How to Cut Plywood with a Table Saw? Step By Step. Plywood cutting table saw

How to Cut Plywood with a Table Saw? Step By Step

Plywood is pretty handy. This can be used for many purposes. From tables to partition boards to interior design, you can use plywood in almost every situation.

Getting the perfect piece for a certain use is pretty tough.

Cutting down plywood to a perfect shape is a bit complicated.

However, using table saws is one of the best methods of cutting plywood.

So, how to Cutting Plywood with a Table Saw?

You just have to choose the right blade, support the entire sheet and cut with the good face up.

But people often start cutting without knowing the process in detail. As a result, they sometimes ruin the whole sheet.

Don’t fret. We’re here to help you out. We have prepared a 6-step guide here to help you out.

So, let’s get going with the details- How to Cut Plywood with a Table Saw

Step 1: Choose your Blade

Most stock blades will give you rough cuts and good luck getting a clean edge from those. So, loosen up your a bit and get a high tooth count blade such as 80TPI plywood blade.

Step 2: Raise your table saw blade

If you raise your blade, then its teeth will change direction while entering the wood.

If your blade is in a lower position, then the blade teeth enter the cutting area at a specific angle. As you raise the blade higher, you’ll start getting perpendicular cut. As a result, you’ll get a smoother surface.

Don’t raise your blade all the way up. Keep it within 1 inch above the plywood. Raised blades can cause danger. So, while using a raised blade you should be extremely cautious.

Step 3: Start Using a Zero-clearance insert

A lot of table saws have a gap between the blade and throat plate. The throat plate is where the blade sits in the table saw. A zero clearance insert closes this gap.

As a result, your sheet gets support and you get smoother cuts.

There are two ways to get a ‘zero clearance insert’.

The first way is to buy one online or at the local hardware store.

So, here are the steps of making a ‘Zero clearance insert’-

- Carefully put a piece of plywood onto the table saw. At this step be careful not to slip away the piece. Also, don’t let the blade pull away from this piece from your hand.

- Clamp the insert down once the blade goes all the way through. At this stage, the blade needs to be quite high.

- As the insert sets up, you can now cut on the insert. As a result, the bottom layer of your plywood now won’t chip down.

It’s suggested to make the insert only when a large amount of plywood needs cutting. However, to make safe cuts make sure that your plywood is straight and supported on the other side.

Step 4: Build Support for the Entire Sheet

Handling big plywood sheets are sometimes problematic.

Check constantly while cutting those on a table saw. Because these sheets tend to chip downwards and create an angled cut.

over, without the support, you might not be able to maintain a steady feed rate. This feed rate is the speed or running wood through the saw.

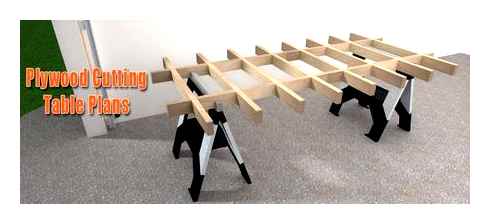

So, stabilize your sheet on sawhorses or ask someone to help you hold it steady. You can also use a circular saw to break the sheet down to manageable pieces.

Step 5: Tape off the Cut Mark

Take a painter’s tape or any low adhesion tape on both faces of the plywood. This will prevent the sheet edges from splitting. over, this will keep wood fibers from splintering.

You can peel the tape off slowly once you’re done with the cutting.

Step 6: Start Cutting

It’s preferred that while cutting you put the good face up of your plywood sheet. This is recommended because in this process the saw will enter the sheet from the top and exit from the underside of the sheet. And all of the tear outs and splintering happens where the saw comes out.

Now, it’s time for the cutting. While cutting with a table saw you have to do two things continuously. These are-

Your hands must be well coordinated in this step or else, you’ll have to make peace with an uneven cut.

So, let’s got through the cutting process-

- Press the sheet forward using your closest hand to the blade. Press the sheet towards cutline by using your other hand.

- As the end of the cut approaches, get your two hands on two sides of the blade.

- Finish off the cut carefully in this position.

Now, you have successfully cut your plywood sheet. Repeat the same method to cut again.

Safety Measures

Using table saws can be pretty dangerous too. Though modern tables saws have finger safety methods still you should be prepared. Here are some safety measures-

Bottom Line

At first, using table saw might be difficult for you. But with the time you’ll be able to control more. One day you might even find out a hack of your own.

Now you know details step how to cut plywood with a table saw properly. If need read again to confirm every step you understand to Cutting Plywood with a Table Saw. Now your turn

Don’t ever forget to keep the safety measures in mind.

How to Prevent Tearout and Splintering When Cutting Plywood, Once and For All

Plywood is awesome. It’s affordable, easy to work, and, when used properly, looks great. Plywood is especially great for a beginner DIY-er who wants to try a few different projects but doesn’t want to spend the money on anything high-risk.

Plywood also brings its share of headaches, specifically, tearout: the rough, jagged edges that result from cutting through the thin veneers. It’s frustrating, and it looks absolutely terrible. Any woodworker who’s ever used it can speak its woes, which can ruin an otherwise high-quality project. That alone can leave a bad taste in a beginner DIY-er’s mouth and here at ManMade we want to give you the tools to keep doing it yourself.

So, my friend, it doesn’t have to be this way. Whether you’re building a simple shop project or a full fleet of custom kitchen cabinets, you, too, can virtually eliminate tearout.

What is tearout?

Tearout happens when you cut across the grain. Here, the fibers aren’t supported by those next to them, so, when they take an impact, they naturally flex themselves. This gets them out of the way, taking your nice clean edge with them.

So, to get rid of tearout, we need to adjust two things in that equation: how well the fibers are supported, or, how intense the impact to the fibers are. We’ll do both in the steps below.

First things first: Choose the right blade. Choose the right face.

Naturally, you’ll want to select a fine tooth blade that works well to cut plywood. These tend to have more teeth per inch, as well a higher bevel angle that can slice through the wood. For a circular saw, you can easily pick up a plywood blade for 20 at any home center, and it will work magic on your cuts. On the table saw, you might not need an expensive specialty blade, though they can help. Just make sure you’re using a high-quality combination blade with at least forty tooth blade.

Secondly, you want to cut the wood so that blade enters the wood on the show face. For a circle saw, this means placing the good side down, and on a table saw, the good side up.

Always use a zero-clearance insert.

No matter what tool you’re using, the best way to reduce tear-out is to surround the blade or bit with a zero-clearance surface. This is equally important on the Band saw, drill press, miter saw, or table saw. A zero-clearance insert creates the smallest amount of open area around the blade to support the wood fibers surrounding the cut as much as possible. Hopefully, you’ve dealt with this in your shop, but if you’re still using the stock throat plate, it’s time to make or purchase an upgrade.

Score the cut line first.

Tearout looks so shaggy because the top and bottom veneer get snapped off in unpredictable ways when they take an impact. So, one way to prevent the rough edges is to intentionally cut the fibers where you can control them. They’re going to snap somewhere, so you might as well tell them where to do so.

You can cut across the grain with a straight edge and sharp blade, or if your cut is close enough to an edge, a marking gauge makes quick work of this step. You can even cut your parts oversized, score, then go back and make your final cut to size.

Since you can only score one side of the kerf, make sure you set up your cut so that the “good” side sits at the intended side of the blade.

Support the wood fibers around the cut with tape.

Since tearout occurs when the fibers get pushed in all directions, you can help these stay in place by placing painter’s tape over the cut line.

I’ve had a lot of success with this method on simple shop projects, jigs, etc, so it’s worth the extra couple of seconds and the cost of the tape whenever you’re crosscutting plywood. I keep a roll of blue tape on my table saw cart so I never have to decide whether it’s worth it or not.

Make Two Passes on the Table Saw

Whenever you’re making furniture-quality cuts, or perhaps you’re working with melamine or some large panels, tackle the cut in a two-step process. Many cabinet shops even have table saws with two blades, one for scoring and one for through-cutting. This does the exact same thing, but you just take a full pass for each cut.

To make the initial scoring cut across the bottom of the wood, set your blade about 1/16″ above the table, and make a complete pass.

Here, there’s not a lot of downward pressure from the blade, so it doesn’t impact the fibers as much, and leaves a nice, clean surface. (If you’re setting your alignment with a fence or stop-block, you could even hack this system by first making a scoring cut on the show face, then flipping it to make your final cut.)

Next, raise the blade to the appropriate height to cut to size. By creating this scoring relief cut, you’re reducing the impact to the fibers, keeping them where they belong.

Each of these methods work, so try them with a scrap of your particular sheet of plywood and tool/blade setup to see which gives you the best results. You’ll end up using each idea, or a combination, for different approaches, so commit them to memory, and save the frustration for another part of the project.

Table Saw Guide: How to Use a Table Saw

The heart of most woodworking shops is a table saw. Knowing how to use a table saw lets you do anything from cutting sheet goods down to size to making very small parts for models or crafts. When you have the choice of using a track saw vs table saw, table saws still find a home in most serious woodworking and DIY workshops. Of all the tools, the best portable table saws provide tons of versatility. With the right jigs, you can cut box joints, spline joints, tenons for mortise and tenon joints, and many more. This table saw guide should get you started regardless of your skill level.

How To Make A Homemade Table Saw With Circular Saw

Using a homemade crosscut sled for your table saw, you can crosscut boards more accurately than you can with a miter saw. Taper jigs let you make cuts that are difficult to do by any other method. My cabinetmaker teacher who taught me how to use a table saw in college could even make an entire round bowl using nothing but a table saw! Here is a video by Colin Knecht of WoodWorkWeb.com using a similar technique.

Types of Table Saws

Rather than go over the various types of table saws again, we can summarize under the categories of benchtop, jobsite, contractor, and cabinet table saws. We also wrote a helpful article on buying a table saw. There is one saw type worth mentioning again—the sliding table saw. I own a small version of this saw that you see pictured in many of the photos.

Sliding table saws, also known as European table saws are industrial saws. They are huge. Much bigger than cabinet saws. The advantage of them is they can take full sheets of plywood and push them through the blade on a movable table. This makes them the ultimate saw for accuracy and efficiency. If I had the space, this would be my dream saw. They come with a nightmare price tag though. A modest one starts at 5,000 and I have seen them as high as 15,000. Ironically enough, about 25 or 30 years ago, Ryobi made an amazing smaller portable sliding table saw. This is the saw I have been using for the past 25 years.

Safety Rules on How to Use a Table Saw

Let’s get one thing straight. Table saws are one of the most dangerous tools in the shop. According to the National Consumers League, every year 40,000 people go to the Emergency Room because of table saw accidents. Every day 10 amputations occur from a table saw. This table saw guide should help you avoid some of that.

I am not telling you this to scare you off from using one. It is usually not the new users learning how to use a table saw that get hurt. It’s often those who have used them for years. We can get too complacent and forget the safety rules. Always be careful, follow the rules below, and you should be okay.

Rule #1 – Don’t Cut Rough Sawn, Cupped, or Warped Lumber on the Table Saw

Table saws are meant to cut wood that is finished (dressed) on at least one face and one edge. The smooth finished face rides down on the table and the finished edge goes against the fence. Cutting cupped or warped wood on the table saw can pinch the blade and lead to kickback. Kickback is where the blade grabs the wood and hurls it back at you at over 120 MPH (193 KPH)! Kickback is the number one way people get injured on table saws.

Some Quick Math: My table saw uses 10-inch blades and spins at 4,800 RPM. That means the teeth are traveling at approximately 150,816 inches per minute (or 9,048,960 inches per hour). Covert inches into miles and that translates into 142.82 miles per hour! Under load, the blade slows down which is why I estimated 120 MPH earlier.

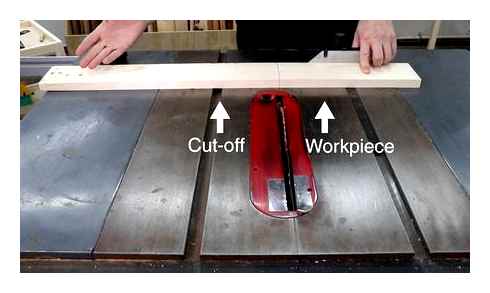

Rule #2 – Prevent Kickback by Never Using the Miter Gauge and Rip Fence at the Same Time

When you do, the piece that gets cut off can get trapped between the blade and the fence. This can lead to kickback. Instead, move the fence far away from the blade when using the miter gauge. You can still use the fence as a stop, but you need to put a stop block in between the fence and the end of the wood. If this table saw guide teaches you anything—ensure you only use one of these at a time.

Rule #3 – Always Use the Riving Knife and Guard as Much as Possible

Guards keep your fingers/hand out of the saw blade. Riving knives reduce kickbacks. These safety mechanisms work by preventing the wood from pinching the blade. It also does this by keeping the wood from twisting—preventing the teeth on the backside of the saw blade from lifting the piece up and throwing it at your body!

There are a lot of people out there who immediately remove the guards as soon as they get their hands on a table saw. This is a bad idea and is the equivalent of cutting the seatbelts out of your car because in some instances it is not convenient to use.

Newer table saws have guards that are much easier to use than older saws. If you have an older saw like mine that is not as easy to use as a modern saw, at least always use a riving knife. Keep in mind, there are some instances where you have to remove it, such as when you use a dado blade.

Rule #4 – Keep Your Fingers and Hands Away from the Blade

Do I really have to say this? Well, I have watched the dumb things people do on YouTube, so… yes, yes I do. Imagine a laser beam in line with the blade. When you start making your cut, keep both hands out of this line and NEVER put your hands in line with the blade while operating the saw.

When I am making a cut I am focused on the wood where it is contacting the fence. I am also focused on where the wood is contacting the table. It is important to also concentrate on whether the blade is following my line. I don’t have enough brainpower to keep track of where my hands are because my attention is divided too much already. Therefore I have made it a 30-year habit of always making sure my hands are out of the danger zone before starting my cut.

A table saw will cut off your fingers so cleanly and so quickly that you will not even know you have just amputated your fingers. Instead of putting your finger near that spinning blade see rule #5.

Rule #5 – Use Push Sticks When Proximity to the Blade is Unavoidable

If the table saw were an oven, push sticks would be the oven mitts. They keep your fingers attached to your body by giving your something to safely manipulate the wood. They come in a variety of shapes and sizes but this is my favorite set. These work with table saws, router tables, shapers, Band saws, and jointers. You can also make your own. Make sure to keep at least one within reach at all times while guiding or pushing wood through the table saw blade. I keep one of these push sticks in my shop apron at all times.

Rule #6 – Never Use the Rip Fence to Make Cross-Cuts

A table saw’s rip fence is for ripping. The miter gauge is for crosscuts and miters. When you use the wrong tool for the job, you not only get poor results, you increase your chances of kickback. Never guide a piece of wood through the table saw using both the rip fence and miter gauge.

Rule #7 – Always Hold Wood Tight to the Table and Fence at the Same Time

This particular point in our table saw guide both prevents kickback and also gives you the most accurate, straightest cuts. I often imagine my left hand is holding the wood like a pool cue with a couple of fingers wrapped around the left edge and my pointer finger and thumb on top of the board. My right hand feeds the wood forward while my left hand is pushing the wood down and to the right towards the fence in front of the blade.

For larger pieces, use a feather board if needed. Feather boards apply lateral and/or downward pressure against the wood to keep it tight against the fence or against the table. You can make them or buy them. When using feather boards, don’t put them so they apply pressure again the spinning blade or that can result in kickback. These are meant to guide your material through the table saw blade smoothly and precisely.

Rule #8 – NEVER Freehand a Cut on a Table Saw

You never want to freehand a cut on a table saw. That means never making a cut without using either the table saw rip fence, miter gauge, or some other jig to guide or hold the material. Violating this rule is an easy way to lose a few fingers or get a board thrown at your face. Enough said.

Table Saw Safety – Saw Stop

Years ago, Saw Stop came out with the technology to sense when your fingers make contact with the blade and almost instantly stop and lower the blade below the surface of the table. This revolutionary technology has undoubtedly saved many fingers from permanent injury. Today, Saw Stop is a manufacturer of high-end table saws with their own line of saws. You have the Sawstop portable jobsite saw, a contractor saw, and also full-size cabinet saws. Now that Festool acquired Sawstop, we expect to see even more products with this technology. If you are in the market for a new saw, it’s worth at least considering. Expect to pay more for this saw technology, however, if it protects you from a single injury, we consider it well worth the investment.

Using the Various Table Saw Controls

When learning how to use a table saw, you will quickly find that every saw has the same basic controls. They may be in a different location or operate slightly differently, but when you learn to work one table saw, you can use them all. On the front or sometimes the side, you will find handwheels to raise and lower the blade. You will also find a wheel to tilt the blade. On many saws, the handwheel to raise/lower the blade and the tilting wheel are combined into one wheel with a lever to shift its function.

Using a Table Saw for Cutting Wood

When you get ready to make your cuts, check your wood first. Look for rough edges that might catch on the lip of the table saw as you feed it forward. Look for loose wood or splinters that could poke you as you feed the wood forward. As annoying as getting a splinter is, do not be tempted to wear gloves while using a table saw. This is a very dangerous practice. The blade can catch the material of your glove and jerk your entire hand into the blade.

Another thing to watch out for is nails and screws in the wood. Examine each board closely before you make a cut, especially if it is reclaimed wood. Make sure your cut line is free and clear of metal. I recently built a rolling barn door out of old pallets that were full of nails, staples, and screws. A cheap handheld metal detector saved my saw blade as the wood was full of nails or staples that I couldn’t see.

If you do woodworking long enough, you are going to hit a bullet embedded in the wood. Typically a hunter missed their mark, hit the tree, and the tree healed over the bullet. Carbide blades can cut through the occasional nail or screw without much damage, just don’t make it a habit.

How to Make Rip Cuts

This guide keeps talking about how to use a table saw to make rip cuts and crosscuts. Let me define them more thoroughly for those who don’t know the difference. A rip cut is a cut that cuts with the grain of the wood. This is almost always the long dimension of the board as shown below. This is why you probably bought a table saw in the first place. A crosscut is a cut at 90 degrees to the grain of the wood. Miter cuts are any other angle cut to the grain. Most people immediately think of using a miter saw for making crosscuts and miters cuts. The table saw is perfectly capable of making those cuts in all but the longest boards.

With very long boards, it may take two people to feed the work through. The second person should hold the work with palms up like a shelf (see the photo below). THEY SHOULD NOT GRASP OR HELP PULL THE WORK AT ALL! This can cause poor quality cuts as well as lead to kickback since you now have two operators trying to control the board and they may be fighting each other without realizing it.

How to Use a Table Saw to Make Crosscuts

While I usually reach for my miter saw when I need to make crosscuts, if I am cutting small parts or need to be very precise, I use the table saw. A table saw crosscut sled (see photo below) is the most accurate method for cutting crosscuts in all but the longest board as there is always going to be play in miter saws. Crosscut sleds are also the safest method for cutting small pieces that are too small to be safely handled on a miter saw. Some woodworkers keep a pencil by their table saw and will use the eraser end as a hold-down device on a crosscut sled when cutting very tiny pieces.

You can find many plans on the Internet for how to make crosscut sleds. Some involve basic no-frills jigs like the one pictured above and others incorporate stop blocks, measuring gauges, hold-down clamps, and safety guards.

My table saw came with a miter gauge, why do I need a crosscut sled!?

The answer is simple. The miter gauge that came with your saw has side-to-side movement in it so the cut will not be any more accurate than a miter saw. An after-market miter gauge is a different story. Many of them come with ways to take out the play and to make them slide through the miter gauge slot perfectly. If they don’t, or if you only have the original miter gauge, add layers of tape to one side of the bar to make it a precise fit. The downside is you will have to replace it periodically. This still does not solve the safety issue when cutting small pieces, so you still need a crosscutting sled.

How to Use a Miter Saw to Make Miter Cuts

When learning how to use a table saw, a necessary skill is learning how to use the miter gauge. Not just to cut crosscuts but also to cut miters. No table saw guide would be complete without teaching this skill. Many miter gauges have stops or detents at commonly used angles such as 45 and 22.5 degrees. The biggest mistake people make when cutting miters is not holding the wood securely enough against the miter gauge so the wood slips as it is being fed through the blade. If you are lucky this results in a poor quality cut. If you are unlucky, this results in kickback.

Many woodworkers will attach a larger wooden board to their miter gauge. This gives them more surface area to hold the wood against when making cuts. Others will go so far as to use spray adhesive and glue sandpaper to the wooden board on their miter gauge to make it extra grippy.

Pro Tip: After you finish making your miter cut, loosen the miter gauge screw, flip the miter gauge upside down and put it in the miter gauge slot. Now push it against the front edge of your table saw which will be 90 degrees. Tighten the miter gauge screw, pull it out and flip it rightside up. You have just perfectly set your miter gauge to 90 degress without even looking at the scale.

A Guide for Cutting Sheet Goods on a Table Saw

Here I’m going to be controversial but this comes from 30 years of experience. Unless you have a big table saw with a big fence and a big outfeed table, I would not use a table saw to make the initial cuts on full sheets of plywood. Even then, if I needed really accurate cuts, I would not use the table saw. It is too easy to let the sheet drift away from the fence just a little. Full sheets are just too heavy and bulky to keep perfectly against the fence. I am sure some of you can do it. I can’t without a second person to act as a human featherboard, and I work alone most of the time.

In my cabinet-making class, we got a letter grade off for every 1/64-inch off we were on our year-end project. If I want that kind of accuracy on full sheets, I am going to use a track saw. Once I break the sheet down into smaller parts, then I switch from the track saw to a table saw. Track saws are great for large sheet goods, but they cut more slowly overall. Once the sheet gets smaller than 4 feet by 4 feet, I will exclusively use my table saw. Finally, nothing beats a table saw when it comes to repeatable cuts.

How to Use a Table Saw for Dado and Rabbet Joints

You can make a multitude of joints with a table saw. None is more ubiquitous than the dado and the rabbet. While you can make these on the router table, they are far slower and require multiple passes. They also wear out your router bits much faster than a dado blade.

Cutting Large Sheet Stock on a Table Saw | Rockler Skill Builders

Using dado blades is actually prohibited by EN and IEC standards. That means you cannot use them in the European market. In fact, table saws manufactured there typically use shortened arbors so you can’t make your own stacks or buy them from third-party sellers. If you can’t use a dado stack, a full-size (not thin kerf) flat ground rip blade works but you need to make multiple passes.

You make both dados and rabbets on the table saw using a dado set. A stacked dado set consists of two sawblades on the end with more than one chipping blade sandwiched in the middle. By varying the number of blades along with some brass shims between them, you can achieve various thicknesses. If you use a Sawstop table saw, you need a different brake cartridge when using dado sets. You also cannot use a blade guard or riving knife with a dado set.

Dust Collection While Using a Table Saw

Table saws make a lot of dust. I mean they make a LOT of dust. They also throw that dust everywhere, including in your face. For this reason alone you should always wear eye protection. The blade guard on most saws will help keep the dust from flying up at you. Most table saws also come equipped with dust ports for either a shop vac or a dust collector. I always use them. Jobsite and contractor saws are open on the bottom allowing the dust to fall through and collect on the ground under the saws.

I always keep a large plastic bin under them to collect the dust, but it also gives me a place to toss my cut-off scraps. Cabinet-style table saws are fully enclosed on the bottom and therefore their dust collection works much better. That is one of the things you get for that higher price tag.

How to Use an Outfeed Table with Your Table Saw

If you have the room, and you can locate your table saw in a permanent location, build yourself an outfeed table. This table sits on the back of your saw and extends the size (depth) of your table saw. It lets you more easily and safely push large boards and sheets of plywood through the saw. There are many plans on the Internet for how to build them. They range from simple tables to full cabinets with drawers and additional storage space under the table.

Make sure your outfeed table matches the height of your table saw. It should also not interfere with your fence. We also like when they allow the miter gauge slots to continue for a few extra feet.

Wrapping It Up

We hope this guide on how to use a table saw proves helpful. Nothing beats experience. The table saw is such an amazing and versatile tool that entire books have been written on them. In fact, books have been written just on jigs you can make for the table saw.

Use this guide as a starting point and refer back to it as needed—especially the safety rules. Leave a comment below if you have questions.

Track Saw vs Table Saw. Side-by-Side Comparison

The best way to cut large sheets of plywood or other materials is with a table saw, right?

A table saw does have its place in the workshop, but it can be dangerous and difficult to use.

A track saw is safer and easier to use than a table saw. It can be more accurate too!

So which one do you choose? I’ll go over the pros and cons of each tool so you can decide which one (or both!) is right for your workshop.

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What’s the difference between a track saw vs table saw?

Here’s a quick list of the main differences between the two tools:

- Track saws are portable, while table saws are typically stationary.

- Track saws are much safer than table saws.

- Table saws are more powerful than track saws.

- Track saws allow you to cut large sheet goods that may be difficult to handle on a table saw.

- Table saws allow easy repeatability when making rip cuts.

- Track saws can make splinter-free cut edges with the track’s splinter guard.

Can a track saw replace a table saw?

This question gets asked a lot! A track saw can accomplish most of the same tasks as a table saw, sometimes even better! But can it replace a table saw entirely? Here are a few instances where I’ll reach for my track saw first.

Splinter-free edges

One of the best features of a track saw is its ability to cut splinter-free. Plywood cut on the cross grain at the table saw can leave jagged, splintered edges that are hard to hide. If you’re struggling with burning along the cut, you might need to clean your saw blade!

The magic happens with that little rubbery bit on the edge of the track. It holds those wood fibers in place while you make the cut, resulting in a perfectly smooth edge!

On my Festool track saw, you can achieve splinter-free cuts on both sides of the blade with the splinter guard that extends down from the side of the saw. This presses against the wood surface on the waste side, so you can use that edge on your next piece!

Long angled cuts

Instead of setting up a complicated jig or sled at the table saw, just place the track wherever you want the cut! I would have great difficulty cutting the angle on my kids bookcase at the table saw.

Wider plywood cuts

One drawback to a jobsite table saw is the limited cutting capacity. I can only extend my fence out 28″, so I need to get creative to cut a wider piece. But there’s no limitation with a track saw!

Extra long cuts

Need to rip the factory edge off a 4’x8′ sheet of plywood? You’ll need more than 16 feet of space to do that with a table saw (and a second person to help!) I don’t have that kind of room in my one car garage workshop.

With a track saw, this task is simple to do by yourself. I have an 8 foot length of track just for this purpose! It stores away on my workshop ceiling with these handy rail clips.

Cutting irregular edges

At the table saw, you always have to reference a straight edge against the fence or miter gauge. With a track saw, the track is your straight edge, so you can cut anywhere! This is especially helpful when dealing with live edge lumber like these floating shelves, which require a flat back against the wall.

You can also use the track saw as a makeshift jointer for milling rough lumber. It creates a square edge that can then be used against the table saw fence to cut to the final width.

Drawbacks of the track saw

While I love my track saw, there are plenty of times where the table saw is the better option. Here are some of the tasks that are more difficult (but not impossible!) to do with a track saw.

- Repeat cuts are easier with a table saw, because you just set the fence once. Parallel guides can make the process quicker, but it’s still faster to do this at the table saw.

- Narrow boards is harder to rip on a track saw because the track can tip. You have to add scrap wood underneath to hold the track at the same level as the work piece.

- Specialized tasks, such as cutting splines or dados, would be very difficult to accomplish with a track saw.

- The track saw cutting depth is usually limited to about 2″, whereas the table saw can typically cut about 3″. If you’re making chunky table legs, you’d have to make two passes and hope they line up in the middle.

- You have to check that the track is square to the front edge when making a 90 degree cut, instead of relying on the table saw fence that’s already calibrated. Track saw squares can take the guesswork out of this task, but they don’t come with the saw itself.

What is a track saw?

A track saw is similar to a circular saw. However, the track saw has a fully enclosed blade and operates in conjunction with a corresponding track. You can find out more about the difference between a track saw and a circular saw in this article.

- Blade: Most track saws sport a 6.5-inch diameter blade; however, larger sizes are available.

- Bevel adjustment: Like a circular saw, you can adjust the track saw to make bevel cuts up to 45 degrees.

- Speed adjustment: Many track saws allow you to adjust the speed of your blade. This comes in handy if you’re worried about burn marks on a particular species of wood.

- Vacuum port: Track saws typically have great dust collection. The enclosed blade allows a shop vacuum to keep your work area clean.

- Track: The track saw uses an aluminum track with grooves that keeps the saw cutting straight. You can buy these in different lengths or join two together to create a longer track.

When should I use a track saw?

Track saws are great for breaking down large sheet goods like plywood. You can keep the plywood flat on the work surface and pass the saw over it instead of pushing a huge sheet through the table saw.

The track saw can also be handy for making perfectly straight cuts on a job site, as these tools can easily make shorter cuts. Track saws can also make safe plunge cuts (unlike circular saws, where your fingers need to lift the blade guard).

Track saws are perfect for small workshops that don’t have a lot of room for an infeed and outfeed at the table saw. You can accomplish many of the same tasks as a table saw in a much smaller footprint!

How do I use a track saw?

Each track saw will operate in different ways, so consult your owner’s manual! Below, we cover some general guidelines for using a track saw.

- Safety. Remember your hearing and eye protection!

- Choose the right blade. If you’re making rip cuts (with the grain), use a ripping blade with a lower tooth count. For cross-cutting (across the grain), choose a blade with a higher tooth count.

- Protect the work surface. You don’t want to be cutting into your workbench, right? I like to use sheets of rigid foam insulation underneath the board, and it can take hundreds of cuts before it starts wearing out.

- Set the cut depth. Make sure the blade will cut all the way through the board without sticking out too far on the other side. There should be a depth gauge on the saw, both for use with a track and without. I prefer to set mine one click past the actual depth of the wood.

- Place your track. Line up the edge of the track with your cutting line. Ensure that your track grips the project, and clamp it down if it’s slipping (such as when using prefinished plywood).

- Make your cut. For softwoods, you can use higher speeds. For hardwoods, consider slowing your saw down. After you plunge the blade into the material, ensure you push directly in line with the track. if you inadvertently force the saw to either side, you could mess up your perfect edge. Let the saw do the work!

Here’s a good video explaining some tips for using a track saw.

Do I need a track saw?

If you frequently travel between job sites, you’ll find a lot of use for a track saw. Also, if you have a small workshop, or don’t have the budget for a full table saw, you can accomplish many of the same tasks with a track saw. Many woodworkers and builders say they didn’t realize what they were missing until they purchased a good track saw!

What is a table saw?

The table saw comes in two main forms: a stationary saw, commonly called a cabinet saw, and a more mobile saw, often referred to as a contractor or jobsite saw. I have a small workshop, so I built this table saw stand with loads of storage to increase the cutting capacity of my SawStop jobsite table saw.

Both the stationary and semi-portable table saws function in the same way. However, the cabinet saw can easily handle larger tasks with power and precision.

Here are several parts of the table saw:

- Blade: A table saw blade is usually 10-inches in diameter. Like many saws, you can install different types of blades (high and low tooth counts).

- Blade guard: The blade guard helps ensure you keep your hand away from the blade. For beginners, it’s a good idea to leave this in place. However, advanced woodworkers usually choose to remove their blade guards to make some tasks easier.

- Riving knife: The riving knife sits behind the table saw blade. do not remove this! The riving knife helps prevent kickback by preventing the wood from pinching together after the cut.

- Rip fence: The rip fence runs parallel to the blade and slides back and forth to dial in the width of the cut.

- Height and bevel adjustment: This is the crank wheel on the front of the saw that raises and lowers the blade. Some models use the same wheel to tilt the blade at an angle for bevel cuts.

- Power button: The power button is usually located on the front of the table saw. Typically, the power button is set up so you can turn off the saw with your knee quickly.

- Push stick: Not exactly part of the table saw, but very important! Use a push stick to move material through the blade, keeping your hand away from the blade!

When should I use a table saw?

The table saw is one of the most useful tools in my workshop, and I use it for almost every woodworking project. Where the table saw shines is with repeated cuts. Set the fence once and all your cuts will be the exact same size.

You can also use it to make cuts that only go partway through the board. These grooves or dados are useful for cabinet back panels or drawer bottoms.

How do I use a table saw?

Safety. That’s the key with table saws. Though you don’t want to be timid while operating a table saw, you should approach this tool with a healthy fear. Table saws can inadvertently pull your hands into the blade, especially when the saw is misused. Do your research before you even plug in the saw.

Here are several steps to using a table saw:

- Safety: Wear ear and eye protection, and inspect your saw before use. Make sure all safety features are in place.

- Set your blade: Typically, set your blade so it just clears the material. You don’t need a lot of extra blade protruding from the surface.

- Set your fence: Make sure your rip fence is secure and double-check your dimensions.

- Start the saw: Make sure you’re ready before starting the saw. Have supports in place so the board doesn’t fall off the side and verify that your push stick within reach.

- Keep pressure against the table and fence: As you begin pushing the wood through the saw, keep the wood pressed against the fence and down on the table. this ensures your hand doesn’t slip toward the blade and also mitigates the risk of kickback.

- Use a push stick: Use a push stick to prevent your hand from creeping dangerously close to the blade. This is especially important on thinner boards where there’s not much room between the blade and the fence.

- Support large boards: If you’re cutting a large piece of wood, set up outfeed and side support. You don’t want the wood falling off the table, causing excessive pressure on the blade.

Here’s a great video on how to use a table saw to get you started.

I’m Vineta, otherwise known as The Handyman’s Daughter!

My goal is to teach people how to fix up their homes and furnish them with custom woodworking projects that are perfect for their space.