How to work properly with an electric jigsaw. Plastic and plexiglass

Tips when working with an electrician article

We already wrote about how to choose an electric jigsaw, and also made a rating of the best models in the opinion of the buyers themselves. And in this article we will talk about how to use them correctly. Although this tool seems simple, but, as it usually happens, there are always nuances. We’ll say right away that for experienced people who have already managed to work with an electrician, most information in this material will not be new, but beginners will definitely find something useful for themselves. Of course, without practical experience, all these tips themselves are useless, but at least they will help to quickly get comfortable with this power tool and get a really good result.

In reviews about different models, you can read about the quality of the cut, usually people write that it is even (accurate) or vice versa). But everything is not so simple here. In fact, any electrician has an uneven cut, because its design already contains some freedom of the saw canvas. Does this mean that it is impossible to make an accurate cutter with an electric jigsaw? Of course, no, you just need to understand that for this it is necessary to comply with the main principles of work, as well as have some dexterity. The basic rules that you need to know are only a few.

Electricity is not the tool that requires great efforts. It must be very weakly pressed to the surface and gently set the direction. Of course, such work does not look too fast, but here either slowly and accurately or fast and bad. There are no other options.

When working with this tool, in principle, you have to make a choice between quality and speed. It is not always necessary quality, this is a fact, but if an even cut is a priority, then here you need to not rush and do not use some functions. For example, the pendulum move will accelerate the work, but the quality will suffer. These are the design features.

With experience comes the understanding that each material needs its own frequency. No, everyone knows about it, but only with experience people really see how important it is. Below we will write a few recommendations on how to work with different materials, but we note that these are only general tips.

Additional functionality is useful, but in fact, the power of the electrician will be in the first place. It is she who determines how thick the tool will cope with the material. And how quickly he can do it. And the difficulty here is that for different tasks, both too powerful and very weak models can be bad. But this is partially leveled by the fact that modern jigsaws have the opportunity to change many parameters and, in this sense, more advanced (and expensive models) will be better. But in general, everything is like with any other power tool: it needs to be chosen under your tasks, and not try to tighten the nail with a screwdriver.

The saw canvas (saw) also is of no small value. And then and the most important. Today there are many varieties of files, which is good on the one hand, as it allows you to choose the best option for your tasks. But on the other hand, it makes you get confused and the newcomers from variety eyes scatter. And there is always a desire to save, and not buy a bunch of files for different tasks. And this is also acceptable, but if the quality of work is not in the first place. In general, you can write a separate material about the choice of files for the jigsaw, there are a lot of nuances there.

These are the basic principles of working with an electrician, one might say, a kind of foundation. Of course, this is far from all, there are many others, which in themselves are not so important, but in aggregate very affect the result. Here are a few:

The workplace should be well lit. It is worth considering that the housing of the jigsaw will give a shadow, which is especially true when using the upper lighting. Therefore, professionals either choose linen linas or use additional light sources to illuminate the working area.

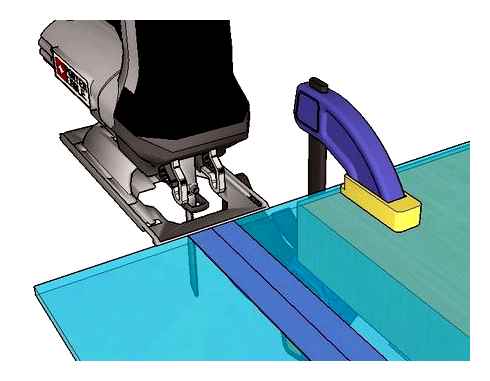

Do not forget about additional devices, such as stops, guides, etc.D. All this requires spending more time, but if you need an exact cut, there is no other choice. We recommend watching a video on YouTube on this topic, where there are very interesting examples and real life hacks. This is just the case when it is better to see once than read ten times.

It is believed that the thickness of the material should be at least three teeth of the saw. In itself, this is not so important in itself, but this proportion will make it easy to choose the right file. That is, the thicker the material, the larger the teeth. A very simple way, although not too accurate, because the characteristics of the material itself are not taken into account here. But for wood is relevant.

Files should be changed without unnecessary thoughts, do not forget that this is a consumable. If you feel that the teeth have swept away, you need to throw a file and take another. Dumb teeth very much affect both speed and quality of work.

Of course, changing the files is not too nice, because they can be expensive. Especially if you take them from well.Known manufacturers. On the other hand, expensive saw canvases for electrician and serve much longer. But their service life also depends on operation. For example, do not allow overheating, which really affects their wear. When heated, the metal becomes softer, which leads to faster wear.

Safety precautions during work

In general, an electrician in its structural features is safer than Ushm and disk saws. The real danger when working with a jigsaw is to get a hand or another part of the body to a working file. This is most likely under the workpiece, where the end of the file invisible on top comes out.

We recommend that you read more about the choice and design of the electrician in this article.

You can not cut small blanks, holding them with your hand near the file. The workpiece should be recorded by any means: clamps, visas, self.Tapping screws, clamps, etc.D.

- A bummer of a file with a rebound of a sharp piece aside in an unpredictable direction. It happens extremely rarely. Often, the saw just breaks into two parts, one of which remains in the workpiece, the second in the rod. If the part is bounced off, then with a slight force, since the speed of the canvas is low, from 500 to a maximum of 3200-3500 tactes up and down per min. This is much less than 12,000 rpm in the Ushm disk and up to 5000-6000 about \ min in a manual circular. At the same time, the peel of the jigsaw has only reciprocating movements, but not rotation. So, there is no centrifugal force, which is formed only during rotation and throws away the released particles to the side.

- Sawdust. Often the operator leans to the file to control the coincidence of the cutting line of the cut and the position of the canvas. At the same time, the air flow from the electric motor cooling fan or a random draft can bring sawdust into the eyes. To protect against this, on the corps of electrician, there are leaning transparent protective covers. Sometimes they interfere with the review and throw them back. Then you should work in protective glasses or at least not lean too close to the working area.

Wood sawdust caught in the eyes. And metal, sawdust from adhesive resins of sheet material, plastic, can damage the eyes. Therefore, it is not worth neglecting a protective casing or glasses.

In the photo operator with glasses, at a safe distance.

The rules of electrical safety for jigsaws are the same as for any electrical appliances.

- You can not use bare wires;

- The contact of the fork and sockets should be dense, without sparking and heating;

- When working, the outer outlet should not be underfoot;

- The possibility of wire falling under a working file should be excluded.

From the point of view of fire safety, an electrician is also safer than other cutting tools. Does not form a stream of sparks, as during the operation of a monkey (Ushm) and open flame, as when cutting gas/electric welding in cutting mode.

Preparation of the tool

First of all, the file suitable for the material is selected. You can not use strongly worn, bent files with broken and erased teeth. If they saw it, then slowly, with an overload of the engine, with great departure to the side.

We also recommend reading a useful article about the choice of files for an electrician.

The screws of fastening of the file should be tightened tightly, but not excessively so as not to disrupt the thread or the slots of the head.

Before the cut of business material, it is advisable to make a trial saw out on an unnecessary workpiece. Wherein:

How To Cut Plexiglass The Easy Way

- The behavior of an electrician is determined, the quality and speed of the cut, the presence of chips;

- Adjustment selects the optimal frequency of tactes of the canvas (electric motor revolutions).;

- On the wood, a pendulum course (rocking) with an assessment is turned on, as the jigsaw saws, better or worse. On metal, laminate, brittle plastics and solid materials, the pendulum course does not include.

After adjustment and trial cuts, they begin to cut business material, already knowing the possibilities of the jigsaw, speed and quality of sawing.

Preparation of the workplace

It is more convenient to saw with an electrician, placing a workpiece on the desktop. (Except when you have to saw on the floor). In any case, the workpiece is located so that the saw is guaranteed not to touch the floor, the edges of the desktop and other extraneous items.

The sawing line should be as close as possible to the support (table cover, workbench, paved on the floor of bars, etc.D.). If you drank too far from the support, the workpiece will jump, vibrate, which is incompatible with a normal even cut and can lead to a breakdown of the canvas.

It is also risky to dispose of the line from the edge of the support too closely, since the saw can hook support. Optimal-5-7 cm for thick unsuccessful materials, 2-3 cm for fiberboard, thin plywood, etc.D.

Before starting the saw, you need to look under the workpiece and make sure that there are no extraneous objects under the cutting line, and that the canvas will not hook the edge of the workbench.

The workpiece should be fixed by any means (clamp, clamps, screws, stops, etc.D.) You can not hold it with one hand, as it is unreliable and limits the operator in movements, distracts from the main operation. The saw.

In the photo. The workpiece is correctly fixed.

With a long cut, it is necessary to provide for how the wire will stretch. Is it enough for the end. Or in the middle you will have to turn off the jigsaw and throw, for example, an extension cord with a fork on a sheet of material.

What materials can be cut

With this tool, you can saw all the materials for which files are produced. Its purpose, as a rule, is indicated on the canvas in one English word.

Additional tips on the selection of saws

The quality of saw canvases should be even better than the quality of the electrician itself, because it is blunt cloves, easily bending in different directions, can spoil the work of even the most experienced master.

In addition, it makes sense to choose different saws for different types of cutting:

- For straight saws, wide canvases that have greater stability and, accordingly, provide an even line in the end.

- The more important the cleanliness of the cut itself, the thinner the teeth on the canvas are selected.

- If it is necessary to achieve a perfectly clean cut line, absolutely without a single chip, choose a canvas that has the return to the tooth.

- With the need for quick and rough sawing, large saws with widely diluted incisors are used.

- Files without wiring are quite productive and convenient to work with thick blanks.

- If the productivity and the quality of the cut are equally important, then files with teeth installed with a moved step (the step is large below, and as it approaches the front part of the part, it gradually smalves).

How to cut a circle with an electrician

The work of a wood jig provides for certain knowledge. And then with the help of this tool it will be possible to make parts and blanks with smooth bends and lines.

- First, determine the center of the workpiece.

- Then fix the guide to cut the circles and fix the jigsaw.

- Keep your jigsaw tightly, pressing it to the surface so that the saw does not go to the side.

- When cutting a circle, hold the workpiece tightly.

If you know how to use a jigsaw correctly, you can get a perfectly even circle, without burrs.

Features of sawing

The electric jigsaw easily copes with rectilinear sawing. Also, using the tool, you can perform various cuts at an angle and cut an oval or circle in the workpiece. The execution of each type of incision has its own characteristics.

Round and oval elements

The contour of the figure is applied to the prepared canvas. After that, using a drill in the workpiece, a hole is made in which the cutting element of the jigsaw is installed.

The cutting process begins and ends in a hole done. If you drill several holes, then the circle or oval can be cut in parts.

Straightforward

With this type of cut, the electric jigsaw copes the easiest way. The marking is made on the canvas, according to which the tool is smooth.

For direct sawing of the material, you can set the highest speed. Before starting work, it is recommended to fix the workpiece.

At an angle

Such a cut of the material is performed when preliminary installation of the sole under the required degree of slope. After fixing the required angle, the same actions are performed as with straightforward cutting.

Lobzik care

Like any mechanism, a jigsaw requires care and maintenance. Especially if you often operate it intensively.

Practice shows that in order to increase the life of the jigsaw, you need to regularly lubricate the gearbox and rod. In addition, the greased tool works quieter and softer.

The shaft of the lobby electric motor rotates on ball bearings. They are durable and can work without additional lubrication the entire life of the tool. But a jigsaw is not only an electric motor.

The rotation of the shaft is converted by a special mechanism into the reciprocating movement of the stem of the jigsaw. The swinging device adds to these movements up and down the longitudinal fluctuations of the rod forward-up. All this complex mechanics are collected on sliding bearings. They are transmitted to them loads from the working nozzle. Hedgehog is clear that the lubrication here is the necessary component.

For electrolobsics, consistent lubrication varieties are used. They must be enough tight. When working, the mechanism heats up from friction in the nodes and from the nearby electrical windings of the motor. Ordinary lubricants are thinned and squeezed out of friction couples.

We have selected for you a video that shows a disassembly of an electrician for subsequent lubrication:

Tips for working with an electric jigsaw

Are lobes now producing without a pendulum pass? But when Andrei acquired his first jigsaw. There was no this function on it. Only then, when the author bought a jigsaw with a pendulum, he realized how convenient it was.

How To Cut Plexiglass The Easy Way

The pendulum course allows you to conduct a more aggressive, and a quick cut of the workpieces due to the swing of the file. And we will now see this on the example of a workpiece from a laminated chipboard. Take four segments with a different course of the pendulum.

As we see, as the amplitude of the pendulum passes increases, a large number of chips are formed on the workpiece. But the cut goes faster and easier. So you constantly have to look for a compromise between speed and purity of cutting.

Now about connecting a vacuum cleaner to a jigsaw. You can make an adapter to a jigs of pvc pipe with a diameter of 32 millimeters. Especially if you do not have a corporate adapter, this option may be suitable for you. Despite its nondescence, it allows you to quickly connect the vacuum cleaner to any tool, and not just the jigsaw.

Bending plexiglass with a heat gun

Structurally, the jigsaw is arranged so that it blows out the flow of air at the saw.

How To Cut Acrylic Sheet By Hand

If the hole closes for some reason, it will be terribly inconvenient to saw due to a large number of sawdust.

Jobs for jigsaws are made from ordinary carbon steel with the designation of HCS. Also from high.Speed steel with the designation HSS. What is the difference?

When sawing, the files are heated hard, and from heating they lose their strength and dull. From ordinary steel, a file is stupid already at a temperature of 250 degrees, and from high.Speed steel at a temperature of 550 degrees. Therefore, if you do not allow overheating, the streaks made of high.Speed steel will last much longer.

For cutting plastic with a jigsaw, choose a file with a large tooth, and put small engine speeds. Let’s start sawing at small speeds. The chips are going even, and it saws well.

We look at what happened? First a smooth cut, and then one molten porridge. Therefore, the jigsaw stopped and stopped sawing.

For example, we saw aluminum. We put low speeds, turn off the pendulum (it is useless here). The cut goes well. We change the speed to high. Also excellent.

For better sliding saw and better cut, you can drop a drop of oil. And everything will go like clockwork.

Rules for working with this electric tool

Change the canvas in time, a stupid file does not make an even cut, and the engine will work with overload.

When working with thin materials, put a sheet of plywood, so no bullying is formed.

To extend the life of the file, it is necessary to ensure moistening with water when cutting metals.

Using the low speed of sawing, take frequent breaks, since the engine in this mode quickly heats up.

Use only the files corresponding to the materials.

Do all the manipulations with the working parts of the electrician with a tool disconnected from the network.