How to Test a Magneto Coil with a Multimeter. Lawn mower coil tester

How to Test an Ignition Coil

This article was co-authored by Rocco Lovetere. Rocco Lovetere is the Owner and a Master Mechanic at Rocco’s Mobile Auto Repair in California. With over 20 years of experience, he specializes in Honda, Acura, Toyota, Nissan, Infiniti, and Volvo cars. He is an ASE Certified Automotive technician and has worked in automotive repair since 1999.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, several readers have written to tell us that this article was helpful to them, earning it our reader-approved status.

This article has been viewed 762,874 times.

The ignition coil, a vital component of any vehicle’s ignition system, is responsible for providing electricity to the spark plugs. When a vehicle will not start, misses often or stalls frequently, its ignition coil may need replacement. Luckily, a relatively quick, simple test can determine whether the ignition coil is functioning properly and thus whether a trip to the auto parts store or mechanic’s garage is warranted. See Step 1 below to get started!

Performing an Ignition Coil Spark Test

- One sure-fire way to find the ignition coil is to locate the distributor and follow the wire that does not connect to any spark plug.

- Before beginning, it’s very wise to ensure you’re wearing safety goggles or other eye protection and that you have access to insulated tools (especially pliers) to protect from electric shock.

- If your vehicle has been running for a while, its internal components are likely to be very hot. A car that has been driven for as little as 15 minutes can heat the engine to around 200 degrees. Allow the car to sit and cool for an hour to prevent significant injury.

- To save time and avoid potentially damaging your spark plug, consider using a spark plug tester instead. Instead of attaching the spark plug back to the wire, attach the spark plug tester to the wire. Ground the alligator clip. Then skip ahead and have your friend crank the engine, watching for sparks in the tester’s gap.

- Using a spark plug tester also means you won’t expose your combustion chamber to debris.

Fastest Way to Check a Coil (Magneto) on Older Small Engines

- From this point forward, be careful not to let anything drop into the empty hole left where your spark plug was. Leaving debris in this hole can cause damage to the engine as the vehicle runs and, since removing anything from this hole can be a big pain, it’s best to take preventative care to ensure nothing of the sort happens.

- Cover the cavity with a clean rag or towel to prevent debris from entering the combustion chamber.

Attach the spark plug back to the spark plug wire. Now, carefully reattach the spark plug to its wire. You should be left with a spark plug that’s connected to the distributor but not seated in its “hole.” Handle the spark plug with insulated pliers to avoid the possibility of electric shock.

- Again, hold the spark plug carefully with insulated pliers (and, if possible, gloves). Don’t risk electric shock in the next few steps by neglecting this simple safety measure.

- Failing to remove the fuel pump relay means cylinder being tested will not fire because there is no spark plug. It will, however, still be flooded with fuel, which may cause serious damage.

- Check your manual to locate the fuel pump relay.

Have a friend “crank” the engine. Get a friend or assistant to turn the key in the vehicle’s ignition. This will provide power to the car’s electrical system and, thus, to the spark plug you’re holding (assuming your ignition coil is working)

- Orange sparks are a bad sign. These mean that the ignition coil is supplying insufficient electricity to the spark plug (this can be for any number of reasons, including cracked coil casings, “weak” current, faulty connections, etc.).

- The final possibility you may observe is that no spark occurs. This is usually a sign that either the ignition coil is completely “dead,” that one or more electrical connections are faulty, or that you’ve done something wrong in your test.

Performing an Ignition Coil Resistance Test (“Bench Test”)

- Refer to your service manual for precise instructions on removing your ignition coil. Usually, you’ll need to disconnect it from the distributor wire, then unscrew it from its mounting with a wrench. Ensure your vehicle is turned off and has had a chance to cool before beginning this process.

- Generally speaking, most automotive coils will have a resistance reading of about.7. 1.7 ohms for the primary winding and 7,500. 10,500 ohms for the secondary winding. [1] X Research source

- Note that some newer models of ignition coil have contact configurations that differ from this traditional arrangement. Consult your vehicle’s manual for information if you are unsure which contacts correspond to the primary winding.

Position the leads of the ohmmeter on the poles of the secondary coil. Next, keep one lead on one of the outer contacts and touch the other to the central, inner contact of the ignition coil (where the main wire to the distributor connects). Record the resistance reading. this is the resistance of the coil’s secondary winding.

Determine whether the readings you recorded fall within your vehicle’s specifications. Ignition coils are delicate components of a vehicle’s electrical system. If either the primary or secondary windings are even a little outside of your vehicle’s specifications, you’ll want to replace your ignition coil, as your current one is likely damaged or malfunctioning.

Expert QA

Aftermarket ignition coils are built to different specifications and tolerances that can affect the performance of the ignition system. Always choose high quality replacement parts.

If you do not see sparks, check the output on a voltage/ohm meter. The primary coil should produce readings between 0.7 and 1.7 ohms.

You Might Also Like

How to Fix an Ignition Key That Doesn’t Turn

How to Disconnect a Car Battery Like a Pro

Ignition Switch Replacement: An Easy-To-Follow Guide

About This Article

This article was co-authored by Rocco Lovetere. Rocco Lovetere is the Owner and a Master Mechanic at Rocco’s Mobile Auto Repair in California. With over 20 years of experience, he specializes in Honda, Acura, Toyota, Nissan, Infiniti, and Volvo cars. He is an ASE Certified Automotive technician and has worked in automotive repair since 1999. This article has been viewed 762,874 times.

The ignition coil in your vehicle sends electricity to the spark plugs, and you might need to test the coil if your vehicle isn’t starting or frequently stalls. You can usually test your ignition coils by plugging a diagnostic machine, like an ODB2 scanner, into the port underneath the dashboard and turning it on. On most scanners, a code P0352 indicates that your coils aren’t working correctly. If you don’t have a diagnostic tool, you can remove the coils to test them instead. The ignition coils in your vehicle should be located on the right side of the engine, next to the spark plugs. Remove the cables from each spark plug, then unscrew the first ignition coil carefully and lift it out of the engine block. To test the primary resistance on the coil, grab a multimeter and attach the positive probe to the positive terminal on the coil. Then, attach the negative probe to the negative terminal. Set the multimeter to 200 ohms in the resistance category and take the reading. Typically, the primary resistance should be somewhere between 0.4-2 ohms. Next, check the secondary resistance by moving the negative probe to the metal piece that connects the coil to the spark plug. Generally, the secondary resistance should be between 6,000-8,000 ohms. If either reading is off, that means your coils likely aren’t working properly. Look up your vehicle’s ignition coil requirements online since the ideal level of resistance for each reading can vary by vehicle. For tips from our mechanic reviewer on performing a resistance test, keep reading!

Reader Success Stories

“I wasn’t sure how to test my car’s coil, although I suspected that it was the issue. This article walked me through the steps in such a way that I feel confident now in how to perform the needed steps. Thanks!”. ” more

How to Test a Magneto Coil with a Multimeter?

In this post, you’ll learn how to test a magneto coil with a multimeter and evaluate its efficiency.

If you have a magneto-based ignition system in your motorcycle or lawnmower, with time, you may face a low spark in the plug, causing failure in ignition. It indicates a fault in the magneto, and it’s time to examine your magneto coils.

A vehicle cannot produce enough spark required for ignition, or there is no spark.

Lack of acceleration as the engine loses power.

The dashboard engine check light glows.

How to test a magneto coil with a multimeter?

We measure resistance between different components of a magneto coil using a multimeter. The purpose is to evaluate the efficiency of magneto coils and wires if they produce current and carry it to the spark plug for ignition.

To test a magneto, you should have a multimeter and the recommended resistance range of your magneto model to compare with the multimeter readings.

There are three components on the magneto coil that you have to test in different ways.

- The metallic core is an A-shaped iron frame.

- A kill switch terminal is a small piece of metal coming out of the rubber casing of the coils. The kill switch is grounded with kill wires to shut down the magnetic field and spark.

- HT lead or spark plug cable that carries current from the secondary coil to the spark plug for ignition

Test 1: Primary coil or kill terminal test

The first test is carried out on the magneto coils’ metal base (iron core) and the kill switch terminal.

Set up multimeter

Set your multimeter to the resistance mode and adjust the range in ohms. You can also adjust it for auto-ranging. Auto range resistance setting will measure any readings between ohms and kilo-ohms.

Connect probes to testing points

Turn on your multimeter. Attach one probe of the multimeter anywhere on the coil base (iron frame). Put the other probe on the kill switch terminal.

You can place any probe on either component because resistance is non-directional.

To get an accurate reading, you can use an alligator clip at the end of probes to firmly hold the components of the coil.

Evaluate Readings

If the multimeter reading is constantly changing, it could be due to layers of rust formed on a component, hindering a good connection. Remove it by scratching the rusted part with a pin or metal.

If the multimeter displays OL, there is no continuity in the coil base and the kill switch. It could be due to a blown-up magneto or a short circuit. In such cases, the only option is to replace it with a new one.

Compare readings with the recommended range.

Compare the multimeter reading with the resistance range of your specific magneto model.

Coils in different engines will have different resistance ranges, and you can find your magneto model resistance in the manufacturer’s manual.

If the multimeter measures resistance below or above the range, your coils are not efficiently working.

Usually, a primary working coil will have 2-8 ohm resistance, but a good coil will have 3-5 Ω resistance.

Test 2: Secondary coil resistance test

This test is carried out to measure the efficiency of the secondary coil components. We measure resistance between the iron base of the magneto coil and the end of HT lead, going from the secondary coil to the spark plug.

Multimeter Setting

Please turn on the multimeter and set it to the resistance setting in the kilo-ohms range. As the secondary coil is larger in terms of size and producing current, that’s why its resistance is also higher as compared to the primary coil.

Probes Connection

Attach one probe to the magneto iron core (metal base) and the other probe to the end of the spark plug wire inside the cap.

Read and Compare Multimeter Readings

If the multimeter displays OL, there is no continuity, and the current cannot flow to the spark plug due to a short circuit or dead component.

If the multimeter shows a continuously changing value, try to scratch the probe inside the spark plug cap and on the iron core to remove rust. Unstable reading is due to rust hindering a proper connection in probes and components or the windings are loose.

After measuring the resistance between the spark plug and the iron core, detach the probe from the iron core and place it over the kill wire terminal. This resistance must be the same as in the previous reading.

Evaluate Multimeter Reading:

After you get resistances, compare it with the resistance range of your magneto model, available in the manufacturer manual; otherwise, you can find it online.

A working secondary coil will have a resistance between 2-15 kΩ. While one having resistance between 3-8 kΩ is considered a good coil. A coil with resistance above or below the range might be overused, rusted, or faulty.

This is how we test a magneto coil to evaluate its efficiency in producing current and carrying it to the spark plug for ignition.

What is a magneto?

A magneto is a small generator in the engine that produces pulses of high-voltage alternating current, which is used in ignition through the spark plug.

A fixed magnet on the rotating flywheel generates a changing magnetic field that drives electrons in the magneto coils and produces current.

Magnetos are mainly used in piston aircraft engines, tractors, marines, lawnmowers, and motorsports like snowmobiles and motorcycles.

How does magneto work?

Structure and Components of Magneto

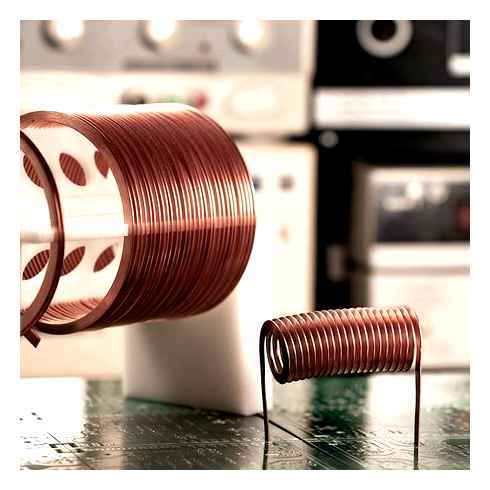

A magneto coil consists of two copper wire coils. The first one is a primary coil made of around 70 loops of thick wire.

Over the primary coil is a large secondary coil made of thin wire and thousands of loops. Both coils are fixed around an iron core, and each component is.

The primary and secondary coil in magneto is essential in generating a current that is used to produce a spark and acts as a transformer.

Also, there is a tiny insulated trigger coil, also known as an initiator, made of copper windings wrapped around a small iron piece.

Each time the rotating magnet passes through the trigger coil, the magnetic field pushes electrons of the coil toward the primary coil.

Working of Magneto

As we start the engine, a magnet fixed on the flywheel rotates with it, and each time the magnet passes the electronic coil, it generates an electric charge.

The flywheel rotates quickly, and the magnet passes the trigger coil multiple times a second. The trigger coil also feels the magnetic field from the rotating magnet.

Each copper atom has a free electron, and a wire consists of billions of atoms, which means billions of free electrons in a wire; that’s why copper is an excellent conductor.

A magnet attracts the free electrons and pulls them in a uniform direction.

As the identically charged particles repel, the free electrons in the coil will repel each other. Each time magnet passes through these electrons. Its magnetic field will drive electrons in a uniform direction. The motion of electrons produces an electric current.

After the current moves from the trigger coil to the primary coil, it generates a magnetic field. The magnetic field in the primary coil also influences the secondary coil.

As a result, the flow of electrons in the secondary coil increases multiple times due to its larger size. This is how the magneto acts as a transformer by magnifying a low voltage in the primary coil to a higher voltage in the secondary coil.

From the secondary coil, the current is carried to the spark plug via HT (high tension) lead. All processes repeat when the flywheel rotates, and the magnet comes near the coils in each rotation.

This is how flywheel magneto generates pulses of high voltage alternating current for the ignition system.

How to test a magneto on a motorcycle?

First, check if there is a spark in the spark plug. Remove the spark plug, insert a screwdriver tester inside the spark plug cable and put your finger on top. Crank the bike engine(run). If the spark plug has a spark, the tester screwdriver will light(glow). Now we’ve to check the motorcycle coil.

We perform a resistance test using a multimeter to test a motorcycle magneto. Remove the plug/connector from your motorcycle coils’ power and trigger lead.

Set the multimeter to resistance mode ‘Ω,’ and connect both probes to power and trigger terminals on the coil. If your motorcycle coil(magneto) is fine multimeter should read 3-5 ohms.

Now set the multimeter to kiloohms and connect one probe to the power/trigger terminal(lead) and the second probe inside the spark plug (inside the spark plug cap).

A fine magneto should read around 10 kΩ between the power/trigger lead and the spark plug. If the multimeter displays OL or 1, it means there is no continuity, and it is a reason for no spark while ignition.

FAQs

How do I know if my magneto is bad?

If your bike engine cannot produce enough spark required for ignition, or there is no spark, it’s a symptom of a bad magneto.

A faulty magneto generates a low-power spark or cannot carry to the spark plug due to a damaged or burnt component, short circuits, or faulty wiring in the coil or the spark plug cable.

Is a magneto AC or DC?

A magneto coil is a mini generator in engines that produce pulses of alternating current due to a continuously changing magnetic field.

Magneto is used to provide ignition power instead of auxiliary power to operate lights and other heavy loads such as air conditioners or cooling fans.

What is the difference between a magneto and a.c generator?

Magneto and AC generators produce current, but their working principle differs. In a magneto, a fixed magnet on a flywheel rotates around the coils to create a magnetic field, generating a current.

Inside an AC generator, a coil rotates around a magnet to produce a constantly changing electromagnetic field, converting mechanical energy to electric current.

What does a condenser do in a magneto?

A condenser is a capacitor in a magneto coil that prevents power loss when current passes from one component to another and also aids in collapsing the magnetic field.

Conclusion

If you are facing issues in your vehicle’s ignition, you have to test magneto coils, as they are responsible for producing sparks for ignition.

Generally, we use a multimeter to measure resistance between the magneto components. By measuring resistance, it’s easier to determine the functionality of magneto and the condition of winding and secondary wires in coils.

Hopefully, this post was helpful to you in understanding how to test a magneto to measure its efficiency and how a magneto works to generate current.

How To Test a Spark Plug on a Lawn Mower: A Complete Guide

How to test a spark plug on a lawn mower can be a useful skill to acquire for anyone. First, it is a straightforward procedure that barely takes an hour to accomplish. Second, if you learn how to test spark plugs on lawnmowers, you can also test plugs on all vehicles.

Read our complete guide below to learn the steps and the various methods of testing these plugs on a lawn mower.

What Are the Steps To Test a Spark Plug on a Lawn Mower?

The steps to test a spark plug on a lawn mower starts with preparing the equipment and turning off the mower. Once your lawn mower is off, take the spark plug out after cleaning it, and then use either the visual method or the millimeter method to test it.

You can also try out the tester method, which doesn’t require the removal of the plug.

Prepare the Equipment You Will Need

If you own a lawn mower or any other vehicle, you will inevitably have to test its spark plug. That is why investing in spark plug testing equipment is a worthwhile investment. If you want to avoid purchasing them, they can also be borrowed from a nearby hardware store.

- A standard spark plug wrench is a must-have tool because these cannot be unscrewed using regular wrenches.

- It helps to have a spark plug wire puller because pulling by hand might require a bit of force.

- You will need ordinary wrenches for removing the external covering of the plug and other related equipment.

- You need insulated pliers if you test the plug without using a millimeter.

- A multimeter is optional but recommended for proper testing of mower plugs.

- You will also need paper towels, rags, and grease cleaners for cleaning the equipment.

Get the Plug Removed First

Removing the plug from a mower involves more than just taking it out. You must follow a standard procedure for your safety and the machine’s health.

- After turning the mower off, disconnecting its battery is the next step. Loosen the nut that connects the ground wire to the battery’s negative terminal using an appropriately-sized hand wrench. After this, you can leave the positive wire without removing it.

- Next, expose the plug, often located behind the air filter, and disconnect its wire. Removing the spark plug wire might require a little bit of controlled force and will come off with a pop.

- Cleaning the area around the plug is important before taking it out. Otherwise, all the dirt, grit, grime, and oil accumulated around it will fall through the hole created by the plug’s absence into the mower’s engine system. This debris might damage the mower engine, and you might find that the mower won’t start the next time you try.

- Finally, use a spark plug wrench to unscrew it from within the mower. Any regular wrench cannot remove this. These plugs come only in one size, so that a standard plug wrench will remove all kinds of spark plugs.

- Rotate the plug with its socket by rotating the wrench in a counter-clockwise motion. If it is still hot, put it aside until it cools down for inspection and testing.

Look for Signs of Physical Damage

First of all, test the plug to make sure that it has not incurred physical damage. A normal plug should appear light grey or tannish when held to a light source. It should not have any product build-up occurring on its surface.

Another important thing to look for here is the spark plug gap, which is the distance between its side and center electrodes. A plug gap determines the voltage needed to produce the spark that will ignite the engine.

Quick tip: testing coil (magneto) on a lawnmower with multimeter

Standard mower spark plugs should ideally have plug gaps between 0.02 to 0.035 inches to produce the perfect spark in the ignition coil. You will have to purchase a plug gauge for measuring this gap and if the gap is insufficient, adjust it accordingly.

Check for Signs of Carbon Fouling

When a fuel with a skewed air-fuel ratio is used consistently to power a lawn mower, you risk developing carbon fouling on its spark plug. Using a relatively higher fuel ratio can lead to carbon deposits solidifying all over the surface of the spark plug. This cannot be left as it is because it eventually starts impairing the plug’s hardware.

You do not need to worry much because carbon fouling can be easily removed using a brake cleaner and a rag. Have a serious conversation with your gas pump owner about the quality of the fuel being supplied to you.

See if the Plug Is Wet From Oil

Whenever oil leaks occur from a mower tank, the oil is bound to trickle down the engine all over the spark plug. You can wipe these off using rags and oil-removing cleaners that can easily be ordered online. You must complete this step so that this oil will leak into the engine once you take the plug out.

Within the engine’s parts, it can block channels and attract grime to solidify. This oil clogging would severely damage the engine in the long run. As for the oil leakage, you will have to see where it is happening and how to fix it.

Look for Signs of Burns or Wear

It is important to rule out signs of burns or wear on a plug because, in that case, it will have to be replaced by a new one. Blisters will appear on the insulator tips when this equipment has been burned due to overheating issues.

Other hard-to-miss signs of a burnt plug are molten plastic and burnt metal. A burnt insulator also means that your mower is overheating and its insulation needs to be fixed.

When a plug has been used for a long time, you need to say goodbye to it eventually. If the plug has been used for years, it will fall apart while removing it from the mower. It will also appear visibly worn, broken, and ready to be removed.

Test the Plug Without a Multimeter First

If you want to test a plug’s functioning without using a multimeter, it is better to call in a friend for help. While the plug is still removed from the mower, reconnect it to the ignition wire of the engine. Next, ground the spark plug by connecting its threads or porcelain coverings with insulated hand pliers.

Now ask your friend to turn the engine over carefully and very slowly. You will not be able to achieve it yourself if your mower is ignited by pulling a starter robe or turning the key. Look out for bright blue sparks produced in the plug after turning the engine.

There are better methods to test a plug than this, so you must be very careful when doing it. The insulation on your grounding pliers needs to be in perfect condition, and you must not touch the plug with bare hands.

Test the Spark Plug Using a Multimeter

A lot of people need help with using a multimeter. After reading the step-by-step guide below, you will see how easy reading a multimeter is.

- Make sure to choose the right setting on your multimeter before starting and set it to ohms, which is the unit for measuring resistance. Some multimeters represent ohm by its greek symbol Ω while others will have OHM written in the settings. You can set the multimeter’s dial to 10, 20, or higher ohms per your wishes.

- Check to see no resistance between the two probes of the multimeter. When you touch the probes together and the resistance drops to zero, you know that your meter will give an accurate reading.

- Look for a metal tip emerging from the spark plug attached to the terminal. Take one lead of the multimeter and set it against this metal tip.

- The tip of the second multimeter lead needs to touch the spark plug’s electrode. This electrode is the part of the plug that sticks slightly out of its porcelain sheath on the side facing the engine. To get an accurate reading, the probe needs to rest on the flat tip of the electrode instead of its cylindrical part.

- Turn the multimeter on to see what reading your spark plug gets. The result will be represented in ohms in the ones or tens but represent the thousands. A healthy and functioning lawn mower spark plug should read between 5,000 to 15,000 ohms.

- For example, if your multimeter gives a reading of 6.0 ohms, then this means that the actual reading is 6,000 ohms, and your mower is in perfect functioning condition.

Test the Spark Plug With a Tester

You can also test a potentially faulty spark plug without removing it completely from the lawn mower. Buy a spark plug tester and follow the steps given below to carry out this testing.

- Start by turning the lawn mower ignition off and taking out its key. Then gain access to the spark plug by removing its protective covering on the side of the mower.

- One end of the plug tester is to be attached to the ignition wire of the mower. The other end must be attached to the spark plug without disconnecting it from the engine.

- Try putting the key back in and starting the ignition, then turn the engine on again and look at the tester’s transparent sides. A noticeable glow or spark should appear on the sides if the spark plug is working.

Be Aware of Safety Precautions

No matter how often you have done this, never compromise your safety while handling electric equipment.

- Start by putting on thick insulating rubber gloves and eye goggles.

- Always turn the engine off and disconnect the spark plug first because you do not want to give yourself a bad electric shock, trust us.

- Make sure that you wait for the engine to cool down fully after it has been turned off. This might take longer in summer, but it is always worth the wait. Accidentally touching a hot plug or engine component is not good for its health and might cause burns if you are not wearing gloves.

- Never make the mistake of directly touching a spark plug while the mower’s engine is still running. With an electric current of around 20,000 volts running through it, this can lead to lethal consequences.

- Never put your hand near any equipment that is still moving in any capacity.

Conclusion

Before you go, it is important to recap this step-by-step guide on how to test a lawnmower spark plug.

- Don insulating gloves and turn the small engine of the mower off before starting the testing in order to prevent getting electrocuted.

- Remove the plug from its assembly within the mower, which can be done using only a single standard plug wrench.

- Carefully inspect your plug to see if it is physically damaged or has carbon fouling because such a plug will have to be removed.

- You can test the plug using a multimeter, without a multimeter, or through a plug tester.

- The range of voltages exhibited by a multimeter should be between 5,000 to 15,000 ohms.

Testing the engine spark plug should be your number one priority when a lawn mower problem arises. In only a few simple steps discussed above, you can determine whether or not the problem lies in the spark plug and if there is any need to replace it.

Lawn Mower Ignition Coil Test With Multimeter

There are many helpful uses of multimeters around your house and while many of these are typically used on your vehicle or in your home, it is also very useful for smaller engines you use including your lawnmower.

If you have ever tried starting your lawn mower and pulled that cord over and over without any luck, it could mean many different things including a fault with fuel/oil, the induction coil, or the spark plug.

Checks before testing the ignition coil

After eliminating things like oil and gas being present and that the cord is connected to the spark plug, wait 10 minutes after you’ve tried starting it and then try starting it again as an initial troubleshooting.

If it still won’t start, before you begin testing the ignition coil, it’s important to first check the spark plug to eliminate that as an issue.

Before you start the next steps, it’s important that you wear leather work gloves to protect your hands from different parts of the engine that may be sharp or spark.

Spark plugs

Often get dirty and worn down over time. If you’ve been using the same spark plug for a while, you may want to pull it out and check for different signs of problems with your lawnmower. Removing the spark plug is easy by using a socket wrench and twisting it out.

If your spark plug has some light-brown deposits on it, it means it’s normal. If you see black carbon deposits then it’s a sign that the fuel-to-air mixture is too rich and that your carburetor has an issue. Safe to say if you know you’ve had the same spark plug for the past year in your lawn mower, it’s time to change it.

You can also use a spark plug tester (purchased in most auto stores) which you can replace the spark plug with and try to pull the cord of the lawnmower to start it.

If you see a spark appear in the tester, you know that the lawnmower is in good condition but the spark plug was faulty and it’s time to replace it. A spark plug tester is an easy way to check that.

What is an affordable multimeter to test this on?

There are many great multimeters on the market and if you’re looking for the best brand, then the Fluke brand is definitely the one to go for. The Fluke 116, Fluke 117, and Fluke 87V are some of the best on the market.

If you are looking for a good multimeter that’s a bit more affordable, then I would instead suggest the Innova 3340 which is a much better choice for DIY and homeowners.

Testing your ignition coil by using a multimeter

After you have ensured the spark plug is not an issue, it’s time to check on the ignition coil.

Make sure you continue to wear your leather gloves through this part.

Here are the steps to follow to check the ignition coil:

- Remove the spark plug cover which is usually a rubber cord that pulls right off the spark plug easily with a little tug.

- Remove the engine cover which is on the top of your lawn mower. Depending on the type of lawnmower you are using, there may not be a cover (in the case of a riding lawnmower, the hood may already be the cover).

- Locate the engine’s flywheel which looks like a circular piece with multiple blades going around in a circle. Each engine is different so if you are unsure you should check your lawn mower’s user manual to determine what/where it is.

- Remove the flywheel using a wrench and then inspect the coils. The ignition coils are situated on top of the engine beside the flywheel with two ends touching the flywheel rim. One of the coil’s terminals should be shown leading to the spark plug.

- Now, set your multimeter to test resistance (ohms) by first placing the red lead into the socket which has this symbol: Ω. Then set your multimeter to measure ohms(Ω).If you need more information on measuring resistance, check this articlehere.

- Touch the positive(red) probe to the metal connector inside the spark plug housing. The negative(black) probe should then be placed against the metal that extends out of the second terminal on the ignition coil.

- Allow your multimeter to measure for a few seconds until it stops fluctuating. If the meter is showing 0, your coil is no longer working and you will need to bring it in for repairs.

- On a working ignition coil, you should get a reading of between 0.5 and 1.3 ohms. If it’s below 0.5 it needs to be replaced as it will cause damage to your engine.

Why does the ignition coil break?

Typically, the ignition coil can go bad over time due to either long-term wear and tear or due to bad spark plug ignition cables.

If the spark plug ignition cables are getting faulty, it will have a much higher than normal resistance which causes additional voltage to be generated by the ignition coil which causes excess heat.

This, in turn, melts the coil’s wire insulation causing the wires to break requiring a new ignition coil.

Wrap up

The things you can do with a multimeter is endless and you can find so many different benefits from using it that it’s no doubt one of the best devices to keep around the house.

I often talk about many of these tasks that you should do yourself at home not only save you time and effort, but also to save you money.

Doing the above test may have caused you up to 50 at a small engine shop which you could do yourself. Start saving time and money by learning these awesome multimeter life hacks.