Lawn mower engine disassembly. How to Repair a Gas-Engine Lawn Mower

Online Small Engine Repair Course

You can complete ICS Canada’s online Small Engine Repair Career Diploma course in as little as four months. With ICS Canada you can train to take the first step towards a new career at home and at a pace that’s right for you.

You’ll learn how to troubleshoot and repair small gasoline engines with hands-on exercises and tools, as well as disassemble and rebuild all types of small engines, including two-stroke, four-stroke, outboard, and riding mower engines.¹

Program Goal and Outcomes

The Small Engine Repair program provides students with a working knowledge of basic small engine repair to gain employment in the small engine repair field.

Upon completion of the program, students will be able to:

- Understand the role of a small engine technician and the career opportunities in the outdoor power equipment field

- Describe the basic operation of small engines and identify the parts of a typical small engine

- Discuss the theory and operation of the cooling, lubrication, and fuel of a typical small engine

- Describe the theory and operation of the electrical systems of a small engine, including the operation of the ignition system

- Describe how to disassemble, rebuild, and reassemble a typical two-stroke and four-stroke engine

- Identify the types of drive trains found in outdoor power equipment and summarize how to service lawn and riding mowers as well as garden tractors

- Identify the typical troubleshooting and repair procedures for the most common types of outdoor power equipment

- Describe the ownership and management of an outdoor power equipment repair business

Instruction Set 1

The advantages of learning at home; types of study materials; types of examinations; accessing and using the features of our website; determining what kind of learner you are; establishing a study schedule; using study tips; preparing for and taking examinations.

Introduction to the small engine field and OPE repair; tools and tool usage; shop and equipment safety.

EXPERT! REBUILD a Briggs and Stratton Lawnmower AUTOMATIC CHOKE CARBURETOR

Instruction Set 2

Introduction to small engine terminology and operation theory; basic engine components; major engine systems.

The purpose of this small engine practical exercise is to help you apply your knowledge of engine components and operation to some real-life examples. Answer questions related to hypothetical scenarios and photos of actual engines.

Instruction Set 3

Basic components; lubricants and coolants used.

Electrical theory and terminology; ignition system operation, service, and troubleshooting.

The purpose of this small engine practical exercise is to help you apply your knowledge of small engine lubrication, cooling, and ignition systems to some real-life examples. Answer questions related to hypothetical scenarios and photos of actual engines.

Instruction Set 4

Basic circuit theory; DC and AC power sources; troubleshooting and repair of small engine starting, charging, and accessory circuits.

Fuels used to power OPE; carburetor operation and related engine components.

The purpose of this small engine practical exercise is to help you apply your knowledge of small engine electrical systems and fuel systems to some real-life examples. Answer questions related to hypothetical scenarios, photos of actual engines and parts, and electrical diagrams.

Instruction Set 5

Disassembling a four-stroke and two-stroke engine.

Using precision measuring instruments; reading service manuals; replacing worn engine parts.

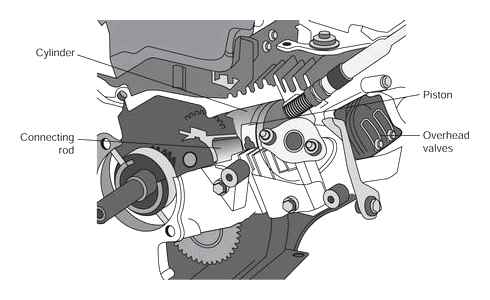

Pistons, rings, connecting rods, crankshafts, and valves.

Reassembling the two-stroke and four-stroke engine; engine starting and troubleshooting.

The purpose of this small engine practical exercise is to help you apply your knowledge of small engine electrical systems and fuel systems to some real-life examples. Answer questions related to hypothetical scenarios, photos of actual engines and parts, and electrical diagrams.

Instruction Set 6

Transferring power from the engine to working equipment; drives, clutches, transmissions, final drives, and differentials.

Theory of operation, maintenance, troubleshooting, and repair of lawn mowers.

Transmissions, electrical, steering, and braking systems of complex garden tractor systems.

The purpose of this small engine practical exercise is to help you apply your knowledge of lawn mower, riding mower, and garden tractor servicing to some real-life examples. Answer questions related to hypothetical scenarios, illustrations of actual machines and parts, and manufacturer’s information.

Instruction Set 7

Basic maintenance and servicing procedures necessary for most forms of OPE.

Servicing and repair procedures for many types of outdoor power equipment.

The purpose of this small engine practical exercise is to help you apply your knowledge of outdoor power equipment servicing to some real-life examples. Answer questions related to hypothetical scenarios and illustrations of actual machines and parts.

Instruction Set 8

Differences between standard small engines and marine craft engines; servicing and maintenance tips.

Registration and incorporation of a business; tax collection; payroll remittances; tax payments; local or special permits.

Supplement: Work Experience Option

The purpose of this practical exercise is to help you apply your knowledge of outdoor power equipment servicing and business ownership to some real-life examples. Answer questions about provided business scenarios.

Graduation Gift

(Sent to you when all program requirements and financial obligations have been met.)

- Four-Cycle Service and Repair Manual (Briggs and Stratton)

- OPE Certification Exam Prep Book

Computer Specifications As you know this is an online academic program. This means you will need access to high-speed internet to begin your program. In addition, you will need access to a Microsoft® Windows® based computer running Windows 10® or later or an Apple® Mac® computer running macOS® or later, and an email account to complete your program.

We reserve the right to change program content and materials when it becomes necessary. In order to further enhance your performance in this field, ICS has researched and recommended specific practical activities designed to complement your course work. To ensure that you acquire the manual skills which are important in this program area, we encourage you to follow all of the course instructions. Every province/territory has its own apprenticeship requirements in certain trade and technical areas. In a particular field, it may be necessary for the graduate to complete an apprenticeship before he/she is qualified to practice in their field.

Sample Lesson

To view a Small Engine Repair sample lesson, click here.

Outdoor Power Equipment (OPE) Certification

Outdoor Power Equipment (OPE) exams are voluntary international certification exams taken through the Equipment Engine Training Council. The only way to become OPE-certified is to successfully complete these certification exams. This program includes the OPE Certification Exam Prep Book to help you prepare for the two and four-stroke engine OPE examinations.

Small Engine Repair Student Discount Program

Fix My Hog Video ResourcesStudents enrolled in the Small Engine Repair Program are eligible for discounted rates for the Fix My Hog online garage full of premium online how-to videos. This video resource site can serve as a supplement to your ICS Canada program, but is not required to complete your course. Learn more about this offer here.

Small engine repair mechanics maintain and repair a variety of small engines, ignition systems, and fuel systems. Here are a few qualities that effective small engine repair technicians have in common:

- Detail oriented: It’s important to have a sharp eye and check things twice.

- Problem solver: Finding the missing piece can be rewarding and fun.

- Persistent: You work until the job is done, and done well.

- Honest: You are ethical in your work for customers.

I chose to further my education and accounting knowledge with ICS Canada while working as an accounting clerk, which allowed me to move up within the company at which I am currently working. Studying with ICS Canada was a great experience, and the instructors were very helpful when it came to resolving any issues I had while studying.

– Sean S., ICS Canada graduate

I have taken three diploma courses with ICS Canada. It has been very rewarding and challenging. I love to increase my knowledge level and share experiences. ICS Canada is great. Enrol! The contact with them is always very pleasant. You feel like a part of the ICS team.

– Connie K., ICS Canada graduate

Your program includes:

- Customized payment plans with 0% interest

- Books and learning aids

- Study Planner App to customize your study plans and keep track of your progress

- Instructional support from our experienced faculty

- Your personalized online student homepage and learning portal

- Exclusive access to ICS Canada’s Student and Alumni Group

- Additional resources such as our online library and career guidance from Career Cruising

What certifications are linked to the Small Engine Repair program?

Students are eligible to sit for numerous certification examinations upon completion of the Small Engine Repair training program. Students also receive preparatory materials for the Outdoor Power Equipment (OPE) two and four-stroke engine certification tests through the Equipment Engine Training Council. OPE certification is a voluntary international certification designation. The only way to become OPE-certified is to successfully complete the certification exams. This program contains the OPE Certification Exam Prep Book to help you prepare for OPE two and four-stroke engine certification examinations.

¹ In order to enhance your performance in this field. ICS Canada has researched and recommended specific practical activities designed to complement your coursework. To ensure that you acquire the manual skills which are important in this program area, we encourage you to follow all of the course instruction.

How to Repair a Gas-Engine Lawn Mower

Pumping new life into an old mower is easier than you think.

By Colin Aylesworth Roy Berendsohn Published: Mar 17, 2023

Jump to:

I’ve restored dozens of gas engine lawn mowers, and it’s been my experience that people put them out in the trash while the machines have plenty of life left in them. The average mower sitting unobtrusively at the curb usually needs nothing more than a thorough cleaning, an oil change, and some minor repairs. Really, in many cases, that’s all it takes to convert a mower from a heap of dried sod to a solid grass cutter.

You don’t need to be a small engine mechanic with a shop full of tools. You need nothing more than a few screwdrivers, a socket set, a putty knife, and some miscellaneous hand tools. Most mowers are fairly simple machines. Even a self-propelled lawn mower is not difficult to repair.

To demonstrate how simple this process is, and how little these mowers really need, we teamed up and plucked two disgusting and badly-neglected mowers from somebody giving them away for free. For both machines, our work was well short of a complete overhaul. Our cost for parts amounted to about 30 per mower. Here, we’ll show you how to transform one of these mowers from junk to gem.

Why Restore a Mower?

There are lots of good reasons to restore a gas engine mower. Even if you’ve bought a battery-powered mower, you may find that cutting conditions sometimes require the power you get out of a gas engine machine, so it makes sense to invest a little time and effort in your gas engine mower as a backup.

There are plenty of reasons you might want to fix up an old gas engine mower:

- Someone donates a tired grass cutter to your volunteer organization because you need it to handle rough-and-tumble cutting on the shoulder of a trail, around gardens, at a park, or even to mow some tough areas at a cemetery.

- Maybe your kid wants to start a lawn mowing business and you want to teach him or her the value of putting in a little sweat equity to stand an old mower on its feet, then put it to work turning a profit.

- Perhaps you just want to keep your faithful grass cutter running longer. That’s reason enough.

- Also, restoring the mower makes sense if you have someone to give you a hand–mowing your yard goes a lot faster with two mowers than it does with one.

- You don’t want to make the switch to a battery mower but aren’t thrilled with the lower build quality of some of the new gas mowers you’ve seen at your local home center.

- You don’t want to send a lawnmower to the landfill if it still has life in it.

Overview of the Restoration

The most common areas of neglect on a mower include a dulled or damaged blade, a grass-clogged deck, a filthy air filter, worn drive wheels, and a dirty grass bag. Believe it or not, most of the time, the spark plug is still good—replacing it will cost you about 6 at a home center.

For a good little tutorial on cleaning and gapping a spark plug, have a look at this video by engine manufacturer Briggs and Stratton.

The most complex thing that you might encounter is a carburetor that’s been damaged by ethanol gasoline or clogged by the residue that forms when the fuel deteriorates. We treat this topic in a separate section below.

Related Stories

Test Run the Mower

Check the mower’s dip stick to be sure that there’s sufficient oil in the crankcase. Then tip the mower up and look at the blade to check whether it’s bent or severely damaged, such that it would have damaged the engine’s crankshaft. Damage that severe is rare, but when it happens, usually the mower is a candidate for the scrap heap.

On the other hand, I’ve seen blades that were pretty badly chipped from multiple strikes on rocks and roots, and the engine was fine. While you’re checking underneath, it’s a good idea to fit a ratchet and socket to the blade bolt to make sure it’s tight.

Assuming there’s sufficient oil reading on the dip stick, there’s no sign of severe damage underneath, and there is gas in the tank, pull start the mower. If it doesn’t start, there could be several causes, but the most common causes are old or watery fuel, residue from degraded fuel clogging the carburetor, and a dirty spark plug.

If you run a fuel check (see steps below) and the mower still doesn’t start or it runs erratically, a simple spark ignition tester will help you see whether there’s an ignition problem. The tool has a small window through which you can view the spark produced by the engine. No spark or an erratic spark indicates an ignition problem. Spark problems are rare, in my experience, but we mention it here out of a sense of completeness.

Assuming that the mower starts and runs, even if poorly, move through the restoration process.

Scrape the Deck

One of the most common ailments of a neglected mower is a grass-clogged deck. Fortunately, a few minutes of scraping and brushing are all that’s necessary to get it clean.

The average donor mower has a deck that’s downright packed with grass clippings. Begin the restoration by removing the spark plug boot from the tip of the plug. This safety measure will ensure the mower won’t start while you work on the machine.

Safety first. To prevent the mower from starting during the cleanup process, pull the spark plug boot from the plug. Tuck the wire and boot out of the way before proceeding.

Next, scrape the deck clean with a putty knife. If you find rust flaking off the deck, scrape this, too. If the mower is going to be used often, then regularly cleaning the deck will slow the formation of rust. You can hit the underside of the deck with some spray paint if you want, but it’s not necessary if you keep the deck clean.

Remove accumulated grass clippings with a 1- or 2-inch-wide putty knife. These narrow knives easily follow the deck curvature, resulting in a cleanly-scraped surface.

Honda Small Engine Disassembly (#GCV160LA0MY1R280)/Repair Help

Remove remaining debris with a stiff brush. Be sure to get the dried material out from around axles and crevices where trapped grass can cause a rust hole to form in the deck.

Replace Bad Wheels

One of the most common deficiencies on an old mower is that the treads have worn off the wheels or the gears inside the drive wheel have worn down. Replacing a wheel requires nothing more than unbolting the wheel and replacing it.

Prop the mower up on a block of wood, then use a flat blade screwdriver to pry off the cover that conceals the wheel bolt.

In most cases with self-propelled mowers, it’s only the drive wheels that need replacement. The procedure is the same for both. Front-wheel drive mowers tend to suffer from worn wheels more than rear-wheel drive units.

While you have the wheel off, clean off grass clippings from the dust cover and lubricate the axle and wheel-height adjustment points with dry lubricant. Avoid using any lubricant here that stays wet and attracts dust, dirt, and grass clippings.

With the necessary cleaning and lubrication out of the way, you’re ready to bolt up the new wheel. Align the drive splines inside the wheel with the drive cog and press the wheel into place.

Align the splines on the inside of the wheel with the gear on the end of the drive axle and push the wheel onto the mower. Before tightening on the wheel bolt, clean its threads with a shot of spray lubricant and apply some spray lubricant to its receiving threads. Tighten the bolt on by hand, and finish tightening it with a socket wrench.

Replace the Air Filter

When a mower’s air filter isn’t changed regularly, the dirt and grime on it is obvious. This air filter shows several years of hard use.

A dirty air filter degrades engine performance by blocking air flow. This disrupts the air-fuel ratio that’s necessary for peak power and easy starting. Fortunately, it’s also one of the easiest problems to fix. At most, the only tool you’re likely to need is a screwdriver to take the air filter cover off. Remove the cover, peel the old air filter out, and replace it with a new air filter.

If your air filter cover is cracked or smashed and needs to be replaced, it’s easy to do. Just search online using your mower’s model number, which should be printed somewhere on the deck. This should yield results of parts that are compatible with your mower. An air filter cover should cost somewhere between 9 and 15, depending on size and model. Some even come with the air filter.

Many air filter covers have tool-free access, a few will require a screwdriver.

Some air filter covers are tool free and come off by moving a plastic locking tab out of the way, but others require a screwdriver to open. In the case shown here, remove the single screw holding the cover in place.

Once the cover is off, remove the air filter and replace it with a fresh one.

Few things contribute to mower performance as simply and quickly as replacing a dirty air filter. The filter shown here is a gasketed type (a rubber gasket makes an air-tight seal around the filter’s perimeter). Regardless of whether the filter has a gasket around it or not, peel out the old filter and replace it with a fresh one.

If dust and grass clippings have managed to infiltrate the air filter housing, wipe the surfaces clean before installing the new air filter and replacing the cover.

Sharpen the Blade

Neglected mower. Neglected blade. The two are inseparable. Unlike any other repair on the mower, sharpening a dull blade will contribute directly to lawn health. Grass that’s sheared by a sharp blade loses less moisture and is less disease-prone than grass shredded by a dull one. Begin the processs by spraying the blade bolt with penetrant.

A neglected mower will have a neglected blade. And by neglected, I mean one that’s rusty and dull. Blade maintenance is a multi-step process that we outline in the steps below.

After saturating the blade bolt with penetrant (shown above), place a block of wood behind the blade to keep it from turning and loosen the bolt with a socket wrench. If the bolt refuses to budge, stop and make a second application of penetrant. A badly-neglected mower may require several applications of penetrant before the bolt breaks free.

Sharpen a blade that’s dull (not damaged), using a file. If the blade shows minor damage from hitting small rocks and roots, you can use an angle grinder with a 60-grit flap disk to sharpen it.

Clamp a dull lawn mower blade horizontally in a vise and sharpen the cutting edge with a right angle grinder and a 60-grit flap disk. Work from the center of the blade to the tip. After making several passes on one edge, flip the blade end for end and grind the other side. Try to remove an equal amount of metal from each edge so that the blade will be balanced when spinning in the mower deck.

Once you’ve sharpened your blade, you’ll need to make sure it is balanced, otherwise the mower may not run smoothly. There are several different ways to check a blade for balance. You can clamp a bolt in a vise, and hang the blade on that. You can drive a nail into a stud, and hang the blade on that. You can use a blade balance cone on a work bench and check for balance horizontally. Just make sure your bench is level before using one of these cones.

Clamp a bolt, an awl (shown here), or a large nail in a vise to suspend a mower blade to check its balance. If the blade tips to one side, you know that side is heavier and you must remove metal from it to get the blade to balance. Although this work requires some patience as you oscillate between grinding metal and checking for level, the results are worth it in the form of a sharp blade and a smooth-running mower.

There are a couple of other things to do after the blade is sharp and balanced.

Apply some spray penetrant into the hole that receives the blade bolt. It’s not unusual on a neglected mower to find rust and dirt particles flowing out of the hole as you apply the lubricant. Wipe off the excess lubricant that flows out of the hole.

Place the blade bolt on a drop cloth or a clean piece of shop towel and flush its threads with spray lubricant or penetrant. Wipe the bolt clean before installing the blade.

General Cleaning and Minor Repairs

Not that it will contribute to the mower’s performance, but it doesn’t hurt to spray down the mower deck, engine housing, and plastic parts using spray cleaner and a shop towel.

And while you’re at it, a filthy grass bag isn’t just gross, if its air vents are blocked, the mower won’t bag effectively. Blow out the bag with a leaf blower then wash it down.

After emptying the bag of all debris, use a heavy-duty spray cleaner such as a degreaser, a scrub brush, hose and nozzle to clean the bag inside and out. Rinse the bag thoroughly and stand it outside in the sun to dry. If you have a pressure washer, you can power wash the bag using the same cleaner that you use on your house. Be careful not to damage the bag by holding the spray nozzle too close to its surface.

Other minor repairs

One of our mowers had its drive belt cover worn through. We patched this area with aluminum foil duct tape that we painted black to match the rest of the housing.

Repair a worn drive belt cover by applying some aluminum foil tape to the inside of the cover then carve off the excess with a sharp utility knife. Then patch the outside of the cover in the same way. You can spray paint the cover with some flat black paint to blend it in. After cleaning grass clippings from around the belt and wiping the area clean, reinstall the drive belt cover.

Use some WD-40 to lubricate cables.

Spray some lubricant in at the cable access point and let it run downhill. While you’re at it, spray any part that pivots or turns, such as wheel height adjustment mechanism, axles, screws and bolts. Basically, if it’s metal on metal, lubricate it. Once you’ve added some lubricant, move these parts to work in the lubricant. You should find that control levers and pivoting or turning parts should start to move easier.

Run the mower for a couple of minutes to warm up the crank case oil, then stop the engine, disconnect the spark plug, remove the oil fill cap, tip the mower over, and drain the oil into an empty pan. After the last bit of dirty oil has poured out, tip the mower upright and refill with an appropriate small-engine oil.

Check and Clean the Plug

While you certainly can replace the spark plug, I’ve found that it isn’t necessary if the engine otherwise runs fine. To keep the spark plug firing optimally, you can simply scub any deposits off with a small brass wire brush. If you have one, you can also check the gap of the spark plug using a gap tool.

If the spark plug appears to be sound (it’s not cracked or its threads are not damaged), then gently scrub off carbon deposits with a small brass wire brush. If the plug shows any type of damage, such as cracked porcelain, replace it with a fresh plug.

Step two of refurbishing the plug is to spray it clean.

Use electrical contact cleaner to remove residue on the spark’s threads or its electrode. Place the plug over a drop cloth or a shop towel and blast it clean with a jet of the cleaner. Let the excess drip off. This cleaner leaves behind no residue.

A refurbished plug should look almost as good as one right out of the box.

A refurbished plug has bright clean threads and a clean (and properly gapped) electrode. This plug is ready to install in the engine.

If you’ve never installed a spark plug before, have a look at this tutorial at the Champion spark plug website. It explains tightening both gasket-base and taper-base plugs.

Thread the cleaned plug into the hole until it’s finger tight and then finish tightening the plug with a ratchet wrench and spark plug socket.

Test Run the Machine in Grass

An hour or two of work should yield a machine that starts easily, runs well, looks good, and cuts grass practically like a new mower. The two most important telltales that you want to look for are a smooth pull start, and lack of vibration when the mower comes up to speed (indicating a mechanically sound engine turning a balanced blade).

Adjust all four wheels so the mower is level, then walk the machine into some grass. A full operational test would include bagging and mulching. Of course, if the mower still has its side discharge chute, walk slowly into into some tall grass; with a properly-sharpened blade and the deck height adjusted for tall grass, you should find the mower produces a steady stream of clippings out of the side chute. We use the same test when evaluating new mowers at Popular Mechanics.

If the mower isn’t performing in some respect, you need to investigate. A bogging engine may indicate a fuel-supply problem or lack of spark under load. Vibration may indicate that the blade isn’t as balanced as you thought. If the machine isn’t bagging, have you pulled the mulch plug out of the back of the deck or forgotten about the hinged mulching door at the back of the mower?

Don’t laugh. I’ve seen more than one mower owner complain about performance while overlooking the obvious.

But as we say above, in most cases, a dirty old mower that has seen some basic mechanical attention will perform surprisingly well.

Carburetor Problems

The float bowl on this carburetor shows the result of today’s ethanol-containing gasoline. The fuel in the bowl is a syrupy mess and the bowl itself is contaminated with varnish and gunk left from the chemically-degraded fuel.

At this point in the story, we’ll switch mowers in order to show you what a fouled carburetor float bowl looks like. The Murray mower shown elsewhere ran perfectly well, indicating there were no carburetor issues. Not so with the Craftsman mower that was the FOCUS of another round of repair efforts.

Some background is helpful. Today’s standard gasoline contains ethanol, a form of alcohol that’s added to gasoline to reduce air pollution (that’s the theory, anyway). But the alcohol-rich fuel degrades rapidly and leaves behind slimy deposits in the gas tank, in the carburetor bowl, and in fuel lines. If your mower sits for a few weeks or longer without running, the ethanol in the gasoline may begin to degrade and cause engine issues.

If your mower won’t start after winter, you may very well have an easy-to-fix fuel supply issue. To test this out, remove the air filter and spray some carburetor cleaner into the carburetor opening behind where the filter sits, then try starting the mower. If it runs for a second but then dies, that’s a good indication your carburetor is clogged.

Pinch off the fuel line with a pair of locking pliers, place a piece of shop towel under the carburetor to catch spilled fuel, and use a socket wrench and socket to remove the carburetor’s float bowl.

Once the bowl is removed, blast it clean with some spray carburetor cleaner.

Hold the float bowl over a shop rag and using the red nozzle extension, blast the bowl clean with a couple of shots of carburetor cleaner.

A couple of more cleaning steps, and you’re ready to reattach the bowl to the carburetor then test run the mower.

Wipe the bowl clean with a shop rag. There shouldn’t be a trace of residue left in the bowl; it should be bright and clean.

Use the red straw extension again to blast clean the orifices in the float bowl’s screw. After that, put the bowl back in place and fasten it with the newly-cleaned screw.

If this basic cleaning doesn’t work, your best bet is to fully remove the carburetor to clean it or replace it. Have a look at this brief tutorial at the Briggs and Stratton website to give you an idea of what’s involved with these engines. Rebuilding a carburetor is fairly simple, involving disassembly and reassembly with some screws, a few small parts, and gaskets and seals. A rebuild kit will cost anywhere from 8 to 30. If the work seems overly fussy to you, and you don’t want to be bothered with it, replace the carburetor. New carburetors cost anywhere from 20 to 50. In terms of what the old mower is worth, in most cases a rebuild kit is more cost effective, but you’ll have to be the judge of what is effective in terms of your time and trouble.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

How to Repair Small Engines

Small gas engines serve us in many ways. They power lawn mowers, tillers, cultivators, trimmers, edgers, snowblowers, chain saws, pumps, generators, air compressors, and other useful home tools. They also power our fun: outboard boats, snowmobiles, motorcycles, all-terrain vehicles, ultralight aircraft, and other toys. To keep them operating efficiently, an owner of these tools and toys should know about small engines: how they work and what to do when they don’t.

Small gas engines are made up of individual systems that work together to produce power. Each system has many components. Internal combustion gasoline-powered engines require six systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. In this article, we will discuss the systems and components that make small engines work.

Fuel and Exhaust

The fuel and exhaust systems are critical to operation. They furnish the fuel for combustion and remove exhaust gases. The following are components of a fuel and exhaust system.

Gasoline: Gasoline is a combustible liquid that burns relatively slowly. However, when sprayed as a mist and mixed with air, it is quite explosive. All it needs is a spark. Two-stroke engines require that oil be mixed with the gasoline to lubricate internal parts. Four-stroke engines use a fuel-air mixture.

Fuel Tank: The fuel tank stores fuel in preparation for mixing by the carburetor and use by the engine. Some fuel tanks are pressurized with air to help deliver fuel to the carburetor. Other tanks are non-pressurized and depend on a fuel pump to deliver fuel to the carburetor.

Fuel Line: Fuel is moved from the tank to the pump and/or carburetor through a fuel line. Pressurized fuel systems often have a squeeze bulb in the fuel line for building pressure.

Filter: A carburetor jet has a small opening that can easily become clogged. A fuel filter traps dirt and sediment from the gas before it is delivered to the carburetor.

Pump: A fuel pump produces a vacuum that pulls the fuel from an unpressurized tank, then delivers it to the carburetor.

Carburetor: The carburetor has one job: to mix the correct proportion of gasoline and air for the engine. Too much gasoline in the mixture makes it rich; too little gas makes it lean.

Throttle: The throttle controls the amount of fuel-air mixture that enters the engine from the carburetor. The throttle thus controls the speed of the engine.

Primer: A primer injects a small amount of gasoline into the carburetor throat to make the initial fuel-air mixture rich. A primer is used to help start a cold engine.

Choke: Some engines control the richness of the fuel-air mixture at startup by controlling the air rather than the fuel. A choke reduces the amount of air in the fuel-air mixture.

Governor: A governor is a device that automatically opens the engine’s throttle when more power is needed and closes it when the load is light.

Muffler: Small gas engines, especially two-stroke engines, are noisy when they operate. A muffler reduces the sound of the exhaust gases by passing them through baffles.

Spark Arrestor: A spark can exit the exhaust port of a small gas engine, potentially starting a fire on nearby combustibles. A spark arrestor on the exhaust port can reduce the chances of such a fire. Spark arrestors are especially important on chain saws, motorcycles, and all-terrain vehicles operated in dry woodlands.

Ignition

The ignition is a primary system within all small gas engines. It produces and delivers the high-voltage spark that ignites the fuel-air mixture to cause combustion. No spark means no combustion, which means your engine doesn’t run. Below are the components found in small engine ignition systems. Some systems will include breaker point ignitions while others depend on solid-state ignitions.

Magneto-Powered Ignition System: A magneto uses magnetism to supply electricity in ignitions where there is no battery. The magneto is turned by the crankshaft, which rotates when the manual recoil starter is pulled. The three types of magneto ignition systems are mechanical-breaker, capacitor-discharge, and transistor-controlled.

Battery-Powered Ignition System: If your small engine includes a battery for starting, the ignition coil will also use it to supply spark to the spark plugs. A battery stores electrical energy until needed. Battery ignition systems also use mechanical-breaker, capacitor-discharge, and transistor-controlled ignitions.

Mechanical-Breaker Ignitions: High-voltage electricity must be sent to the spark plug at the appropriate time. In mechanical-breaker ignitions, this job is performed through the contact points and a condenser.

Points: As the crankshaft rotates, a cam opens and closes a set of contact points. These points function as an on/off switch: Closed is on, and open is off.

Condenser: Because the spark moving across points can damage their surfaces, the condenser stores voltage to reduce arcing between points.

Capacitor-Discharge Ignitions (CDI): A capacitor is a large condenser. A CDI stores and delivers voltage to the coil using magnets, diodes, and a capacitor

Transistor-Controlled Ignitions (TCI): Transistors are electronic controllers. A TCI uses transistors, resistors, and diodes to control the timing of the spark.

Coil: An ignition coil is simply two coils of wire wrapped around an iron core. The coil changes low voltage (6 or 12 volts) into the high voltage (15,000 to 30,000 volts) needed by the spark plug.

Spark Plug: A spark plug is an insulated electrode that is screwed into the top of the engine cylinder. High-voltage timed electricity from the magneto travels by wire to the spark plug. The base of the plug has an air gap of about 0.030 inch (30 thousandths of an inch), which the current must jump.

Wires: The primary wire from the coil to the breaker point and secondary wire from the coil to the spark plug(s) deliver electricity to the ignition components.

Distributor: A distributor is an ignition system for engines with more than one cylinder and spark plug. It distributes the spark to the appropriate cylinder using a rotor, cap, and individual spark plug wires.

Combustion

The combustion system of a small gas engine is where the work gets done. Components of the combustion system include the cylinder block, cylinder head, camshaft, valves, piston, connecting rod, crankshaft, timing gears, and flywheel. To better understand small gas engines, let’s look at how this vital system works.

Cylinder Block: The largest single part in a small gas engine is the cylinder block. It is a piece of metal in which the cylinder hole is bored or placed.

Cylinder Head: The cylinder head is the top, or ceiling, of the cylinder and is attached to the block with bolts. Depending on the type of engine, the head may or may not include valves.

Piston: A piston is the movable floor in the combustion chamber. Its upward movement compresses the fuel-air mixture. After combustion, its downward movement rotates the crankshaft.

Crankshaft: An engine’s crankshaft is a metal shaft with an offset section onto which the connecting rod is attached. Rotation of the crankshaft moves the piston up in the cylinder. Movement of the piston down in the cylinder then rotates the crankshaft.

Connecting Rod: Between the piston and the crankshaft is a connecting rod. At the larger end of the connecting rod is a bearing that allows rotation around the moving crankshaft. The small end is attached to the piston pin.

Valves: Valves simply open and close passages. A reed valve in a two-stroke engine is activated by changes in air pressure.

Flywheel: At the end of the crankshaft is a circular weighted wheel called a flywheel. The flywheel delivers the engine’s power to devices (wheels, blades, etc.) and helps keep the crankshaft turning smoothly.

Combustion and friction produce heat. Heat and friction.- if not controlled.- can quickly damage an engine’s components. Small gas engines are typically cooled by air. Friction is reduced using movable bearings and lubricants.

Air-Cooling Fins: For simplicity, most smaller gas engines are cooled by air. Metal fins around the outside of the combustion chamber help dissipate the internal heat.

Friction: Friction is resistance that occurs when one surface rubs against another. Friction causes wear. In an engine with many moving parts, friction is reduced with bearings and lubricants.

Bearings: A bearing is a replaceable part that takes the brunt of the friction. A friction bearing relies on lubricants to minimize friction. A nonfriction bearing uses hard steel rollers or balls to prevent wear, though it too requires some lubrication.

Lubricants: Lubricants such as oil and grease reduce surface friction by coating parts with a film. Lubricants in two-stroke engines are applied to surfaces by mixing oil with fuel.

Viscosity: An oil’s viscosity is its resistance to flow. The thicker a lubricating oil or grease is, the higher its viscosity number.

Filters: Friction happens. Moving parts wear, even with the best lubricants. The resulting metal as well as carbon from the combustion process must be cleaned from the oil to ensure long lubrication. Some small engines use oil filters to remove contaminants from the circulating oil.

Regularly servicing your small engine will ultimately save you money and time. In the next section, we’ll review how, where, and when to service this engine.

The Benefits of Regular Small-Engine Maintenance

Purchasing a small engine-driven implement can make a dent in your budget. Tools and toys powered by small engines can cost anywhere from 100 to 10,000. That’s why it’s a good idea to invest in periodic servicing of your small engine. Replacing an engine every couple of years is an annoying and needless expense. Below we will review detailed information on how to service two-stroke gas engines. Following these procedures could help you put more money in the bank and less into your mechanic’s

Benefits of Regular Service

Servicing your small engine tool or toy on a regular basis offers many advantages over the Wait-Until-It-Breaks Maintenance Program.

- By establishing a service schedule, you will gain confidence that whenever you need the unit it will be ready for use.

- By performing a number of service functions together, you will save time. You can pick up all needed parts and lubricants in one trip to the parts store. Then you need to disassemble a component only once to perform numerous service procedures rather than taking it apart many times.

- Regular service gives you a chance to visually inspect the entire engine and related components for damage, wear, and other potential problems.

How, Where, and When to ServiceKnowing how to service is as important as knowing when. Some service procedures can be performed wherever you store your tool or toy: in a garage, storage shed, or tool shed. If the unit is heavy, you can build a ramp up to a sturdy table that is at a handy height for working. Or you can use a ratchet winch to lift the engine. Units weighing less than 40 pounds may be lifted to a workbench or table as long as you lift with your legs rather than with your back. Get help if you need it, and make sure that the unit will remain sturdily in place as you service it. Remember to always put safety first!Servicing a small engine is easy once you know what to do and when to do it. A service chart can help you determine common service requirements as well as track what service has been done. Your engine-powered unit may have a service chart in the owner’s manual or service manual. Typical recommendations include changing engine oil every 25 hours of use and tuning up the engine at least once a year.The purpose of ongoing service, also known as preventive maintenance, is to keep your engine-driven tool or toy in good operating condition. Ongoing service procedures include air cleaner service, crankcase breather service, cooling system service, muffler service, lubrication, and tune-up.Lubrication service means making sure that all moving parts have sufficient lubrication (oil and/or grease) to minimize wear. Lubrication service procedures include mixing oil with fuel in two-stroke engines, and lubricating other moving parts.A tune-up consists of the adjustment and/or replacement of parts critical to smooth and efficient engine operation. Those parts include components in all engine systems: fuel, exhaust, ignition, combustion, cooling, and lubrication. Ignition tune-ups are more important for mechanical-breaker ignitions than they are for self-contained solid-state ignitions. Regular tune-ups will keep your small engine running smoothly and reduce the need for repairs.In addition, you should check other systems and make adjustments as needed to keep them operating smoothly. This includes adjusting the throttle, choke, and governor linkage, and cleaning off debris.Engine-driven tools and toys usually come with an owner’s manual. While some manufacturers’ manuals are more complete and better written than others, most manuals include basic information on safe operation and service. Unfortunately, product manuals are often written to reduce the manufacturer’s liability for accidental misuse rather than to help the owner service the product. In addition, manuals for engine-driven products typically show how to service the nonengine components: the grass catcher, wheel adjustments, blades, chains, and other parts. Service information for the engine may be minimal or nonexistent in the owner’s manual.

What can you do about this lack of information? Fortunately, there are numerous after-market publishers of service manuals for specific models of small engines. If you don’t have an owner’s manual, you can contact the manufacturer directly to purchase one; manufacturers also sell service manuals. Most manufacturers keep product manuals for up to 20 years. If they only have one original copy left, you can often request a photocopy for a small charge.

Knowing how to service the fuel system is an important part of caring for a small engine. Learn how to care for fuel filters, carburetors, and other major fuel system parts in the next section.

How to Repair a Small-Engine Fuel System

The function of a small engine fuel system is to store and deliver fuel to the combustion chamber. Maintaining a fuel system includes servicing the fuel filter, air cleaner, fuel tank, and fuel lines; adjusting the carburetor; and adjusting the governor. Of course, not all small engines have all of these components.

Servicing Fuel Filters

Some small engines have a fuel strainer in the bottom of the fuel tank. Others have a removable fuel strainer in the fuel line. Still other small engines use disposable in-line fuel filters made of pleated paper. To clean sediment from a tank:

Step 1: Drain or siphon all fuel from the tank.

Step 2: With a flashlight, find the lowest point in the tank: the sediment reservoir. Clean all sediment from the reservoir indentation.

Step 3: Wipe sediment from the end of the filter element.

Step 4: Wipe the inside of the tank with a clean rag.

Step 5: Refill the fuel tank.

Here is how to clean sediment from a fuel strainer:

Step 1: Find and close the shutoff valve on the fuel line.

Step 2: Loosen the lock nut on the bowl retainer and remove the sediment bowl.

Step 3: Empty and clean the sediment bowl. Clean the filter screen. Refill the sediment bowl with fresh fuel.

Step 4: Reinstall the sediment bowl and bowl retainer, tightening the lock nut.

Step 5: Open the shutoff valve.

Here is how to replace an in-line fuel filter:

Step 1: Find and close the shutoff valve on the fuel line or use a clothespin to pinch the fuel line closed.

Step 2: Disconnect the fuel filter from the fuel line.

Step 3: Replace the in-line fuel filter with an exact replacement part.

Step 4: Open the shutoff valve.

Servicing Air Cleaners

The purpose of an air cleaner on a small engine is to keep large particles in the air from clogging the carburetor. The two types of air cleaners used on small engines are oil bath and dry. Hereis how to service an air cleaner:

Step 1: Remove the cover of the air cleaner, typically by unscrewing a nut on top of the cleaner.

Step 2: If it’s an oil cleaner, remove all oil and contaminants from the center channel of the cleaner, wipe it clean, then replace oil to the indicated level. A dry cleaner cannot be cleaned and therefore must be replaced.

Step 3: Replace the air cleaner cover and make sure all fasteners are securely tightened.

Servicing Fuel Tanks and Lines

Fuel systems with pumps use nonpressurized fuel tanks. Outboard engines typically use pressurized tanks. Fuel lines are usually made of neoprene. Here’s how to service a fuel tank and line:

Step 1: Remove the cap from the fuel tank.

Step 2: Using a flashlight, check for sediment in the fuel tank. If sediment is found, clean the tank and replace the fuel. Replace the fuel cap when done.

Step 3: Check the fuel line and siphon bulb, if there is one, by squeezing them and inspecting for cracks. If damaged, replace with a line or a bulb of the same inside diameter. Make sure it is approved for use with fuel.

Adjusting Carburetors

A carburetor mixes fuel and air in the correct proportion for use by the engine. The three types of carburetors commonly used in small engines are natural draft, updraft, and downdraft. These names describe the direction that air flows from the inlet to the engine manifold. To maintain your small engine, you will want to make sure the carburetor’s speed and mixture are correctly adjusted.

There are many types and models of carburetors used on small gas engines. Some have more available adjustments than others. Depending on the design, some carburetors are set at the factory and don’t include adjusting screws. For example, a carburetor may allow adjustment of high speed, idle speed, and idle mixture while another only allows high and idle speed adjustments. Here’s how to adjust the typical three-adjustment carburetor:

Step 1: With the engine running, open the throttle wide. Turn the high-speed adjustment needle forward and backward until the highest speed setting is found.

Step 2: Move the throttle to the slowest running speed. Adjust the idle-speed needle until the recommended idle speed is found.

Step 3: Once the idle speed has been set, adjust the idle mixture until the engine runs smoothly.

Adjusting Governors

A governor is a device that controls the speed of the engine as the load changes. As the load slows the engine down, the governor opens the throttle to return the engine to a set speed. Governors are commonly used on engine-powered electrical generators where constant speed is important. Two types of governors are installed on small engines: mechanical and air-vane.

Caution: An incorrectly adjusted governor can cause the small engine to operate at excessively high speeds and damage or destroy it.

Unfortunately, there is no universal adjustment sequence for small engine governors. Much depends on the type of governor, whether the crankshaft is horizontal or vertical, the complexity and pivot points of the linkage, and the intended operating range. Because of these factors, refer to an owner’s manual or service manual for your specific engine and application to adjust the governor.

In the next section, learn how the ignition system needs to be routinely serviced so it can deliver a high-voltage spark to help start a small engine.

Small Engine Repair School

Learn how to troubleshoot and repair small gasoline engines with our Penn Foster Career School’s accredited online Small Engine Repair Training Program. With self-paced classes, you can prepare for a hands-on career in the field on your schedule.

- Learn fundamental mechanical concepts including cooling, electrical, and fuel systems, servicing lawnmowers, tractors, and outboard engines, and more.

- Prepare for optional Outdoor Power Equipment Association (OPE) certification, which can help you stand out when applying for jobs.

- Students enrolled in the program receive a discount for Snap-on tools.

- Our online programs are flexible enough for you to finish them at a pace that works for you, based on how much time you can dedicate to your coursework each week.

Save up to 190 Ends 7/25/2023

59/month, Start for as low as 20

What You Will Learn

- How to describe the operation of carburetors, ignition systems, and starting systems, and explain how a transmission can be used to increase the output horsepower and torque of an engine.

- How to identify types of small-engine lubrication and cooling systems, as well as how to properly service and maintain these systems.

- How to troubleshoot and repair electrical systems for small engines.

- How to disassemble small gasoline engines, as well as repair and rebuild them.

Small Engine Repair Career Outcomes

Through the online small engine repair training program, you’ll prepare for work in the field. There are opportunities to use your small engine repair skills in a variety of locations, including dealerships, repair shops, hardware and other retail stores, equipment rental agencies, and even your own small engine mechanic business.

State Licensing Requirements

Licensing and/or certification requirements for small engine repair jobs are not the same in every state and may include educational, testing, and/or experiential requirements beyond those offered in the Penn Foster program. Prospective students should contact the state professional licensing board or similar regulatory body in the state(s) where they plan to work to determine their requirements before enrolling in this program. See the State Licensing page for contact information for state licensing/regulatory boards and certain industry licensing information.

Small Engine Repair Curriculum

Estimated completion time:

With Penn Foster, you can learn at whatever pace works best for you. Some learners will be more comfortable moving faster, and dedicating more time, and the fast track estimate will apply to them. The average track will apply to most learners who can dedicate a few hours per week to completing their coursework.

In our Small Engine Repair Diploma Program, you’ll learn the knowledge and skills that can help you prepare for a career as a small engine mechanic. Your online units include:

- Small Engine Ignition Systems

- Small Engine Fuel Systems

- Engine Disassembly and Reassembly

- OPE Transmission Systems

Small Engine Repair Student Experience

Our graduates have gone on to find work in mechanic shops, hardware shops, and dealerships. Learn more about their experience with the Penn Foster program.

Penn Foster Graduate, 2021

“It was an awesome program, and the flexibility is something that is needed in today’s fast-moving world.”

Looking for skilled trades training for your workers?

Penn Foster currently works with hundreds of leading employers to meet their unique organizational needs.

Small Engine Repair Program Tuition

Take the first steps toward a new career with our online Small Engine Repair Program. Simply choose from one of our low-cost customized payment plans and get started today!

Save up to 190 Ends 7/25/2023

Option 2: Monthly Auto Pay Plan

- Pay 59 per month

- Start for 20 down

- All major credit and debit cards accepted

Option 3: Monthly Mail Pay Plan

California residents please click here for Required California Disclosures.

Need more info or ready to enroll?

Looking for more information on transfer credits, military benefits, or our refund policy? Find this information and more about tuition and enrollment here.

We’re here to help. Call 1-800-275-4410 9AM. 9PM EST

Our Proven Automotive Repair Learning Model

- 24/7 access to online resources

- Online student community

- Student Portal Help Center

Related Programs

Learn how to repair and maintain motorcycles and ATVs with Penn Foster’s online Motorcycle Repair Technician Career Diploma Program.

Learn how to maintain and repair diesel-based engines and trucks with our online Diesel Mechanics/Heavy Truck Maintenance Career Diploma.

Prepare for ASE certification and learn the skills to become an auto mechanic with our Online Automotive Repair Technician Program.

What types of small engines will I learn to repair in this course?

Penn Foster’s online Small Engine Repair Program prepares students to repair typical two-stroke and four-stroke engines, outboard engines, and marine engines.

Why become a small engine mechanic?

Small engine mechanics play a vital role in servicing and repairing outdoor equipment such as lawn mowers and leaf-blowers. Mechanics who work on outdoor power equipment and other small engines will continue to be in-demand because of the widespread use of these engines in gardening, tree work, landscape construction, and similar activities. The average national salary for small engine mechanics was 39,050 in 2021, according to data from the Bureau of Labor Statistics.

How long does it take to become a small engine mechanic?

Depending on your education and experience, it can take up to a year to become a small engine mechanic. While postsecondary education isn’t required and many shops and businesses will provide some on-the-job training, job prospects are best for those who have completed training programs, according to the Bureau of Labor Statistics.

What qualities make a good mechanic?

Good small engine mechanics are detail-oriented, have strong troubleshooting and mechanical skills, and are able to work in a variety of environments. They should also have a strong understanding of customer service and organizational skills. Many skills can be developed through training in our online Small Engine Repair Program, including how to start your own repair business.

Bureau of Labor Statistics, U.S. Department of Labor. Small Engine Mechanics. Occupational Outlook Handbook. Accessed September 26, 2022.

Statements found in the United States Department of Labor Occupational Outlook Handbook are not a guarantee of any post-graduation salary, in part because the data used to create the Occupational Outlook Handbook includes workers from differing educational backgrounds, levels of experience, and geographic areas of the country.

Snap-on Student Excellence Program

Students enrolled in the small engine repair training program are eligible to participate in the Snap-on Student Excellence Program. This program allows students in trades and technology education programs to purchase high-quality Snap-on tools at a preferred student discount. Some restrictions may apply for total purchases and quantities of certain items. Click here to see the new Snap-on Catalog.

Outdoor Power Equipment Association Small Engine Repair Certification

This certification is voluntary and not required for employment, though it can help you stand out from other applicants when applying for engine repair jobs. The only way to become OPE-certified is to successfully complete their certification exam. Penn Foster Career School’s Small Engine Repair program includes the OPE Certification Exam Prep Book to help you prepare for the examination.

On average, learners can complete their program in as few as 7 months. Faster learners, or those with more time to dedicate to their coursework, can finish in as little as 4 months. If you don’t have lots of time to dedicate to your program, that’s ok too! You can learn at the pace that works for you and your schedule.