How to Clean a Clogged Fuel Line. Gas line lawn mower

How to Start a Push OR Riding Mower After It Runs Out of Gas

Let’s face it, you were just having way too much fun listening to your favorite podcast with your headphones to notice that your lawn mower was running out of fuel, weren’t you? After coming to a complete stop, you add more fuel.

Except now, your lawn mower won’t start. It’s trying to turn over if it’s a rider, and you can tell its trying to work when you pull the cord on a push mower, but it just won’t fire up.

Go ahead and set aside the frustration because we’re going to get you back in business in a few minutes.

Generally, both a push lawn mower and a riding lawn mower will fail to start after having run out of gas if either the fuel being added is stale or if there is air or debris trapped in the fuel lines. Stale fuel will not combust and air in the fuel lines will not allow gas to flow to the carburetor.

Air Trapped in Fuel LinesTo remove stale fuel, pump out the fuel tank with a battery pump, disconnect the fuel line at the carburetor and blow out the tank with an air compressor or by mouth. Be sure to drain the carburetor bowl as well.

Push Mower Won’t Start After Running Out of Gas

When I’ve serviced push mowers over the last 7 years, I have found that stale fuel is a major culprit for an engine failing to run — especially if it was just running a few minutes prior and needed a refill after having run out of gas.

Gasoline is generally pretty clear but turns to a Mountain Dew color as it oxidizes and loses its combustible properties.

It’s an honest mistake to use up the last bit of gas in a gas can mow the lawn, run out of gas, and reach for another gas can where you’re not quite sure when you last filled it.

Was it this year? A few months ago? Two years ago?!

Regular E10 gasoline will start to degrade in as little as a month without a fuel stabilizer and you’ll likely see a significant performance decrease after 3 months.

Ethanol free gasoline (marine gas) will start to degrade after 3 months or so and you’ll probably see significant performance loss after 4-6 months.

To prevent this from ever happening again, buy yourself a bottle of SeaFoam (Amazon). You simply add 1 fluid ounce per gallon in your gas cans, screw on the nozzle, shake the gas for a second, and then it will last for 2 years without a problem. I have personally tested this and the two year claim on the bottle is accurate.

1 fluid ounce of SeaFoam is all you need to keep your gasoline good for up to 2 years! No need to worry about your lawn mower not starting up the next time you pour gas into it.

If you think you’ve added stale fuel to your tank, simply disconnect the fuel line from the carburetor and let the stale fuel drain into a jar or container. Contact your local hazardous waste materials agency and find out how to best dispose of it. If the fuel is less than a year old, you should easily be able to add a quart or so to your car on a full gas tank to dilute it an use it up.

Don’t forget to drain the small amount of stale fuel in the carburetor bowl as well.

In the last 7 years though, I haven’t had one push mower that wouldn’t start because of air or debris in the fuel lines. I’m not saying that it can’t happen, but the fuel line from the tank to the carburetor is so short and so direct that not much can go wrong.

Still, it is possible and worth checking if you know that your engine was just running, it ran out of gas, and the new fuel is not stale.

To do this, pinch off the fuel line between the tank and the carburetor. Then remove the fuel line from the carburetor. Before working on the carburetor, be sure to pinch off the fuel line from the gas tank (right) to the carburetor (left). A pair of these needle nose vice grips work great!

Release the pinch for just a second to see if gas flows out of the hose. If it does, then pinch it off again.

With the hose pinched off, drain the gas (if there is any) from the carburetor bowl from the drain screw (if yours has one). If yours doesn’t, like mine, go ahead and remove the bottom bolt to remove the bowl. Clean any debris from the bottom of the bowl.

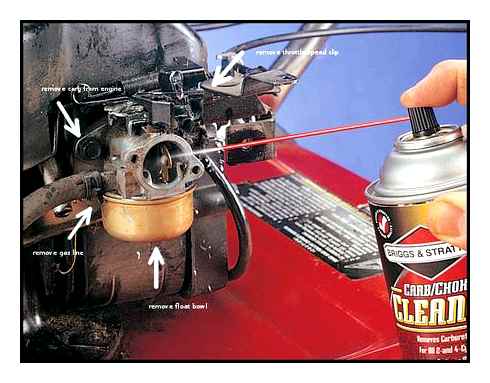

If you have a lawn mower that has a carburetor that looks like the picture above (Snapper), then the next two steps are optional. But since we already have the bowl off, it’s a good practice.

First take a can of carburetor spray cleaner with the small red straw that comes with it and squirt a few shots into the main tube that runs up the carburetor (see the picture) to clear out any possible debris. It’ll be a tight squeeze and you’ll have to bend the straw a little bit. The main jet might be up there, or it may be the actual bolt that holds the bowl onto the carburetor (see the second picture).

Squirting carburetor cleaner into the emulsion tube The main jet for this push mower is actually the bolt that holds the bowl onto the carburetor itself. Make sure the hole that runs through the side of it is clear, and then make sure the hole at the top of the bolt is clear as well.

Secondly, since the fuel line is disconnected from the carburetor, go ahead and squirt a few shots of carburetor cleaner in to the connection point of the carburetor where the fuel line hooked up (fuel inlet). The fuel should spray out the bottom of the carburetor if the float is dropped down (which it should be with the bowl removed).

Some carburetors have a small screen in there between the float needle seat and where you connect the fuel line. If the screen got caked with debris that was floating around at the bottom of your tank and made its way down the line with the last of the gas on your first tank, then this will keep gas from entering the carburetor.

If that’s the case, you’ll have to remove the air filter assembly and the carburetor. You’ll then need to remove the float and squirt carb cleaner back through the float needle seat and blow the debris out of the fuel inlet.

Some fuel inlets can be removed with vice grips by pulling and twisting to access the dirty screen as well.

Now, back to what we were doing as far as checking gas flow.

With the gas line still pinched and the bowl of the carburetor still off, go ahead and reconnect the fuel line to the carburetor. Release the pinch for a moment and see if gas starts flooding out of where the carburetor bowl should be.

If it does, that you know that you have fuel that is flowing properly and this isn’t your problem.

Again, I haven’t seen this be the issue before. In theory it’s possible, but I find that stale gas is the leading cause of a push mower failing to start after it has been refueled.

Riding Mower Won’t Start After Running Out of Gas

Riding mowers, on the other hand, have more of a chance from my experience of not starting due to air in the lines if you just rain out of gas and refueled.

The gas tank is often located in the back and there are several feet of hose that winds down to the engine. It’s much easier to get an air blocking things.

Again though, make sure that you don’t have stale fuel added to the tank. If you do, either pump it out or disconnect the fuel line from the inline fuel filter and drain it out into the original gas can that had the stale fuel to begin with. Dispose of properly.

To prevent this from ever happening again, buy yourself a bottle of SeaFoam (Amazon). You simply add 1 fluid ounce per gallon in your gas cans, screw on the nozzle, shake the gas for a second, and then it will last for 2 years without a problem. I have personally tested this and the two year claim on the bottle is accurate.

If you know the fuel is good, we’re going to go ahead and try to remove the trapped air in the fuel line.

Most of these lawn tractors (at least all of them that I’ve worked on) are not gravity fed from the tank to the carburetor. There is a fuel pickup tube that sticks down from the top of the fuel tank to near the bottom, and fuel is sucked up through that tube and down to the carburetor via a vacuum fuel pump that is attached to the engine.

If we get too much air in the line, the process won’t work. It’s just like driving a hand-pump well down into the ground and expecting to get water when you start cycling the handle. Nothing is going to happen.

A little air will work its way out, but big gaps of air — like when you ran the tank completely empty and the hose started sucking air — will result in an engine that won’t start.

The first is if you don’t have an air compressor.

Make sure to wear safety glasses.

With the gas cap removed, place your mouth up against the gas tank (make a seal with your face and the tank) and slowly but forcefully blow into the tank. Obviously, do not breath in through your mouth!

Blowing air gently, but forcefully into the gas tank will push air through the fuel lines. The air you breath into the tank will expand the tank and build up pressure. This will displace gasoline in the tank which will be sucked up through the pickup tube and sent down the lines towards the carburetor. Air in the lines will work its way down to the carburetor and be expelled. I am breaking my rule just for the photo op and not wearing safety glasses. My apologies.

A friendly reminder is to slowly reduce your air pressure going into the tank before you back your face away. If you blow really hard and pull your face back, you’re likely going to get splashed in the face with some gas.

This will push any stubborn air bubbles down the line to where they can eventually vent out through the carburetor.

Do this process until you see a decent amount of fuel in the fuel filter (assuming it’s clear) and then try starting the mower again.

If you’re not seeing any fuel make it to the filter, you can always disconnect the fuel line from the fuel filter and try blowing into the tank again. If no fuel comes out of the hose, then it’s likely clogged from debris.

You can try snaking a relatively flexible wire in the fuel line to see if you can loosen the blockage and try blowing into the tank again.

The second method is to use an air compressor. You don’t want the PSI to be too much when doing this. Probably 20psi or so will be fine and we’ll only be using short 1-2 second bursts.

You can either use this in place of your mouth on the gas tank by placing your hand over the gas tank fill hole and then pushing the air compressor nozzle between your thumb and index finger. Go ahead and give it a few short bursts with a few seconds in between. Using the air compressor to blow a few short bursts into the tank to force gasoline down the fuel line and work out the air that is trapped.

You’re essentially filling the gas tank with excess air, it expands, and as it tries to return to its normal volume the air will displace the liquid and force the liquid gas up the pickup tube and down to the carburetor.

You can also do this process from the opposite end of the lawn tractor. Go ahead and make sure the gas cap is securely on the tank and then remove the fuel line from the fuel pump on the engine. Go ahead and do the same thing where you squirt air into the fuel line for a second or so.

Vacuum Fuel Pump on a lawn tractor (riding mower). If you do this method, make sure to blow air into the right hose. There are 3 hoses that attach to the fuel pump. Do NOT use the short one that runs to the engine itself. Do NOT use the one that runs to the carburetor. Use the one that traces back to the fuel tank!

This will drive air s back into the gas tank, and as the tank expands and pressurizes, it will displace the liquid gas and force it up the pickup tube and down to your end of the hose.

It might take a few short bursts, but once gas starts flowing out go ahead and immediately hook it back up to the fuel pump and try to start the mower.

Robert lives in central Michigan and enjoys running, woodworking, and fixing up small engines.

Recent Posts

Power outages are an inevitable part of life, often occurring during severe weather conditions or due to technical issues with the electricity supply. During these times, it’s essential to know how.

Power outages can be a major inconvenience, especially if you rely on well water for your household needs. The question of whether you can still use your well water during a power outage depends on.

About Me

Hi! I’m Robert and this blog started with my journey of learning about battery banks, generators, and power outage preparations. I’ve been an avid hobbyist in these fields for over 7 years and I enjoy sharing what I’ve learned in a way that’s geared for beginners and those just getting their foot in the door with small engine repair and prepping. I’ve been doing maintenance and handyman work for the last several years and I’ll be including little home and garage tips and tricks that I learn along the way as well. Thanks for stopping by!

Legal Information Disclaimer

This site is owned and operated by Robert Van Nuck. Home Battery Bank is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Home Battery Bank also participates in advertising through Google AdSense and Ezoic. Home Battery Bank is compensated for referring traffic and business to these companies. The advice given on this website is for informational purposes only. Working with electricity can be deadly if you are not careful. Please consult a certified electrician if there is anything you are uncomfortable with.

How to Clean a Clogged Fuel Line

If your lawn mower is sputtering as if your engine is running out of gas even though there is plenty of gas in the fuel tank, then the issue could be as simple as a clogged fuel line. The fuel lines transport gasoline from the fuel tank through the fuel system and into the carburetor. It doesn’t take much to block a fuel line and prevent this process from happening. So if you’re having difficulty with fuel delivery to your lawn mowers engine, then cleaning your fuel line might be the solution you need.

Disclosure: This article may contain affiliate links, meaning I may get a small commission if you make a purchase through links on this site at no additional cost to you. Click here to find out more.

How to Clean a Clogged Lawn Mower Fuel Line

To clean the fuel line on your lawn mower, you first need to remove the gas from the fuel tank and then remove the fuel lines. Now, you can clear any blockage in the fuel line and reinstall the fuel line onto your lawn mower. The cleaned fuel line should now easily transport fuel into your mower’s engine.

Symptoms of a Clogged Fuel Line

The first thing you will notice if you have a clogged fuel line on your lawn mower is that the engine will struggle. Here are four common symptoms you might encounter if you have a clogged fuel line on your lawn mower:

- Problem starting your lawn mower’s engine

- Inability to increase engine RMPs

- The engine sputters during operation

- Your lawn mower engine will stall

How to DEEP clean fuel lines

Do Fuel Lines Need to be Cleaned?

Cleaning the fuel line does not need to be part of your mower’s routine maintenance. If your lawn mower receives good clean fuel and no debris gets into your fuel tank, then there should be no need to clean your fuel lines. Fuel lines only usually need to be cleaned when debris, such as grass clippings, works its way into the fuel tank and the fuel lines. Nine times out of ten, the clog is caused by debris getting into the tank and blocking the fuel line. However, if you leave unprotected fuel in your lawn mower for more than 30 days, then a fuel gum can form, potentially restricting fuel flow through the lines. If you’re worried about bad gas in your engine, check out my article on how to test for bad gasoline.

How Do I Know if My Fuel Line is Clogged? (6 Steps)

If you suspect your fuel line is clogged, you’ll need to do a visual inspection. My preferred method is to remove the line completely and check for blockages visually.

Here are the 6 steps to inspect a fuel line for blockages:

- Turn off the fuel cut-off valve on the bottom of your lawn mower’s fuel tank. If you do not have a fuel cut-off valve, you will need to remove the fuel from the tank first. Check out my guide on how to drain fuel from a lawn mower.

- Using a pair of pliers, compress the spring clips located at each end of the fuel line and move the spring clip 1-2 inches down the pipe.

- Twist and pull the fuel line off of the fuel tank.

- Twist and pull the other end of the fuel line to remove it from your lawn mower.

- With the fuel line removed from the lawn mower, hold the pipe straight and up to the light. If the fuel line is clear, you should be able to see straight through. If there is only partial or no light, the fuel line is clogged.

- Repeat the process for all the fuel lines on your lawn mower.

How to Clean a Clogged Fuel Line (The Method I Use)

To clean the blockage out of your clogged fuel line, you either need to blow or push the blockage clear. One of the easiest methods is to use a thin straw cleaner that is small enough to fit inside the fuel line. Then, simply insert the straw clearer into the fuel line and push the blockage free. Once you remove the blockage, you can use the straw cleaner to clean out any small particles that could work their way to the carburetor.

Alternatively, you can use an air compressor with an air gun attachment to blow the blockage free. While this method works to clear the blockage, it won’t clean the inside of the fuel line. But it will blast out any small particles. In an ideal world, you would use both methods.

Once you have cleaned the blockage, you can reinstall the fuel line back onto your lawn mower, reposition the spring clips, refill the fuel tank, or open the fuel cut-off valve.

What You’ll Need to Inspect Clean a Clogged Fuel Line

Before reinstalling the fuel line, you will want to inspect for cracks or splits. Fuel lines tend to break down over time and become brittle, resulting in small cracks that eventually turn into a split fuel line.

So, if you notice anything unusual, I suggest you replace the fuel lines on your lawn mower and avoid any unwanted fuel leaks. Here’s my guide on how to replace a lawn mower fuel line.

How to Clean a Lawnmower Fuel Line?

When your lawnmower does not start, it can be a real mood destroyer. Similar to when the mower starts but stops running after a few minutes. There could be many possible reasons behind these problems. A a faulty spark plug, no gas or bad gas, oil-related problems, a carburetor issue, a defective starter, or a dirty and clogged fuel line. In this blog post, we will explain what to do when the fuel line is the cause of the problem. In gas mowers, the fuel line connects the gas tank with the carburetor. A dirty or clogged fuel line means a disruption in the fuel supply and problems with starting or running. The fuel line is one of the most critical fuel system components and works together with the fuel filter. This blog post will show you how to clean the fuel line and the components connected to it. Most of the work is fairly simple and does not take a lot of time.

How to clean the fuel line of your gas mower:

Locate the fuel valve and turn it off. If there is not fuel valve, empty the fuel tank. Empty the fuel line after disconnecting it from the carburetor. Use a flashlight to check for holes, dirt, and debris in the fuel line. Use a fuel cleaner to clean the dirty fuel line. If that does not help you have to replace the fuel line. Check the filters and vents for any dirt and debris and clean if needed.

This blog post will show you how to clean the individual components of a gas mower’s fuel system in more detail.

Small Engine Fuel system:

The engines of most gas mowers can be regarded as small engines. Most small engines have similar fuel systems, only the location of the components will differ from type to type. The job of a fuel system is to store fuel and deliver it to the carburetor. The carburetor prepares the fuel-air mixture, also called power charge, to the combustion chamber, where the mixture is compressed and combusted to produce power.

It is quite common for small engines’ fuel systems to become dirty and clogged after extended use. When the fuel system becomes clogged, the carburetor’s supply is disrupted, and the carburetor fails to prepare the right fuel-air mixture. When the fuel-air mixture with wrong ratios is fed to the combustion chamber, its combustion is improper and incomplete. This results in less power. Therefore, a small engine with a faulty fuel system will fail to run smoothly and efficiently. A defective fuel system can also cause other problems, such as not starting.

The most common fuel system components of a small engine include the fuel tank, fuel pump, fuel valve, fuel line, fuel filter, air cleaner, carburetor, and governor. The fuel system should be checked, serviced and cleaned regularly.

Before starting with any fix, ensure that the mower is turned off. Disconnect the spark plug cables to make sure that the engine can not start unintentionally. Use safety goggles to protect your eyes. In general, cleaning the fuel line is not a big job for users that are familiar with the fuel system. If you are less familiar, it is good to learn more about the fuel system first. This helps to find the location of the various components and how they are connected. Often you can find detailed information in the manufacturer’s manual.

Fuel Line:

A fuel line is a hose responsible for the supply of fuel from the tank to the carburetor. Fuel lines of small engines are usually made of synthetic rubbers such as neoprene. Fuel lines can become dirty and clogged over time, and when this happens, they must be either cleaned or replaced.

Fuel line servicing:

To service a fuel line, the first step should be to turn off the fuel valve. If your lawnmower does not have a fuel valve, empty the gas tank. If your lawnmower has a fuel valve, it is often located near the gas tank base, at the location where the fuel line is attached to the fuel tank body.

Once this is done, disconnect the carburetor’s fuel line from the carburetor. Empty the fuel line and inspect it for hairline cracks or damage on its surface. If the fuel line is cracked or damaged, there is no point in trying to repair it. It would be best if you replaced it with a new one.

Use a flashlight to inspect the fuel line for any accumulation of dirt and debris in it. Dirt and debris can reach the fuel line because of dirty fuel or a dirty fuel tank. You can remove dirt from the fuel line by blowing air through it or using a thin wire to push it out. If you use a thin wire to clean the fuel line, be careful because it is easy to rupture it.

Gas sitting in the tank for an extended period of more than a month or longer can produce a sticky gum-like substance that can clog the fuel line and the carburetor. You can use a fuel cleaner to remove the substance. We will provide details on using a fuel system cleaner in a later section in this blog post.

For your fuel system’s health, never let gas sit in the tank when your store the mower. Remove it before storing your mower, or use a fuel stabilizer.

Fuel Filter:

The fuel filters clean the gas before it goes to the carburetor. There are different types of fuel filters, depending on the brand and model. Some lawnmowers use a fuel filter at the bottom of the fuel tank, while others use a fuel filter that is present somewhere along the fuel line’s length. Some lawnmowers even use disposable in-line fuel filters that are made of folded paper.

Just like a dirty fuel line, a dirty fuel filter can also disrupt fuel flow. Cleaning fuel filters is usually not very easy, and the best approach is to replace them.

-Fuel filter located at the fuel tank bottom:

The first step to clean a fuel filter located at the bottom of a fuel tank is to close the fuel valve. Then take off the sediment bowl by loosening and removing its retainer nut. Empty the sediment bowl and clean it. Then clean the filter screen.

Once cleaned, fill the sediment bowl with fresh fuel and install it back, tightening the bowl retainer’s lock nut.

-In-line fuel filter:

An in-line fuel filter usually cannot be cleaned and must be replaced for undisrupted fuel flow. To replace an in-line fuel filter, shut off the fuel valve, or clamp the fuel line to block flow. With this done, remove the fuel filter from the fuel line, and install the new one. The new in-line fuel filter should exactly match the one being replaced. Once the new filter is installed, turn on the fuel valve, or unclamp the fuel line.

Fuel Tank:

A clean fuel tank is crucial for an unclogged fuel system. A fuel tank may be pressurized or unpressurized depending on whether the mower has an onboard fuel tank or a fuel pump, respectively.

Gas tank servicing:

To service your gas tank, the first thing to do is ensure that there is no vapor lock. The fuel tank’s gas cap has a small hole in it to escape hot gases and entry of fresh air. If this hole gets clogged, it will result in a situation that causes a vapor lock. Vapor lock can prevent gas flow from the tank to the fuel line and cause the fuel to flow back from the carburetor into the fuel line. So, take off the gas cap and check if its hole is dirty. If it is dirty, clean it.

The next step is to drain the gas out of the tank. You can do this by disconnecting the carburetor’s fuel line and allowing gas to drain through it into a bottle or a pan. Once the tank is empty, use a flashlight to examine its bottom surface for a buildup of sediments and debris. Clean the tank thoroughly with soap and a slim brush and allow it to dry before refilling it.

How to Clean Dirty Fuel Lines / EASY

If the gas tank is cracked, it must be replaced.

Using a Fuel System Cleaner:

Gas sitting in the tank for a prolonged time can cause a gummy buildup at various locations in the fuel system. Depending on the gas type, this can already start from a month. The best way to remove this gummy material is by using a fuel system cleaner. Make sure you use a cleaner suited to your lawnmower. In this regard, consult the manufacturer.

Using a fuel cleaner is to fill up the tank with a gallon of fresh fuel and add two tablespoons of cleaner to it. Start your mower normally, and run it with a normal throttle. Use the mower until the added gallon of fuel is used. Then fill your tank with fresh gas for later usage.

We recommend adding a fuel system cleaner to your mower’s gas tank once every 30 to 60 days to keep the fuel system clean.

Final Remarks:

A small engine’s fuel system is an essential part of your gas lawnmower. A clean fuel system is necessary to deliver an undisrupted supply of fuel to the combustion chamber. Keeping the fuel system clean and clear requires regular maintenance, which is not too difficult and can easily be performed by the user. In addition to regular maintenance, using a fuel system cleaner can also ensure a clean fuel system.

Water in Gas Lawn Mower: How to Get it Out?

Home » Water in Gas Lawn Mower: How to Get it Out?

To start working regularly, your gas lawn mower needs three essential elements, air, spark, and fuel. If you clean the filter periodically or replace it when needed, air won’t be a problem since it is always available. As for the spark, it is never a problem if you take care of the spark plug.

The third element can be a huge problem if you have missed maintaining components for proper gas distribution. Actually, if your mower doesn’t work at all after you haven’t used it for a longer time, you should check the gas tank first. Perhaps the cause of the problem is water in it.

Why Water Occurs in Your Gas Lawn Mower

It is not rare that you have a problem with water in your gas lawn mower after heavy rains. The other possibility is that stored gas has picked up water throughout winter, especially if stored in a metal canister or in a location where it alternately warmed up during the day and got cold overnight.

That process usually leads to making a partial vacuum which pulls moist air into a fuel tank where it may condense and settle to the bottom. When you try to use your mower in spring, the first thing which will get into the tank is water.

Contamination of your mower’s fuel system by water may cause severe performance problems. Long-term damage of the unit can include corrosion in the tank, carburetor, and fuel lines.

How to Know if Water is in Your Gas Lawn Mower

Before you start getting panic and do anything, check the basic symptoms to become sure that water has got into the gas tank of your lawn mower. Knowing what to inspect may help you save your machine.

Hard starting

Since water is denser than gas, you may expect it to sink to the fuel tank’s bottom. The problem appears because your mower, as most of the models, probably draws gas from the bottom. Therefore, when you try to start the engine, water will be drawn into the carburetor before fuel and almost immediately cause the problem with starting.

If you haven’t use your mower throughout the whole season, there will be no enough fuel to go to the carburetor when you try to start the engine. The more water is at the bottom of the tank, you will face the bigger problem.

Poor performance

When the amount of water in the fuel system is not significant, you can start your engine without disturbing, but it is likely that surges won’t accelerate appropriately while increasing the throttle.

In some cases, it is possible that the engine dies under load over time. The only cure is to disassembly your mower and to dry all water which has accumulated on the bottom of the carburetor and fuel tank.

Running and stopping

In the case when there is just a small amount of water on the bottom of the fuel tank, you will be able to start the engine in the beginning. Since enough fuel come to the spark plug, the engine will start running smoothly.

However, the problem will appear when the engine keeps working as a result of the subsequent water uptake in the fuel supply. Then your mower may suddenly stop running. Sometimes it will be possible starting it again, but the same thing may repeat.

Fuel system damage

Always keep in mind that you usually may not spot the most significant damage before it is too late. If you notice any performance issues caused by collected water in the fuel system, check your engine as soon as possible.

It is the only way to see the engine’s structural and possible operational problems caused by water and prevent consequential damages such as corrosion or rust on time.

What to Do First?

When you decide to use your mower for the first time after the long, cold winter, you may face a few problems. If your mower begins to sputter all of a sudden or you notice smoke from the engine, you can be sure that the fuel in the engine is contaminated with some amount of water. Let’s see what to do in such situations.

Check the tank

Your first thought should be to check the gas tank. Since water sinks to the bottom, you need to use a flashlight to spot it. The best way is to bring your mower indoors and examine the lowest parts of the tank. If there is water inside, you will quickly notice visible, bubble-like globules of liquid in the gasoline.

Drain contaminated fuel

No matter what the cause, when water comes into the device, the crucial thing is to dry it out. So, you don’t have time to lose, and you need to react immediately.

Firstly, you should empty the gasoline tank. After disconnecting the fuel line, removing the diluted gasoline, and its depositing at a recycling station, try to dry the tank by using a small rag, compressed air, or spraying it with WD-40. Then, you should just reconnect the fuel line and to refill the tank with fresh gasoline.

Service the engine contaminated with water

If you have concluded that there is water in the tank and carburetor of your mower, you need to clean them. Don’t forget to remove the spark plug before you start working. Then, remove the carburetor, clean it, check the level of moisture in the combustion chamber, and add some engine oil to the piston chamber to coat its walls.

After cleaning and drying all parts of the engine thoroughly, you can add clean, fresh gasoline and engine oil and start your mower. Don’t worry if you missed some moisture parts. After running the engine, it will become warm and less humid spots will dry.

However, if you don’t have any experience with engine repair, maybe it is a wise decision to ask for professional help.

Summary

No matter if you have a reel mower, self-propelled lawn mower or electric cordless lawn mower, you need to protect them appropriately during winter. It is even more important to protect your gas lawn mower and its engine in which condensed water can quickly mix with fuel.

The only way to avoid every inconvenience is to store your mower in a protected place during winter. If it is not possible, buy a plastic cover and keep your machine safe.