How to lubricate the gearbox Stihl lawners. Removing and lubrication of the upper shaft of a trimmer for grass

Lubricant for a trimmer gearbox for STIHL Evdiral grass.Ru

Reducer Motokosa Purchase of any equipment in its kind a lottery, but much also depends on the gardener. In caring hands and Chinese samples serve for a long time and do not let their owners at the wrong time. And if you forget to lubricate the motorcosa gearbox in time, do not clean filters, use cheap low.quality gasoline, then garden equipment from the most eminent brands will be a headache.

Lubrication of the gearbox Motokos is one of the most important elements of maintenance of a gasoline trimmer for grass, which the user should be carried out directly.

Time and procedure for the prevention of the gearbox

I recommend that the prevention of a new gasoline trimmer for grass immediately after purchase, with the addition of lubrication in the gearbox. For all the high cost of garden technology, some manufacturers save and lay lubrication only at a minimum, for the duration of the run.in.

How often to lubricate the gearbox motokos

Often, a preventive inspection of the transmission with the addition of liquid consistent lubrication is carried out once a year at the beginning or end of the season. If the gasoline trimmer for grass is used not in professional volumes, this is enough.

With large volumes of the mowing, lubricate the motorcosa gearbox every 20-50 hours of work. If the conditions of the operating mode of garden equipment are difficult, for example, a large field is pumped out at a time, and at the same time the lawn mower does not have time to cool down, or cheap lubricants are used, then the lubricant must be checked and added every 20 hours of work.

Indirect evidence that it is necessary to lubricate the gearbox to overheating or increased noise of the node.

I also recommend a complete replacement of lubrication, with disassembly and flushing of the node, when buying a used gasoline trimmer for grass.

Lubrication for gearbox of gasoline trimmer for grass

Assortment of lubricants for garden technology

According to the instructions for lubricating the conical gearbox, a special transmission liquid consistent grease should be used. As a rule, manufacturers of garden equipment produce and recommend the chemistry of their brand as the most adapted to their devices.

At the same time, to reduce the cost of the operation of garden equipment and increase the attractiveness of a brand of auto chemistry, grease for garden equipment usually produces multifunctional. It is intended not only for lubricating gearboxes of gasoline trimmers, but also for processing hoses, transmissions and gearboxes of any garden equipment and mechanical devices operating under high loads.

Such lubricant for the gearbox is sold in the tubes convenient for use and subsequent storage.

Even if a specialized lubricant for the gearbox was almost completely developed during operation, the additives still create an effective lubricating protective film on the surface of the gears.

It should be noted that many owners of the motorcycle in the vast CIS for lubrication of the gearbox use ordinary litol-24 or lubricant for Circus on a lithium basis. It is convenient to refuel the gearbox using a 5-cc medical syringe.

A undoubted plus of the use of lithola and lithium.based lubricant for refueling the transmission of motorcycles is a reduction in operation. But there are nuances because of which spears are breaking on the forums of the Internet gardeners. My thoughts on the topic, what can be lubricated with lubric.based lubricants, and what is not read in the article “Litol as lubrication of the motorcosa gearbox”.

How to lubricate the motorcosa gearbox, gasoline trimmer for grass

Side Bolt on 17 on the gearbox of a gasoline trimmer for grass

In order to avoid random launch, all preventive work on a motorcycle is necessarily carried out with a removed electric cap / plug from a candle. Do not turn the trimmer for the grass to avoid gas leakage.

We unscrew the side screw on the motorcosa gearbox. Depending on the company.manufacturer of a garden tool, instead of a screw for a hexagon, there may be a turnkey bolt, more often at 17. The thread is ordinary, unscrew counterclockwise. Do not lose the sealing puck.

If the lubricant is not visible on the internal end part of the screw, then it is necessary to add 3. 4 grams. Scroll through the gear with your hand, changing the direction of rotation so that the lubricant is distributed through the gears.

Then set the screw in place, tightly tightening it.

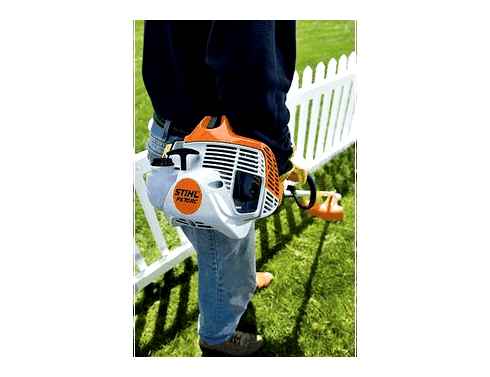

Why choose a FS 55 lawn mower

If you still do not know which model of the described equipment to choose, then you should read reviews about the gas tanks “Stihl FS 55″. Having familiarized themselves with them, you can understand that consumers identify many reasons that made them bow towards the described model. So, for example, instead of a strap, the manufacturer supplied the device with a belt. This allows you to distribute the load from the device throughout the back. Otherwise, the weight would be focused on only one shoulder. With this option, even after a very long operation, there is no back pain.

Buyers like a bicycle handle that increases the convenience of management. When working, the hands will be widely placed, so it is easier to control the aggregate. He is very maneuverable. Buyers like that the handle and belt can be adjusted for the needs of the operator.

The tool can be easily configured for comfortable use. Control elements are on one handle. You need to stretch anywhere, everything is located under the palm. The Stihl FS 55 lawn mower, according to consumers, is also convenient for the fact that it has a couple of protective covers, one of which is installed for a knife, while the other is for fishing line. The casing for the latter has a narrowing of the bar.

A trimmer for grass has a head that is clearly visible and allows you to process narrow places. The departure of stones from under the knife will be excluded thanks to a special casing. This allows you to protect the operator. With the help of an existing primer, you can pump up fuel into a carburetor. Even after a long downtime, as consumer reviews testify, the lawn mower is quite simple. The start of the engine is light due to a special light starting system. As the home craftsmen emphasize for a long stretch of the cord, now you will not have to spend strength, because for this it will be necessary to make 2 jerks.

Rod and the drive of the working body

The bar has two very fundamental functions: 1st-forms a hard frame of the entire structure, 2nd-snitches of an iron hollow rod passes the shaft, which connects the working body to the engine. By the appearance of the rod, you can find the class class, if the bar is curved, this is comfortable for work, but in this case, the drive is a flexible shaft, which cannot convey a large torque. If the rod is flat, the snuts pass the hard iron rod, it can transmit more reliably and a torque. Therefore, the profile tool always has straight rods.

Sometimes with intensive mowing of grass, a trimmer for grass begins to gingern and make unpleasant sounds, which indicate the lack of reducer lubrication. This node is considered the most loaded, and therefore wears out faster. If it is not lubricated in a timely manner, then soon the drive can jam!

The algorithm for self.lubrication of the gearbox

To make lubrication of the gear ratio, its preliminary disassembly is not needed. A special hole for these purposes has already been laid in the device (it is shown in the photo below)

In addition to gears, when lubrication, you need to pay attention to such elements of the mechanism:

Pour oil or apply solid grease through a tavniper closed by a screw. At the same time, they perform actions in the following sequence:

- The gearbox body is cleaned of dirt and adhering grass, especially thoroughly the plot around the plug so that the garbage does not get inside the mechanism;

- Using the appropriate tool (often it comes with a trimmer), the cork is unscrewed;

- The selected lubricant is introduced from the tube into the open technological hole, or using the syringe, as shown in the photo further;

- screw the cork in place.

When making lubrication, you need to rotate the knife so that it is evenly distributed through the teeth of moving gears.

If for any reason the gearbox needs to be disassembled, then the old lubricant must be completely removed from the entire surface of the gears and housing, shaft, and only then use the new. The disassembled mechanism is conveniently lubricated with solid compositions.

The entire reducer lubrication process is demonstrated in the video:

Lubricating the gear node is required at least once during the year, but it is recommended to do this every 20 hours of intensive use of motorcycles. If the first signs of malfunctions with the mechanism appear, then you need to make lubricants as quickly as possible.

Husqvarna | Adding Grease to Brushcutter Bevel Gear.

Used types of lubrication

When choosing lubrication, it is necessary to take into account the following factors:

Famous manufacturers, for example, STIHL, Husqvarna and others, in addition to trimmers, produce lubrication for them. Such products not only reduces wear, but also protects the metal of gears from corrosion. Therefore, for motorcycle from these brands, it is better to use their lubricants.

If the composition used for lubrication has good adhesion, then it is practically not squeezed out of the gearbox through the gaps.

For different models, lubrication is consumed in different ways. This is determined largely by the intensity of the use of motorcycles and heating the transmission mechanism. It is believed that the lubricant is enough if the temperature of the gearbox during operation does not exceed 40 ° C.

By consistency, lubricants for a trimmer for grass can be:

In terms of composition, the following types of lubricants are in demand:

- graphite, significantly reducing friction, as a result of which the rotation of the gear improves;

- lithium, which are also an excellent anti.corrosion composition, saturated with increasing the wear resistance of metal with additives without harmful substances;

- universal, containing high.degree mineral oils and improving operational characteristics components.

An example of suitable lubricants are: Champion EP-0, Gear Grease Oregon, Oleo-Mas, Azmol 158, Litol.24

You should also pay attention to the advice of manufacturers on this issue and use the materials they offer. You can buy them at specialized retail outlets

A lubricant Champion EP-0 Universal 120 gr

What lubricant should be used for a trimmer gearbox for grass?

In the process of work, the mechanical part of the trimmer for grass is loaded with contact efforts on the teeth, resistance reactions from adhering grass (sometimes with dirt), dynamic, shock loads due to a constantly changing torque. The lubricant for the gearbox of the trimmer for the grass should fully consider these features, so the selection of the brand should be strictly individual.

The following factors are taken into account:

- Manufacturer’s brand. Repair of a trimmer for the grass Champion T 336 with your own hands of the lawn mower how to lubricate the shaft pcs video. Example. Each trademark is not unreasonably focused on lubricants of its own manufacture (you can talk about cheap Chinese products later). This applies to manufacturers such as Husqvarna, Stihl, Huter, Makita, etc. The exception is trimmers for domestic grass: for example, the caliber in the user’s instructions does not indicate a lubrication brand at all.

- Break of lubrication. As you know, all lubricants are divided into three groups. high.speed (colloidal systems containing various additives), plastic compounds of universal use and hard lubricants softening during operation.

- Good adhesion to the surface of the parts of the gearbox, as a result of which the lubricant is not squeezed into the gaps or outside the node.

- The intensity of lubrication consumption by the gearbox. Here you have to focus on their own experience and recommendations of specialists, since some manufacturers of trimmers, hoping for their own service centers, do not give clear recommendations at all regarding the period of the reducer between two lubricants.

Reducer device trimmer for grass

Regardless of the manufacturer and model, the modern trimmer for grass is equipped with a gearbox for changing the angle of mechanical energy between the drive shaft and the head with a fishing line. The most widespread in the benzocos were conical gears, since, unlike straight.tooth, gears with screw teeth are able to carry huge speeds, have a more smooth clutch and have increased bearing capacity.

In the duralumin case (1) there is a shaft-shuster (2) and a gear conical wheel (3), pressed on a driven shaft (4). To reduce friction forces during rotation, rolling bearings (5) are installed at the support points of the shafts. Any gear gear is a highly loaded mechanism, whose duration and reliability of which depends primarily on the lubricant. Therefore, in addition to the main components of the trimmer gearbox, the trimmer reducer includes a special hole, through which you can grease bearings and gears without disassembling the assembly.

Lubrication for gearbox of gasoline trimmer for grass

Assortment of lubricants for garden technology

According to the instructions for lubricating the conical gearbox, a special transmission liquid consistent grease should be used. As a rule, manufacturers of garden equipment produce and recommend the chemistry of their brand as the most adapted to their devices.

At the same time, to reduce the cost of the operation of garden equipment and increase the attractiveness of a brand of auto chemistry, grease for garden equipment usually produces multifunctional. It is intended not only for lubricating gearboxes of gasoline trimmers, but also for processing hoses, transmissions and gearboxes of any garden equipment and mechanical devices operating under high loads.

Such lubricant for the gearbox is sold in the tubes convenient for use and subsequent storage.

Even if a specialized lubricant for the gearbox was almost completely developed during operation, the additives still create an effective lubricating protective film on the surface of the gears.

It should be noted that many owners of the motorcycle in the vast CIS for lubrication of the gearbox use ordinary litol-24 or lubricant for Circus on a lithium basis. It is convenient to refuel the gearbox using a 5-cc medical syringe.

A undoubted plus of the use of lithola and lithium.based lubricant for refueling the transmission of motorcycles is a reduction in operation. But there are nuances because of which spears are breaking on the forums of the Internet gardeners. My thoughts on the topic, what can be lubricated with lubric.based lubricants, and what is not read in the article “Litol as lubrication of the motorcosa gearbox”.

How to lubricate the motorcosa gearbox, gasoline trimmer for grass

Side Bolt on 17 on the gearbox of a gasoline trimmer for grass

In order to avoid random launch, all preventive work on a motorcycle is necessarily carried out with a removed electric cap / plug from a candle. Do not turn the trimmer for the grass to avoid gas leakage.

We unscrew the side screw on the motorcosa gearbox. Depending on the company.manufacturer of a garden tool, instead of a screw for a hexagon, there may be a turnkey bolt, more often at 17. The thread is ordinary, unscrew counterclockwise. Do not lose the sealing puck.

If the lubricant is not visible on the internal end part of the screw, then it is necessary to add 3. 4 grams. Scroll through the gear with your hand, changing the direction of rotation so that the lubricant is distributed through the gears.

Then set the screw in place, tightly tightening it.

Characteristics and features of lubricants for bells

When servicing any manual tool, where there are mobile parts, a lubricant is used that has the following characteristics and features:

- It should not have solid particles that can cause painting mobile parts of the mechanism.

- The temperature at which the lubricant becomes liquid, should be more than 120 degrees.

- Oil should not absorb moisture, must form a strong film that protects the parts from corrosion.

- And also, most importantly, the oil should be such a viscosity that he has the opportunity to stay on mobile details.

The consistency or viscosity of the lubricant is divided according to NLGI (National Lubricating Grease Institute), while in certain cases it is necessary to use the oil of a certain density. The viscosity of the oil is selected depending on the speed of rotation of the gearbox, the higher it is, the more liquid should be oil. So, depending on the tool, viscosity is selected:

- Drills, peorators, jigsaws, where the gearbox has a low rotation speed. Lubrication with the NLGI-2 index which is soft.

- Light peorators and shock drills. Class NLGI-1, in consistency very soft.

- Corner grinder, circular saws, motorcycles. Class nlgi-0, half-liquid in consistency.

- Heavy peorators, junk hammers. Class nlgi-00, in consistency is liquid.

How to lubricate the gearbox of a trimmer for grass?

In the upper part of the case, where the gear unit is installed, there is a technological hole that, when operating the trimmer for the grass, is drowned out with a screw. This screw is twisted, and 1.5 2 ml of grease is introduced into the hole using a nose available on a tube. If the lubricant was purchased in another packaging, then a regular disposable medical syringe is suitable for this operation.

After that, the screw is installed in its former place. This procedure, regardless of the user’s recommendations, should be performed every 10 15 hours of operation of a trimmer for grass in working mode. Other reasons for updating or replacing the reducer lubrication are the independent performing of small regulatory work (for example, cleaning and washing the gear of the gearbox before the start of the summer season), repair of the node, preserving the trimmer for grass for the winter period, etc. D.

If the reducer node is disassembled, it is recommended to completely remove the remaining lubricants from the surface of the parts, even if it does not have traces of oxidation and pollution. And only then apply a new grease. After applying the lubricant, it is recommended to handle the shaft several times manually, and make sure that the grease is evenly distributed over all the details of the gearbox.

When lubricating, special attention is paid to the following elements:

- Flywheel: on its surface, as a rule, intensively sticks the remnants of grass, and thickening herbal juice creates additional resistance.

- Dog of a starter coil, which in the process of turning on the drive is constantly in contact with the grooves on the flywheel. At the same time, not only mechanical wear occurs, but also the mechanochemical corrosion of the Makhovik-Sobachka compound, since the materials of this pair are different (the flywheel is aluminum, and the dog is steel).

- Bearings, if their seals are worn out, and through them the remaining lubricants are squeezed out. In this case, the unit begins to vibrate intensively when loading. This happens with trimmers of Chinese.made, so it is worthwhile to think about replacing a bearing unit with a better, for example, from the Swedish company SKF.

How to replace a trimmer gearbox for grass: an algorithm of action

To replace the gearbox with a similar part from the same manufacturer, it must first be disassembled and removed from the bar. At the same time, they act according to the following algorithm:

- weaken the fitting bolts located under the transfer mechanism;

- Using round.drawers, remove two corkscrew rings;

- Applying the puller, pull the bearings from the driven and the leading shafts;

- Then collect the mechanism, in the reverse order by installing all spare parts.

The disassembled transmission mechanism is shown in the photo below.

If the puller is not at hand, then you can try to gently knock down the bearings. When they have stuck and do not move at all, you can heat them using an industrial hair dryer (at a temperature of 600 ° C) and remove.

Collecting a gear node is easier than disassemble it. Only a light tapping with a hammer for planting parts in place may be needed. After assembly, it is imperative to check that the driven shaft turns out by hand.

Когда есть необходимость замены передаточного узла неоригинальной деталью, тогда следует учитывать их взаимозаменяемость. At the same time, it should be taken into account:

- the diameter of the bar (this parameter often is 25.4 or 26 mm);

- The parameters of the drive shaft. the shape of the docking space and the diameter (its common value is 8 mm);

- option of consolidation of protection.

If the considered parameters coincide, then it will be possible to set a part from other models.

Timely lubrication of the gearbox will ensure its prolonged operation without repairs. In addition, modern materials protect the metal from corrosion well, increase its wear resistance. When choosing, preference should be given a lubricant recommended by the manufacturer of the operated trimmer for grass. If such compositions are not possible to purchase, then the analogs considered or other suitable in properties should be applied. When it is necessary to disassemble the mechanism during the repair, this should be done carefully so as not to damage individual parts.

Serving gasoline trimmer for grass

Most motos and trimmers have a flexible shaft in their design. Its condition must be checked at least 1 time for 50 working hours. To perform this operation, you need to remove the tip tip, pull out the shaft and inspect it, then grease it.

Inexpensive materials are suitable for the shaft care, it is more difficult to choose them for a trimmer gearbox for grass. How to lubricate this mechanism-depends on the tool manufacturer. It is best to use the materials that contain molybdenum disulfide. The latter provides smoothing and filling cracks on the work surface, therefore it is especially appreciated among users.

Important: the use of a large amount of lubrication with high density leads to overheating of the mechanism, increased friction of working couples and fuel consumption. Therefore, the process of selecting materials and prevention should be attributed responsibly

During the operation of a gasoline trimmer for grass, the gearbox begins to make rattling sounds, which are a sign of a lack of lubrication, or loss of its properties. Of course, the owner may not attach particular importance to extraneous noises, but their ignoring will lead to jamming the gears and, as a result, the upcoming expensive repair. Therefore, in order to avoid the prerequisites for the appearance of a rattle, it is necessary to observe the lubrication of the gearbox of the trimmer for grass, recommended by the manufacturer.

How to replace a trimmer gearbox for grass: an algorithm of action

To replace the gearbox with a similar part from the same manufacturer, it must first be disassembled and removed from the bar. At the same time, they act according to the following algorithm:

- weaken the fitting bolts located under the transfer mechanism;

- Using round.drawers, remove two corkscrew rings;

- Applying the puller, pull the bearings from the driven and the leading shafts;

- Then collect the mechanism, in the reverse order by installing all spare parts.

The disassembled transmission mechanism is shown in the photo below.

If the puller is not at hand, then you can try to gently knock down the bearings. When they have stuck and do not move at all, you can heat them using an industrial hair dryer (at a temperature of 600 ° C) and remove.

Collecting a gear node is easier than disassemble it. Only a light tapping with a hammer for planting parts in place may be needed. After assembly, it is imperative to check that the driven shaft turns out by hand.

Когда есть необходимость замены передаточного узла неоригинальной деталью, тогда следует учитывать их взаимозаменяемость. At the same time, it should be taken into account:

- the diameter of the bar (this parameter often is 25.4 or 26 mm);

- The parameters of the drive shaft. the shape of the docking space and the diameter (its common value is 8 mm);

- option of consolidation of protection.

If the considered parameters coincide, then it will be possible to set a part from other models.

Timely lubrication of the gearbox will ensure its prolonged operation without repairs. In addition, modern materials protect the metal from corrosion well, increase its wear resistance. When choosing, preference should be given a lubricant recommended by the manufacturer of the operated trimmer for grass. If such compositions are not possible to purchase, then the analogs considered or other suitable in properties should be applied. When it is necessary to disassemble the mechanism during the repair, this should be done carefully so as not to damage individual parts.

Gasoline trimmer for FS 55 grass

This is a model from a lightweight ruler this price of a braid for grass quite justifies, especially if you use the knives with an attack. Productivity grows to such an extent that the fuel ends after an hour of work. Everything in the trimmer is thought out to the smallest detail and is most balanced. This explains its popularity among buyers of many countries. The design is based on a reliable and unpretentious internal combustion engine, which has a volume of 27.2 cubic centimeters. To increase wear resistance inside there is a special chrome coating. As a result, the service life of the product is extended.

Given many years of experience, the carburetor has been finalized, preventing pipe clogs. Manual pump provides ease of supply of gasoline during the cold launch of the motor.

In order for a trimmer for grass to instantly start in any, even the most difficult circumstances, an electronic ignition system in the airtight case is provided. The use of high voltage support made it possible to quickly receive a spark and extend its combustion, which reduced the amount of exhaust gases thrown into the atmosphere.

How to adjust the carburetor of the Stihl FS 55 lawn mower

The trimmer for the grass does not apply to complex household appliances, since most of its malfunctions are mechanical and can be successfully eliminated with their own hands. Even if the engine fails for good reason. For example, damage to the piston ring, repair is reduced to the replacement of parts.

And in a relative design, such a part of the device as the carburetor should be adjusted.

How does it work

Carburetor. This is the energy system module in which liquid fuel and air are mixed before supplying to the engine cylinders. Depending on the instrument and its operating mode, mixing and supply are regulated accordingly.

How to Grease the Flex Cable in Your Trimmer in 7 Quick Steps

Carburetor cutter is uniform in almost all cases. The price of FS 38 for recreation should be adjusted using a carburetor screw. Belongs to the category of floating devices. How to adjust the carburetor on a scooter. Honda part AF-34. The latter provide constant characteristics of the finished consistency.

The mechanism of the module is as follows.

- The air enters the body of the tube with an air damper. Adjustment of the carburetor of the cooler of the trimmer for grass FS 55 in the video How to adjust the carburetor. The latter increases or decreases the flow of air depending on its position.

- In the zone where the gas supply hole is formed, the tube has a hood. diffuser. Adjustment of a trimmer for the grass of the carburetor carburetor fs 55 in the video is performed to adjust the blank speed. Here the flow rate increases.

- Fuel from the float chamber through the nozzle is supplied to the pipe. The level of the float determines the amount of fuel supplied. How to adjust 24, I removed the carburetor from the diode, I do not know the rings on the pistons of Honda Dio 34. Since the pressure in the chamber is normal, and in the pipe is low due to a large air vacuum, the gas is absorbed through the nozzle.

- The accelerated air flow collects fuel and spray it, forming the fuel.air mixture of the corresponding density.

- The mixture is sucked into the cylinder through the pipe.

The larger the air damper in the pipe is open, the higher the density of the air flow and more fuel enters the cylinder. A carbon tunnel settings are reduced to the damping coefficient, in which the consistency of fuel becomes good.

Signs of imbalance

Carburetor adjustment, of course, is carried out in the manufacture of the device. Typically, the need to regulate owners will be able to independently deliver fuel only after serious breakdowns, during which the module was removed and, for example, cleared.

Signs of a malfunction in the settings are as follows:

- It starts, but the engine stops here. Since the engine can only operate when a certain amount of very “bad” gasoline is supplied, in other words, blocking the supply channel, the engine stops;

- Very high fuel consumption, many exhaust gases. The result of incomplete combustion of consistency. In this case there is a lot of fuel, and the mixture is very thick.

Carburetor gasoline braids are quiet, Makita, Husqvarna and others are regulated by adjusting screws. Sometimes a prerequisite for a malfunction is a violation of fixation. due to vibration or damage to a protective cap. You can find such a breakdown by just trying to turn the screw a little: if the lock is not hard, you must check the settings.

Lubricant for a trimmer gearbox for grass

Buying any equipment in its kind is a lottery, but much also depends on the gardener. In caring hands and Chinese samples serve for a long time and do not let their owners at the wrong time. And if you forget to lubricate the motorcosa gearbox in time, do not clean filters, use cheap low.quality gasoline, then garden equipment from the most eminent brands will be a headache.

Lubrication of the gearbox Motokos is one of the most important elements of maintenance of a gasoline trimmer for grass, which the user should be carried out directly.

Time and procedure for the prevention of the gearbox

I recommend that the prevention of a new gasoline trimmer for grass immediately after purchase, with the addition of lubrication in the gearbox. For all the high cost of garden technology, some manufacturers save and lay lubrication only at a minimum, for the duration of the run.in.

How often to lubricate the gearbox motokos

Often, a preventive inspection of the transmission with the addition of liquid consistent lubrication is carried out once a year at the beginning or end of the season. If the gasoline trimmer for grass is used not in professional volumes, this is enough.

With large volumes of the mowing, lubricate the motorcosa gearbox every 20-50 hours of work. If the conditions of the operating mode of garden equipment are difficult, for example, a large field is pumped out at a time, and at the same time the lawn mower does not have time to cool down, or cheap lubricants are used, then the lubricant must be checked and added every 20 hours of work.

Indirect evidence that it is necessary to lubricate the gearbox to overheating or increased noise of the node.

I also recommend a complete replacement of lubrication, with disassembly and flushing of the node, when buying a used gasoline trimmer for grass.

Lubrication for gearbox of gasoline trimmer for grass

Assortment of lubricants for garden technology

According to the instructions for lubricating the conical gearbox, a special transmission liquid consistent grease should be used. As a rule, manufacturers of garden equipment produce and recommend the chemistry of their brand as the most adapted to their devices.

At the same time, to reduce the cost of the operation of garden equipment and increase the attractiveness of a brand of auto chemistry, grease for garden equipment usually produces multifunctional. It is intended not only for lubricating gearboxes of gasoline trimmers, but also for processing hoses, transmissions and gearboxes of any garden equipment and mechanical devices operating under high loads.

Such lubricant for the gearbox is sold in the tubes convenient for use and subsequent storage.

Even if a specialized lubricant for the gearbox was almost completely developed during operation, the additives still create an effective lubricating protective film on the surface of the gears.

It should be noted that many owners of the motorcycle in the vast CIS for lubrication of the gearbox use ordinary litol-24 or lubricant for Circus on a lithium basis. It is convenient to refuel the gearbox using a 5-cc medical syringe.

A undoubted plus of the use of lithola and lithium.based lubricant for refueling the transmission of motorcycles is a reduction in operation. But there are nuances because of which spears are breaking on the forums of the Internet gardeners. My thoughts on the topic, what can be lubricated with lubric.based lubricants, and what is not read in the article “Litol as lubrication of the motorcosa gearbox”.

How to lubricate the motorcosa gearbox, gasoline trimmer for grass

Side Bolt on 17 on the gearbox of a gasoline trimmer for grass

In order to avoid random launch, all preventive work on a motorcycle is necessarily carried out with a removed electric cap / plug from a candle. Do not turn the trimmer for the grass to avoid gas leakage.

We unscrew the side screw on the motorcosa gearbox. Depending on the company.manufacturer of a garden tool, instead of a screw for a hexagon, there may be a turnkey bolt, more often at 17. The thread is ordinary, unscrew counterclockwise. Do not lose the sealing puck.

If the lubricant is not visible on the internal end part of the screw, then it is necessary to add 3. 4 grams. Scroll through the gear with your hand, changing the direction of rotation so that the lubricant is distributed through the gears.

Then set the screw in place, tightly tightening it.

Control of the correctness of lubrication in the gearbox angular grinder

The last step during the maintenance of an angle grinding machine is to check the correctness of the application and distribution inside the gearbox of the lubricant. For this, after the gearbox is assembled, the power tool is included without load for several minutes, while there should be no extraneous sounds, smell and other things. If they occur, it is necessary to immediately turn off the angular grinder from the network. The heating of the gear unit is also checked. The lubricant should distribute heat evenly and the temperature of the gearbox should not be very high.

After short work, 4 screws are unscrewed, then remove the lid from the gearbox. Visually, the braid gears should be examined for their lubricants. If it is absent, then too small the amount of lubricant was laid and should be reported. If in the process of work it is squeezed out of the cracks, then it means it was laid much and excess should be removed. After making any changes, again check the operation of the corner grinder without load.

How to lubricate the gearbox of a trimmer for grass

Almost every motorcosa gearbox is equipped with a small technological hole, which in the mode of operation is drowned out by a special bolt. After thoroughly cleaning the node from the remains of grass and debris, it is necessary to unscrew the screw and enter the gearbox into the cavity of 1.5 to 3 ml of lubrication depending on the brand of the tool. For the convenience of dosage, you can use a traditional medical syringe. During the operation, it is impossible to allow foreign particles and objects inside the gearbox, since this can lead to intensive wear of the gear gear, as well as its jamming.

We examined all the oils of the STIHL line, and found out that the most popular lubricant for 2 strokes is Stihl HP. It is it that needs to be used in ordinary conditions, t. to. at the same time you do not have to overpay, and the engine will be reliably protected.

The saw chain, ordinary users, must be lubricated using Bioplus, t. to. The remaining options are intended for difficult conditions or work in the winter period. Also, we figured out that the correct ratio of gasoline with butter is 1:50, but during the period of the time it can be slightly changed and the mixture is made in a proportion of 1:40, t. e. 25 ml per 1 liter of gasoline. We learned how to distinguish the stihl bioplus fake from the original.

Gear lubrication of a trimmer for grass: selection criteria

During the operation of a gasoline trimmer for grass, the gearbox begins to make rattling sounds, which are a sign of a lack of lubrication, or loss of its properties. Of course, the owner may not attach particular importance to extraneous noises, but their ignoring will lead to jamming the gears and, as a result, the upcoming expensive repair. Therefore, in order to avoid the prerequisites for the appearance of a rattle, it is necessary to observe the lubrication of the gearbox of the trimmer for grass, recommended by the manufacturer.

Regardless of the manufacturer and model, the modern trimmer for grass is equipped with a gearbox for changing the angle of mechanical energy between the drive shaft and the head with a fishing line. The most widespread in the benzocos were conical gears, since, unlike straight.tooth, gears with screw teeth are able to carry huge speeds, have a more smooth clutch and have increased bearing capacity.

In the duralumin case (1) there is a shaft-shuster (2) and a gear conical wheel (3), pressed on a driven shaft (4). To reduce friction forces during rotation, rolling bearings (5) are installed at the support points of the shafts. Any gear gear is a highly loaded mechanism, whose duration and reliability of which depends primarily on the lubricant. Therefore, in addition to the main components of the trimmer gearbox, the trimmer reducer includes a special hole, through which you can grease bearings and gears without disassembling the assembly.

Lubrication of the shaft of the lawn mower, trimmer for grass

Dismantling the barn with a lawn mower (gasoline trimmer for grass) for lubrication of the shaft on the example of PRorab-8406 motorcycles. The extraction of a shaft from the bar is slightly different than shown on some videos on the Internet. Take into account when disassembling such devices.

First of all, we remove the lower part of the rod from the connecting coupling, and then disconnect the coupling from the upper part of the bar (here we are talking about a coupling connecting two halves of the bar).

Trimmer for PRorab-8406 grass with a detachable coupling and the lower part of the bar

Now the most interesting thing: on some videos, as on this, holding the ticks of the shaft with ticks, sticking out of the upper part of the bar from below, knock out it with blows on the rods from the rod along with the rolling bearing (here we are talking about the coupling connecting the upper and lower shafts). Some have a gas station with a collapsible bar, as in the video, a coupling connecting the upper and lower shafts, it is put into the rolling bearing.

With our trimmer Prorab-8406 and such a number will not pass like him. They do not have a rolling bearing, and the connecting coupling (sleeve) is a continuation of the shaft of the upper rod. A locking ring is installed in the upper part of this shaft, which must first be removed.

The place of fastening of the upper part of the bar to the clutch clutch body

- We turn off the central screw completely. It fixes the upper part of the bar, partially entering the hole drilled in it. We loosen the side clamping screws and remove the bar from the clutch clutch body.

- We put out the shaft from the upper part of the bar on ourselves how much the backlash allows to get to the stop ring and remove it. A special puller may be needed. We extract a locking ring.

Stop ring on the upper shaft Motokos

- Without a locking ring, the upper shaft is easily extracted from the bar from the opposite side. Lubricate it, not forgetting about the slots in the bushings (couplings) on the shaft of the bar and on the clutch shaft.

- The greased shaft is installed in place in the upper part of the rod and fixed with the locking ring. We insert the bar into the hole of the clutch clutch cover and combine the hole on the bar with the threaded opening of the fixing screw.

- We screw the fixing screw and fix the upper part of the trimmer rod for the grass with side screws in the clutch lid.

- Clean the connecting coupling of the bar from the garbage and install from below on the upper part of the bar.

I don’t have a puller, and I use two large stationery paper clips to extract a locking ring. Previously, they need to be straightened, on one side make a half.ring for the fingers, and on the other. bend small hooks.

We capture holes in the locking ring and try to push them apart. With difficulty, but it turns out, and the ring is afraid of. If you know another way to remove a locking ring without a puller, share in the Комментарии и мнения владельцев.

In many videos, masters recommend using lubrication for a clock, this is the best option. In its absence, to lubricate the shaft of the gas mowing rod, you can use lititol-24, which is focused on temperatures up to 130 ° C. But solidol, with the worst lubricants and working at temperatures up to 70 ° C, is not recommended to use.

However, if you urgently need to lubricate the shaft of the rod motorcosa, but there are no suitable materials, then solidol or even ordinary motor oil will be better than nothing at all.

Removing and lubrication of the lower shaft of the lawn mower

To extract the shaft from the bottom of the bar, we initially remove the coil gearbox.

- We unscrew the completely central fixing screw. On the back of the lower clamping screw, we turn the nut and unscrew the screw completely to disconnect the coil gearbox from the protective casing.

- Weaken the upper clamping screw and remove the lower part of the bar from the coil gearbox body. We take out the lower shaft from the bar from the gearbox side.

- Clean the shaft of pollution and grease it with a lubricant for a shred or lititol-24, not forgetting to clean and grease the coupling (sleeve) with slots in the gearbox.

- We install the shaft in the bar, and the bar in the lower gearbox of the lawn mower and combine the hole on the bar with the hole for the central screw. We screw the central screw. Next, wrap the lower screw, clamp the lower part of the bar in the gearbox body with the upper and lower screws and tighten the nut on the back of the lower screw.

- Add 20-30 ml of lubrication to the coil gearbox through a hole closed by a screw located in the photo on the right.

In the instructions for the operation of a trimmer for grass gasoline PRorab 8405m, 8406M, it is recommended to lubricate the gearbox with solidol or its analogues, in extreme cases pour liquid engine oil. Excess oil will flow out, since the gearbox does not have sealing oil seals.

In the guide of the user of a trimmer for grass gasoline PRORAB 8402R, 8403R, 8405R, 8406R it is written that the use of motor oil for two.stroke engines is allowed as a lubricant for the gearbox. There are no mention of solidol and his analogues.

In order not to bother, lubricate the lower gearbox with your lawn mower with the same grease as the shaft of the bar or fill the engine oil.