How To Check The Ignition Coil Of Lawn Mowers

How to check the ignition coil on Tilleri?

Most often, this important element of the tiller ignition is checked using a known working test sample. If during testing it turned out that with the installation of the sample everything began to work as it should, then the standard tiller ignition coil is faulty.

However, not everyone has a test sample at hand. If it is not there, then you need to try to check the built-in coil in other ways. Before that, you need to exclude any breakdowns that may appear in the start button and high-voltage wiring. In addition, the user should carefully study the wiring diagrams. In which the location of the elements of the ignition system is indicated.

Further verification methods include:

- Measuring the resistance of the built-in ignition coil. It should be noted that it is not always used by users of agricultural machinery. First, the operator must know the exact parameters of the resistance created by the standard coil. Secondly, in addition to the inductance coil, semiconductor components are provided in the design of the ignition system, which are required to generate the required electrical impulse. Problems with all These elements can only be detected when they are heated. To properly check the ignition coil, you will need to disconnect the cap and the standard armor wire from it. Knowing about the exact resistance parameters of the built-in element, the operator will be able to understand which part of the system is faulty;

- Checking the generated spark using a special device. it must be connected to the place where the electrical circuit breaks between the high-voltage wires of the standard coil and the candle;

- Testing the coil with the built-in spark plug. to do this, unscrew the built-in spark plug and carefully attach it to the cylinder with the body. Then you need to pull the starter handle and pay attention to the spark that forms between the factory contacts of the plug. It should be noted that this method of checking the existing coil is Approximate. in this case the spark plug is NOT under load, due to which there is no compression in the internal combustion engine cylinder. As a result, the standard engine flywheel will rotate faster.

Each of THESE methods provides rough information on the condition of the ignition coil. It must be remembered that you can find the exact cause of the malfunction of a part with the introduction of specialized testers, which are only in specialized workshops.

How to set the ignition on a tiller?

In the need for an urgent adjustment of the gap in the ignition system, the following signs will prompt:

- The need for frequent unsuccessful pulling of the cord;

- Delayed reaction of the tiller engine to manipulations with the starter;

- Complete lack of starting the internal combustion engine of the agricultural unit.

Each of THESE faults indicates that the operator must install the ignition of the tiller used in the household. The correct procedure for this can be found in the operating instructions for the existing equipment. However, the operator’s manual is not always at hand. In this case, the gap between the built-in ignition module and the flywheel can be set in the following sequence:

- First, the operator must close the candle with a special square;

- Then its body will need to be pressed against the head of the standard internal combustion engine cylinder;

- Next, the candle must be turned in the direction opposite to the hole provided in the end of the chrome-plated cylinder;

- After that, it is necessary to carefully return the crankshaft of the tiller’s internal combustion engine. for this it is enough to pull the trigger cord;

- As a result of the actions performed, a bright blue spark should slip between the built-in electrodes. If this does not happen, then it is necessary to check the distance between the magneto and the tiller’s starter. it should be from 0.1 to 0.15 mm. If these requirements do not meet these requirements, the gap between the elements will need to be adjusted.

Many experienced users adjust the ignition of a household tiller by ear. For this, both contact and non-contact magneto are suitable. To configure the system yourself, you must:

- Start the engine and slightly loosen the standard distributor;

- Slowly return the breaker to each of the possible directions;

- Achieve maximum speed of the factory engine and quickly secure the structure;

- Listen and find the moment at which a spark instantly appears;

- Turning the breaker, wait for a clear clicking sound;

- Fix the standard distributor fasteners.

In some cases, a stroboscope will help to correctly adjust the available gap.

To configure you need:

- Warm up the power unit of the tiller;

- Connect the device to the power supply network of the agricultural unit;

- Install the sound sensor on the high-voltage conductor connected to one of the cylinders of the standard internal combustion engine;

- Carefully remove the vacuum tube and plug it with any available means;

- See where the light from the stroboscope will be directed. it should “look” towards the regular pulley;

- Start the engine and leave it to idle;

- Scroll the distributor;

- Once the marks on the built-in pulley match the mark located on the cover of the device being used, return the factory breaker nut to the end.

Each of THESE methods is suitable for adjusting both gasoline and diesel tiller. The main thing in the self-tuning process is not to remove the coil and other elements of the ignition system. this can lead to a malfunction of the entire unit.

Tiller ignition device

The ignition system belongs to the list of the most important components of both a branded and a homemade tiller. Its main function is to generate a spark, which is needed for ignition and gradual combustion of fuel in the chrome-plated cylinder of the internal combustion engine.

The simplicity of the factory assembly of the unit allows you to carry out your own repair of the tiller ignition. Yakiy, most often, consists in setting a gap between its elements. However, to do this correctly, you need to study the construction of the node.

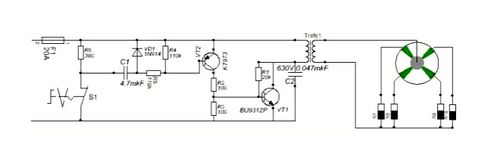

The ignition device of any agricultural agricultural unit includes a coil, which is initially connected to the electrical power supply of the system, as well as magneto and candles. During the start of the tiller’s power unit, voltage is applied, as a result of which a pronounced spark is formed between the magnetic “shoe” and the standard candle. It is necessary for the instantaneous ignition of the fuel, which at this moment is in the combustion chamber of the engine. details about the structure of the ignition system of the used tiller will tell the photo.

The tiller’s electronic ignition system is also often equipped with breakers, which are automatically triggered when any of the unit malfunctions occurs. This leads to an emergency shutdown of electrical power in the network.

Ignition Tilers

Ignition is the mechanism responsible for generating the electrical impulse required by the tiller to ignite the fuel being refueled. The first start and subsequent operation of the agricultural unit engine depends on the health of the ignition system. Like the rest, this mechanism needs regular maintenance and timely repair. this will be the key to stable operation of the internal combustion engine under all weather and operating conditions.

What to do if there is no spark on tillery?

If, after the tests carried out, it turned out that the spark was missing. Then the cause of this breakdown must be sought in the main elements of the ignition system of the agricultural unit.

This will require:

- Inspect the candle. it must be turned out using a special key;

- The spark plug may be completely dry. this indicates that the fuel does not enter the engine cylinder, that is, the fuel pipes are clogged or the carburetor is malfunctioning;

- In some cases, the part is wet with gasoline and engine oil. The reasons for this lie in an overabundance of lubricant contained in the fuel, or in its seepage from the engine oil sump directly into the cylinder. In this case, the operator must remove the plug and dry it thoroughly. After that, you need to dry the cylinder, several times intensively pull the starter cable on the engine with the spark plug turned out;

- Less often, due to the lack of correct and timely maintenance of agricultural machinery, a thick continuous layer of carbon deposits and dried resinous deposits forms on the tiller candle. To restore a candle, you need to carefully heat it with a lighter and rinse off the resin residues with clean gasoline. After that, the part will need to be dried and screwed into place. If this does not help, then the candle needs to be replaced.

It is important to be extremely careful when removing, cleaning and reinstalling the spark plug. Any careless movement can damage the electrodes of the part, due to which it will no longer be able to generate a spark.

Magneto for a tiller. testing at home

Magneto on a tiller is a structurally complex element, which is in constant contact with high-voltage wiring and interacts with electricity. Due to the operation of the tiller in damp weather, accidental shock and interruptions in the supply of electrical power, this part gradually fails. It is quite simple to check it for serviceability, but the operator will have to act at his own peril and risk, since the only way to test a part in the field will be very dangerous for the entire ignition system.

To check the tyler’s magneto, you will need:

- On the candle screwed into its regular place, carefully dismantle the cap and insert a small nail instead. The latter must be clean with no signs of corrosion;

- The nail should be installed at a distance of 7 mm from the cylinder wall of the standard cylinder of the tiller’s power unit;

- Start the engine of the agricultural unit;

- Check for spark when starting the engine. It should be bright blue and clearly visible. If it is not, then the magneto is out of order.

If the magneto breaks down, it will need to be replaced. You can do it yourself. Removing the faulty one and installing a new part.

Causes of malfunctions

There are several reasons due to which the ignition coil completely or partially fails. Among them:

- Mechanical damage. This can be trivial aging, due to which insulation breaks down. There is also the possibility of oil leaking through the seals, which gets on the insulation or coil body and destroys them. Repair in this case is hardly possible, so the best option would be a complete replacement of the unit.

- Damaged contact connection. In warm weather, a prerequisite for this may be the ingress of moisture into the engine compartment. For example, during heavy rain, driving through deep puddles, car wash. In winter, it is likely that the composition will hit the coil, which is sprinkled on the road surface to combat icing.

- Overheat. Individual coils are often subject to it. Overheating can significantly reduce the life of the ignition coils. The overheating process is difficult to control, but try to use high-quality coolant and make sure that the engine cooling system works normally.

- Vibration. They are especially detrimental to individual ignition coils. Vibration usually comes from the cylinder head (cylinder head). To reduce the number and amplitude of vibrations, make sure that the engine runs in normal mode (without detonation and with serviceable pillows).

Ignition coils are fairly reliable and durable units, and their failure is most often associated with aging and / or insulation breakdown. Next, consider the methods for diagnosing coils.

How to check the ignition coil

The ignition coil is designed to generate high voltage, which is then used by the spark plug. Therefore, its proper operation is necessary for the normal functioning of the ignition system. In fact, the coil is a small transformer, to the primary winding of which comes standard 12 V from the battery, and a voltage of several kV comes out. It is used in all ignition systems. contact, contactless and electronic. The reasons for coil failure are typical. As a rule, this is a wire break, insulation damage, mechanical deformation. Next, we will consider the symptoms of a malfunction and methods for diagnosing the ignition coil.

The principle of operation of the ignition coil

As mentioned above, the ignition coil is a step-up voltage transformer that converts the resulting 12 V voltage into a voltage with a value of several kilovolts. Structurally, the coil consists of two windings. primary and secondary (respectively, low and high voltage). However, depending on the type of coil, the windings and their locations differ.

Let’s start with the simplest common coil. Here on the primary winding there are 100 150 turns. The winding is wound with insulated copper wire. Its ends are brought out to the coil body. The number of turns of the high voltage winding is 30-50 thousand (depending on the model). Naturally, the wire used here is of much smaller diameter. The “minus” of the secondary winding is connected to the “minus” of the primary. And “plus” is connected to the terminal on the cover. This ensures that the resulting high voltage is removed.

To increase the magnetic field, the windings are wound around a metal core. In some cases, to avoid overheating, the winding and core are filled with transformer oil (it not only cools the system, but also acts as an insulator).

Now let’s move on to considering the individual ignition coil. There are also two windings here, but the difference lies in their location. In particular, they are wound in reverse order. The primary winding is of an internal type and the secondary is of an external type.

Individual ignition coils are installed in electronic ignition systems. Therefore, their design is complicated. So, a diode is provided for cutting off a significant current in the secondary winding. Also, a feature of the individual coil is the fact that the resulting high voltage does not go to the distributor (as in classic systems), but directly to the spark plugs. This was made possible by a design that included an insulated body, rod and spring.

Another type of coil is two-lead. It supplies voltage to two cylinders at once. There are several varieties of them. As a rule, such coils are combined into one common unit, which is essentially a four-lead ignition coil.

Regardless of the type of ignition coil, their main technical parameter, which should be guided by when diagnosing, is the resistance of the windings. In particular, the resistance of the primary winding is usually in the range of 0.5. 3.5 ohms, and the secondary. 6. 15 kohms (these values may differ in different coils, so it is better to find reference information for the exact model that is used in your car). Measurements are made using traditional instruments. multimeters or ohmmeters. If the value obtained is very different from the specified, then there is a high probability that the coil is out of order.

You also need to be aware of the fact that each coil has different indicators:

- Resistance of windings;

- Spark duration;

- Spark energy;

- Spark current;

- Primary inductance.

Therefore, in order to understand how the coil readings correspond to the norm, it is necessary to clarify the technical characteristics of your individual coil. This is especially useful for you if the spark is missing, since the ignition coil is one of the first elements of the system, which must be checked.

Trouble symptoms

There are several characteristic signs of a faulty ignition coil. Among them:

- The motor begins to “triple”, and this problem is exacerbated over time;

- In the cold, the motor “troit”, Until it heats up;

- Interruptions in engine operation in wet weather;

- With a sharp press on the accelerator pedal, a failure in the engine is observed.

If the coil is faulty on cars with an ECU, the Check Engine icon is activated on the dashboard. However, these symptoms may also indicate other malfunctions, in particular, with spark plugs. But when at least one of them appears, you need to diagnose the ignition coil (s).

How to check the ignition coil

There are two main ways by which you can independently check the performance of the ignition coil. Let’s list them in order.

The principle of operation of the ignition coil

As mentioned above, the ignition coil is a step-up voltage transformer that converts the resulting 12 V voltage into a voltage with a value of several kilovolts. Structurally, the coil consists of two windings. primary and secondary (respectively, low and high voltage). However, depending on the type of coil, the windings and their locations differ.

Let’s start with the simplest common coil. Here on the primary winding there are 100 150 turns. The winding is wound with insulated copper wire. Its ends are brought out to the coil body. The number of turns of the high voltage winding is 30-50 thousand (depending on the model). Naturally, the wire used here is of much smaller diameter. The “minus” of the secondary winding is connected to the “minus” of the primary. And “plus” is connected to the terminal on the cover. This ensures that the resulting high voltage is removed.

To increase the magnetic field, the windings are wound around a metal core. In some cases, to avoid overheating, the winding and core are filled with transformer oil (it not only cools the system, but also acts as an insulator).

Now let’s move on to considering the individual ignition coil. There are also two windings here, but the difference lies in their location. In particular, they are wound in reverse order. The primary winding is of an internal type and the secondary is of an external type.

Individual ignition coils are installed in electronic ignition systems. Therefore, their design is complicated. So, a diode is provided for cutting off a significant current in the secondary winding. Also, a feature of the individual coil is the fact that the resulting high voltage does not go to the distributor (as in classic systems), but directly to the spark plugs. This was made possible by a design that included an insulated body, rod and spring.

Another type of coil is two-lead. It supplies voltage to two cylinders at once. There are several varieties of them. As a rule, such coils are combined into one common unit, which is essentially a four-lead ignition coil.

Regardless of the type of ignition coil, their main technical parameter, which should be guided by when diagnosing, is the resistance of the windings. In particular, the resistance of the primary winding is usually in the range of 0.5. 3.5 ohms, and the secondary. 6. 15 kohms (these values may differ in different coils, so it is better to find reference information for the exact model that is used in your car). Measurements are made using traditional instruments. multimeters or ohmmeters. If the value obtained is very different from the specified, then there is a high probability that the coil is out of order.

You also need to be aware of the fact that each coil has different indicators:

- Resistance of windings;

- Spark duration;

- Spark energy;

- Spark current;

- Primary inductance.

Therefore, in order to understand how the coil readings correspond to the norm, it is necessary to clarify the technical characteristics of your individual coil. This is especially useful for you if the spark is missing, since the ignition coil is one of the first elements of the system, which must be checked.

Causes of malfunctions

There are several reasons due to which the ignition coil completely or partially fails. Among them:

- Mechanical damage. This can be trivial aging, due to which insulation breaks down. There is also the possibility of oil leaking through the seals, which gets on the insulation or coil body and destroys them. Repair in this case is hardly possible, so the best option would be a complete replacement of the unit.

- Damaged contact connection. In warm weather, a prerequisite for this may be the ingress of moisture into the engine compartment. For example, during heavy rain, driving through deep puddles, car wash. In winter, it is likely that the composition will hit the coil, which is sprinkled on the road surface to combat icing.

- Overheat. Individual coils are often subject to it. Overheating can significantly reduce the life of the ignition coils. The overheating process is difficult to control, but try to use high-quality coolant and make sure that the engine cooling system works normally.

- Vibration. They are especially detrimental to individual ignition coils. Vibration usually comes from the cylinder head (cylinder head). To reduce the number and amplitude of vibrations, make sure that the engine runs in normal mode (without detonation and with serviceable pillows).

Ignition coils are fairly reliable and durable units, and their failure is most often associated with aging and / or insulation breakdown. Next, consider the methods for diagnosing coils.

Trouble symptoms

There are several characteristic signs of a faulty ignition coil. Among them:

- The motor begins to “triple”, and this problem is exacerbated over time;

- In the cold, the motor “troit”, Until it heats up;

- Interruptions in engine operation in wet weather;

- With a sharp press on the accelerator pedal, a failure in the engine is observed.

If the coil is faulty on cars with an ECU, the Check Engine icon is activated on the dashboard. However, these symptoms may also indicate other malfunctions, in particular, with spark plugs. But when at least one of them appears, you need to diagnose the ignition coil (s).

How to check the ignition coil

The ignition coil is designed to generate high voltage, which is then used by the spark plug. Therefore, its proper operation is necessary for the normal functioning of the ignition system. In fact, the coil is a small transformer, to the primary winding of which comes standard 12 V from the battery, and a voltage of several kV comes out. It is used in all ignition systems. contact, contactless and electronic. The reasons for coil failure are typical. As a rule, this is a wire break, insulation damage, mechanical deformation. Next, we will consider the symptoms of a malfunction and methods for diagnosing the ignition coil.

How to check the ignition coil

There are two main ways by which you can independently check the performance of the ignition coil. Let’s list them in order.

Functional check

Before starting to diagnose magneto, you need to make sure that the problem is actually in this node. To do this, you need to check the entire chain and make sure that there are no other reasons for the breakage of the trimmer.

- First, you should carefully inspect the coil for cracks and other external defects on the case. Next, you need to study all the elements and nodes that conduct current, and make sure that they are clean.

- The next step is to inspect the high voltage wires. They must be in good working order and securely attached to the contacts, free from rust and with intact insulation.

- The next step is to check the spark plug cap. As a result of careless actions of users, he often tears it off the high-voltage wire, and then improvises and creates a homemade mount. You need to understand that any poor-quality connection in this place significantly reduces the power of the electric arc of the candle.

- Then you should make sure that the candle itself is working properly. Filling the mower with poor quality gasoline will significantly reduce the life of this part. In addition, it can be flooded or have a large carbon deposit that interferes with operation. Sometimes the candle even sticks and does NOT unscrew.

- Next, you need to inspect the circuit breaker. On trimmers and chainsaws made in China, it often breaks.

After completing all these steps and excluding the listed nodes from the list of possible causes of failure, you should proceed to check the coil. This can be done in several ways.

Method 2

Diagnostics of magneto by means of a multimeter is a solution that can be realized on our own with such a measuring device. In this case, you must do the following.

- Switch on the resistance mode on the measuring device and set the value to 200 Ohm to test the primary winding.

- Connect the multimeter electrodes to the magneto ground and the output contact. If the winding is intact, the resistance will vary from 0.4 to 2 ohms.

- Switch on a 20 kΩ tester to perform a secondary diagnosis. In this case, the first probe is connected to the “mass”, and the second is installed in the spark plug cap. Normal values are at least 4-6 com. If the circuit is damaged, then the tester will show infinity, and in case of short circuit. zero.

The exact data on what the tester should read when checking the primary and secondary winding can be found in the instructions for use of the trimmer.

Method 1

The first method, by which the ignition coil is checked, involves the use of special equipment (stand). At home, it is not available. you can find it only in service centers.

Typical problems. causes

The faults most often occurring with magneto, typical for trimmers from different manufacturers. As a rule, this is a weak spark or its absence, as well as the presence of interruptions in this process.

Trimmer ignition coil. faults and repairs

lawn mowers are a popular seasonal tool designed to remove unwanted vegetation from house areas. Like any other technique, these devices break down periodically. Repairing the trimmer ignition coil is one of the popular problems common to gasoline braids. The ignition system itself is designed in the same way on two- and four-stroke internal combustion engines, so the elimination of breakdowns is performed almost the same for tools from different manufacturers, be it Lux, Huter, Husqvarna or another brand. Ways to restore the working capacity of the ignition coil or replace it with a new one. in the material below.

Unstable sparking

If the spark is intermittent with the magneto, you must first check the contacts. They could be burnt or oily. The carbon deposits found are cleaned with a file, and the oil is wiped off with suede, previously soaked in gasoline. The second possible cause of the problem is the adjustment of the gap between the contacts. To eliminate it, you need to set the correct distance.

If the spark appears intermittently, it could also mean that the breaker arm pad is wearing. To eliminate the malfunction, you must change the lever to a new one. In addition, the clearance should be adjusted, as with another possible cause of breakdown. misalignment of the outline.

Capacitor breakdowns can also be the culprit for interruptions in spark formation. In such a situation, replacement of the damaged part is required, since it is impossible to repair and recharge it.

Do-it-yourself troubleshooting

In order to repair the magneto with your own hands without involving specialists, you need to know how to disassemble it, and how to change the breaker contacts to new ones.

No sparking

If the Spark does NOT give out magneto at all, the main reason is an open circuit in one of the transformer circuits (primary or secondary). The defective part must be replaced to fix the mower. If the primary circuit is shorted to ground, it can also cause no spark. You need to fix it to fix the problem.

Magneto. design and operating principle

The purpose of the ignition coil is to convert the rotational energy into a high-voltage discharge and form a spark that ignites the fuel mixture. In an internal combustion engine, this part is called a magneto, since in it an alternating current is generated from the rotation of a permanent magnetic rotor or armature.

Magneto structurally consists of two windings: high and low voltage. A capacitor with breaker contacts is connected in parallel to the latter. Whereas the leads of the high voltage winding are connected to the candle and the body. Both of them are wound on a core, between the poles of which a rotating magnet is installed, magnetized longitudinally.

Useful Tips

First of all, the ignition coil has a limited resource, which often does not exceed the mark of 80-100 thousand km. However, failures can start earlier. It is for this reason that you need to know how to check the ignition, as well as timely diagnose (both planned and in case of the slightest signs of malfunction).

It is also important to consider that a number of factors affect coil life, from the general condition of the high voltage wires and spark plugs to moisture, oil and dirt entering the engine compartment. For this reason, it is necessary to prevent heavy contamination or water ingress during engine wash. It is also important to make sure that the coil is properly fastened, since vibrations with insufficient fastening destroy the element.

Ignition coil faults: signs and symptoms

So, a faulty ignition coil often manifests itself as obvious failures in the operation of the ignition system itself. As a rule, symptoms can be distinguished in the form of a weak spark (low-power discharge) or a complete absence of the sparking process on candles. Even if the engine starts, the engine does not run smoothly, the mixture in the cylinders burns out defective, power is lost, etc.

For example, in the case when the insulation is damaged, the spark discharge will pierce. In a situation where the ignition coil breaks through, it will go to the steel elements located next to or on the “mass”. In any case, there will be no spark on the spark plug electrode.

Of course, the signs of a malfunctioning ignition coil in such a situation are quite obvious:

- There will be ignition interruptions in the cylinder;

- The engine will not start well;

- Idling will float;

- During acceleration, a jerk may appear;

- Pops in the exhaust system, fires in the exhaust pipe;

- If the coil is completely defective, the motor will not start;

- With a faulty individual coil, the internal combustion engine will work, but will start to triple.

How the coil works

If we consider the general principle of operation of the ignition heater and its device, the high-voltage pulse-boosting converter has a primary rotation and a secondary.

The primary winding with a few turns of thick wire is designed for low voltage. The second winding of the iron has many more turns from the thin wire. Due to the electro-magnetic induction on the secondary winding, it is possible to create a high voltage at the output.

Further, through the high-voltage wires, the voltage is transmitted to the interrupter-distributor (distributor) in the car with battery ignition. As for the models with a diesel or electronic ignition, in this case, the voltage is supplied to the ignition control unit, after which it is supplied to the spark plugs.

By the way, when starting the engine with a dead battery, you should carefully close such a resistor (you can use a screwdriver or wire). This will allow the engine to start easier and faster.

- You can also highlight the fact that there are several types of “fiery”, although the device of “fiery” ignition is often not very different. The first type is the general atyša, which generates a high-voltage voltage. Installed before the distributor-distributor or electronic ignition control unit.

The second type is an individual ĸatyshu, which works on only one cylinder. Such a solution is placed in front of the spark plugs and is considered more reliable due to the fact that if one coil fails, the engine will still be able to work. We also note that on different cars the ignition engines have different characteristics, which depends on the type of vehicle, the class of the car, the power of the internal combustion engine, etc.

Checking the ignition coil: what you need to know

The ignition coil is a voltage converter that converts low voltage in the vehicle electrical system into high voltage. In short, the voltage in the car’s on-board network does NOT exceed 12V for passenger cars, 24V for trucks, while for normal operation of the ignition system, a voltage of at least 20,000 volts or more is required.

Of course, during operation, various elements of the ignition system may fail. At the same time, spark plugs on many cars are generally considered consumables, high-voltage wires may also require frequent replacement, and in some cases, malfunctions of the ignition coil itself occur.

Causes of malfunctions and how to check ignition coils

As for verification, in order to find the causes, it is necessary to know the general structure and principle of the coil. Immediately, we note that in the conditions of the garage itself, you can only check the coils on the car with battery ignition. In turn, an accurate check of the ignition coils on more modern cars, as well as individual ignition coils on each cylinder, is carried out on specialized equipment.

As can be seen from the device of the transformer itself, the reasons for the malfunction of the “worse” ignition can be different. Also, the most suitable diagnostic method will depend on the device and the type of the coil itself (for example, methods of how to check the ignition coil of a VAZ carburetor may differ slightly from a similar test of the coils on an injection car).

During a visual inspection, it is possible to reveal a break in the low-voltage wire, as well as gaps in the supply line, etc. It is also possible to diagnose a breakdown of the distributor, breaks of explosive wires and other problems.

As for injection cars, Please note that ignition malfunctions may also occur due to malfunctions of the position sensor of the crank shaft (DPKV). In systems with electronic ignition, in some cases, the module itself fails. For this reason, you need to know how to check the ignition module if necessary.

Naturally, there can be a lot of all kinds of cases in which a malfunction of the ignition coil occurs. At the same time, in practice, the best solution for diagnostics with your own hands in a garage environment is to check with a multimeter. In other words, you need to know how to test the coil of a multimeter. Let’s figure it out.

- So, if the visual inspection did not give anything, and the coil is also tested for Spark, at the initial stage you should figure out how to remove the ignition coil from the car. For THESE purposes, you may need to study the manual for the operation and maintenance of the car.

After removing the coil, you need to put the multimeter in the resistance measurement mode, that is, the meter. After you need to measure the resistance of the ignition coil, pre-cleaned the contacts, since corrosion and dirt interfere with Getting accurate data.

I put the probes of the device on both contacts, the multimeter is set to the 20 ohm position. Depending on the type of coil and car model, the indicator can range from 0.4 to 2 ohms. The main thing is that the resistance is always the same.

We also add that the coil is also checked using the so-called discharge, which imitates the operation of the ignition system, but such equipment is often only available at the service station. Also another way to ring the coil is to use an oscilloscope. At the same time, it is impractical to purchase this equipment for personal use.

Let’s sum up

As you can see, the ignition coil is simple in terms of design, but the most important element of the ignition system. The specified coil is used both on simple carburetor engines and on injection engines. In case of malfunctions and malfunctions in the ignition, this coil needs special attention. In some cases, the skills and knowledge of how to check the ignition coil with a multimeter can quickly localize the malfunction.

Causes of malfunctions and how to check ignition coils

As for verification, in order to find the causes, it is necessary to know the general structure and principle of the coil. Immediately, we note that in the conditions of the garage itself, you can only check the coils on the car with battery ignition. In turn, an accurate check of the ignition coils on more modern cars, as well as individual ignition coils on each cylinder, is carried out on specialized equipment.

As can be seen from the device of the transformer itself, the reasons for the malfunction of the “worse” ignition can be different. Also, the most suitable diagnostic method will depend on the device and the type of the coil itself (for example, methods of how to check the ignition coil of a VAZ carburetor may differ slightly from a similar test of the coils on an injection car).

During a visual inspection, it is possible to reveal a break in the low-voltage wire, as well as gaps in the supply line, etc. It is also possible to diagnose a breakdown of the distributor, breaks of explosive wires and other problems.

As for injection cars, Please note that ignition malfunctions may also occur due to malfunctions of the position sensor of the crank shaft (DPKV). In systems with electronic ignition, in some cases, the module itself fails. For this reason, you need to know how to check the ignition module if necessary.

Naturally, there can be a lot of all kinds of cases in which a malfunction of the ignition coil occurs. At the same time, in practice, the best solution for diagnostics with your own hands in a garage environment is to check with a multimeter. In other words, you need to know how to test the coil of a multimeter. Let’s figure it out.

- So, if the visual inspection did not give anything, and the coil is also tested for Spark, at the initial stage you should figure out how to remove the ignition coil from the car. For THESE purposes, you may need to study the manual for the operation and maintenance of the car.

After removing the coil, you need to put the multimeter in the resistance measurement mode, that is, the meter. After you need to measure the resistance of the ignition coil, pre-cleaned the contacts, since corrosion and dirt interfere with Getting accurate data.

I put the probes of the device on both contacts, the multimeter is set to the 20 ohm position. Depending on the type of coil and car model, the indicator can range from 0.4 to 2 ohms. The main thing is that the resistance is always the same.

We also add that the coil is also checked using the so-called discharge, which imitates the operation of the ignition system, but such equipment is often only available at the service station. Also another way to ring the coil is to use an oscilloscope. At the same time, it is impractical to purchase this equipment for personal use.

Checking the ignition coil: what you need to know

The ignition coil is a voltage converter that converts low voltage in the vehicle electrical system into high voltage. In short, the voltage in the car’s on-board network does NOT exceed 12V for passenger cars, 24V for trucks, while for normal operation of the ignition system, a voltage of at least 20,000 volts or more is required.

Of course, during operation, various elements of the ignition system may fail. At the same time, spark plugs on many cars are generally considered consumables, high-voltage wires may also require frequent replacement, and in some cases, malfunctions of the ignition coil itself occur.

How the coil works

If we consider the general principle of operation of the ignition heater and its device, the high-voltage pulse-boosting converter has a primary rotation and a secondary.

The primary winding with a few turns of thick wire is designed for low voltage. The second winding of the iron has many more turns from the thin wire. Due to the electro-magnetic induction on the secondary winding, it is possible to create a high voltage at the output.

Further, through the high-voltage wires, the voltage is transmitted to the interrupter-distributor (distributor) in the car with battery ignition. As for the models with a diesel or electronic ignition, in this case, the voltage is supplied to the ignition control unit, after which it is supplied to the spark plugs.

By the way, when starting the engine with a dead battery, you should carefully close such a resistor (you can use a screwdriver or wire). This will allow the engine to start easier and faster.

- You can also highlight the fact that there are several types of “fiery”, although the device of “fiery” ignition is often not very different. The first type is the general atyša, which generates a high-voltage voltage. Installed before the distributor-distributor or electronic ignition control unit.

The second type is an individual ĸatyshu, which works on only one cylinder. Such a solution is placed in front of the spark plugs and is considered more reliable due to the fact that if one coil fails, the engine will still be able to work. We also note that on different cars the ignition engines have different characteristics, which depends on the type of vehicle, the class of the car, the power of the internal combustion engine, etc.

Ignition coil faults: signs and symptoms

So, a faulty ignition coil often manifests itself as obvious failures in the operation of the ignition system itself. As a rule, symptoms can be distinguished in the form of a weak spark (low-power discharge) or a complete absence of the sparking process on candles. Even if the engine starts, the engine does not run smoothly, the mixture in the cylinders burns out defective, power is lost, etc.

For example, in the case when the insulation is damaged, the spark discharge will pierce. In a situation where the ignition coil breaks through, it will go to the steel elements located next to or on the “mass”. In any case, there will be no spark on the spark plug electrode.

Of course, the signs of a malfunctioning ignition coil in such a situation are quite obvious:

- There will be ignition interruptions in the cylinder;

- The engine will not start well;

- Idling will float;

- During acceleration, a jerk may appear;

- Pops in the exhaust system, fires in the exhaust pipe;

- If the coil is completely defective, the motor will not start;

- With a faulty individual coil, the internal combustion engine will work, but will start to triple.

Useful Tips

First of all, the ignition coil has a limited resource, which often does not exceed the mark of 80-100 thousand km. However, failures can start earlier. It is for this reason that you need to know how to check the ignition, as well as timely diagnose (both planned and in case of the slightest signs of malfunction).

It is also important to consider that a number of factors affect coil life, from the general condition of the high voltage wires and spark plugs to moisture, oil and dirt entering the engine compartment. For this reason, it is necessary to prevent heavy contamination or water ingress during engine wash. It is also important to make sure that the coil is properly fastened, since vibrations with insufficient fastening destroy the element.

Let’s sum up

As you can see, the ignition coil is simple in terms of design, but the most important element of the ignition system. The specified coil is used both on simple carburetor engines and on injection engines. In case of malfunctions and malfunctions in the ignition, this coil needs special attention. In some cases, the skills and knowledge of how to check the ignition coil with a multimeter can quickly localize the malfunction.