DIY guide for the Metabo saw. Smile emphasis

Inexpensive guide for manual circular saw with your own hands

If the plywood tire for some reason does not satisfy your requirements, you can make a more complex design guide. Below are a few more examples of guides for a manual circular, which everyone can do with their own hands.

Aluminum profile tire

Such a tire differs from a simple plywood in that a P-shaped aluminum profile is installed in the guide gap. Its advantage is that the stiffness of aluminum slightly increases the accuracy of the cut.

For a better sliding saw on the tire, you can attach not a thick plywood as limiters to the guide of the sole, but a couple of cylinders of a suitable height of fluoroplast or other material with a low friction coefficient.

Line from the construction rule

There are long aluminum rules that are used by finishing walls to align the walls. For the manufacture of a guide line with your own hands, rules are suitable, the design of which provides for a guttural for free movement of the handles.

The main advantage of such a line is the absence of elements protruding above the surface of the workbench. To do this, you need to take two collapsible clamps and slightly upgrade them.

The handles are removed from the rule, and their upper parts, which are replaced by polypropylene or fluoroplastic inserts, are removed from the stripes. The profile of these inserts should be T-shaped so that they can be established by a wide part of the Rules and hold there and hold there.

The result is a ruler that is attached to the workbench only by the lower part. This will allow you to freely move the saw in the working area, without fear of catching up for something.

However, such a tool cannot be called a full.fledged bus. This is precisely the line that needs to be configured before each rez.

Rail knock

This device is more often used for transverse cut (ending) of the material.

Usually it consists of two parallel metal corners, the ends of which are rigidly fixed on a plywood or metal base.

Through the corners, as on rails, the saw platform freely moves.

The corners are attached using bolts or studs, which, in addition, are used to adjust the height of the “rails” relative to the base. The height should be such that the cut material passes freely under the corners.

So that the movement of the saw is more smooth, the corners on the inside can be glued with a high sliding coefficient. For even more smooth movement, you can install the sole of the saw on the platform with metal wheels.

Remanding carriage on bearings

The circular on the remote carriage is more similar to a stationary format-disk machine. This design has high stability, and, accordingly, provides high cutting accuracy.

The remote carriage is made of a metal I.beam, which is firmly attached to the lower plane to the workbench. The carriage itself is moved along the upper plane. a platform, the lower edges of which are bent inside the offspring and equipped with bearings, allowing it to slide freely. The same bearings, tightly pressed to the axis of the I.beam, exclude the side backlash of the carriage.

Parallel to the carriage on the remote guide is attached to the sole of the saw. The guide can be made of two parallel corners or pipes. thus, moving the sole of the saw, you can configure the size of the cut of the material.

This design is good in that the supporting saw platform adjacent directly to the workpiece, which means that the cut depth does not decrease.

Cost for transverse and angular cuts

A device for transverse cuts is also often used. With it, the cuts of the boards pass quickly and exactly at an angle of 90 °. Such emphasis is also used for the ending of the boards. Its base is a sheet of plywood 10 mm thick. On it with glue or self.tapping screws, a guide block or a rail with a height of at least 20 mm is fixed. The emphasis is attached on the bottom of the base, perpendicular to the guide and made of the same bar.

The extra part of the base (from the guide to the saw disk) is cut off. Since this distance for each model of a manual circular is different, the device is always made individually. It is usually attached to the processed material with clamps.

Advanced craftsmen make their fasteners made of wooden goals, one of which has the shape of an eccentric. The clamp is carried out with a lamb nut on the screw. Such a clamping device allows you to very quickly fix the emphasis on lumber of different widths.

If, on the other side of the guide, set the same bar, but fixed at an angle of 45 ° to the first, and then cut off the part of the base at 45 °, then the angular universal emphasis for cuts and under 45 ° will be obtained and under 90 °. A more universal structure of the angular stop will turn out in the case of ensuring the rotation of the bar. And you can monitor the conveying of the angle along the transporter mounted on top. It should be noted that the manufacture of the transporter for the circular with your own hands is a more difficult task.

The machine consists of three main structural elements:

The base and the sawing table itself are not very complex structural elements. Their design is obvious and not so complicated. Therefore, in this article we will consider the most complex element. parallel emphasis.

So, the parallel emphasis is the mobile part of the machine, which is a guide for the workpiece and it is along it that the workpiece moves. Accordingly, the quality of the cut depends on the fact that if the emphasis is not parallel, then it is possible either to jam the workpiece or the saw curve.

In addition, the parallel emphasis of the circular saw should be a rather stiff design, since the master makes efforts, pressing the workpiece to the stop, and if the shifts of the stop are possible, this will lead to non.parallelism with the consequences indicated above.

There are various designs of parallel stops depending on the methods of its fastening to the circular table. We give a table with the characteristics of these options.

| The design of a parallel stop | Advantages and disadvantages |

| Fastening at two points (front and back) | Advantages: a rather stiff design, allows you to place the emphasis in any place of the circular table (to the left or right of the saw disk); It does not require the massiveness of the guide.studies itself: for attaching, the master needs to clamp one end to the front of the machine, as well as bypass the machine around and fix the opposite end of the stop. This is very inconvenient when selecting the necessary position of the stop and with frequent renovation is a significant drawback. |

| Mount at one point (front) | Advantages: a less stiff design than when fastening the stop at two points, allows you to place the emphasis in any place of the circular table (to the left or right of the saw disk); To change the position of the stop, it is enough to carry out its fixation on one side of the machine, where the master is located in the process of sawing.Disadvantage: the design of the stop should be massive in order to provide the necessary rigidity of the structure. |

| Circular table mount | Advantages: Fast reappropling.Disadvantage: complexity of the design, weakening of the design of the circular table, a fixed position from the line of the saw disk, a rather complicated design for independent manufacture, especially made of wood (made only of metal). |

In this article, we will analyze the option of creating a design of parallel stops for the circular with one mounting point.

Useful tricks and tips

There are small devices that even be shameful to consider. At the same time, they help well with cutting. These are the tricks of experienced masters.

Template

When cutting a large number of identical parts, the first of them can be used as a template for cutting subsequent copies. It is necessary only on one side of the first sample to fix the stubborn part with a width corresponding to the distance from the edge of the stove to the cutting disk. By installing such a template on the cut material, you can make many identical parts without marking.

Installation bars

The simplest detail that facilitates the installation of any stop and guide on the marking is a bar of a small section. Sprinkles are applied on it, the distance between which is equal to the segment from the end of the sole of the saw to the saw disk. Two such bars will help to install any guides quickly and precisely on the required indentation from the marking line. It remains only to fix the guide.

Material protection protection

Any bar can be protection, the corresponding thickness of the cut workpiece is width. If it is fixed at the site of the output of the saw disk from the processed material, then it will work as a limiter and will serve as protection against tearing and chips.

These devices are not limited to a set of beneficial self.proceeds that facilitate work with a manual disc saw. These are the easiest to manufacture. Others require time and skills. But craftsmen even such a device as a circuit transporter are made with their own hands. There would be a desire.

From plywood

This is one of the simplest universal versions of the guide for a hand.made manual circular saw, and therefore it is most common in home workshops. Let us consider in detail the process of its manufacture and the principle of operation.

Best Creative DIY. Making Useful Items. Amazing Homemade tools | KKS Creative #DIY

Necessary materials

For the manufacture of such a tire you will need three segments of plywood 10 mm thick. Their length should be the same and usually equals the length of the workbench at which the work will be carried out. One of the segments should be 25-35 cm wide (it will serve as the base), the width of the other two will be determined during the manufacture of the tire. Also prepare a wooden screw for 16 mm.

Production instructions

When creating a guide, it is necessary to very accurately observe all sizes. Small deviations can lead to a sharp deterioration in the result. If desired, instead of plywood, you can use a laminate.

The plywood guide tire is made a few steps:

- Measure the distance from the inner edge of the saw disk to the guide groove of the longitudinal cut, located on the supporting platform of the tool.

- Cut one of the plywood strips so that its width is 0.2-0.5 mm less than the distance obtained in p.one. The fibers of the upper layer of veneer on the faner should be directed longitudinally.

- With the help of self.tapping screws, fasten the resulting strip to a wide segment of plywood (base), accurately combining their ends. It will be a working edge of the tire.

- Measure the width of the guide groove of the longitudinal cut.

- Screw the remaining plywood strip to the base parallel to the first lane. Between them should remain a gap, the size of which should be 0.2-0.5 mm less than the width of the groove measured in the previous paragraph.

- In order not to damage the sawed material, a layer of soft fabric is glued to the finished guide on the bottom.

Important: Before measurements of the sole of the circular saw, be sure to turn it off from the mains!

Homemade guide is ready, it remains to prepare a manual saw. To do this, drink a narrow strip of thick plywood or other sufficiently durable material. The height of this strip should be 8-9 mm larger than the depth of the guide groove on the sole of the saw. The width corresponds to the width of this groove. A few centimeters length more than the length of the sole.

The resulting restraint strip should be fixed in the guide so that it protrudes for both edges of the sole.

How to use a plywood tire?

To make a cut, you will need two clamps and two flat wooden bar with a slightly larger part. The guide tire is installed with the ends of these bars so that its working edge protrudes a little beyond the edge of the workshop of the workbench. In places where the tire rests on the bars, it is tightly attached by clamps to the workbench.

A cut blade with a cut line, in advance with a pencil, is placed under the tire, and the fishing line for the trimmer cut is combined with its working edge. Finally, the circular with a restrictive strip mounted on it is installed on the tire so that the restriction on the sole definitely enters the prepared gap. Now you can cut, holding the workpiece with your free hand and slightly pressing the saw towards the workbench.

Other species

If the plywood tire for some reason does not satisfy your requirements, you can make a more complex design guide. Below are a few more examples of guides for a manual circular, which everyone can do with their own hands.

Aluminum profile tire

Such a tire differs from a simple plywood in that a P-shaped aluminum profile is installed in the guide gap. Its advantage is that the stiffness of aluminum slightly increases the accuracy of the cut.

For a better sliding saw on the tire, you can attach not a thick plywood as limiters to the guide of the sole, but a couple of cylinders of a suitable height of fluoroplast or other material with a low friction coefficient.

Line from the construction rule

There are long aluminum rules that are used by finishing walls to align the walls. For the manufacture of a guide line with your own hands, rules are suitable, the design of which provides for a guttural for free movement of the handles.

The main advantage of such a line is the absence of elements protruding above the surface of the workbench. To do this, you need to take two collapsible clamps and slightly upgrade them.

The handles are removed from the rule, and their upper parts, which are replaced by polypropylene or fluoroplastic inserts, are removed from the stripes. The profile of these inserts should be T-shaped so that they can be established by a wide part of the Rules and hold there and hold there.

The result is a ruler that is attached to the workbench only by the lower part. This will allow you to freely move the saw in the working area, without fear of catching up for something.

However, such a tool cannot be called a full.fledged bus. This is precisely the line that needs to be configured before each rez.

Rail knock

This device is more often used for transverse cut (ending) of the material.

Usually it consists of two parallel metal corners, the ends of which are rigidly fixed on a plywood or metal base.

Through the corners, as on rails, the saw platform freely moves.

The corners are attached using bolts or studs, which, in addition, are used to adjust the height of the “rails” relative to the base. The height should be such that the cut material passes freely under the corners.

So that the movement of the saw is more smooth, the corners on the inside can be glued with a high sliding coefficient. For even more smooth movement, you can install the sole of the saw on the platform with metal wheels.

Remanding carriage on bearings

The circular on the remote carriage is more similar to a stationary format-disk machine. This design has high stability, and, accordingly, provides high cutting accuracy.

The remote carriage is made of a metal I.beam, which is firmly attached to the lower plane to the workbench. The carriage itself is moved along the upper plane. a platform, the lower edges of which are bent inside the offspring and equipped with bearings, allowing it to slide freely. The same bearings, tightly pressed to the axis of the I.beam, exclude the side backlash of the carriage.

Parallel to the carriage on the remote guide is attached to the sole of the saw. The guide can be made of two parallel corners or pipes. thus, moving the sole of the saw, you can configure the size of the cut of the material.

This design is good in that the supporting saw platform adjacent directly to the workpiece, which means that the cut depth does not decrease.

Useful tips

There are devices that you cannot call the tool, but they still help the master when cutting.

When cutting a large number of the same parts, you can use the first as a template for cutting the rest. It will only be necessary on one side of the first sample to attach a stubborn part, and when installing such a template on the cut material, you can make many identical parts without marking.

This part facilitate the installation of any stop and tire on marking. a beam with a small section. It should have cuts, and the distance between them will be equal to the segment from the end of the saw sole to the disk. A couple of such bars will help to quickly install any guides quickly and simply.

Material protection protection

The protection can be a bar, which in width corresponds to the thickness of the cut workpiece, and if you attach it at the site of the disk, it will serve as a limiter and will protect him from chips and tear out.

- Application mode. The more often you use the circular saw, the better and stronger the materials should be from which the guide tire will be made. Otherwise, friction, which inevitably occurs during work, can lead to wear and decrease the accuracy of the cut.

- The parameters of the processing material. With a large thickness of wood preparations, you should make sure that the saw disk will completely cut it out. For example, a tire of plywood or profile (aluminum), which are described in this article, help reduce the depth of cut to the thickness of the material from which the tire is made.

- Technical capabilities of the tool. These include the maximum diameter of the disk, the possibility of transverse and longitudinal section, a rotary platform, which makes it possible to saw at an angle.

It is worth not forgetting that the accuracy of sawing will depend not only on the quality of the manufactured guide, but also the condition of the device. It is important to ensure that the support of the saw is always well fixed and is not mobile relative to the body. over, do not forget to carry out the replacement or sharpening of the saw disk in time.

During the work, the blunt teeth of the disk will leave a large number of chips on the cutting edge. The use of a tire with a manual circular will help to significantly expand the scope of application. And the possibility of using such a tool not only with a saw, but also with a manual mill or a jigsaw will further increase the value.

DIY Disse Disse Disse

The purpose of the guide tire

Specialized guides for specific saw models

Anyone who worked as a disk saw knows how difficult it is to do it exactly. With all efforts, to direct the tool clearly in marking, he still strives to move aside. As a result of damage to material and waste of time.

Some masters adapt this way: fasten a pair of clamps on the line on the ruler. However, with a manual circular, this method is inconvenient. the clamps are touched by the tool. There are several more arguments for using the guide tire:

- Using the rule, it is necessary to correct its position all the time. It is installed with a slight indentation from the cut line, only then the disk will definitely go along the line. This method will come down with single work. If it is necessary to make many exact cuts. the dreary process;

- The branded guide for the circular saw is designed so that its edge clearly coincides with the cutting line. The master only needs to combine these two stripes and work;

- high.quality tires are additionally glued with a soft ribbon that prevents the chip of material, for example, a wood.fiber plate or laminate;

- at the same time cut and monitor the location of the rule is inconvenient. Slightly transferred or unfinished. and the material is spoiled. When working with the tire, you just need to move the saw forward.

There are many types of guide tires on sale: universal or specialized for a specific model or manufacturer. The price of universal devices is usually higher than specialized. Therefore, many home craftsmen make tires with their own hands.

We make a tire with our own hands

The main task is to make a geometrically accurate product with your own hands, which is not easy. I would like to make a convenient and reliable device, having spent a minimum of time.

The basis can be suitable: a channel, corner, a rectangular pipe and even a laminate. Wooden and pressed guides have a serious drawback. they are sensitive to moisture.

Option 1

Laminate guide tire. the simplest and most affordable material.

- We cut two pieces of laminate of the same length along the ruler (for example, 50 cm).

- We mill one edge.

- We attach self.tapping screws to the base also made of laminate.

- The width of the groove is verified using a sheet of paper A4 format, with a thickness of approximately 0.11 mm: paper is inserted into the device and screwed.

- The guide is fixed to the sole of the disc saw by it with your own hands through the side of the side stop. You can drill a special hole in the case, if not sorry and has passed the warranty period.

- When working with the tire, it should be most advanced in front of a manual disc saw. And the nose of the sole should be thrown a few centimeters to the guide. Now take a disc for cutting the laminate and drain the edges of the guides on the spot so that they are perfectly combined with marking;

Such a device eats a little to the depth of cut (approximately 1.5 cm), but it is very convenient and simply done with your own hands.

Option 2

Now, as the basis for the tire, we take the construction rule. A model with handles that move along the groove is suitable.

- Remove the handles, instead of them we select softly fixed clamps with spring handles. There are models with a removable upper part. they are just suitable. Having removed it, the clamp, with the help of the adapter, is fixed on the rule.

- Adapters will have to be made independently from polypropylene on the milling machine. As a result, parts should be obtained, resembling the letter “T”, they are tightly inserted into the groove for handles.

- In the “leg” of adapters, we make holes and fasten the clamps on the screws.

- The guide is laid on a sheet of material with a groove down and clamps from the bottom is reliably pressed. There is not a single detail on top that brakes the work of the disc saw. There is only one restriction in work. the length of the rule, so you need to take the longest.

Profile Rules of the Strutzin guide assembly

Option 3

To obtain an accurate cut with a disc saw, one important condition is necessary: the edge of the base of the tool that adjacent to the guide should be perfectly even.

Professional units with cast soles have this property by definition. Which can not be said about inexpensive stamped grounds. Therefore, we offer another version of the guide. the rail.

The tool will move along it without resting on the guide rail. At the same time significantly reducing the effort necessary for pushing a hand saw.

An aluminum P-shaped profile is suitable for the rail. Two segments of different sections are required. A smaller profile should be inserted into the larger without gap, but move freely.

The finished guide rail so profiles should be combined

Now you can collect a guide rail with your own hands:

- We take the plywood and screw the guide for a larger diameter. We grind the heads of screws and screws to hide them flush.

- Put the plywood 0 on the strip tightly on both sides and also attach to self.tapping screws. Instead of plywood, you can use a wood-mounted stove.

We saw off the extra pieces in width and the rail is ready for use.

Now you should prepare a manual saw:

- We insert a small profile into the rail and remove the height of the “legs” so that it will fit.

- We fix the cut profile to the sole of the saw parallel to the saw disk. To do this, use a pair of m4 pile screws. If the platform of the disk tool is high.quality and even, you can adhere to its edge.

- We place a manual saw on the guide, inserting the profile into the guide rail, turn on the saw and saw off the excess strip along the width.

- Now, for the perfect cut, it is necessary to lay the edge of the tire on the marking and attach the directing clamps. The main feature of the structure is the rail. When using such a bus, the saw moves smoothly, does not hang out, it is easily served and very accurately cuts.

Tire guide for a circular saw: with your own hands for a manual circular, how to make a home.made ruler

Everyone who at least once worked as a hand circular saw knows how difficult it is to make a clear and even cut with it with its help. Many solve this problem with the help of simple devices, such as a strip of plywood or plastic, which is fixed on the surface with clamps. However, it is more convenient to use a special guide tire for this purpose.

Such a device is very rarely included in the package of manual circular saw, and in stores it is offered at a price, often comparable with the cost of the saw itself. It seems strange, because it is not the complexity of the design. If you have the necessary materials, it is quite possible to make a guide tire independently, which we will talk about in this article.

What it is?

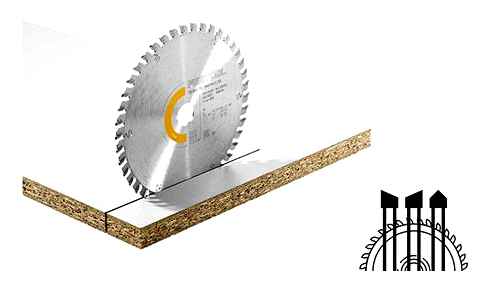

In fact, the tire guide is a rail that provides a sliding of a manual circular saw forward and backwards, and at the same time does not allow the tool to deviate from the saw line. But a properly designed guide not only provides an even cut, it also reduces the number of chips at the site of contact of the saw and material.

Home.made guides have a different structure and are made from various materials. For example:

- guide from plywood;

- rail washed from the corner;

- Aluminum profile tire;

- line from the construction rule;

- Remanding carriage on bearings.

The knock and the remote carriage are most difficult to manufacture. Plywood guide or tire from the profile is much easier structurally, but this does not mean at all that the saw, made with their help, will not be so high.quality. The difference between these varieties for the most part lies in the convenience of use.

From plywood

This is one of the simplest universal versions of the guide for a hand.made manual circular saw, and therefore it is most common in home workshops. Let us consider in detail the process of its manufacture and the principle of operation.

Necessary materials

For the manufacture of such a tire you will need three segments of plywood 10 mm thick. Their length should be the same and usually equals the length of the workbench at which the work will be carried out. One of the segments should be 25-35 cm wide (it will serve as the base), the width of the other two will be determined during the manufacture of the tire. Also prepare a wooden screw for 16 mm.

Production instructions

When creating a guide, it is necessary to very accurately observe all sizes. Small deviations can lead to a sharp deterioration in the result. If desired, instead of plywood, you can use a laminate.

The plywood guide tire is made a few steps:

- Measure the distance from the inner edge of the saw disk to the guide groove of the longitudinal cut, located on the supporting platform of the tool.

- Cut one of the plywood strips so that its width is 0.2-0.5 mm less than the distance obtained in p.one. The fibers of the upper layer of veneer on the faner should be directed longitudinally.

- With the help of self.tapping screws, fasten the resulting strip to a wide segment of plywood (base), accurately combining their ends. It will be a working edge of the tire.

- Measure the width of the guide groove of the longitudinal cut.

- Screw the remaining plywood strip to the base parallel to the first lane. Between them should remain a gap, the size of which should be 0.2-0.5 mm less than the width of the groove measured in the previous paragraph.

- In order not to damage the sawed material, a layer of soft fabric is glued to the finished guide on the bottom.

Important: Before measurements of the sole of the circular saw, be sure to turn it off from the mains!

Homemade guide is ready, it remains to prepare a manual saw. To do this, drink a narrow strip of thick plywood or other sufficiently durable material. The height of this strip should be 8-9 mm larger than the depth of the guide groove on the sole of the saw. The width corresponds to the width of this groove. A few centimeters length more than the length of the sole.

Instructions: DIY carriage carriage

The resulting restraint strip should be fixed in the guide so that it protrudes for both edges of the sole.

How to use a plywood tire?

To make a cut, you will need two clamps and two flat wooden bar with a slightly larger part. The guide tire is installed with the ends of these bars so that its working edge protrudes slightly beyond the edge of the workshop of the workbench. In places where the tire rests on the bars, it is tightly attached by clamps to the workbench.

A cut blade with a cut line, in advance with a pencil, is placed under the tire, and the fishing line for the trimmer cut is combined with its working edge.

Finally, the circular with a restrictive strip mounted on it is installed on the tire so that the restriction on the sole definitely enters the prepared gap.

Now you can cut, holding the workpiece with your free hand and slightly pressing the saw towards the workbench.

Other species

If the plywood tire for some reason does not satisfy your requirements, you can make a more complex design guide. Below are a few more examples of guides for a manual circular, which everyone can do with their own hands.

Aluminum profile tire

Such a tire differs from a simple plywood in that a P-shaped aluminum profile is installed in the guide gap. Its advantage is that the stiffness of aluminum slightly increases the accuracy of the cut.

For a better sliding saw on the tire, you can attach not a thick plywood as limiters to the guide of the sole, but a couple of cylinders of a suitable height of fluoroplast or other material with a low friction coefficient.

Line from the construction rule

There are long aluminum rules that are used by finishing walls to align the walls. For the manufacture of a guide line with your own hands, rules are suitable, the design of which provides for a guttural for free movement of the handles.

The main advantage of such a line is the absence of elements protruding above the surface of the workbench. To do this, you need to take two collapsible clamps and slightly upgrade them.

The handles are removed from the rule, and their upper parts, which are replaced by polypropylene or fluoroplastic inserts, are removed from the stripes. The profile of these inserts should be T-shaped so that they can be established by a wide part of the Rules and hold there and hold there.

Step-by-step instruction

Below is a detailed process of manufacturing a simple carriage for a saw.

Marking guides

Sliding grooves should be clearly parallel to the circular disk. Therefore, on the countertop with a pencil and ruler, the necessary marks are placed and the central axis is drawn. Accurate marking. the key to a quality tool.

Fresis of grooves

Когда главная леска для триммера готова, по обе стороны от нее на равном расстоянии делаются пазы с помощью фрезерного станка. You can insert the profiles of metal (P-shaped) into the grooves so that the grooves serve longer, and the scenes easily move.

Production of scraps

Reiki is cut out of wood. Preference is given to solid breeds. maple, oak and other. The scenes should fit well to the grooves, but not too tightly, otherwise the carriage will not be able to move. If this stage is completed correctly, the basis of the salary will be easily installed on the desktop.

For a drink at a non.standard angle, you need to additionally make a combined square

Installation of the base of the carriage on the shells

Planes glue, after them a plywood sheet is placed on them. During the action of the glue on the plywood, a weighting agent is placed, or it is fixed by any clamp. It is previously desirable to smoke the plywood.

Marking the corners of the carriage

The carriage is installed in the grooves, and the master drinks its front part. 2 corners of 45 degrees are measured from this site. After which the corners are cut on both sides.

Correction of carriage corners

It is necessary to fix the design and perform several blanks to evaluate the functionality of the carriage. If the corners are not correct in sawed rheles, the circus carrier is adjusted: its boundaries are cut. Then you need to do a trial cut again.

This procedure is carried out until the desired effect appears in the size of the cut, the vibrational level and the need to make efforts in the process.

Advantages and disadvantages of a home.made carriage for circular

When creating a carriage for the circular, you can:

- Achieve optimal sizes.

- Change the standard appearance, for example, make a radius carriage for curved shapes.

- Choose suitable materials: aluminum, wood, profiles, etc.D.

- Save. use the tools available at hand.

However, if you make a guide yourself, a number of difficulties will appear. In particular, it is necessary to have appropriate knowledge about the process, to acquire specific tools for work, which may not be at the unprofessional joiner.

Carriages are divided into manual and stationary, amateur and professional

Laminate tire manufacturing

This method of manufacturing a carriage for circular with your own hands is the easiest for execution, it uses easily accessible source materials.

Three blanks are made from the laminate. One of them will serve as the basis for the guide. The other two are cut in the form of two stripes, about half a meter long each. Both in the milling cuts are leveled on one side. With the help of screws, the stripes are attached to each other parallel to even edges. The width of the groove between them is verified using the A4 paper sheet, inserting it into the device and scrolling.

The tire is fixed to the sole of the circular saw using the fasteners of the side stop. If the warranty period of the saw has already expired, for greater reliability of fastening, you can use the circular case, making an additional one more hole in it.

Before starting work, a homemade guide should be put forward in front of the handle of the disc saw. In this case, it is necessary that the guide is closed to the nose of the sole for several centimeters. For the perfect compatibility of the edges of the guide stripes with marks on the material, you need to carefully saw off the laminate cutting disk for laminate cutting.

Option 1

Laminate guide tire. the simplest and most affordable material.

- We cut two pieces of laminate of the same length along the ruler (for example, 50 cm).

- We mill one edge.

- We attach self.tapping screws to the base also made of laminate.

- The width of the groove is verified using a sheet of paper A4 format, with a thickness of approximately 0.11 mm: paper is inserted into the device and screwed.

- The guide is fixed to the sole of the disc saw by it with your own hands through the side of the side stop. You can drill a special hole in the case, if not sorry and has passed the warranty period.

- When working with the tire, it should be most advanced in front of a manual disc saw. And the nose of the sole should be thrown a few centimeters to the guide. Now take a disc for cutting the laminate and drain the edges of the guides on the spot so that they are perfectly combined with marking;

Directioning tire for the disco saw Metabo

Stable anodized aluminum profile Non.sliding coating for reliable support and protecting blanks from scratches tightly adjacent adjustable guide line is suitable for: jigsaws, manual circular saws and upper milling milling 738 and OF E 1229 SIGNAL METABO (under.

Shipment at night, mail, courier, logistics company

METABO guide 1500 mm (631213000)

Metabo FS 80 (629010000) guide at a favorable price

Shipment at night, mail, courier, logistics company

Metabo FS 80 (629010000) guide

For even and safe conduct, protection against chips reduces the danger of chips during cutting, adhesive coating for reliable retention and protection of the surface of the workpiece, with holes for fixing the guide on the workpiece and storage in the suspended state, the possibility.

Shipment at night, mail, courier, logistics company

Metabo FS 80 629014000 guide

For even and safe conduct, protection against chips reduces the danger of chips during cutting, adhesive coating for reliable retention and protection of the surface of the workpiece, with holes for fixing the guide on the workpiece and storage in the suspended state, the possibility.

Shipment at night, mail, courier, logistics company

Metabo FS 310 629014000 guide

Shipment at night, mail, courier, logistics company

Metabo FS 160 (629011000) guide tire

For even and safe conduct, protection against chips reduces the danger of chips during cutting, adhesive coating for reliable retention and protection of the surface of the workpiece, with holes for fixing the guide on the workpiece and storage in the suspended state, the possibility.

Shipment at night, mail, courier, logistics company

Metabo FS 160 629014000 guide

For installing manual circular saws KS 66 and KSE 68 Plus (mouth.; No. order 600543) on the guide tire

Shipment at night, mail, courier, logistics company

Adapter to the guide tire for KS 66, KSE 6.

Purpose: for a disc saw Material: aluminum

Shipment at night, mail, courier, logistics company

For even and safe conduct, protection against chips reduces the danger of chips during cutting, adhesive coating for reliable retention and protection of the surface of the workpiece, with holes for fixing the guide on the workpiece and storage in the suspended state, the possibility.

Shipment at night, mail, courier, logistics company

Metabo FS 250 629014000 guide

The tire-controling AMS FG for Festool Tire is completely assembled with all ribbons and anti-ski production of the fiction tire-German festool ribbons of 1 m tire-0.2mm is delivered only in a hard plastic crate of 4 cm

Shipment at night, mail, courier, logistics company

AMS guide tire AMS FG for Festool lengths.

Director 500×1.0mm, brown at a favorable price

Shipment at night, mail, courier, logistics company

Roller guide 500×1.0mm, brown

Tire guide Interskol 2502002 (1.4 m) at a favorable price

Shipment at night, mail, courier, logistics company

Tire guide Interskol 2502002 (1.4 m)

disk, manual, power: 1200 watts, height cut: 55 mm, disk diameter: 160 mm, rotation speed: 5200 rpm, weight: 3.70 kg

Shipment at night, mail, courier, logistics company

Disk saw Metabo KSE 55 Vario Plus

For even and safe conduct, protection against chips reduces the danger of chips when cutting the adhesive coating for reliable holding and protecting the surface of the workpiece with holes for fixing the guide on the workpiece and storage in an suspended possibility.

Shipment at night, mail, courier, logistics company

METABO FS 160 guide in the FST bag (.

Miter Saw Repair DIY Bearing Replacement

Tire guide Metabo 2.5m FS 250 629013000 at a favorable price

Shipment at night, mail, courier, logistics company

Tire guide Metabo 2.5m FS 250 62901300.

Guide, universal, length 1400 mm

Shipment at night, mail, courier, logistics company

For a convenient connection of two guides

Shipment at night, mail, courier, logistics company

Adapter for the Metabo 6 guide tire.312.

Stable anodized aluminum profile.free coating for reliable support and protecting blanks from scratch.constrained adjustable guide lineup is suitable for: jigsaws, manual circular saws and upper milling cutters 738 and of E 1229 Signal Metabo (when IPP.

Shipment at night, mail, courier, logistics company

Metabo. a guide tire 1500 mm, new

Tire guide Metabo 0.8m FS 80 629010000 at a favorable price

Shipment at night, mail, courier, logistics company

Tire guide Metabo 0.8m FS 80 629010000

Tire guide Elitech 1820.000500 at a favorable price

Shipment at night, mail, courier, logistics company

For even and safe conduct, protection against chips reduces the danger of chips when cutting the adhesive coating for reliable holding and protecting the surface of the workpiece with holes for fixing the guide on the workpiece and storage in an suspended possibility.

Shipment at night, mail, courier, logistics company

Directioning tire for the disco saw Metabo

The price of the proprietary guide tire is approaching the cost of the circular saw itself. Although whether this good hearing is needed, for what purpose it is used, how can you neglect the tire, replace or make it yourself?

At least who, who worked as a disk saw, knows how difficult it is to do it exactly. With all the efforts to direct the tool correctly in marking, he further strives to move aside. Upon completion of damage to the material and embezzlement of time.

Some masters adapt this way: strengthen the pair of clamps on the ruler. But with a manual circular, this common hearing is inconvenient. clamps hurt for the tool. There are several reasons for the introduction of a guide tire:

- Using the rule, you need to constantly correct its position. It is installed with a small indentation from the cut of the cut, only then the disk will definitely go through the strip. This method will come down to single work. On the contrary, you need to make a huge number of clear cuts. the dreary process;

- The branded guide for the circular saw is designed so that its edge correctly coincides with the cutting line. The master needs only to cooperate these two stripes and work;

- High.quality tires are additionally glued with a soft ribbon that prevents the chip of material, for example, the wood.fiber plate, as it is also called laminate;

- immediately saw and look behind the location of the rule awkward. A bit transferred or unfinished. and the material is spoiled. When working with the tire, you just need to move the saw forward.

There are a huge number of types of guide tires: universal or specialized for a certain model in other words of the manufacturer. The cost of universal devices is usually higher than specialized. Therefore, probably home craftsmen make tires on their own.

How to do it with your own hands?

Branded tires from manufacturers are made in such a way that their boundaries coincide with the line along which the cut occurs. Branded products are glued with a special ribbon, it prevents damage to soft material. All these little things are convenient and necessary. Such a tire provides performance, accuracy and comfort in work.

There are also disadvantages in such products: not always a brand tire can correspond to production tasks.

If the tool has to be used from time to time, then buying an expensive tire is optional. The best option: make a tire with your own hands. In terms of quality and functionality, such guides are often not inferior to the best world analogues.

To make a home-made tire, you need to take some kind of durable material as a basis, it may turn out to be:

The material should not be deformed under the influence of excess moisture or temperature difference.

Directs drawings can be found on the Internet. It is easy to bring any sample you like, adjusting it to the features of this equipment

At the same time, it is important to observe all sizes. In manual disk saws, comfortable handles are often made, which improves the quality of work and greatly facilitates the work. Materials that will be required for the manufacture of a universal tire:

Materials that will be required for the manufacture of a universal tire:

For a small circular saw

It is made in the form of a rail. The following elements are needed:

- Construction rule (2 meters);

- fixators;

- propylene fragments;

- a corner or profile of aluminum;

- Bars made of wood 12 mm;

- stoves of woody stove;

- laminate.

For big

Marking is prepared, the places of the future mount should be indicated. The submersible board should move freely parallel to the guide elements, the disk should not be on too large elevation.

From the construction rule and fixators

To make a similar node, the following elements will be required:

- the construction rule (1.5–2 meters), which is used to plastered walls;

- fixators (their number depends on the mounting points);

- guides that are made of the rule, fixators and polypropylene elements.

- The handles are removed from the rule (if they are present);

- adapters are cut from a dense PVC of the material, they should be a little more than the depth of the groove of the rule itself;

- The design made is attached to the wooden bar.

From aluminum

To make a tire from an aluminum profile, the following elements will be necessary:

From wood

Two bars are involved in creating such a design, the dimensions of which vary. And you can also use the stove for these purposes. All wooden elements are mounted on self.tapping screws. The protruding parts are neatly cut off. Such a simple mechanism can also provide an ideal cut.

From profiles of different sizes

In this case, a small profile is installed on a large profile. The created design is attached to the base of the circular saw. Such installation provides the ability to move exactly along a given line. The edge at the base should be impeccably even, it provides the quality of the cut. The profiles form rails, this allows you to significantly reduce the efforts that are necessary to control the aggregate. A smaller profile should not have gaps with a large profile, but there should be free movement.

From the laminate

This material is cheaper, it is easy to buy it, it is quite technologically advanced. The laminate is cut into two identical fragments in the form of strips. One of them will be the main one, the second. auxiliary. All edges are polished, rounding is made. Using self.tapping screws, the material is attached to the basis.

To ensure comfortable work, it is recommended to put forward the tire to the maximum distance. With the help of corner grinder, excess material on the guides is removed.

How to make a homemade guide tire for a circular saw, learn from the video below.

Rail knock for manual circular

This device allows you to cut boards of a given length, bars, small blanks in large quantities quickly and with high quality.

For the manufacture of such a guide, you must have:

- Metal corners of the same size of the shelf and length.

- The base of any available material: boards, plywood, wood-bruise. Its thickness should be more than 15 millimeters.

- Set of fasteners (bolts, nuts, wood screws).

Before cutting workpieces, marking is made. Note the length of the future tire and fastening location. The main conditions when choosing sizes are:

For fastening the structure, bolted joints are used. The parallelity of the fixed corners should be thoroughly hanged. Ensure free sliding of the sole of the circular saw. To do this, glue fluoroplastic stripes. They significantly reduce the coefficient of friction and reduce the load on the circular saw.

Small wheels are installed as another option. As a finished product, you can apply a small diameter of the bearings. It will take extra time and tools. The created design will greatly simplify the cutting operation and ensure proper security.