How Do You Know When to Replace Circular Saw Blades. Table saw blade change

How Do You Know When to Replace Circular Saw Blades?

Jeffrey Coolidge/Getty Images

Has your circular saw been struggling to cut lately? Here’s how to tell when your saw blade is dull and what you can do if it is.

Circular saws are an essential tool for professional tradesmen and serious DIYers alike. Depending on the blade, you can use a circular saw to cut through wood, metal and even concrete. However, a dull blade can dramatically hinder the quality of your saw cuts. Read on to learn how to tell if your circular saw blade is dull, and what you should do if it is.

What Are the Different Types of Circular Saw Blades?

Although a circular saw can cut through a wide range of material, it can only do so with the right type of blade. There are three primary types of circular saw blades:

- Carbide-tipped. These are the most common type of circular saw blades, consisting of a steel disc with carbide-tipped cutting teeth around the outside edge. These blades are typically used for cutting through wood, but specially designed carbide blades can also cut through light-gauge metal. Carbide-tipped blades usually cost between 20 and 100 and can last from six months to a couple of years. The cost and longevity of carbide-tipped blades largely depend on the tooth count and the material they’re used to cut.

- Steel-tipped. Although somewhat rare today, steel-tipped blades are made entirely of steel and were the most common variety of circular saw blades before carbide-tipped options. Steel-tipped blades are usually cheaper than carbide-tipped, costing between 10 and 30, and are easier to sharpen than carbide-tipped blades. However, they aren’t nearly as durable and only stay sharp for about one-tenth as long as carbide.

- Diamond-edged blades. Diamond blades are made for cutting through masonry materials like concrete, brick and tile. The perimeter of the blade is coated in diamonds, and are usually completely round without cutting teeth. Diamond blades usually cost between 15 and 75. They can last between 12 and 120 hours of continuous use, depending on the quality of the blade and material they’re used to cut.

How Do I Know When a Circular Saw Blade is Dull?

Every circular saw blade wears out over time. There are several tell-tale signs that your blade is dull or is getting there. Signs that a carbide-tipped or steel-tipped blade are getting dull include:

- The blade will cut slower than usual or may completely bind mid-cut;

- The blade will create more tears or chipping than usual;

- The blade will produce burn marks on the wood and may start smoking.

Signs that a diamond-edged blade is getting dull include:

- The blade will glaze over, indicating the metal bond that holds the diamonds on the blade has melted over the diamonds;

- The blade will look smooth, which indicates the diamonds have completely worn away;

- The blade will cut slower than usual or completely bind mid-cut, just like carbide and steel blades.

How to change a circular saw blade for beginner

Ignoring these signs can result in reduced cut quality and permanent damage to the blade.

What Should I Do If My Circular Saw Blade Is Dull?

Depending on the type of blade you’re using, you can clean, sharpen or replace it. often than not, a dull carbide-tipped or steel-tipped blade is just dirty and needs to be cleaned. Simple remove it, soak it in an all-purpose cleaner and brush it clean. If you’re still experiencing symptoms after cleaning and reinstalling the blade, you may want to consider sharpening it.

Steel-tipped blades are the easiest to sharpen, and you can usually do so yourself with a hand file or mechanical blade sharpener.

Carbide-tipped blades are more difficult to sharpen because the teeth need to be ground at specific angles with a diamond wheel, so it’s generally recommended to have them professionally done. A professional sharpening usually costs between 25 and 50 cents per tooth, so you should weigh the cost of having it sharpened against the cost of purchasing a replacement.

Diamond-edged blades that are used on table-mounted miter or tile saws can be easily sharpened and deglazed with a dressing stone, but blades used on handheld circular saws typically need to be replaced.

How to Change a Circular Saw Blade ( Blade Direction)

Learn how to change a circular saw blade! We’ll see which direction to install the blade, how to tighten the blade, what size blade you need and more!

How to Change a Circular Saw Blade

It doesn’t matter if we have a DeWALT, Black and Decker, Ryobi, Skilsaw, Makita, Milwaukee, Bosch or another brand of circular saw at some point we’ll need to change the blade. There are a few reasons we may need to change a circular saw blade. First, the blade may be damaged or dull. Or we may need to cut some metal, but we have a wood cutting blade installed on our circular saw. Whatever the reason today we’ll learn how to change a circular saw blade! You may also enjoy How to Change Blade on Miter Saw and How to Set Table Saw Blade Angle This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information. Before we get into how to change a circular saw blade, be sure to click the subscribe button at the bottom of this page to sign up for my FREE weekly newsletter loaded with helpful hole tricks, space-saving workshop ideas, clever DIY tips and more!

What Size Circular Saw Blade Do I Need?

The measurement used to determine the size of a circular saw blade is the diameter. Diameter is the measurement from side to side through the center of the blade.

Blade Diameter

The diameter or size of the blade we need is usually printed on our saw. We can also find the size printed on the blade in our saw.

We’ll need to measure the blade if the size is not printed on the saw or if the size printed on the blade has been worn off due to use.

First, we’ll remove the circular saw blade from the saw. Next, we’ll measure from side to side through the center of the blade. We’ll use this measurement to buy the proper size blade for our circular saw.

Arbor Diameter

There’s another measurement we’ll need to know before we can buy our new circular saw blade. The hole in the center of the blade needs to fit on the shaft or arbor in our circular saw.

The arbor size should be printed on our saw or saw blade. If it’s not, we’ll need to measure the diameter of the arbor hole.

We can also take our old saw blade to the big box home improvement store or hardware store to ensure our new blade will fit.

RPM

The last thing we need to look at is the RPM or revolutions per minute. We need to be sure that the maximum RPM rating of our new saw blade doesn’t exceed the RPM rating of our circular saw.

How Many Teeth Does a Circular Saw Blade Have?

The number of teeth a circular saw blade has depends on the type of material we need to cut.

Typically saw blades with more teeth cut more slowly but produce cleaner cuts. Blades with fewer teeth cut more quickly but usually produce rough, choppy cuts.

Let’s say we need to cut some studs to build a wall. The studs will be covered with drywall so we aren’t concerned about what our cuts look like. In this case, we may use a 14 tooth saw blade to cut the studs. The blade will make the cuts quickly, but the edges of the cuts will be rough or choppy.

Now let’s say we need to cut some plywood for a cabinet we’re building for our dining room. In this case, we may use an 80 tooth saw blade. This type of blade will reduce splintering, produce cleaner cuts and the edges of the cut will be smoother. This is exactly what we want when we’re building our DIY furniture projects.

Types of Circular Saw Blades

Wood is the material we’ll likely be cutting most often with our circular saw. The common types of cuts we’ll make are rip cuts and crosscuts.

A rip cut is made with the grain of the wood or along the length of the board.

A crosscut is made across the grain of the wood or across the width of the board.

Just like a rip cut is different from a crosscut, there are different saw blades designed specifically to make each of these cuts.

Rip Cut Blade

Rip cut blades have fewer teeth. Usually less than 40. When we sight down the teeth of a rip cut blade we’ll notice the tops of the teeth are flat.

Crosscut Blade

Crosscut blades have more teeth. Usually more than 40. When we sight down the teeth of a crosscut blade we’ll notice the tops of the teeth are “V” shaped or form a valley in the center of the blade.

Combination Blade

Combination saw blades can make both rip cuts and crosscuts.

There are also blades available for cutting metal, plastic, and concrete.

Is Your Circular Saw Blade Dull or Dirty?

Did you know a dirty blade can act like a dull blade? With each cut we make wood pitch collects on our circular saw blades. As the wood pitch builds on the blade it can affect the quality of the cuts which makes us think the blade is dull. Wood pitch can also corrode the blade.

How do we remove wood pitch from our circular saw blade? With a blade and bit cleaner. Cleaning our circular saw blades is simple and an important part of properly maintaining our tools.

Please skate over to How to Clean Saw Blades to see which cleaner I use, the simple procedure I use to clean my saw blades and watch the saw blade cleaning video.

Circular Saw Blade Direction

Almost all circular saw blades have an arrow that is either printed or engraved on the blade. This arrow indicates which way the blade should be installed in the saw. The arrow needs to point towards the front of the circular saw. If we don’t see an arrow the teeth need to face towards the front of the saw.

How to Tighten Circular Saw Blade

Most screws are right-hand thread. This means the screw is turned to the left to loosen and to the right to tighten. You may have heard the phrase “righty-tighty, lefty-loosey”!

Circular saws use a left-hand thread screw to attach the blade. Which is the opposite of “righty-tighty, lefty-loosey”. This means a circular saw blade screw must be turned to the right to loosen and to the left to tighten it.

VIDEO: How to Change Circular Saw Blade

Watch this quick video to see how to change a circular saw blade!

Changing a circular saw blade is one of the simplest tool-maintenance tasks—here’s how to do it in quick order.

We may earn revenue from the products available on this page and participate in affiliate programs.

A staple in workshops and on construction sites, circular saws are one of the more popular portable power tools, prized for their ability to make quick, straight-line cuts. Different types of circular saw blades are available to cut various materials, including plywood, hardwood, metal, and plastic. Like anything with moving parts, a circular saw blade will eventually become dull with repeated use.

For the cleanest cuts, when one blade dulls, it is replaced by a new blade. Fortunately, learning how to install a circular saw blade is one of the simplest tool-maintenance tasks.

Keep reading—we’ll show you how to remove a circular saw blade and how to replace a circular saw blade.

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

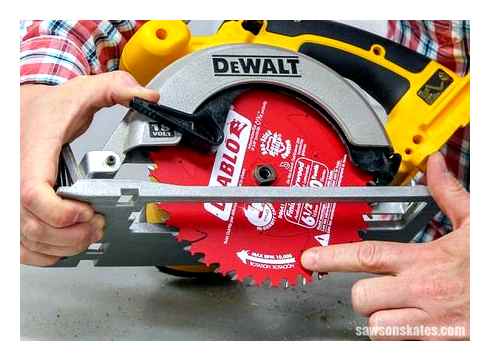

The required tools and supplies list is short for changing a circular saw blade. You’ll need the saw. While blades on all circular saws are replaced in the same manner, we’re demonstrating how to install a blade on a circular saw with the DeWALT 7-¼” circular saw.

BEFORE YOU BEGIN

No special skills or requirements are necessary to change the blade on a circular saw, but it’s helpful to be familiar with how the saw operates.

In addition, the blade tips on both old and new saw blades are sharp. Handle them with care. Wearing a pair of flexible leather gloves, while not required, will protect hands while still allowing the user enough finger dexterity to change the blade easily.

STEP 1: Disconnect the circular saw from its power source.

Safety first. Savvy DIYers know it’s not safe to service any power tool while it’s plugged in. Unplug a corded or pneumatic circular saw from the outlet or hose, and remove the battery from a cordless circular saw. The goal is to disconnect the power source.

STEP 2: Locate the circular saw wrench stored on the tool.

Circular saws come with special wrenches designed for maintaining the tool. This wrench is typically stored in a slot on the saw body and can be removed just by pulling it out.

If the wrench has fallen out or it’s been lost, it’s a good idea to purchase a replacement circular saw wrench. Alternatively, other types of wrenches are likely to fit the bolt on the circular saw, but if the fit isn’t perfect, the tool could slip and damage the bolt.

STEP 3: Depress the spindle-lock button to keep the saw blade from spinning.

Every circular saw has a spindle lock—a button located on the body of the saw that stops the blade from spinning when the button is engaged. If the spindle-lock button isn’t depressed, the blade and bolt will turn when the user tries to remove the bolt holding the old blade in place, making it impossible to loosen the bolt. The sole reason for the spindle-lock button is to lock the blade in place so it’s possible to remove the bolt or put it back on. Press it and hold it down.

STEP 4: Use the circular saw wrench to loosen the bolt that holds the blade in place.

While holding the spindle-lock button down, use the circular saw wrench to loosen and remove the bolt that holds the saw blade in place. Turn the wrench counterclockwise to remove the bolt and set it aside.

In most cases, the bolt is simple to remove with the wrench. However, wood sap residue or even corrosion can make a bolt stick. If the bolt sticks, give it a spritz with a bit of lubricating oil, such as WD-40, and then try again.

STEP 5: Push the blade guard out of the way to remove the old blade.

A circular saw’s blade guard is the protective casing that rotates out of the way when the user begins cutting with the saw. The blade guard rotates back over the blade when the saw is not in use. The guard slides easily back and forth.

Now it’s time to actually remove the old blade, which is now loose. Just push the blade guard out of the way with your hand and pull the old saw blade out of the saw.

STEP 6: Slip the new blade in place and replace the bolt.

Installing the new blade is just as simple as removing the old one—just reverse the steps. Slide the blade guard out of the way, position the new blade on the saw—with the wording facing outward and with the center hole aligned over the spool hole. Put the bolt back on and tighten it with the saw wrench. Once again, hold the spindle-lock button down to tighten the bolt snugly without the blade turning.

Pro Tip: When learning how to put a blade on a circular saw, keep in mind that circular saw blades cut from the bottom upward. The saw blade is labeled as to which direction the tips should face. Some professionals turn saw blades around in order to make specialized cuts, but for the best general use, install the blade in the direction suggested by the manufacturer.

How To: Change a Circular Saw Blade

It may sound simple, but a lot of people can get hung up changing saw blades especially if you don’t do it very often. In this post, I’ll walk you through the basic process of how to change a circular saw blade which is one of the most useful tools any DIYer can use.

When to Replace Your Table Saw Blades!?!

A nice sharp blade can make all the difference in the quality of your work. I would venture to say that many people don’t change their blades nearly often enough which results in poor or difficult to make cuts and also creates more blade kickback than is otherwise necessary. Just check out the video below to see how dangerous kickback is and why keeping a sharp blade is important.

Every saw is a little different, but the basic premise is the same so don’t be thrown off by the little differences.

If you’ve lost yours, you can also use an open-end or socket wrench. Adjustable wrenches can get the job done as well, but a bit harder to work within the limited space.

Unlock and adjust the base plate to the lowest position to allow as much room to work around the blade bolt as possible. Lock the base plate. The base plate adjustment is what determines the depth of cut.

Locate the blade lock button or lever usually found on the backside of the upper guard.

While depressing the button, place the wrench over the bolt and turn the blade with the wrench until you feel the blade lock in place. While you continue to depress the button, use the wrench to loosen the bolt and then unscrew it completely and set aside.

Which Way to Turn?

This is the biggest question most people have because on circular saws the old lefty-loosey, righty-tighty rule doesn’t always apply. The bolt will loosen in the same direction the blade rotates when in use.

Usually, on a corded right-hand circular saw, the bolt will loosen counterclockwise. A left-hand saw will loosen clockwise. You can also look for the arrow on the upper or lower blade guard for the blade rotation. Loosen the bolt in the same direction as the arrow.

What if There is No Blade Lock?

Some older circular saws do not have a blade lock or shaft lock. There are two ways to hold the blade in place while loosening the bolt.

The first is to raise the base plate so that some of the teeth of the blade can be pressed into a piece of wood or work table. While pressing down on the saw and holding it in place, follow the steps above to loosen the bolt.

The second way is to clamp the blade in place with some Vice-grips or other lockable pliers while loosening the bolt.

If you find that the bolt is not loosening, but rather turning the motor while the blade remains secure, give the wrench a tap or a quick snap to break the bolt free.

Remove the outer washer and set it with the bolt.

After the bolt and outer washer have been removed, carefully grab the blade and lift it off the shaft and out through the base plate. You may need to rotate the retractable blade guard for more clearance.

step 3: install the new blade

Before installing the new blade, be sure to inspect and remove any lodged debris from the inside of the upper guard. Also, make sure the inner washer, where the new blade will sit, is clean and free of debris.

When picking the right saw blade refer to my earlier post The Everyman’s Saw Blade Guide to find the right one for your project.

Once you have your new blade, look for the arrow on the new saw blade. This shows which way the blade should rotate when installed. Most saws will have an arrow on one of the guards indicating blade rotation. The blade should be flipped as necessary to match up the arrows so they are rotating in the same direction.

In this case, I’m installing the same old blade since this is just for demonstration purposes.

Retract the lower blade guard and insert the blade up through the base plate. Place the blade onto the shaft and make sure it is snug against the inner washer.

Slide the washer onto the shaft. Turn the washer until it drops in place snug against the blade.

Insert and tighten the blade bolt until it is finger tight. Lock the blade by depressing the blade lock button. Use the wrench to tighten the bolt the rest of the way, about 1/8th of a turn. Do not over tighten.

step 4: Check the Blade and Get to Work

Plug in the circular saw or insert the battery.

While the base plate is still lowered, and the saw held up off of a work surface, pull the trigger, and observe the blade spin. The saw should feel smooth and the blade should not wobble.

Next, use a piece of scrap wood and do a test cut to check that the blade cuts through smoothly, as expected.

If the saw stops cutting and the shaft spins in the blade, remove the saw from the material, unplug and tighten the bolt more. Adjust as necessary until the saw is moving smoothly and consistently through the material.

That’s it! You’re ready to get back to business now that you know how to change a circular saw blade.

When And How To Change Your Circular Saw Blade

Changing your circular saw blade once in a while is very important because they don’t stay sharp forever. They get dull after some use, and dull blades are a pain in the behind.

Whatever type of saw you’re using, whether it’s a circular saw, a compound miter saw or even a table saw, it’s only as good as its blade.

With a bad or dull blade, you’ll find it very difficult to use it to work. Using it will become hard and painstaking, even though every other part is as good as new.

Apart from that, dull blades don’t produce clean accurate cuts, they produce rough inaccurate cuts. So, it’s very important to sharpen your blades or change them entirely if you want to make clean accurate cuts for your projects.

When to change it

Note: This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

There’re several reasons why you might need to change your circular saw blade.

The first one is when the blade is dull. If the blade is dull, it will become difficult to cut through through the wood.

The side of the blade will start to burn through the wood instead of cut through it easily. When you notice this, then you know you need to change the blade.

Another reason why you might want to change your circular saw blade is when you’re working on different materials and you’re using different blades.

Circular saws can be used to cut different types of materials. You just have to change the blade to the specific blade that matches that material.

A blade meant for cutting wood will not be good for cutting granite.

So, if you don’t have two different circular saws for the two materials, then you have to switch the blades each time you want to cut another material.

Additionally, even if you’re not cutting different materials, you might also need to change blades depending on the type of cut you want to make.

There are different blades for rough cuts, finish cuts, cross cuts and even rip cuts. So, if you have only one circular saw, then you might need to change the blades depending on the type of cut you’re trying to make.

Step 1: Unplug the power cord or remove the battery

This is a very important step for obvious reasons. You don’t want the saw accidentally starting when you have your hands there trying to swap the blades.

Do this before any other thing. If you have a corded model, unplug it from the power outlet. If you have a cordless one, remove the batteries.

This is very important. Don’t skip this step.

Step 2: Make sure you have the right replacement blade

A 10 inche blade circular saw needs a 10 inche blade and a 7-1/4 inche blade unit should have a 7-1/4 inch blade.

Don’t try to be Smart and try to fit a 10 inch blade into a 7-1/4 inch circular saw or vise versa. Use the appropriate type and size of blade.

Step 3: Secure the blade guard and arbor

Every circular saw comes with a blade guard that covers the blade. You need to place your saw on a solid surface and pull back the blade guard to expose the blade.

Next, engage the arbor lock if your circular saw came with one. If yours don’t have an arbor lock, press the blade against a wooden surface to secure it in place.

Step 3: Loosen the arbor nut from it

The next step is to loosen the arbor nut using the wrench that came with your saw. On a direct drive circular saw, you need to rotate the wrench in a counter-clockwise direction to loosen the nut and rotate clockwise for a worm drive unit.

Slide the blade out once you’ve loosened the nut.

Step 4: Replace the worn out blade with your new blade

Once the old dull blade is off, you can slide in the new blade into the arbor, slut in the nut and tighten it. Take note not to over tighten the arbor nut, as the nut tends to tighten even further as you make cuts with it.

So, there’s little risk of under tightening the nut. Just tighten it firmly, and you’ve successfully replaced your circular saw blade.

Step 5: Test it

Once the new blade is in place, replace the battery or plug the cord into your power outlet and give it a test run to make sure everything is secure and running properly.

If it is, then you’ve changed your circular saw blade successfully.

Conclusion

Depending on the type, quality or brand of circular saw you’re using, there may be a slight difference on how you change the blade.

But in general, the process remains the same. Also make sure to consult the manual that comes with it for the exact steps to change the blade.

If you’re still having doubts, you can also consult the manufacturer for further instructions or take it to a nearby service center.