Cord for the starter Motokos how to choose. Electric starter on a trimmer for grass

The starter cord does not pull out the gas station

Repair of the starter of a gasoline trimmer for grass may be required at the most inopportune moment. In this case, you can solve the problem in two ways: replace the broken part or change the entire node. The latter option will cost more. To repair the device with your own hands in most cases, you need only a screwdriver with an appropriate tip from the tools. Repair work will not take much time and do not require special knowledge. It is enough to know the device, the principle of operation, the nuances of the assembly-disassembly of the starter on the trimmer in order to achieve the desired positive result.

The gasoline engine is, in principle, the main part of the motorcycles its power lies in the range of 0.5-2.5 liters.With. The movement from it is transmitted by the shaft located inside the hollow bar, and then through the gearbox, consisting of gears, already a fishing line or a knife (working body).

Also, the lawn mower has the following elements:

- protective casing;

- lever;

- a belt designed for ease of use of the device;

- Starter serving for launching a gasoline internal combustion engine.

All parts of the motorcycles are presented in the photo further.

The starter on the trimmer is an integral part, which performs the engine starting into operation. It is shown separately in two photos below.

The starter mechanisms of various models of the benzos work according to the same principle: during the launch of the ICE, the protrusions marked in the photograph above the number 1 are included in the hook with dogs 3. When the engine begins to work, they return to their previous position due to the effects of centrifugal. Similar role is also played by wires 2.

The process of returning to the initial position of the elements of the mechanism occurs due to the presence of a spring screwed around the axis. It unfolds when the rope is pulled. After releasing the cord, it is drawn and winding due to folding the spring. During the launch of the ICE of the lawn mower, the triggering mechanism turns its shaft until it starts to work (starts).

To date, gasoline motorcycles are equipped with two types of starter mechanisms:

The first option is much more common.

The starter on the trimmer can function without breakdowns for a long time. It is impossible to unambiguously indicate the deadline. Everything is determined by the initial quality of the device and compliance with the rules of handling it.

The main malfunctions of the starter of the trimmer for grass

It is not difficult to determine the cause of the breakdown of the starting device. There are several main options:

These details are shown in the photo below.

It may happen that the starting mechanism will be accidentally broken. The consequences will turn out to be deplorable if the ragged rope is wound around the flywheel of a working internal combustion engine: then the spring bursts, the pulley will tear off. But such cases when a complete replacement of the starting node is required, they rarely occur. In most cases, to fix the mechanism, it is enough to put a new spring or replace the cord.

How to repair a starter of a benzo.tool with your own hands?

In the case of a break in the starter cord, everything is clear: we take out the old rope, take the suitable one along the length and thickness (you can linen), stretch it through the hole in the coil, tie the knot. Next, we take the spring to the number we need, only after which we fix the handle. and the voila! about how all this is done is clearly shown below.

Installing or replacing the starter of the starter motorcycles, motorcycle, trimmer for grass

But what to do if everything is in order with the rope, and the coil (pulley) of the starter is not wound? Consider this issue step by the example of the starter of the ADA Grounddrill gasoline motorized car, having a pulley with two metal antennae for 2 hooks.

In the case of other types of manual starters of the similar structure, which are widely used in gasoline motorcycles, trimmers and motorized carriers, the entire starter repair process will look similar, differing only in some nuances.

Starter repair: disassembly

Unscrew the screw with which the pulley is attached to the starter cover. We take out the antennae, spring. We pull the pulley itself carefully so that the spring does not bounce into the face. Even with the most neat disassembly, it usually immediately flies out of the coil and sharply turns into a long metal strip or twisted by rings.

Gently pull out the white.tolerator’s white coil. do not be wounded up by the spring!

If the spring burst or one of its hooks-stalks has broken, then it will not work out to repair the starter and quickly-it is necessary to replace the spring. In order not to spend money on the purchase of a new starter, you can look for only her on sale.

In case the starter spring simply fell off, t. e. One of the hooks came out of the hook, it is enough to insert it, if necessary, slightly tightening the hooks more tightly (just do not break off!) Install the spring with an external hook in the groove of the pulley and begin to twist it, while holding your fingers inside the coil and preventing it from jumping out of there.

Clutching the spring to the pulley, roll the spring in circular motion

It may not seem so easy to insert the starter spring from the first time, but everything comes with experience. Having trained a little, you can easily wrap the spring into the pulley in a maximum of a minute.

The winding of the starter spring is made. It remains only to assemble the starter and take the spring to the desired value

How to assemble a starter?

The most important thing in the process of independent repair of the starter is to collect it correctly.

After the spring is completely wound, you need to carefully turn the coil and insert into the starter case so that the second spring hook enters the groove of the case.

By installing the pulley (in this photo. black), look through the hole in it so that the spring hook gets into the groove on the starter cover

Then, if there is a spring under the screw, we install it first, not forgetting to put the washers from below and from above the spring.

Gently insert a cup with antennae into the grooves of the coil and tighten the screw.

Then keep sure that the puck is on the sprout does not fall. Why is it important? The fact is that the spring scratches a plastic cup with its end, as a result of which the latter wear out and begins to tightly pressed with a screw to the reel. For this reason, a situation may arise, very similar to the breakdown of the spring: the handle stretches out of the starter, but does not return back. However, when the starter is weakened, this problem disappears. It is easy to eliminate such a starter malfunction: it is enough to choose a spring of the same diameter, but a little longer, or put an additional washer. If we simply slightly tighten the screw, then it will be twisted and fly out, and this will increase the likelihood of a spring breakdown, since the pulley will not fit tightly with the starter case.

The coil to the body was screwed, now we need to pull the spring. Before this, it is necessary to remove the starter’s handle from the rope in advance. If the knot is too durable, then you can just cut it or try to untie it, for example, using a pair of pliers. This is done so that after you bring the spring, you can pass the rope into the opening of the starter cover. The second end of the rope should be fixed in the coil even before it is installed in the case, it is not required to be roped on the pulley before pulling the spring. you will do it after.

How to Replace the String on a Toro Trimmer : Lawn Care & Power Tools

Manual starter malfunction associated with the spring

A dense starter spring with a hook is the main element of the design of a hand starter. In addition to the spring, the starter also includes the following components:

Rating of gasoline trimmers: TOP-15 of the best models of 2021 and tips on how to choose a spring repair-the main component of a hand starter, boils down to replacing the element.

On a chainsaw, for example, it is an element in the form of a circle, inside which a flexible spring is wound.

Springs in this form are sold in the technique store. It remains only to buy a part and replace.

Repair of a hand starter may also imply a replacement for a cord. If it is incorrectly wound on the pulley of the springs, then the generator will not occur.

- Wind the cord from the end of the pulley (done to avoid scrolling);

- The second end of the cord is drawn into the cover of the lid;

- The winding of the cord should continue until it stops, t.e, as far as the length of the rope is enough;

- After winding, the cord is pulled by 15-20 cm, to check the turn of the pulley of the spring;

- After winding, you should also check how the spring works after stretching and letting go (if everything works clearly, it is recommended that the cord is soaked for another revolution).

At portable power plants, the repair of the spring and cord is carried out as follows:

- From the side of the generator there is a circiva circle recorded by three screws that need to be unscrewed;

- Remove the pulley with a spring and a cord;

- Check the condition of the cord, which can be completely removed from the side of the holder (the upper cap of the holder is removable).

Note. Often, a bundle of the cord, which ensures it from above, weakens. To correct the situation, you need to heat the end of the nylon rope with a lighter, and then wind a new knot.

As for the pulley with the spring, it changes in the same way as it was described above.

The main malfunctions of the starter of the trimmer for grass

It is not difficult to determine the cause of the breakdown of the starting device. There are several main options:

These details are shown in the photo below.

It may happen that the starting mechanism will be accidentally broken. The consequences will turn out to be deplorable if the ragged rope is wound around the flywheel of a working internal combustion engine: then the spring bursts, the pulley will tear off. But such cases when a complete replacement of the starting node is required, they rarely occur. In most cases, to fix the mechanism, it is enough to put a new spring or replace the cord.

Removing and disassembling the starter, replacing broken parts

To repair the starter of the trimmer for the grass, you will need to disassemble it first, and then collect it. This process is not a particularly difficult occupation. For work, you will need a screwdriver with the tip of the desired shape.

Everything should be done carefully, observing safety precautions, mainly that the spring does not injure the master if an accident.

Parsing the starting node

They disassemble the launch mechanism in order to install new parts instead of broken in the following sequence:

- spin a screw with a screwdriver, fixing the pulley with a starter lid;

- take out a spring and antennae;

- Remove carefully with the pulley (you need to unscrew the head or work, having dressed the glasses and gloves before);

- determine why the launch mechanism has broken;

- If the spring collapses almost completely, then it is replaced;

- When the spring exits from the hook, it is installed in the original place, bending the antennae before this (the photographs show the laying process);

To change the spring, you should work carefully and accurately: it can, under the influence of the effort caused by the installation of it in place, accidentally burst. Even if you carefully remove the video, then the spring strip flies very quickly from the coil and can injure your hand with its sharp edges.

Immediately putting a springy plate in the same place does not always work. It often slips, so attempts are required to repeat until the desired result is achieved.

Starter assembly

The assembly of the starting node is carried out in a number of stages:

When making the stated manipulations, it is necessary to lay two goals. If this is not done, then the spring over time damage the plastic cup, and when it is pulled. Because of this, a feeling appears, as if the spring had flown. To eliminate such a drawback, you need to install this part of a larger length or an additional goal.

When such spare parts are absent, you can just unscrew the screw a little, and the starter knot will begin to work without shaken. But this option is temporary. it is better to repair qualitatively as quickly as possible.

Spring tension

After installing the spring, it should be pulled. The following actions are performed for this:

- Remove the handle from the starter cord;

- Then the rope is inserted into the coil groove;

- They stretch the spring, rotating the coil in the direction opposite to the clock of the clock arrow (reviews);

- make the desired number of revolutions specified in the instructions for the use of the trimmer model used and the corresponding length of the cord used;

- At the very end, the rope is threaded into a hole designed for this, located in the starter cover;

- put the handle in place, fixing it with a node.

If after the repair the spring continues to fly, then you can get rid of this in the following ways:

- Squeeze the suitable piece of the plate into the groove at the location of the spring hook;

- drill holes on two sides of the groove in the coil, into which the spring hook is inserted and fix it using a wire.

Replacing a torn cord

A torn rope is replaced in the following sequence:

- The old cord is removed;

- choose a suitable rope (thickness and length);

- Having reached it through a special hole in the coil, a knot is tied;

- Sprinkle a spring, producing the required number of revolutions;

- Fix the pen.

It is better to stretch the spring plate along with the partner so that the edge of the cord does not hit the starter mechanism.

Best String Trimmer (Battery Powered)? EGO, Milwaukee, DeWalt, Ryobi, Kobalt, Makita, Atlas, ECHO

It is easy to assemble a starter on a trimmer and wound a spring, only you should do it carefully and with caution. For different models, the gas tanks of the launching mechanisms are the same, so they are repaired in a similar way. In this case, there are some nuances associated with their constructive features.

How to change the starter cord?

It happens that in the impossibility of starting a starter is not a spring to blame, but the cord itself. He can seize or completely break. Dismantling the starter of the lawn mower or trimmer for grass is universal in its steps.

- Remove the starter block from a trimmer for grass or lawn mower.

- Unscrew the main bolt holding the handbrake.

- Pull the coil and melt the remains of a worn cord from it.

- Unscrew the knot on the handle of the cord and pull its end from it.

- Untie the knot at the other end (at the beginning of the coil) and remove the old cord. The nodes that have become tight are unleashed with pliers or ticks.

- Tie a knot on one of the ends of the new cord, prone it through the hole at the beginning of the coil (closer to its axis).

- Shin a few turns of a new cord to the coil. If it is long, then cut the excess.

- Season and soak the spring tensioner (if it starred) and spring.loaded elements in the correct sequence.

- Put the coil in place and take the free end of the cord to the outlet of the starter and in the handle.

- Install the starter block in place.

Twist the starter by the cord, start the engine of the lawn mower or a trimmer for grass. The larger and more powerful the engine, the more cord jerks will be required when starting, the norm is no more than 7 times. The result is a quick and smooth launch of the motor, the readiness of the unit for work.

Repair of the starter of the gas trimmer for grass may be needed at the most inopportune time. At the same time, there are two ways to solve the problem: replace a broken part or replace the entire assembly. The last option will cost more. In most cases, only a screwdriver with a tip is required to repair the device with your own hands. Repair does not take much time and does not require special knowledge. To achieve the desired positive result, it is enough to know the device, the principle of operation, the nuances of the assembly-disassembly of the starter for the trimmer for the grass.

The device and principle of the starter on the trimmer

Gas engine. This is mainly the main part of the brush. Its power lies in the range of 0.5-2.5 liters.With. Movement from it is transmitted to the shaft located inside the hollow rod, and then through the gearbox, consisting of gears, already stabbed or knife (working body).

Bigorezes also have the following elements:

- Corrugated board;

- lever arm;

- belt designed for simplicity of use;

- Starter used to launch an internal combustion gasoline engine.

The starter of the trimmer for grass is an integral part of the engine start. This is shown separately in two photos below.

Starting mechanisms for different models of gasoline braids work according to the same principle: when starting an internal combustion engine, the tongues indicated by the number 1 in the photo above are hooked by dogs 3. When the engine is launched, they return to the previous position due to centrifugal force. A similar role is played by wires 2.

The process of returning to the initial position of the elements of the mechanism is due to the presence of a spring wound around the axis. It turns around when the rope is pulled. After the release of the cord, it is pulled and wound with a spring assembly. When the internal combustion engine is launched, the trigger rotates its shaft until it starts to work.

Today, gasoline scooters are equipped with two types of starter mechanisms:

The first option is much more common.

The trimmer starter for grass can work without breakdowns for a long time. It is impossible to clearly indicate a continuous period of time. Everything is determined by the initial quality of the device and compliance with the rules of its operation.

The main malfunctions of the trimmer for the grass of the starter

It is easy to determine the reason for the refusal of the starting device. There are several main options:

Perhaps the starter mechanism is accidentally broken. The consequences will be deplorable if the wrapped cable is wrapped around the flywheel of the internal combustion engine: then the spring will burst and the pulley will break. But such cases when a complete replacement of the starter is required are extremely rare. In most cases, it is enough to fix a new spring or replace the cord to fix the mechanism.

Removing and disassembling the starter, replacing broken parts

To repair the starter of the trimmer for the grass, you will need to disassemble it first, and then collect it. This process is not a particularly difficult occupation. For work, you will need a screwdriver with the tip of the desired shape.

Parsing the starting node

They disassemble the launch mechanism in order to install new parts instead of broken in the following sequence:

- spin a screw with a screwdriver, fixing the pulley with a starter lid;

- take out a spring and antennae;

- Remove carefully with the pulley (you need to unscrew the head or work, having dressed the glasses and gloves before);

- determine why the launch mechanism has broken;

- If the spring collapses almost completely, then it is replaced;

- When the spring exits from the hook, it is installed in the original place, bending the antennae before this (the photographs show the laying process);

After the spring plate is installed inside the groove, it is carefully twisted. To change the spring, you should work carefully and accurately: it can, under the influence of the effort caused by the installation of it in place, accidentally burst

Even if you carefully remove the video, then the spring strip flies very quickly from the coil and can injure your hand with its sharp edges

To change the spring, you should work carefully and accurately: it can, under the influence of the effort caused by the installation of it in place, accidentally burst

Even if you carefully remove the video, then the spring strip flies very quickly from the coil and can injure your hand with its sharp edges

Starter assembly

The assembly of the starting node is carried out in a number of stages:

The coil is turned over, installing it so that the spring bend exactly stands into the groove of the case, as in the photo below;

When making the stated manipulations, it is necessary to lay two goals. If this is not done, then the spring over time damage the plastic cup, and when it is pulled. Because of this, a feeling appears, as if the spring had flown. To eliminate such a drawback, you need to install this part of a larger length or an additional goal.

When such spare parts are absent, you can just unscrew the screw a little, and the starter knot will begin to work without shaken. But this option is temporary. it is better to repair qualitatively as quickly as possible.

Spring tension

After installing the spring, it should be pulled. The following actions are performed for this:

- Remove the handle from the starter cord;

- Then the rope is inserted into the coil groove;

- They stretch the spring, rotating the coil in the direction opposite to the clock of the clock arrow (reviews);

- make the desired number of revolutions specified in the instructions for the use of the trimmer model used and the corresponding length of the cord used;

- At the very end, the rope is threaded into a hole designed for this, located in the starter cover;

- put the handle in place, fixing it with a node.

If after the repair the spring continues to fly, then you can get rid of this in the following ways:

- Squeeze the suitable piece of the plate into the groove at the location of the spring hook;

- drill holes on two sides of the groove in the coil, into which the spring hook is inserted and fix it using a wire.

Replacing a torn cord

A torn rope is replaced in the following sequence:

- The old cord is removed;

- choose a suitable rope (thickness and length);

- Having reached it through a special hole in the coil, a knot is tied;

- Sprinkle a spring, producing the required number of revolutions;

- Fix the pen.

It is easy to assemble a starter on a trimmer and wound a spring, only you should do it carefully and with caution. For different models, the gas tanks of the launching mechanisms are the same, so they are repaired in a similar way

In this case, there are some nuances associated with their constructive features.

Device

The device of the chainsaw starter includes the following elements:

- Screw of the ignition system;

- Return spring;

- launch system coil;

- deflector;

- lid;

- magneto;

- drum;

- spark plug;

- the electronic unit;

- wiring;

- power button;

- pen and cable.

The main parameters of the chainsaw launch system:

After pressing the power button, the flywheel begins to rotate with the magnet, which is located on it.

The system appears in the system. The current current using an electronic unit is converted into electrical signals, which are transmitted to driving elements.A spark forms that provokes ignition of the fuel-air mixture.

How to put a spring

In order to install a new spring, the following actions must be performed:

- Gently extract the clip of mechanism.

- Conduct an inspection of the inner part of the clip in which the spring mechanism is located near the C-shaped element.

- Fix and pull the upper part of the spring with your finger and pull the launch mechanism to the side.

- Extract a worn.out mechanism and wind a new spring. Excesses and twisting of the element should be avoided.

- Collect a new spring mechanism. It is recommended to do this slowly so that the mechanism does not unwind.

- Twine the spring and insert it into the starter mechanism.

- Gently fix the clip.

Read what kind of fishing line diameter is selected for a trimmer for electric grass

Replacement of the cord

In order to replace the cord, the following tools will be required:

Replacing the launch cord is as follows:

- You need to unscrew the fasteners that hold the side cover with a screwdriver.

- Then dismantle the starter from the tool body.

- After that, you need to turn the lid and conduct an inspection.

- Then dismantle the clip and spring.

- Untie the knot on the rope.

- You need to pull out the pulley on which the cord is wound. Remove the cord and replace it with a new.

- Then get the pulley in place and tie the rope on the knot. Set the clip and spring.

- After that, tighten the lid using fasteners.

- At the end, install the starter in place and fasten the fasteners.

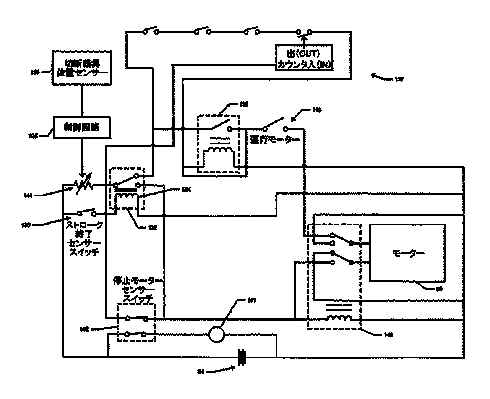

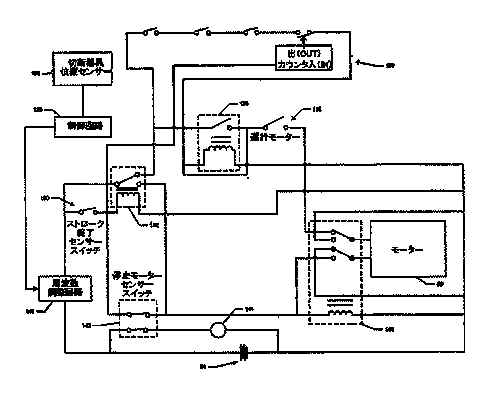

Motobobok ignition system

Ignition adjustment

The ignition coil for the Neva walk.behind tract is adjusted as follows by the ignition adjustment overview of the motor block engine

One of the main factors of the correct operation of the ignition system plays a gap between the starter and the flywheel. It should be in the range from 0.1 to 0.15 mm.

To adjust it on the Neva walk.behind tractor, it is necessary to remove the housing and unscrew the stator bolts. Then put the probe and set the necessary gap, tighten the bolts back and check the gap over the entire surface of the flywheel.

Generator, malfunctions, elimination

The generator is an important component of the entire mechanism. It is designed to charge the battery and work headlights

When choosing a generator, you need to pay attention to its power. It should exceed the power of all connected devices to ensure uninterrupted operation

For the Neva walk.behind tractor, it is possible to use an old car generator.

Important! During its installation, it is necessary to observe the scheme presented below. Otherwise, the generator is possible

There are 4 wires in the generator. Two of which are blue. It is thanks to them that the converter is connected. Red, connects to the headlights, and gives tension on them.

Electrostarter

Many people seek to improve their walk.behind tract. In the winter seasons, he does not start poorly due to the fact that the manual starter does not scroll. In solving this problem for the walk.behind tractor, Neva came up with a special electric starter. This is an autonomous device that, when the ignition is turned on, begins to rotate and gives a spark.

Elektrostarter is a complex design, and it is not realistic to make it at home. You can use any other automobile electric starter that could stay from the old car.

Candles

What candles are needed for, and how to change them we have already figured out. Let’s look at the brands that are necessary for each specific type of Neva engine:

| Engine model | A candle on the engine | Possible replacement of a candle |

| DM-1K (CJSC Krasny October-Neva) | BRISK NR17C | Bosch WR8AC |

| I/c 6.0 (Briggsstratton) | Champion RC12YC | NGK BKR5E |

| Vanguard 6.0 (Briggsstratton) Mod.117 | Champion RC12YC | NGK BCPR5ES BRISK DR17YC |

| Honda GX200 | 98079-55876 (NGK BPR6ES) | DENSO W20EPR.U BRISK LR15YC Champion RN9YCC BOSCH WR7DC Engels A17DVRM |

| EX17 (Robin Subaru) | 065-01401-50 (NGK BR6HS) | BRISC NR15C BOSCH WR7AC Champion RL82CC |

| Honda GC160 | 98079-56846 (NGK BPR6ES) | DENSO W20EPR.U BRISK LR15YC Champion RN9YCC BOSCH WR7DC Engels A17DVRM |

| I/c 8.0 (Briggsstratton) | Champion RC12YC | |

| Ey15 (Robin Subaru) | 065-01401-50 (NHSP LDE6C) | NGK B6HS NGK BR6HS Champion L86C Champion RL86C |

| Honda GX120 | 98079-55876 (NGK BPR6ES) | DENSO W20EPR.U BRISK LR15YC Champion RN9YCC BOSCH WR7DC Engels A17DVRM |

In standard configuration, Neva Motobobes are not equipped with a headlight. However, this option is presented as an additional. Since work in the evening is almost impossible without headlights.

If desired, you can install the headlights yourself from the car, scooter, tractor, etc.D. To do this, with the help of welding, make a special box for the headlight and get it there. And attach the wires from it to the generator. But not directly, but through a switch that should be in the middle and be responsible for turning on and off the headlights.

Repair of the starter of the gas tanker, lawn mowers, trimmers for the grass with your own hands

No matter how high.quality gasoline tools you use, everything can happen to it in the process of construction, and at the most inappropriate moment for this moment. Often problems arise due to the breakdown of the starter. It happens that you will get drunk with a gasoline hole for installing the fencing pillars or mowing the grass with a trimmer, you will start starting the unit, and just have time to pull the starter handle a couple of times, as the rope breaks off, and the engine has already started, dashingly wrapping the rest of the cord to the flywheel, the spring bursts run to the new store buy. But these, of course, are extremes.

Today we will consider the most common case when the breakdown is not so serious and show how to carry out the repair of the starter with your own hands if the cord has broken without any destructive consequences or is not wound due to the fact that the spring just flew inside, went out of the cloth. At least initially I want to believe in it. But in order to find out whether it is or not, you will need to disassemble the starter.

How to repair a starter of a benzo.tool with your own hands?

In the case of a break in the starter cord, everything is clear: we take out the old rope, take the suitable one along the length and thickness (you can linen), stretch it through the hole in the coil, tie the knot. Next, we take the spring to the number we need, only after which we fix the handle. and the voila! about how all this is done is clearly shown below.

Installing or replacing the starter of the starter motorcycles, motorcycle, trimmer for grass

But what to do if everything is in order with the rope, and the coil (pulley) of the starter is not wound? Consider this issue step by the example of the starter of the ADA Grounddrill gasoline motorized car, having a pulley with two metal antennae for 2 hooks.

In the case of other types of manual starters of the similar structure, which are widely used in gasoline motorcycles, trimmers and motorized carriers, the entire starter repair process will look similar, differing only in some nuances.

Starter repair: disassembly

Unscrew the screw with which the pulley is attached to the starter cover. We take out the antennae, spring. We pull the pulley itself carefully so that the spring does not bounce into the face. Even with the most neat disassembly, it usually immediately flies out of the coil and sharply turns into a long metal strip or twisted by rings.

Gently pull out the white.tolerator’s white coil. do not be wounded up by the spring!

If the spring burst or one of its hooks-stalks has broken, then it will not work out to repair the starter and quickly-it is necessary to replace the spring. In order not to spend money on the purchase of a new starter, you can look for only her on sale.

In case the starter spring simply fell off, t. e. One of the hooks came out of the hook, it is enough to insert it, if necessary, slightly tightening the hooks more tightly (just do not break off!) Install the spring with an external hook in the groove of the pulley and begin to twist it, while holding your fingers inside the coil and preventing it from jumping out of there.

Clutching the spring to the pulley, roll the spring in circular motion

It may not seem so easy to insert the starter spring from the first time, but everything comes with experience. Having trained a little, you can easily wrap the spring into the pulley in a maximum of a minute.

The winding of the starter spring is made. It remains only to assemble the starter and take the spring to the desired value

How to assemble a starter?

The most important thing in the process of independent repair of the starter is to collect it correctly.

After the spring is completely wound, you need to carefully turn the coil and insert into the starter case so that the second spring hook enters the groove of the case.

By installing the pulley (in this photo. black), look through the hole in it so that the spring hook gets into the groove on the starter cover

Then, if there is a spring under the screw, we install it first, not forgetting to put the washers from below and from above the spring.

Gently insert a cup with antennae into the grooves of the coil and tighten the screw.

Then keep sure that the puck is on the sprout does not fall. Why is it important? The fact is that the spring scratches a plastic cup with its end, as a result of which the latter wear out and begins to tightly pressed with a screw to the reel. For this reason, a situation may arise, very similar to the breakdown of the spring: the handle stretches out of the starter, but does not return back. However, when the starter is weakened, this problem disappears. It is easy to eliminate such a starter malfunction: it is enough to choose a spring of the same diameter, but a little longer, or put an additional washer. If we simply slightly tighten the screw, then it will be twisted and fly out, and this will increase the likelihood of a spring breakdown, since the pulley will not fit tightly with the starter case.

The coil to the body was screwed, now we need to pull the spring. Before this, it is necessary to remove the starter’s handle from the rope in advance. If the knot is too durable, then you can just cut it or try to untie it, for example, using a pair of pliers. This is done so that after you bring the spring, you can pass the rope into the opening of the starter cover. The second end of the rope should be fixed in the coil even before it is installed in the case, it is not required to be roped on the pulley before pulling the spring. you will do it after.

Before taking a spring, estimate how much the reel revolutions should be wrapped in a rope. Suppose the length of the rope at the starter of the Motor ADA Grounddrill-5 corresponds to 5.5 revolutions around the coil. In this case, we make at least 6 revolutions of the coil in the direction opposite to the direction of wiring.

So, let’s get down. Without wrapping, insert the rope into a groove specially designed for it in a coil. Everything is ready, proceed to pulling the spring. To do this, we rotate the coil counterclockwise. in the direction opposite the direction of rotation of the coil when watching the rope. It is more convenient to do this not on the knee, but pressing the starter with one hand to the floor, and the second turning the coil right behind the rope mounted in it. If the experience is not enough, then you can rotate with both hands directly the pulley itself, but the rope will interfere with it, which can create additional inconvenience. After the required number of revolutions is made, we spread the end of the rope through the hole in the starter cover, put on the handle, fix it with a knot. It is more convenient to do this together with a partner, so that the end of the cable does not hit the end of the starter by chance.

By the way, on your own, you can introduce some refinement to the design of the starter in order to more reliably fix the end of the spring inside the coil. There is enough fantasy here. Now I will explain what it happens for. It often happens that the spring in starters of this type after the first such independent repair and installation of the starter on the unit flies after a few jerks again. there is no hook in the groove of the coil. And this despite the fact that the coil is almost tightly adjacent to the starter cover and the spring there, well, should not even hang up and down freely, and even more so until the spring out of the gear. It turns out that when the cable is jerking, it pulls the spring, pulls out of the groove. In this case, you can make the following: cut a narrow strip of metal, which in thickness could squeeze closely into the groove of the coil with the hook itself. So the hook will not hang free in the groove, which means that it will not be so easy to break out.

Repair procedure

Features of the operation of the starter imply a sharp and gross effect, which sooner or later affects the form of breakdowns. Fortunately, in this mechanism, there is nothing particularly to break and the instructions described further affect all possible causes of malfunctions. Starting with how to restore or how to insert a spring into a chainsaw starter, and ending with the installation of dogs with a flywheel film. Step.by.step guides, sequentially, for each problem.

Restoration of the spring

The most popular case of breakdown is associated with the riding of the mounting ear of the main strip spring that reinss the cable. It is not necessary to search and buy a new spare part, since the procedure requires a minimum of time and tools. Only 2 things will be needed: source of fire (a gas burner or stove) and pliers.

Gently take out the spring from the body. You can put a slotted screwdriver.

At the site of a broken ear, you should make a new one by performing an ordinary bend of the tape. So that the metal does not burst, before the bend it must be heated red.hot and bend it to cool (it is better to do this directly above the fire).

How to install a chainsaw starter spring

The basic dexterity and standard dexterity of the hands, combined with simple technology, will reduce time costs, allowing the operation to quickly and almost naturally. The installation of a return spring begins with a fixing of the ear on the recess, in the direction counterclockwise (if you look at the inside of the spring body).

The tape is invested gradually, layer by layer. The already placed part of the spring adheres to the thumb of the right hand, while the finger of the left laid a new segment. Having put about 1/3 of the circle in the case, the tape is pressed with the thumb of the left hand, the right one is brought to it and the cycle is repeated. The entire installation process takes no more than a minute.

Even easier to insert a new spring purchased as a spare part for the starter. It can be in a fixing winding that is gradually removed when installing. The already twisted element is simply inserted into the case. The easiest option is a ready.made kit with a strip spring in the case, which are put in place of old elements in one motion.

Replacement of the cord

Cases of a cut of the handle cable are quite common and characteristic, both Chinese models and branded manufacturers. Since this connecting element is subjected to serious loads and periodically breaks, the process of cornering is extremely simplified. First of all, it should be determined how long the cord should be on the chainsaw. Depending on the size of the drum and the diameter of the cable, the value is located in the region of 120. 140 cm (necessarily with a small margin). Having prepared a suitable segment, you can take a cross screwdriver and proceed to the replacement.

Remove the starter from the chainsaw and unscrew the central screw on the ratchet.

We take out the drum and remove the old cord.

We spread a new cord through the hole from the inside of the drum groove (for convenience, the ends can be melted with a lighter).

We pull the end from the hole ≈ by 10 cm and tie it into the knot so that the cable does not fly.

Into a special recess under the drum, lay the knot and the remaining part of the cable. In order not to rest against the spring body, it is advisable to leave about 1 cm.

We install the drum in its place, combining the spring with the ear, and press the puck with a puck (do not wind the cord).

We spread the opposite part of the cord through the starter case and the hole in the handle, after which we make a fixing node at the end.

The cord winding is carried out due to the spring. Just slightly pull the cable from the hole in the drum to its edge, and holding it at this point, rotate the drum clockwise. The spring is strained, and when released, the cable itself wraps up. Repeat the procedure until the handle is tightly pressed against the body.

How to assemble a starter correctly

The nuances of the design and interaction of the details of the mechanism determine the complexity of its maintenance. Manual starting of a chainsaw consists of a minimum set of components, whose work is built on an extremely simple principle, intuitively understandable during the first, thoughtful analysis. You can explain how to assemble the starter of the chainsaw, you can very briefly, a couple of the following sentences:

The strip spring is invested in its case and is installed with it on the starter. The drum with a fixed cord is placed on the spring, clinging to her ear. The design is pressed with a screw with a puck through a hole in the ratchet.

This runaway excursion reflects the main assembly steps. A more detailed description of each movement, with the nuances of various models, the process of tensioning the cord and replacing dogs, is clearly presented in the above instructions. Choose the topic of interest to you, read, see and implement.

Starter is one of the most important mechanisms in the device of any modern chainsaw. The launch of the tool engine under any weather conditions depends on it. The starter for the chainsaw is released by a simple design, it is easy to serve and repair it with your own hands. However, in order to eliminate the breakdown, you must first find its cause. For this, most often it is necessary to completely disassemble the standard mechanism.

Oleo-Mac Sparta 25

Thanks.Yes, I really like the same as Oleo responds to gas.I cleaned my oleo, such a neglected area was just a guard.Naturally, not at once and not overwhelming the braid.He ran her everything.How is it written in the passport.And really after 6 hours I felt that it became more powerful, a little gazanya and responds.Yes, now I will constantly check the same damper.This is all fatigue.I mowed a lot for three days in a row, so I got it.As they say, they learn from mistakes, but better on strangers.

There is a question, after I conquer a braid that time is twitching the spool, this is only when I lead to the cold. And how I work and drown out, and then I conquer it to hot, this is not.Of course I read about this in the subject, but not to shove the whole topic.Tell me, what could it be?Thanks.

Olegych thanks.Otherwise I already thought that something was wrong with my scythe.

Somewhere in the instructions I came across the fact that when the spray rotates at idle in the SC (joke)

ERV wrote: I heated a broken spring with a burner and one round bent, (only the ear was broken off, which clings to the block), then he tempered the spring, of course I understand that this is a dead pincere,

ERV wrote: I heated a broken spring with a burner and one round bent, (only the ear was broken off, which clings to the block), then he tempered the spring, of course I understand that this is a dead pincere,

ERV wrote: it makes sense to change the clutch entirely (it is in stock)

The bridge wrote: you or in the service? Look for how to work as it is

I don’t remember how much I stretched it, I think no more than 1.5-2 mm, as far as the pads diverge not Meril. Of course, I will get tired of the pads, but this trimmer for the grass went to parents for free after several seasons in the housing office, repair and write.off (the reason for the repair is unknown), so it is unknown, but it was clearly driven daily. I myself have developed it from the force of 15 hours, I worked and pleased with the spring breakdown.

The main malfunctions of the starter of the trimmer for grass

It is not difficult to determine the cause of the breakdown of the starting device. There are several main options:

These details are shown in the photo below.

It may happen that the starting mechanism will be accidentally broken. The consequences will turn out to be deplorable if the ragged rope is wound around the flywheel of a working internal combustion engine: then the spring bursts, the pulley will tear off. But such cases when a complete replacement of the starting node is required, they rarely occur. In most cases, to fix the mechanism, it is enough to put a new spring or replace the cord.

How to change the starter cord?

It happens that in the impossibility of starting a starter is not a spring to blame, but the cord itself. He can seize or completely break. Dismantling the starter of the lawn mower or trimmer for grass is universal in its steps.

- Remove the starter block from a trimmer for grass or lawn mower.

- Unscrew the main bolt holding the handbrake.

- Pull the coil and melt the remains of a worn cord from it.

- Unscrew the knot on the handle of the cord and pull its end from it.

- Untie the knot at the other end (at the beginning of the coil) and remove the old cord. The nodes that have become tight are unleashed with pliers or ticks.

- Tie a knot on one of the ends of the new cord, prone it through the hole at the beginning of the coil (closer to its axis).

- Shin a few turns of a new cord to the coil. If it is long, then cut the excess.

- Season and soak the spring tensioner (if it starred) and spring.loaded elements in the correct sequence.

- Put the coil in place and take the free end of the cord to the outlet of the starter and in the handle.

- Install the starter block in place.

Twist the starter by the cord, start the engine of the lawn mower or a trimmer for grass. The larger and more powerful the engine, the more cord jerks will be required when starting, the norm is no more than 7 times. The result is a quick and smooth launch of the motor, the readiness of the unit for work.

Repair of the starter of the gas trimmer for grass may be needed at the most inopportune time. At the same time, there are two ways to solve the problem: replace a broken part or replace the entire assembly. The last option will cost more. In most cases, only a screwdriver with a tip is required to repair the device with your own hands. Repair does not take much time and does not require special knowledge. To achieve the desired positive result, it is enough to know the device, the principle of operation, the nuances of the assembly-disassembly of the starter for the trimmer for the grass.

The device and principle of the starter on the trimmer

Gas engine. This is mainly the main part of the brush. Its power lies in the range of 0.5-2.5 liters.With. Movement from it is transmitted to the shaft located inside the hollow rod, and then through the gearbox, consisting of gears, already stabbed or knife (working body).

Bigorezes also have the following elements:

- Corrugated board;

- lever arm;

- belt designed for simplicity of use;

- Starter used to launch an internal combustion gasoline engine.

The starter of the trimmer for grass is an integral part of the engine start. This is shown separately in two photos below.

Starting mechanisms for different models of gasoline braids work according to the same principle: when starting an internal combustion engine, the tongues indicated by the number 1 in the photo above are hooked by dogs 3. When the engine is launched, they return to the previous position due to centrifugal force. A similar role is played by wires 2.

The process of returning to the initial position of the elements of the mechanism is due to the presence of a spring wound around the axis. It turns around when the rope is pulled. After the release of the cord, it is pulled and wound with a spring assembly. When the internal combustion engine is launched, the trigger rotates its shaft until it starts to work.

Today, gasoline scooters are equipped with two types of starter mechanisms:

The first option is much more common.

The trimmer starter for grass can work without breakdowns for a long time. It is impossible to clearly indicate a continuous period of time. Everything is determined by the initial quality of the device and compliance with the rules of its operation.

The main malfunctions of the trimmer for the grass of the starter

It is easy to determine the reason for the refusal of the starting device. There are several main options:

Perhaps the starter mechanism is accidentally broken. The consequences will be deplorable if the wrapped cable is wrapped around the flywheel of the internal combustion engine: then the spring will burst and the pulley will break. But such cases when a complete replacement of the starter is required are extremely rare. In most cases, it is enough to fix a new spring or replace the cord to fix the mechanism.

You should make sure that the spring does not injure the owner in case of accidental departure.

Starting analysis

Disassemble the starter mechanism to install new parts instead of broken in the following order:

- unscrew the screw, fastening the pulley using the starter cover using a screwdriver;

- Remove the spring and antennae;

- Carefully remove the pulley (you need to turn your head or practice, after putting on your glasses and gloves);

- determine why the trigger has broken;

- If the spring fell apart almost completely, it is replaced;

- когда пружина выйдет из крючка, установите его на место, согнув перед собой антенну (на фотографиях показан процесс установки);

- By inserting the spring plate into the groove, carefully tighten it.

To change the spring, the work should be done carefully and carefully: it can accidentally explode under the influence of the force caused by its. Even if the video is carefully removed, the spring tape breaks very quickly from the coil and can injure the hand with sharp edges.

Immediate replacement of the spring plate does not always work. This often slips, so attempts should be repeated to achieve the desired result.

Starter builder

The assembly of the starting installation is carried out in several stages:

- The coil turns over, installing it so that the bend of the spring accurately enters the groove of the case, as in the photo below;

- make two goals between which the spring is located;

- Put a cup for a mustache in place;

- Tighten the screw (photo below).

Make the above manipulations to put two goals. Failure to fulfill this requirement can lead to damage to a plastic glass over time, and when it is removed, it will begin to jam. Because of this, it seems that spring has come. To eliminate this drawback, you need to install this longer piece or additional washer.

When such details are absent, there is only a little unscrew the screw, and the starter assembly will begin to work without fixing. But this option is temporary. It is better to repair it as quickly as possible.

Spring tension

After installing the spring, tighten it. To do this, follow the following actions:

- Remove the handle from the starter cord;

- Then the rope is inserted into the groove of the coil;

- The spring is tightened by the rotation of the turn counterclockwise (winding);

- perform the required number of revolutions specified in the instructions for the operating of the used trimmer model for grass and the length of the cord used;

- At the very end, the rope descends into the hole in the starter cover;

- Place the handle in place by blocking it with a node.

If after the repair the spring continues to fly, you can get rid of this in the following ways:

- Insert the corresponding piece of the plate into the groove at the location of the spring hook;

- Drill holes on both sides of the groove in the coil to insert the spring hook and fix it with wire.

Replacing a torn cord

The broken rope is replaced in the following order:

- The old cord is removed;

- choose a rope of the desired size (thickness and length);

- Having passed it through a special hole in the coil, tie a knot;

- inflate the spring, making the required number of revolutions;

- Fix the pen

It is better to tighten the spring plate with your Partner so that the edge of the cord does not bend inside the starter mechanism.

Assemble a starter for a trimmer for grass and tighten the spring is easy, only you need to do this carefully and carefully. For different models of gasoline brushes, the launching mechanisms are the same, so they are repaired in the same way. There are some nuances associated with their constructive features.