of the sheet is almost adjacent to it, then tightened with a clamp.

- Apply a square one side to the chipboard, the other to the circle. It is necessary to set the grinder in a vice so that the circle and chipboard are strictly at right angles to each other.

- Turn on the grinder, put the bus on the surface of the chipboard, process its edge with a cleaning circle to remove the curved groove layer. First on the one hand, then on the other, if necessary.

- Check the evenness of the tire of the square. If the unevenness is removed, the tire in the saw is set. If not, carefully cut it again.

How Do Chainsaw Chaps Protect You From Injury?? WE PUT THEM TO THE TEST! | eReplacementParts.Com

If after processing the rib is exactly, the curvature of the groove is removed.

Krivnaya sawing due to uneven sharpening of teeth

If the tool saws one side, then the first thing you need to check the chain. The teeth should not just be sharp, but also properly sharpened. Correct sharpening is when each tooth grows at the same distance with the previous. In this way of sharpening, it is possible to exclude the occurrence of a chain imbalance during sawing. The instructions for the instrument indicate that each tooth when sharpening should grind at the same distance. If this requirement is not fulfilled, then besides the fact that the chainsaw will be taken aside, an increase in the load on the engine is not excluded.

If a beginner performed sharpening the teeth, then it is worth making sure after the work done in the correctness of its implementation. Some sawmills are based on a simple rule. Sharpening with a file must be performed in the same amount for each tooth. However, this assumption is not true, since the teeth of the chain wear out unevenly. As a result, it turns out that the acce of each tooth leads to the restoration of their severity, but not the uniformity of wear. When the saw begins to saw crookedly, you need to check all the teeth on the chainsaw for their sharpening and uniform wear.

It is interesting!If there is an uneven wear of the teeth of the chain, then it is necessary to resort to their restoration. You can only verify the uniformity of sharpening visually.

To exclude the uneven wear of the chain, the teeth should be sharpened in a timely manner, that is, every 15-20 hours of work, sharpen the file. Once every 2-3 months (depending on the operating frequency of the tool) to sharpen using a special machine.

If you are not sure that you sharpen the teeth of the chain correctly, then it is worth entrusting this work to a professional. Although this is a costly business, but much effective. If you want to learn to correctly hide the chain of chainsaws, then this material describes a detailed instruction for beginners.

It is interesting!It is worth paying attention to one very important nuance. If in the process of sawing a chainsaw under the cutting headset a metal object, stone or earth, then this will lead to an accelerated wear of teeth. It is after such a nuance that a consequence of the crooked sawing of a chainsaw often occurs often.

Violation of the uniformity of sharpening

According to the instructions, the teeth are stuck at the same distance, regardless of the side of the location of the teeth. But in practice, rarely anyone observes this parameter, because the unevenness of the teeth is overwhelmed is the most popular cause of the crooked cut.

Home masters rarely attribute a detail to a professional, preferring to drag the elements with a file. This is incorrect. When calculating the number of movements by a file, there is a risk of different pressure, which is why the teeth will again be worn unevenly. In the process of work, the tire will lead, the cut will turn out to be a crooked.

How to eliminate an uneven sharpening defect

- Buy a brass machine. If you have to work often with a saw, the purchase of a machine is a reasonable attachment. Equipment will increase the life of the chainsaw. The machine is set up according to the most worn element. Automatically selects the shortest tooth, carries sharpening by its size. As a result, all the teeth of the saw will be sharp and the same.

- Give a saw to the workshop. Here the process will be similar, the master will sharpen the tool on the most short tooth.

The process of grinding teeth according to the most short element reduces the resource of equipment.

To increase the period of use of the saw, during work, they monitor the presence of nails, metal brackets. Metiza often come across in old boards, and they lead to rapidly grinding the teeth of the saw.

Why is a chainsaw not starting on hot. Why the oil flows

Many owners of chainsaws are faced with a problem such as flowing oil from under the unit. Most often, oil flows due to damage to the oil hose connected to the oil pump. The photo below shows exactly the case when the end of the hose exploded and does not dress tightly on the pump pipe.

But in order to get to this place, you need to remove the clutch mechanism from the shaft. In some models, the oil can flow at the junction of the oil pump with the oil tank hose (the photo is indicated by the arrow).

To eliminate the leakage of the lubricant, you need to stretch this hose from the landing site. To do this, you can use the pliers, pulling it for its outer part. At the end of the hose you will see a rubber cork, which is the cause of oil flowing. This cork must be wiped well to remove the remaining oils, after which its seat must be compacted with something. You can use a car sealant or fum tape, as shown in the following photo.

Collected according to the instructions. It will not start. I checked the spark on the candle. Absent “.Alexander Goncharov, product manager of Khuskvarna LLC, is responsible for the buyer’s request.

One. I give below the information “just in case”, to the future that is relevant for using any tool, any manufacturer:

It’s not in the know what methods were checked by sparking, but if the verification “on the spark” was made by grandfather methods, by twisting the candle and “examination”, there is a spark or not, even pressing it to the body, supposedly creating the effect of “mass”, then It is strongly recommended to do this (read: it is strictly prohibited).Modern electronic ignition systems installed on a modern benzo.Tool do not withstand the “gap” of the contact in the circuit, and it is the spinning of the spark plug and scrolling the starter with the ignition on that can lead to the failure of the entire ignition module.At the same time, the electronic system creates on electrodes such a category, which without a special device that has a trained service specialist, “ordinary look” can not be considered.

How to adjust/tune a Poulan chainsaw carburator

Perhaps in your case and not everything is so regrettable.It is possible that without sufficient experience and having performed several “not those” actions on the factory, the engine simply “oversaturated” with fuel, which prevents the launching.

To fix this, it is necessary:- turn off the ignition (lowering the red switch down) and make sure that the air damper lever (blue) is “drowned” to the stop (“pushed” towards the engine)- remove the cylinder cover (unscrewing 3 screws),- unscrew The candle again,- when the ignition is turned off, twist a few times by the starter, and it is better to keep the saw “down” by the saw, in order to more effectively remove the excess of the fuel mixture. Usually it happens in abundance, and about a dozen jerks are required to “blow” the cylinder.- Twist the spark plug, throw a high-voltage wire on it- pull the blue lever of the air damper. At the same time, the red electric circuit breaker itself will “rise” upward, turning on the ignition- click 5-6 times with the thumb of the cylinder on the fuel pumping pump (primer) until the fuel mixture “approached” to the carburetor,- placing the saw on the ground, To rest on the front handle with your left hand, standing with your right foot on the site of the rear handle of the saw, pull the statra’s handle several times, until I “grunted”, then “push” the blue lever of the air damper, not touched to the upper. Red circuit breaker and pull the starter handle again.- As a rule, after a couple of “twitches” a saw will start starting.

Krivnaya sawing due to uneven sharpening of teeth

If the tool saws one side, then the first thing you need to check the chain. The teeth should not just be sharp, but also properly sharpened. Correct sharpening is when each tooth grows at the same distance with the previous. In this way of sharpening, it is possible to exclude the occurrence of a chain imbalance during sawing. The instructions for the instrument indicate that each tooth when sharpening should grind at the same distance. If this requirement is not fulfilled, then besides the fact that the chainsaw will be taken aside, an increase in the load on the engine is not excluded.

If a beginner performed sharpening the teeth, then it is worth making sure after the work done in the correctness of its implementation. Some sawmills are based on a simple rule. Sharpening with a file must be performed in the same amount for each tooth. However, this assumption is not true, since the teeth of the chain wear out unevenly. As a result, it turns out that the acce of each tooth leads to the restoration of their severity, but not the uniformity of wear. When the saw begins to saw crookedly, you need to check all the teeth on the chainsaw for their sharpening and uniform wear.

To exclude the uneven wear of the chain, the teeth should be sharpened in a timely manner, that is, every 15-20 hours of work, sharpen the file. Once every 2-3 months (depending on the operating frequency of the tool) to sharpen using a special machine.

If you are not sure that you sharpen the teeth of the chain correctly, then it is worth entrusting this work to a professional. Although this is a costly business, but much effective. If you want to learn to correctly hide the chain of chainsaws, then this material describes a detailed instruction for beginners.

High degree of wear

The crooked arc of the saw can speak of the unsuitability of the saw headset. Visually check wear on the inspection of the contacting surfaces. Do this:

Looking through the entire groove, they see how worn out the left and right side of the tire in relation to the groove. The standard is uniform wear on both sides, a large curvature in one direction or another is an occasion to replace a defective part.

As a prevention, do not forget about the lubrication of equipment, checking the supply nozzle. If it is clogged, the lubricant does not arrive, the wear of the tire increases. Low.Quality lubricant, poor oil, uneven supply of the composition will also quickly disable the tire.