How to make a do-it-yourself snow blower from a grass trimmer

Step-by-step instructions for converting a grass trimmer

To make a snow blower with your own hands, you need to have welding skills. They will be needed to make a casing through which snow will fly out, removed from the tracks.

First you need to remove the circular knife from the grass trimmer, which is used for mowing grass in summer.

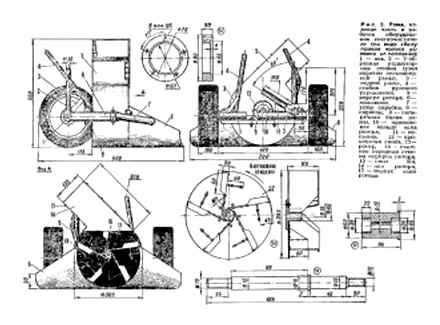

Diagram of a rotary snow blower from a grass trimmer with your own hands

To make a snow blower body, you need to cut a piece of about 150 mm from the beer barrel along with the bottom. Or build a structure from a piece of pipe or a sheet of steel bent into a circle and weld a cap-bottom to it on one side. A hole is made in the bottom. The hole diameter must be suitable for the overhang of the grass trimmer gearbox.

A wide square hole, about 100 mm in diameter, is made in the side of the cylinder through which snow will be thrown. Then a disc is made for the blades that transport the snow masses to the place of discharge. They are made as follows. blades are welded to a sheet of steel with a diameter slightly less than the bottom of the cylinder. As a disc, you can take a knife from a grass trimmer. The blades must be made at least four. They must be exactly the same size. Then you should weld them to the surface of the disc.

Benefits of a homemade snow blower

It may be necessary to create a snow blower from a grass trimmer when the first is available, but the second is needed. Modification will allow you to use the same garden tool for different purposes.

The main advantage of a homemade snowplow is its low manufacturing cost. There is no need to purchase a specialized unit. Homemade and / or purchased accessories are used to reorient the tool. Not every mower is suitable for converting into a snow blower.

Before starting this process, you should make sure of its feasibility. To do this, it is necessary to evaluate the characteristics of the existing automatic grass scythe.

Tips for operating a homemade snow blower

Warm up the engine and use seasonal lubricant before starting work.

Also follow some guidelines.

- Run your snow blower at full capacity.

- Eliminate unnecessary and frequent pressing on the gas, as this can damage the engine.

- Do not run over solid obstacles, do not try to break the ice.

After the completion of all work, the snow blower is cleaned and stored in a dry place. This will prevent it from breaking.

How to make a snow blower from a grass trimmer with your own hands

To work, you need the following tools:

- angle grinder and drill;

- metal sheets;

- steel barrel or pipe;

- welding machine;

- self-tapping screws, bolts.

The procedure for creating a homemade snowblower

- Start by creating a corpus. It is best made from a metal beer barrel, but if you don’t have one, you can use a large diameter pipe. Cut a piece 15 cm long, leave the bottom. The gearbox will be mounted on it.

- In the very center of the bottom of the pipe or barrel, you need to make a hole so that the working shaft of the grass trimmer will pass through. Place markings in the form of three points for attaching the gearbox and drill holes for bolts in their place.

- Make an exit (deflector). It is needed so that snow is thrown out of the snow blower. A hole is cut out in the body of the homemade product, with a diameter of 10 cm.Later, you will need to weld the pipe. But before that, cut out a workpiece in the shape of a semicircle from a metal sheet and weld one part of the front side of the case with it. Thus, the plug will not allow the spread of snow, but direct it into the deflector. It should also be located in the center front of the plug.

- Make a rotor (impeller) with which the snow will be collected. To do this, take a grass trimmer disc knife, and cut out four blades from the metal, each of which has a size of 25×10 cm.These blanks are welded to the disc knife cross-to-cross.

- Begin to complete work on the deflector. Attach the nipple to a hole in the body, which can be made of steel. The size of the tool should be 10 cm. Attach a knee of the same length so that the snow is thrown to the side. If the deflector is round, the elbow can be taken from a plastic sewer pipe.

- Next, a shovel is made from a steel sheet, measuring 30×40 cm.On its sides, the sides are bent, the height of which is 2 cm.The structure should be welded to the lower part of the tool body.

- The collection of parts begins with a grass trimmer. The gearbox is bolted to the bottom of the homemade product, and then the wings are put on the shaft. The handle of the snow blower can be the grass trimmer handle itself, you can also make a more comfortable design.

A snowplow from a grass trimmer with your own hands needs to be put on the frame, for which a special rectangle is made. From below, skis or ordinary wooden runners are attached to it, which will allow you to push the unit through the snow.

The final stage

DIY grass trimmer snow blower

The blade of a homemade grass trimmer snow blower is made from a sheet of steel with curved or welded edges about 2 cm high and welded to the bottom of the cylinder. You need to make it so that it matches the width of the bottom of the cylinder or fits it. Then all the snow mass from the scraper will fall into the snow blower.

To make the movement of the device from the grass trimmer convenient, it is worth welding the wheels or runners on the sides to it. Wheels can be attached from both sides to a crossbar welded to the rear wall of the cylinder.

Then the structure is connected to the trimmer using bolts. self-tapping screws and welding in such a way that the gearbox starts the rotation of the blades.

At this stage, the manufacture of the snow blower is considered complete.

Tools and materials

The set of tools required to make a snow blower may vary depending on the chosen path to achieve the goal. Some homemade modifications are not reusable, while others are intended for permanent use.

Minimum set of tools:

- angle grinder;

- drill and drill;

- welding machine;

- hammer, pliers, wrenches and others.

an angle grinder is necessary for cutting out the necessary parts from metal and their subsequent processing: grinding, cleaning, sharpening. Drill. for drilling holes for fasteners: bolts, rivets, clamps. The inverter is needed to weld all structural elements together.

- sheet metal (thickness varies depending on the chosen design);

- pipe sections: metal, plastic;

- bolts, nuts, washers;

- metal clamps.

The drum body, blades and cleaner bucket are formed from metal sheets. The pipe is necessary for arranging a directional snow discharge. Through it, the jet is ejected. Fastening threaded accessories are needed to fasten parts of a collapsible structure. Clamps can be used to attach the harvesting attachment to the grass trimmer bar.

Mounting the auger and rotor on the snow blower

On the listed steps, the manufacture of a snowplow from a grass trimmer does not end. In the future, you have 2 options. mounting the auger or installing the rotor. Let’s consider each of them separately.

The grass trimmer auger snow blower works like a household meat grinder. The only difference is that in the kitchen appliance the worm mechanism pushes the meat to the knives, and in the snow blower the auger pushes the snow towards the snow deflector. The advantage of this grass trimmer snow blower is that it can throw snow over a distance of more than three meters. In addition, with the help of augers, it is possible to get rid of thin ice and heavy wet snow masses. It is impossible to make a screw with your own hands, since this requires special turning equipment. It is best to purchase a ready-made assembly from another snow blower.

DIY leaf blower attachment for grass trimmer

In a rotary snow blower, the rotor is responsible for clearing snow, the function of which is to generate an increased centrifugal force. After the snow passes through the branch pipe, it is thrown up to a distance of 6 meters. However, such a grass trimmer snow blower cannot be used to clear ice from an area. over, it is unsafe for the machine itself, since ice particles hitting the rotor blades of the snow blower severely damage them. At the same time, it is much easier to make a rotary snow blower from a grass trimmer than an auger unit. The rotor can be taken from any utility unit equipped with a gasoline engine, and at the end of the winter season, install the part back.

Whichever option you choose, be sure to keep in mind that a homemade grass trimmer snowplow is not very powerful. Therefore, if you do not want to harm the engine, do not overload it and make sure that snow and moisture do not get inside it.

Snow Blower Assembly Manual

Not every grass trimmer is suitable for making a snow blower. If the farm has an electric or lawn mower with a curved bar, in which torque is transmitted to the knife by a flexible cable, then the conversion process does not even need to start. The fact is that such trimmer models are low-power. The performance of the snow blower will be weak and the engine will constantly overheat.

A good snow blower will come from a powerful grass trimmer with a straight boom. For such an electric or gasoline scythe for grass is characterized by the transmission of torque to the knife through a rigid shaft and a gearbox.

The device of snow removal equipment is simple. The working element is a nozzle, which is placed instead of a knife. It is an impeller with blades. For the manufacture of this part, you need steel with a thickness of 1.5 mm. The impeller must be placed in a casing. a snail. For its manufacture, a large-diameter pipe segment is taken, usually within 300 mm.

Converting a grass trimmer with your own hands into a snow blower will do without complicated drawings, but at least the simplest diagram should be at hand. It will help create a general understanding of the design.

Now let’s take a step-by-step look at how to make a do-it-yourself snow blower from an electric or brushcutter:

- Snow blower manufacturing begins with the body. If you are lucky enough to get a beer barrel, then you need to cut off a piece of 150 mm long from it. The workpiece is needed together with the bottom, as the grass trimmer gearbox will be fixed on it.

- A hole is drilled in the center of the bottom. Its diameter should be enough to allow the grass trimmer to pass the working shaft, on which the impeller attachment will be put on. Around the large hole, mark the mounting points of the gearbox. Usually there are three points. Bolt holes are drilled according to the marking.

- Now for the snow blower you need to make an exit. a deflector through which snow will be thrown out. A hole is cut in the side shelf of the case. It can be made square or round as you wish. The hole diameter is 100 mm. The branch pipe is welded to it later. And now you need to cut a blank in the shape of a half circle from a sheet of steel. This plug is used to weld 1/3 of the end of the face of the snail body. The plug will prevent snow from flying out of the snail forward, but will direct it into the deflector. The vent hole should be centered on the front cover.

- Next, you need to make a rotor for the snowplow, that is, the impeller itself, which will throw snow. It is based on the grass trimmer’s circular blade. But first, four blades of 250×100 mm are cut out of steel. The workpieces are made ideally the same size to avoid imbalance. Finished blades are cross welded to the disc.

- Now it’s the turn to finish the deflector. The hole on the body is already ready, now you need to fix the pipe to it. It can be bent out of galvanized steel. The branch pipe is made 100 mm high and welded to the body. A knee is fixed to it of a similar length so that the snow is ejected to the side. It is better to make the deflector round. You don’t have to make a knee on such a pipe. It can be taken from a plastic sewer with a diameter of 100 mm.

- The last piece left to make is the guide vane. It is cut from a sheet of steel. You should get a workpiece with a size of 300×400 mm. On the sides, the sides are folded with a height of 20 mm. The finished blade is welded to the bottom of the body from the front side.

- All parts of the snow blower are ready, it remains only to assemble them into a single structure. First, the grass trimmer gearbox is bolted to the snail. A shaft comes out inside the housing. They put on a homemade nozzle with blades.

A do-it-yourself snow trimmer from a grass trimmer will be considered ready when the rotary structure is installed on the frame. It is enough to weld a regular rectangle from the corners. Wooden runners are fixed to the frame from below. On skis, it is easier to push the snow blower through the snow. The control handle is the native grass trimmer bar.

The video shows an example of a snow blower from a grass trimmer:

What is better to attach to the trimmer: auger or rotor

When making a snow blower from a grass trimmer, there are two options for installing the working mechanism: the auger and the rotor. Let’s look at what is the difference between the designs, as well as their positive and negative sides.

Converting a grass trimmer to a snow blower

The device of such a homemade product is so simple that you do not have to build complex drawings and grind out details. You just need to make an impeller, which is attached to a grass trimmer instead of a knife, and place this whole structure in a casing.

Auger mechanism

In terms of efficiency, the auger outperforms the rotor. The mechanism consists of screw circular knives. As they rotate, they cut even stale, wet and icy cover. The spiral turns move the collected mass towards the center of the body, where the blades push it through the deflector. If you connect such a nozzle to the trimmer, it will be able to throw snow to the side at a distance of up to 3 m. However, it must be taken into account that the auger mechanism creates a large load on the engine. This is especially true when removing hard snow. Only a powerful grass trimmer can be used with this attachment.

How to make a snow blower from a grass trimmer blueprints

Rotary mechanism

The advantage of the rotary mechanism is the ease of assembly. After all, the mechanical part practically remains native. The impeller is made of a circular blade that fits to the grass trimmer head. The range of snow throwing for such a design can reach 6 m.

The disadvantage of the rotor is its use only on loose and freshly fallen cover. Wet snow will stick in the snail, and pieces of ice can wedge between the blades.

The mechanical part of the snow blower can be chosen as you wish. But in any case, you must remember that the grass trimmer is not designed for such a heavy load. The engine must be taken a break during operation so that it does not overheat.

Steps to create a grass trimmer snow blower

The creation of a snowplow is as follows:

- Before starting work, make up a diagram according to which the assembly will take place.

- You need to make a snow trimmer body for your grass trimmer. It is convenient for him to use part of a barrel or an old gas cylinder. The pipe is less convenient, since the bottom will have to be welded onto it. It is necessary to cut off such a piece so that the edge length is 150 mm.

- The place where the center is located is determined on the part made. A hole is drilled in it. Its diameter should be 2-3 mm larger than that of the shaft.

- Several additional holes are made around the main one. In most cases, three is enough.

- It is necessary to provide for the presence of a deflector, which is necessary for throwing snow. It is installed on the side of the device. A round hole with a diameter of 100 mm is made here. It is cut out by welding. Weld a branch pipe made from a piece of pipe, having a length of 100 mm.

- Cut half a circle out of a sheet of steel. It is welded on the side of the deflector. The radius should be one third of the body diameter.

- For the rotor, a sheet of steel with a thickness of 1.5 mm is used. This is a round piece that must rotate inside the body. 4 blades of such steel are welded to the sheet, having a size of 100×250 mm. They must be perpendicular to the surface.

- Make the abduction knee. It is bent from galvanized sheet and put on the deflector branch pipe.

- A blade is mounted in the lower part of the body. It is a round piece that must be welded on one side. The shovel will pry off the snow and send it to the rotor.

- The snow blower is being assembled. To do this, the brushcutter’s body, the impeller and other parts are bolted to the gearbox with bolts. Then skis or wheels are installed. Scroll, checking for free play.

Required tool

To make a snow blower from a grass trimmer with your own hands, not every device is suitable. It must meet the following conditions:

- If a device with a weak motor is selected, then it will be very hot. It makes sense to rework if the power of the grass trimmer is at least 1.6 kW.

- What matters is the design of the barbell. It should be straight. If the bar is bent, then it will not fit.

If you have a suitable grass trimmer available, you can start converting it. In order to make such a mechanism, a special attachment for the snow blower for the grass trimmer is created. It is used as a working head. The nozzle is a round part, inside which knives or blades rotate.

Homemade TRIMMER Scooter / DIY

For the case, you can use a piece of pipe with a diameter of 300 mm, part of a metal barrel or part of an old gas cylinder. It is necessary to stock up on sheet steel with a thickness of 1.5 mm. For the nozzle to work, it must be equipped with wheels or skis, so that it is convenient to move during operation.

To make a homemade snow blower from a grass trimmer, you will need: a welding machine, an angle grinder, a drill with drills, a hammer, wrenches, pliers, screws and bolts. Snow blower parts may also be needed.

DIY grass trimmer snow blower

Making a snow blower with your own hands is not difficult if you have a grass trimmer, the necessary tools and materials. In this case, a grass trimmer snow blower will cost almost nothing. The device can be manufactured in just a few hours. If everything is done carefully, then such a snow blower will last for many years, although, of course, it will not replace a gasoline snow blower.

Advantages and disadvantages of the device

A self-made snow blower will allow you to conveniently clear snow in the yard. This device will be ineffective in a small yard or where the surface has a complex shape. It is convenient to use if the area is spacious and flat.