3 Important Things on Using a Jeweler’s Saw. Jewellery saw blade sizes

Important Things on Using a Jeweler’s Saw

Starting out in jewelry making? Need to brush up on your pre-existing knowledge? Either way, you’ll need to know how to use a jeweler’s saw. And this can be pretty tricky if you’re learning it for the first time. So to help you on your way, we’ve listed everything you need to know for using a jeweler’s saw – from attaching the right blades to the correct way to use them. Find out the 3 Important Things on Using a Jeweler’s Saw.

Size of Jeweler’s Saw Blade

First things first, you need to use the correct size blade. Depending on the thickness of the metal you’re using, your saw blade will need to match. For thinner metals, use a blade with more teeth and vice versa.

Steps on Attaching a Blade in a Jeweler’s Saw

Now you’ve sorted the right sized blade, next up is attaching it to the saw frame.

- First up, you’ll need to establish the teeth’ direction – they need to face downwards when in the frame.

- Next, loosen the thumbscrew on the top of the frame and insert the blade in between the plates with the teeth facing outwards.

- Once you’ve re-tightened the thumbscrew, do the same with the bottom so that the blade is in place.

- The last step to ensure the blade is fitted properly is the sound test. Pluck the blade as you would a guitar string. If you hear a ‘twang’ – it’s not tight enough. If you hear a ‘ping,’ you’re ready to start sawing.

Top tip: While tightening the bottom screw, push the frame against your workbench. This helps to make sure that the blade is fitted tightly.

Avoid Breaking the Blades

You’ve attached your blade, and you’re ready to start sawing, but there are still a few key tips to consider. Here’s how to use a jeweler’s saw to avoid breaking blades:

- Avoid twisting the blade. This sounds fairly obvious, but it can happen without you noticing. If you’re sawing a design with many curves, make sure the blade isn’t twisting to the side as it can snap pretty easily.

- Be careful with corners. If you’re sawing something with sharp corners, all is not lost. You can saw the corners without breaking a blade every time. All you have to do is stop when you reach the corner, continue the sawing motion without adding pressure and then gradually turn the blade.

- Stabilize the metal with your hand. This will help to keep your metal in place, so you don’t make any sudden or sharp movements with your saw.

- Use beeswax. You can also prevent saw blades from breaking by coating them in beeswax – that way; the blades won’t stick to your designs.

- Keep checking the tension. Using the sound test mentioned previously, it’s important to keep checking that your blade is taut enough.

- Don’t add too much pressure to the blade. Instead, hold the frame lightly and use longer, even strokes.

- Start sawing with an indentation. Do this by just sawing a few times upwards when you begin. This will guide you in the right direction for a more accurate result.

Feeling ready to give it a go? If you feel unsure while trying it, re-read our blog on How To Use A Jeweller’s Saw.

How To Use A Jewellers Piercing Saw

Sawing metal sheet is a technique you will do at the very start of your jewellery making journey and with practice and patience, it will be a skill you will master.

We’re sharing with you top tips on using the saw when making jewellery, how to attach saw blades and provide all the supplies you need to get started.

Another alternative to cutting metal sheet is using metal cutters/shears, however with a piercing saw you are able to create many intricate shapes, cut holes and shapes within the metal. This gives you endless possibilities and the chance for you to get really creative at the bench!

Why Use A Jewellers Saw?

The possibilities are endless when it comes to using a jewellers piercing saw and we often turn to the saw for most of our cutting needs.

The jewellers saw is a must-have in the workshop, allowing you to easily cut metal wire and sheet, such as cutting D-shaped wire for making a ring Band/bangle or cutting intricate shapes out of metal sheet.

Using a saw instead of metal cutters has it’s advantages, as a saw enables you to cut without curling or distorting the metal which is what you would experience using metal cutters. Using a saw for cutting out shapes will minimise the need for filing and flattening your work.

Allows Precision Needed For Soldering

A saw will also allow you to cut a nice flat edge which is essential for a solder joint. If you were making a ring Band for example, when bending the wire together to form a Band ready to solder. you can overlap the wire and use your saw to cut through them to create a neat, flat edge for your solder joint.

Cut Out Intricate Shapes Internal Shapes In Metal

If you would like to cut our a detailed shape in metal sheet, the saw is your go-to tool!

Shop Jewellers Swiss Piercing Saw Frame

We offer a high-quality jewellers Swiss piercing saw frame for cutting metal sheet, metal tubing and metal wire. This classic design has a comfortable wooden handle, with easy tension adjustment to prevent blades from breaking. It also has an adjustable length which allows you to use different length saw blades to suit your needs.

Choosing blades for the jewellers saw

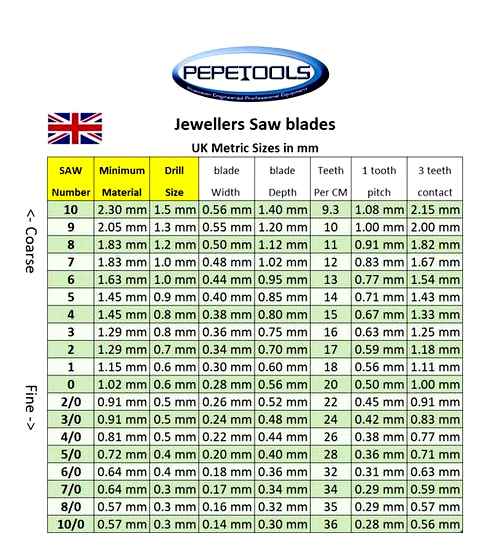

Saw blades are available in a range of sizes for different gauges of metal, the most appropriate grade will depend on the thickness of the metal. A finer blade should be used for thin metal, cutting curves or delicate work. If you’re a beginner, we would recommend starting with medium or coarse blades until you feel confident in your sawing technique.

The general rule of thumb for choosing the correct coarseness of a saw blade is that there are at least 3 saw teeth in contact with the metal when sawing i.e 3 teeth per thickness of the metal sheet.

Shop Swiss Piercing Saw Blades With Kernowcraft

These high-quality AF Gold Shark branded blades are to be used alongside our Swiss piercing frame. These blades are made of hardened tempered steel, with sharp uniformly honed teeth for accurate and Rapid cutting. The blades are designed to aid detailed cutwork as the back non-cutting edge is rounded to assist in cutting right curves.

How to attach saw blades to a saw frame

Hold the saw frame so the frame faces away from you.

Loosen the top thumb screw and insert the end of the blade.

Make sure the teeth on the blade face outwards and teeth downwards.

Loosen the bottom thumb screw and place the bottom end of the blade between the plates.

Push the frame up against a table as you tighten up the screw. this will ensure a tight fit.

Pluck the blade and if you hear a high pitched ‘ping’ you’re good to go!

How to use a jewellers saw for cutting metal

When you first start using the jewellers saw, it’s important to keep the frame vertical while sawing, to keep in control of what you’re cutting.

When you first pierce the metal you want to start at a slight angle and saw downwards to allow the blade to ‘bite’ the metal, then continue to saw vertically.

Wear safety goggles

Safety is important when it comes to sawing metal. Wearing safety goggles will ensure no particles get in your eyes.

Lubricate your saw blades with beeswax

Lubricating your saw blades before and while using the saw will help the blades glide gently and smoothly through the metal, preventing it from breaking. Simply swipe the blade through the wax once, you can also use it on the back of the blade to keep the wax from clogging the teeth.

Support the metal with your hand

When sawing you will need to use an anvil and bench pin. Rest your metal on the bench pin and use your hand to hold the metal while sawing.

It can be easy to put a lot of pressure on the saw when you’re a beginner. Relax! Have a loose grip and let your elbow do the work.

Turn the metal when creating corners

When it’s time to create a curve in the metal, you don’t want to move the saw but instead, you can use your hand to move the metal.

Be patient. you will break your saw blades!

Everyone will experience broken and snapped blades, don’t be alarmed if this happens as it doesn’t mean you are doing anything wrong. You can prevent this from happening by lubricating your blades with beeswax, not putting pressure on the saw while sawing and continuing to check that your blade is taught.

Jeweler’s Saw Blades – 12 Pack

For choosing the right blade size, we recommend using a jeweler’s saw blade sizing chart.

Please note: Express Overnight Shipping deliveries will require a signature. Please ensure someone is available at the delivery address to provide a signature to avoid any issues.

| Economy | 9.95 |

| FedEx Ground Shipping | 14.95 |

| FedEx 2 Day | 19.95 |

| FedEx Overnight | 44.95 |

| USPS Economy | 9.95 | 29.95 | N/A |

| USPS Priority Mail International | N/A | 49.95 | 59.95 |

| FedEx International Economy | 29.95 | 39.95 | 44.95 |

| FedEx International Priority | 39.95 | 49.95 | 69.95 |

Please be aware that orders with certain products may take longer to deliver depending on their stock levels and lead times.

For information about our Return Policy, please check here.

How to use Saw Blades and Frames in Jewelry. Part 1

Jeweler’s Saw Frame 2-3/4″ Deep Adjustable

Contact Info

Fix Kits

Technical Resources

Privacy Policies

We will not sell, trade, or rent your information to third party businesses or marketing companies!

Registering with J.L. Smith enables you to more quickly make your purchase without having to enter your data over and over again. It also allows you to receive the latest news and information from J.L. Smith including intermittent promotions geared to your organization and needs, access to free samples, information kits, instructional videos, a free subscription to the J.L. Smith newsletter, as well as premium customer support.

By providing us with your personal information you consent to our collection and use of your information in accordance with the terms of this privacy policy and the other terms and conditions published on our site. We reserve the right to change these policies and we will post any changes on this page.

How Do We Use the Information You Provide Us?We may use any information you provide us within our own company for marketing and research purposes. We may also use information about your product preferences to send special offers or items we believe you might be interested in via email, postcards or brochures. You may elect to be removed from our mailing list by written request sent by email to [email protected] or mailed to J.L. Smith, 901 Blairhill Rd., Suite 400, Charlotte, NC 28217.

Occasionally we use third party suppliers to give you the best service possible and we may need to share your information with them in order to drop-ship your products to you. Our vendors are expressly forbidden to use this information in any other way, however J.L.Smith’s business partners, suppliers and associated third parties reached through our web site have separate privacy policies which may have different terms from our policy or they may have no privacy policy at all. J.L. Smith has no responsibility for these polices and accepts no liability for the actions of these third parties.

We retain the right to release your personal information to proper authorities when required by law or when we, in good faith, believe that we must release the information in order to: (a) satisfy a legal order or comply with legal process; (b) defend the rights of J.L. Smith, its affiliates or business partners; or (c) protect the personal safety of J.L. Smith employees, agents, affiliates, business partners, customers or site users.

How can you Change your Profile information?We strive to maintain only accurate data on all of our customers and web site users. If you find errors in any of your personal information, please notify us in one of the following ways, and we will be happy to correct it.1. Edit your registration information online by clicking on the My Account button in the e-commerce section of the site.2. Send an email with your corrections to [email protected].3. Mail your changes to:J.L. Smith Co.901 Blairhill Rd., Suite 400Charlotte, NC 282174. Or call us at toll free at: 800.659.6073

Technology Used To Protect Your PrivacyWe use the latest SSL Server Certified 128-bit encryption to protect your data. J.L. Smith protects you and your information by using a Secure Socket Layer (SSL). SSL transparently encrypts the data between your browser and our server, so we can better process credit card orders, protect sensitive personal information.

Cookies and Your Privacy?There are two main types of cookies that can be transmitted via a web page interaction.

How to Fit a Saw Blade in Jewellers Piercing Saw

Transient cookie: This puts data into the temporary memory of your browser to convey information (if you are filling out an order form for example) from one screen to the next. This type of cookie only lasts as long as your browser is open (or it can time out at about 20.120 minutes or so). Once you close your browser this cookie disappears and is gone for good.

Persistent Cookies: these are bits of data that are stored on your machine’s hard drive. These can be used to store ID’s, logins, passwords, etc. to make your online experience easier. While unscrupulous web developers may put these on your hard drive to collect data about you, reputable companies, such as J.L. Smith, your bank, and most e-commerce stores, only use them to make your life easier with passwords and such.

J.L. Smith does not use cookies to collect any additional information other than the information you provided us at the time you register. The J.L. Smith cookie will not damage your system or files in any way. If you have any additional questions about J.L. Smith’s use of cookies, please contact us at [email protected]. If your browser does not support cookies, or if you have turned them off, you will still be able to use our site but the e-commerce ordering may not be as easy or simple.

You can delete the cookies on your machine from your Internet Explorer browser by going to the “Tools” menu, clicking on “Internet Options…” and clicking on the “Delete Cookies…” button.

You can block cookies in IE by clicking on the “Security” tab in “Internet Options” and selecting a medium or high security level on the slider. You can also block cookies using a third-party tool such as ZoneAlarm from ZoneAlarm.com. This is a free product that also acts as personal firewall.

Who do I Contact if I have Additional Questions or Комментарии и мнения владельцев?If you have any questions about our privacy policies, our website or J.L. Smith in general, please contact us at:

J.L. Smith901 Blairhill Rd., Suite 400Charlotte, NC 28217800.659.6073

Ultimate Guide To The Jewelers Saw (And Jewelers Saw Blades)

The jeweler’s saw is one of the most important pieces of your silversmithing kit. It’s used for much more than just the occasional bit of cutting, and learning about them is critical to success. From blade choice to your grip, it’s all important to know.

So, let’s take a look into the world of the jeweler’s saw, starting with helping you find the right saw for your toolkit.

Choosing a Jeweler’s Saw

Your sawing begins with choosing the right saw and blades. Let’s take a look at the saw first, but you should remember one simple thing while I show you some great examples: the best saw in the world won’t save you from bad blades.

Quick Recommendation For a Saw

I just picked a random kit to show you as an example. These cheap saws are readily available from most places, you can get started by going to somewhere like Michael’s this afternoon. These frames are all pretty much the same.

The only issue you may run into is some of these frames will tilt a bit when you’re putting tension on the saw. This usually tilts it a few degrees towards the handle from the top. They’re also a bit of a pain to tension, so breaking blades will break your workflow more.

These saws are cheap, readily available, and they will work. You can go through the generics available and see if you find a handle you’d like but they’ll hold tension, which is the important part. The only other big thing? The blades that come with these are usually trash.

My personal saw is a red Pepe Tools Haymaker, and I can say the high price is worth it. The biggest thing is how convenient it is to change blades since it relies on physical tension. You bend the frame when locking the blade in, resulting in it being pulled tight in just a few seconds.

I’m also a big fan of the handle, which fits my hands pretty well. It’s definitely a more expensive tool than a standard German frame, however, and you won’t be able to use broken blade segments since there’s no sliding mechanism on the arch.

That said, it suits my needs just fine, and I haven’t regretted spending the money on it. The tool itself is well crafted, it’s easy to open and place the blade for piercing work, and it fits well in the hand.

- Well machined, lightweight frame

- Easy to tension and change blades

- Great handle

The Knew Concepts Jeweler’s Saw is something else. While the Haymaker is just a basic saw, perhaps with even fewer features than standard German frames, Knew Concepts has added a bunch of features that should improve your quality of life in exchange for a much higher price.

The saws come with slightly different features, but all of them allow tension adjustment on the fly. I prefer the cam-over system for locking the blade which is found on the high-end models. Those models also boast the ability to change the blade’s direction on a swivel.

Are they worth it? The answer is… maybe. The blade swivels amazed me when I first saw it… until I thought about how little use they are when actually sawing. Likewise, tension adjustment on the fly is pretty cool in theory but rarely used. It’s a great saw either way, and especially lightweight, but the added features are less useful than a beginner would think.

- Tons of extra features including a blade swivel

- Skeletonized aluminum frame for lighter weight

- Many versions available

What’s Important in a Jeweler’s Saw?

The only really important thing about your saw is that it holds proper tension and has a handle you can use under your bench pin. Everything else is pretty much window dressing, providing a bit of convenience in exchange for quite a bit of money.

The added convenience is nice, but many smiths use their cheap saws for years before they upgrade.

- Handle Ergonomics- Most have a similar handle, but some just end up feeling better than others. Grip is rarely an issue with your saw so look for a good palm swell instead of texture.

- Weight- Lighter saws are easier to use for longer periods of time. If you plan on doing intricate patterns for extended periods it’s a concern but the occasional 5-10 minute sawing session doesn’t need any special attention to this detail.

- Features- Features are great, but not necessary. I recommend learning with a cheap saw for a while, you’ll see why a lot of stuff that sounds awesome in theory ends up falling flat in practice.

- Throat Size- 3” is fine for the majority of at-home silversmithing work. Throat size will limit how deep you can cut on a sheet but 3”x3” is the standard size for buying silver sheets. Extensive piercing work (think brass lamps) may require a 5” throat.

The saw is important, but as long as it can hold the blade you’ll be good to go.

Order good blades when you get your first saw. The cheap blades that come with some saws will only frustrate you, and quality blades make a huge difference.

How to Choose the Right Blades

If you’re in a hurry, the short answer is to just buy a pack of 3/0 or 4/0 blades from a reputable brand and call it good. That’s 100% of my blade buying process, and it’s worked out for me this far.

That said, it’s not the best answer if you’re looking to optimize everything in your shop.

Finding Good Blades

You can find good blades through online retailers easily enough. Pike Jeweler, for instance, puts out some great blades at a decent price. They’re not the best on the market but they’re a massive improvement over the cheap blades that come with most saws.

Most jewelry supply houses have their own brand. Pepe Tools sells NANO blades, RIO Grande sells their Laser Gold blades, and these are all top of the line.

Saw blades make a much, much bigger difference in your sawing experience than you’ll find with upgrading your saw. I went from feeling like I couldn’t cut a straight line to handily cutting out complex shapes overnight when I upgraded my blades.

How Important is Having the Right Blade Size?

The general rule of thumb is to use a blade that leaves 2 teeth on the sides of what you’re cutting. In practical use, you can get away with a lot more. I use 4/0 blades for everything from slicing 2mm thick pieces of an ingot to cutting designs in 30 gauge sheets.

An oversized blade can make things a bit rougher, but it’s mostly just a matter of doing more finish work. If you’re looking for perfection, then match your blades and metal to a chart like this one.

Do I Need Anything Else?

You’ll need a few more things for easy sawing, but they’re not hard to get your hands on.

- Bench Pin- Bench pins are needed since we use a jeweler’s saw from underneath it. A lot of generic frames come with one, but you’ll need to find one if yours doesn’t. Or you can make your own with a drill and hacksaw by cutting a wedge into a big drilled hole.

- Lubricant- There are specially formulated waxes I’ll describe later, but you don’t have to use a purpose-made lubricant. 3-in-1 oil works fine, just make sure to wipe it off before heating a piece.

- Safety Glasses- The most unpredictable part of using a jeweler’s saw is the final cut. While some designs don’t have anywhere to go, when you cut things like thick-walled tubing or wire the ends can move in an erratic fashion. That can include coming right back into your eye, just wear the glasses.

- Silversmithing Safety and PPE: A Guide For Beginners

The Basic Mechanics of Your Jewelers Saw

The jeweler’s saw is used differently than any other saw. You’re essentially trying to turn your hand and the saw into a low-speed bandsaw with an up-and-down movement.

It’s a lot easier if you keep the following tips in mind.

It’s All About Tension

Jeweler saw blades are very thin pieces of metal. You can’t use one to cut without it being properly supported in the saw.

The teeth of the saw should be raked back towards the handle when the blade is inserted. The tiny teeth can be hard to see, so a magnifying glass or loupe will help those without good close-up vision.

For that reason, good cutting starts as soon as you put the blade in. Unlike a hacksaw, you can’t just stick it in and let it go.

Standard German frames are usually sliding. You put the blade into both screws and then slide the top of the saw out until it’s tense before you fix the slide.

On the other hand, tension saws like the Haymaker require you to put the blade in on one end and tighten the screw. You then slip the blade into the loosened front nut and force one end of the saw to bend by pressing it against something (usually your sternum or belt buckle, but anything can work). Tighten the nut containing the loose front part of the blade while it’s bent and it will be at a good tension.

In any case, the saw blade should “sing” when you flick it. If the blade is too loose it won’t make a sound, when it’s too tight the blade usually ends up warped in some fashion.

If the blade isn’t tensioned correctly and inserted the right way you won’t be able to use the saw at all.

Getting the Right Grip

The saw’s handle should be underneath the bench pin while you’re cutting. That’s the reason the pin is usually at chest height in a professional workshop. Some of us just have to drop our chairs to get there, but the result is the same.

With the blade facing away from you, you’ll want to move the blade up and down in a directly vertical manner. The blade should be facing directly away from you.

Don’t get too tight on the handle. Your grip should be just tight enough to not let the saw move away from its position while you’re sawing into the material.

A big thing that you’ll have to get used to is not putting weight on the saw. Just let it cut at its own pace and you’ll get a smoother cut with less chance of breaking the blade. This is doubly important at the end of a cut, where you want to just maintain little pressure instead of pressing harder and causing the blade to break free too quickly.

Gently feeding the saw helps and is easy to figure out. If your saw is requiring a ton of pressure to cut… it’s time to change blades.

The Bench Pin

Any bench pin should do, and don’t be afraid to modify yours for your own use.

The bench pin needs to be attached to a sturdy workbench or desk. You’ll be surprised at how much force gets transferred to the furniture when you’re sawing, resulting in a bit of movement in less sturdy desks and benches.

Not everyone has a bench where they can set the pin to chest height. While that’s ideal, as long as you can work the saw you’ll be able to do just fine.

Lubrication

I prefer to use waxes when cutting over oils, but either works just fine. All you need is something that will let the blade slide more smoothly through the metal.

The wax lubricant I use, Cut Lube, is also usable for burrs used in a flex shaft. It’s the main reason I use it, but it also helps that it makes less mess than lubrication with oil. The other big reason is I constantly need oil for other equipment, so it lowers demand in the shop.