DIY lawners for lawn mower. Do -it -yourself trimmer knife

How to make a casing for motorcycles

Each master has a corner grinder. This is the most suitable tool for creating a trimmer for grass. Unlike store devices, it is stronger in power and has good speeds. Consider how to make a trimmer for grass from a corner grinder with your own hands, work order:

- First prepare a bracket. It is designed to cover the corner grinder body. The metal plate is applied to the case and bended.

- There are threaded holes on both sides of the case, in which the transit handle is attached. They attach a trimmer for the grass to them.

- In the bracket, holes are drilled on both sides so that they correspond to the openings located on the tool body. For accuracy, the details make notes with a marker, clamp it with a vice and drill.

- Then the guide is attached to the bracket. Its size should correspond to the length of the case or be a little shorter. The guide is attached by the welding machine, the remains of the scale are knocked down. The part is polished with a metal brush.

- A handle (bar) is made from a metal pipe). To fix the handle under the slope, the tip of the pipe is cut under the beard. The finished handle is welded to the structure, the scale is knocked down and the part is cleaned with a brush.

- To attach the tool, you need to unscrew the protective disk of the corner grinder.

- Then the homemade is installed on the wheels. To do this, you can borrow wheels from a cart or a baby stroller with brackets.

- First mount a corner grinder, then a wheel with a bracket. Everything is fixed with a bolt. On the other hand, they make the same fasteners.

- The cutting node is made from a steel cable. A kapron wire designed for trimmers is suitable. It is threaded through the clamping nut and a hole for the key according to the Cross-Cross method. Then the nut is twisted with the cables.

- The wire is fixed with island.

With the advent of the summer of many owners of personal plots, the question is disturbed by a knitted one with how to put a knife on a trimmer for grass. The questions are more burning, why and when it is purposeful to replace the fishing line for a trimmer on a motorcycle with a stronger cutting element. In our article, we will try to make out all this and give useful advice to summer residents.

Power for a trimmer for grass

For more comfortable work with a trimmer, if it is understood to process a large area overgrown with grass, it is advisable to use a special belt. This device relieves fatigue from the hands and back of the mowing operator and greatly facilitates the process when compared with the same work, but without a belt.

Belts are shoulder and ranger. The shoulder belt is the simplest device and consists of a loop with two or one latch (carabiner), with which it is attached to a mowing unit. A plastic plate is usually attached to the second carbine, which protects the side of the operator from pressure with a bar trimmer for grass.

Shoulder belt is usually used with light trimmers weighing 3-4 kg. For heavier units, it is more convenient to use a parapier belt.

A belt for a trimmer for grass can be easily ordered via the Internet or buy in a specialized store where these devices and components are sold to them.

If there is a desire to do it with her own hands, then any mistress, looking at this device, can easily sew it from improvised means (old belts and belts). You may have to buy buckles and carbines. But still, we recommend buying a ready.made ran.out suspension and not waste time and money to make the worst quality than ready.made devices.

From the vacuum cleaner

The trimmer for grass from the engine from the vacuum cleaner is made according to the same principle as from the corner grinder. The motor must be fixed on the rod, and either knives or a plastic or metal disk in which the fishing line for the trimmer is fixed on the engine shaft. On top of the cutting tool is closed with a protective casing.

So that the dust and small particles of mowed grass do not fall into the engine removed from the vacuum cleaner, it can also be hidden in a plastic casing made From the sewer pipe. as shown in the next photo.

Since the engine in the vacuum cleaner is high Provide cooling. Therefore, it is recommended to insert a homemade disk with cut and curved blades under the washer, into which the fishing line is inserted, so that it plays the role of a fan that creates a vacuum. It is required so that the air is sucked through the hose from above and cool the motor.

In order to facilitate the load on the hands of the mowing operator, the unit can Install on the site with wheels. In this case, something similar to the lawnical mower will be obtained.

To fix the fishing line, you can also use either a pulley with a suitable landing hole, or a plastic wheel from a cart.

From a drill

The simplest mower in a matter of minutes is made from a drill or an electric screwdriver. But first you must make a knife from a sharpened metal plate with a hole drilled in the center. A bolt is inserted into this hole and clamped by a nut.

Since a drill with this nozzle does not have a protective casing, such a tool is quite dangerous for the user. To protect yourself, you can place the drill, like a corner grinder (this was mentioned above), on the cuttail cuttings or on an aluminum pipe.

Also, to protect the user of the mowing from knives, you can fix the casing on the drill (attached to the plastic pipe and put on the body of the apparatus).

The drill to the bar is attached using clamps.

Maintenance.

The air filter should always be unsuccessful (without dirt or sawdust); foam filter must be wetted with oil. The fuel filter must be inspected once a week (change as necessary). Checking the tightening of nuts and screws. before work. Cleaning from a muffler carrier (or its grid) and candles. if necessary. Install a coil with a cover 14 to remove the coil 17 how to close the protective casing when closing. Corner gearbox. Clean the dirt once a day (a similar “fur coat” does not allow the gearbox to cool normally) and bring a consistent lubricant for a reducer pair.

lawn mower. How to replace a broken shield. Bent a shield for a few days. Maybe I’m not lucky. T high

Direct rod in a gasoline trimmer for grass and curved in electric

Putting a metal knife on an electric trimmer for grass does not allow its design features.

- The curved rod of the unit reduces the distance from its working part to the legs of the Kosar. In the case of a collision of blades with a stone or other hard object of a braid for grass, it is discarded to the legs.

- The high torque, which we mentioned above, in the event of a collision of a metal knife with a solid object, transfers a large load to the flexible shaft of a trimmer for grass and its engine. What causes their premature failure.

- Handle Electric Knules most often does not have a restrictive bar playing the role of the stop. But you should not rely only on them, since not a casing with a cutting trimmer for grass is designed for. Which does not exclude leg injury.

It is these features that allow the use of exclusively plastic knives on trimmers with electric engines. In a collision with an obstacle, the blades are destroyed, thereby protecting the legs of the mower from obtaining possible injuries.

Plastic knives cope well with outgrown and dry grass. They can mow the nettles and stems of burdocks.

The use of metal knives only on gasoline trimmers is also due to constructive features.

- The direct design of the rod increases the distance to the legs, which provides the Cossacks with complete safety.

- Comfortable U-shaped and J-shaped handles allow you to keep the tool firmly. D-shaped handles Motokos are equipped with a limiter resting in the leg of the Costsa, which does not allow to let the head to the legs when meeting a cutting disk with a solid obstacle.

- The clutch of the gasoline engine allows you to smoothly gain speed to the optimal level. And when the blade collides against a hard surface, it can extinguish part of the blow.

lawn mower. How to replace a broken shield.

lawn mower. How to replace a broken shield. How to make homemade protection for a trimmer for grass with your own hands. How to make a fuel mixture for a trimmer for grass or lawn mower. Bent a shield for a few days. Maybe I’m not lucky. T high.

In addition, working with a trimmer after its assembly should not only be as safe as possible, but also conveniently. Therefore, the holder of the trimmer for the grass should be adjusted to their height, maybe install an additional handle on it from the side, etc. D.

First, the handle of a trimmer for the grass is prepared, on which the drill should be fixed. For fixing the drill will need long bolts and metal clamps. Must necessarily be a drill power supply should be wrapped in a trimmer handle for grass. It is impossible for the wire to dangle and is a danger when it falls under the cutting element of the trimmer for the grass.

lawn mower. How to replace a broken shield.

lawn mower. How to replace a broken shield. How to make homemade protection for a trimmer for grass with your own hands. How to make a fuel mixture for a trimmer for grass or lawn mower. Bent a shield for a few days. Maybe I’m not lucky. T high.

In addition, working with a trimmer after its assembly should not only be as safe as possible, but also conveniently. Therefore, the holder of the trimmer for the grass should be adjusted to their height, maybe install an additional handle on it from the side, etc. D.

First, the handle of a trimmer for the grass is prepared, on which the drill should be fixed. For fixing the drill will need long bolts and metal clamps. Must necessarily be a drill power supply should be wrapped in a trimmer handle for grass. It is impossible for the wire to dangle and is a danger when it falls under the cutting element of the trimmer for the grass.

How to put a knife on a trimmer for grass correctly

a knife for a trimmer for the grass is not so difficult. The manufacturer equips his tools with a special pin that allows you to block the gearbox and the key, with which the spool is unscrewed with the fishing line. The most important thing is to observe when changing the cutting elements safety precautions and the assembly sequence of disassembly.

The algorithm for installing a knife on a trimmer for the grass is as follows:

- Remove the protective casing;

- We block the drive. To do this, it is necessary to combine two holes. in the hub of the shaft and in the gearbox cup. After combining them, insert the pin into the holes;

- We unscrew clockwise a spool with a fishing rod with a fishing line or a mounting nut that holds the boot (if the trimmer for the grass has not yet been used);

- Next, we install the cutting knife, so that the slots on the puck of the hub coincide with the notchs in the hole of the cutting disk;

- Install the boot;

- We twist the mounting nut (counterclockwise) holding the stopped pin;

- We tighten it using a tubular key;

- Return the protective casing in place.

In the summer, so that the country site looks neat, you have to download grass regularly. A trimmer for grass helps to quickly cope with this. a light hand.bore in the form of a cane.

A kind of electric cos, only instead of a blade she has a fishing line for a trimmer.

The well.known drawback of trimmers is that without special protection (masks and glasses) it is impossible to work with it: the grass scatters in different directions with high speed, falling into the face and eyes.

The reason for this is a small shield over a rotating fishing line.

To solve this problem, I cut the “native” plastic shield, leaving only a third part attached to the bar.

Then, from an aluminum sheet with a thickness of 0.2 mm and a size of 250 × 250 mm, made a new one, attached two screws from above to the remaining part of the former shield.

Instead of aluminum, you can use a plate of rubber or linoleum, but then the shields from these materials will have to be fixed with steel wire so that the edges do not accidentally fall under the rotating fishing line for the trimmer.

How to choose?

Before buying a nozzle, you need to determine two nuances:

- The purpose of the weeding: if you need to remove the grass in the aisles or a front garden, then the scores will be enough. When we are talking about the beds themselves and the need to wrest the weeds with the root, preference should be given a cultivator nozzle with teeth, exciting unwanted vegetation.

- Work volumes: if this is a huge plantation, then the fishing line for a trimmer cannot cope with the task, especially in the presence of dense and high weeds (it is better to take disk). And for work between the beds, there will be enough fishing line, which costs 2-3 times cheaper than a disk nozzle, and it will be safer to approach the beds with it.

If the weeds are large, and in the arsenal there is only a head with a fishing line, then you can not even start work. The nozzle will be extremely difficult to cut the massive weed trunks, which will lead to overheating of the motor. A trimmer for grass, experiencing an increased load, will constantly fail and need expensive repairs.

Have several nozzles in stock, since none of them will be superfluous in the household. Mowing barely grown grass after heavy rains. the head with a fishing line will help. Remove the thickets in the garden is disk, but most carefully free the plot from weeds, removing them with the root only of the cultivator.type nozzle.

What knives to put on an electric and a lawn mower

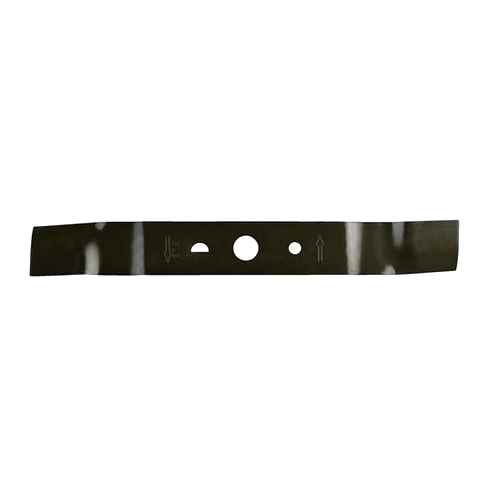

Before taking and putting a knife on a motorcycle, we will find out what they are and in what cases are used. Now manufacturers offer the consumer a huge number of types of these consumables. In general, the entire cutting tool intended for mowing grass can be systematized:

The main material for the production of trimmer knives can be plastic or metal. The introduction of such expenditures in almost everything is depending on 2 characteristics:

Of the judgments of safety precautions, manufacturers do not advise putting iron knives on electronic trimmers for grass for grass. In fact, all motokos operating from the electronic network and battery are equipped with plastic blades. How to put knives on a trimmer for grass (lawn mower). Depending on the manufacturer, they can be a solid disk.shaped design, with several blades or in the form of a special mowing head providing for the installation of removable plastic blades.

What knives to put on an electric and a lawn mower

Before taking and putting a knife on a motorcycle, we will find out what they are and in what cases are used. Now manufacturers offer the consumer a huge number of types of these consumables. In general, the entire cutting tool intended for mowing grass can be systematized:

The main material for the production of trimmer knives can be plastic or metal. The introduction of such consumables is in almost everything depending on 2 characteristics:

Of the judgments of safety precautions, manufacturers do not advise putting iron knives on electronic trimmers for grass for grass. In fact, all motokos operating from the electronic network and battery are equipped with plastic blades. How to put knives on a trimmer for grass (lawn mower). Depending on the manufacturer, they can be a solid disk.shaped design, with several blades or in the form of a special mowing head providing for the installation of removable plastic blades.

FAQ

If the engine of the trimmer for the grass quickly heats up and after 5-7 minutes literally boiling water, whether this is that the nozzle cannot cope with its work?

HOW TO MAKE GRASS CUTTER USING ANGLE GRINDER / an incredible lawn mower idea

Perhaps the reason is that the nozzle is not able to remove powerful thickets of weeds, which leads to an increase in the load. But boiling a gasoline trimmer for grass can also be caused by the absence of oil in gasoline. Check if the correct concentrations and proportions are selected before refueling the tank.

The nozzles must be chosen by the name of the model or some of them are suitable for trimmers for grass of other brands?

Ask the seller who will help make the right choice. Not always the power of the simplest garden trimmer for the grass is enough for the full operation of the cultivator nozzle.

How often you need to sharpen knives on the nozzle for weeding?

How to make a grass cutter DIY at home | lawnmower

As you get dark. If you use it quite often and process more than 10 acres per week, then it is better to drag them every 10-12 days using special equipment.

How to make a casing for motorcycles

In the summer, so that the country site looks neat, you have to download grass regularly. Quickly ordinary braids for grass, a trimmer for grass helps to cope with this. a light hand.bore in the form of a cane.

A kind of electric cos, only instead of a blade she has a fishing line for a trimmer.

The well.known drawback of trimmers is that without special protection (masks and glasses) it is impossible to work with it: the grass scatters in different directions with high speed, falling into the face and eyes.

The reason for this is a small shield over a rotating fishing line.

To solve this problem, I cut the “native” plastic shield, leaving only a third part attached to the bar.

Then, from an aluminum sheet with a thickness of 0.2 mm and a size of 250 × 250 mm, made a new one, attached two screws from above to the remaining part of the former shield.

Instead of aluminum, you can use a plate of rubber or linoleum, but then the shields from these materials will have to be fixed with steel wire so that the edges do not accidentally fall under the rotating fishing line for the trimmer.

Modernization of a trimmer for a trimmer for grass

During the operation of any electric trimmer for the grass, one large drawback is manifested: the formed grass juice and senage fly far to the sides and up, covering the core with herbs from head to toe. We have to use overalls, a mask to protect the face and eyes, but the dust clogs into boots, sits on a headdress. After the hour of work, the span turns out to be “all covered with greens, absolutely all”! We have to spend a lot of time on the subsequent “sanitary”.

The reason is that trimmers for grass have an excessively small shield above a rotating fishing line. In mine, for example, the shield occupies only a sector that corresponds to the numbers from 4 to 8 on the watch dial, which is clearly not enough.

To eliminate this drawback, I cut a plastic shield in my trimmer, left only the third (central) part attached to the bar. Then he made an enlarged shield of aluminum sheet with a thickness of 0.2 mm and a size of 250 × 250 mm, which was attached with two screws from above to the remaining part of the former shield (see. rice.).

As a result, the resulting new shield began to cover the entire semicircle of the rotation of the fishing line facing Kosar, protecting it from flying greens. The effect of such modernization was wonderful! Now even boots do not get dirty above half of the shafts.

In the absence of an aluminum sheet, you can use a plate of rubber or linoleum. To prevent hanging the edges of such material, they will have to reinforce them on top around the perimeter by steel wire. In this case, the peripheral parts of the material should be held by the wire in the raised state. The material of the shield should be attached to the wire in these places, inaccessible to the rotating fishing line.

How to make a casing for motorcycles

Polymeric materials have long been present in our lives, and now they can be found in any industry. But since plastic does not decompose in the usual way, it causes great harm to the environment.

A positive factor is the possibility of its secondary processing. To do this, the plastic is first prepared and brought into the necessary condition, then it is crushed. For this, special devices were created. crushers (grinders, machines, special grinders). You can make any of them yourself.

Types of grinders

There are 3 types of devices that can be divided in accordance with the possibilities of processing the entire material. They are divided into the following options:

From a drill

The simplest mower in a matter of minutes is made from a drill or an electric screwdriver. But first you must make a knife from a sharpened metal plate with a hole drilled in the center. A bolt is inserted into this hole and clamped by a nut.

Next, the bolt is clamped in the drill cartridge, and the trimmer for the grass is ready.

Since a drill with this nozzle does not have a protective casing, such a tool is quite dangerous for the user. To protect yourself, you can place the drill, like a corner grinder (this was mentioned above), on the cuttail cuttings or on an aluminum pipe.

Also, to protect the user of the mowing from knives, you can fix the casing on the drill (attached to the plastic pipe and put on the body of the apparatus).

The drill to the bar is attached using clamps.

What knives to put on an electric and a lawn mower

Before taking and putting a knife on a motorcycle, we will find out what they are and in what cases are used. Now manufacturers offer the consumer a huge number of types of these consumables. In general, the entire cutting tool intended for mowing grass can be systematized:

The main material for the production of trimmer knives can be plastic or metal. The introduction of such expenditures in almost everything is depending on 2 characteristics:

Of the judgments of safety precautions, manufacturers do not advise putting iron knives on electronic trimmers for grass for grass. In fact, all motokos operating from the electronic network and battery are equipped with plastic blades. How to put knives on a trimmer for grass (lawn mower). Depending on the manufacturer, they can be a solid disk.shaped design, with several blades or in the form of a special mowing head providing for the installation of removable plastic blades.

Rules for the operation of homemade moped

To extend the operating time of a moped with a motor from a trimmer for grass, its owner needs to adhere to a number of important rules.

- Timely replacement of consumables. if you do not change the air filter and other moped elements for a long time, then its important mechanisms will begin to work under increased load. This will lead to a more complex breakdown of home.made:

- use high.quality gasoline and motor oil for refueling. if you pour unaccumen.quality gasoline into a moped fuel tank, then quickly the bicycle owner is necessary to replace the engine CPG;

- Lubricate the reducer used in time. this will prevent the functioning of the mechanism under high loads;

- Mix gas and oil strictly in the trimmer indicated by the manufacturer for the grass of the proportion. if you pour more oil than this is indicated in the instructions, this will lead to pouring the spark plugs of the engine;

- Regularly check the condition of fasteners. the bolts that are not covered to the end threaten not only the drop in the engine, but also the injury for the owner;

- To paint scratches and chips immediately after their appearance on the frame. this will prevent further corrosion of the skeleton of a moped;

- prevent the engine from overheating from a trimmer for grass. with frequent operation of a moped, you need to take breaks. At the same time, if the bicycle is used in hot weather, then its motor should be allowed to cool every 15 minutes drive. If it is cool and windy on the street, then the number of breaks can be reduced to 1 time for every 25-30 minutes;

- Timely change the rubber on a moped.trimmer of a moped for grass. in winter, rubber with spikes on the wheels of homemade products you need to install homemade wheels. This will prevent the wheel slip and increase safety during the operation of the bicycle.

Also, the owner of a bicycle with a motor from a trimmer for grass will need to monitor the weight of the cargo transported by home. If the baggage is too heavy, then this can lead to overheating and serious engine breakdown, as well as other mechanisms of adaptation.

Design and fastening options

The design of such a device is usually equipped with one or two pairs of cutting parts. They are attached to the trimmer instead of the gearbox in the lower part of the bar or near the device motor. Weeding with a motorcycle is carried out by burning liquid fuel. In order to enhance the strength and reliability of the design, there is a direct reinforced rod in it, the diameter of which is at least 25 mm. The bar is designed for optimal workload.

Based on the type of device, it often provides for setting up the width of the capture of the cutting elements. As a rule, its indicators vary within 13-25 cm. As for the disk nozzles-cultivators for a benzotrimer, their design can be equipped not only with a couple, but also with several discs with blades fixed on them, bent at a certain angle. As a rule, these hinders also have a protective damper that prevents the entrance of the Earth during the operation of the device.

Read also: Adjusting and safety reinforcement

The design of the gear nozzles can also have more than two cutting elements. Curved knives can be located in a row. At the same time, an increase in the number of knives increases the weight of the cultivator nozzle. On average, it weighs about 5 kg.

The transmission of the rotating moment from the gasoline engine to the hitch is carried out by means of a shaft combined in the bar. Such a node is not interchangeable, in addition, it differs in the number of slots available at the end of the bar. There are 7 or 9 of them. This feature is taken into account by choosing a hitch to the existing benzotrimer. The nozzle-cultivator on a motorcycle with an incoming shaft of 9 slits and a rod of 26 mm is attached instead of a lower gearbox.

Schloven methodology for connecting disks allows freedom to move cutting parts. This is convenient specifically for the cultivation of the soil, since it allows loosening the earth with a wide capture for one passage. In this case, there is no need for a large amplitude of the movement of the bar.