LTspice: Generating Triangular & Sawtooth Waveforms. Saw tooth graph

US2220712A. Saw-tooth wave generator. Google Patents

Publication number US2220712A US2220712A US227453A US22745338A US2220712A US 2220712 A US2220712 A US 2220712A US 227453 A US227453 A US 227453A US 22745338 A US22745338 A US 22745338A US 2220712 A US2220712 A US 2220712A Authority US United States Prior art keywords tube potential condenser coil saw Prior art date 1937-06-21 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired. Lifetime Application number US227453A Inventor Geiger Max Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) Telefunken AG Original Assignee Telefunken AG Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 1937-06-21 Filing date 1938-08-30 Publication date 1940-11-05 Priority claimed from DE516357X external-priority 1938-08-30 Application filed by Telefunken AG filed Critical Telefunken AG 1940-11-05 Application granted granted Critical 1940-11-05 Publication of US2220712A publication Critical patent/US2220712A/en 1957-11-05 Anticipated expiration legal-status Critical Status Expired. Lifetime legal-status Critical Current

Links

- 241001646071 Prioneris Species 0.000 title description 22

- 230000001939 inductive effect Effects 0.000 description 6

- 210000003127 Knee Anatomy 0.000 description 4

- 239000004020 conductor Substances 0.000 description 4

- 230000001808 coupling Effects 0.000 description 4

- 238000010168 coupling process Methods 0.000 description 4

- 238000005859 coupling reaction Methods 0.000 description 4

- 230000000977 initiatory Effects 0.000 description 4

- 230000000903 blocking Effects 0.000 description 2

- 230000003292 diminished Effects 0.000 description 2

- 230000001747 exhibiting Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000008929 regeneration Effects 0.000 description 2

- 238000011069 regeneration method Methods 0.000 description 2

- 230000002441 reversible Effects 0.000 description 2

- 230000000630 rising Effects 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

Images

Classifications

- H — ELECTRICITY

- H03 — ELECTRONIC CIRCUITRY

- H03K — PULSE TECHNIQUE

- H03K4/00 — Generating pulses having essentially a finite slope or stepped portions

- H03K4/06 — Generating pulses having essentially a finite slope or stepped portions having triangular shape

- H03K4/08 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape

- H03K4/10 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only

- H03K4/12 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth voltage is produced across a capacitor

- H03K4/16 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth voltage is produced across a capacitor using a single tube with positive feedback through transformer, e.g. blocking oscillator

- H — ELECTRICITY

- H03 — ELECTRONIC CIRCUITRY

- H03K — PULSE TECHNIQUE

- H03K4/00 — Generating pulses having essentially a finite slope or stepped portions

- H03K4/06 — Generating pulses having essentially a finite slope or stepped portions having triangular shape

- H03K4/08 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape

- H03K4/10 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only

- H03K4/26 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth current is produced through an inductor

- H03K4/28 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth current is produced through an inductor using a tube operating as a switching device

- H03K4/32 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth current is produced through an inductor using a tube operating as a switching device combined with means for generating the driving pulses

- H03K4/34 — Generating pulses having essentially a finite slope or stepped portions having triangular shape having sawtooth shape using as active elements vacuum tubes only in which a sawtooth current is produced through an inductor using a tube operating as a switching device combined with means for generating the driving pulses using a single tube with positive feedback through a transformer

Description

SAW-TOOTH WAVE GENERATOR Filed Aug. 30, 1938 INVENTOR l Amig/G BY j /I/U’bd/l/ ATTORNEY Patented Nov. 5, 1940 UNITED STATES PATENT OFFICE SAW-Toorn WAVE GENERATOR many Application August’ 30, 1938, Serial No. 227,453 In Germany June 21, 1937 2 Claims.

A saw-tooth generator has been disclosed in the prior art comprising a parallel resonance circuit in the grid circuit of a controlled tube, the inductance branch of the said resonance circuit comprising a rectier, with voltage feedback being established between the plate circuit of the said controlled tube and its grid circuit. According to this suggested arrangement, the deflector coil of; a cathode-ray tube is connected between the lament and the plate of the controlled tube by capacitive means.

The present invention has as its object to connect, in saw-tooth Wave or time-base generators predicated upon the same principle as the said organization disclosed in the earlier art, a resistance in series With the control grid of the tube, in a Way as shall hereinafter be described in more detail, with the result that the chances of disturbing actions arising in the circuit organization are greatly diminished.

To more fully and clearly explain the invention, the layout and the operation of a circuit arrangement Without the said resistance shall first be discussed.

My invention will best be understood by reference to the drawing in which Fig. 1 is an example of the prior art,

Referring to Fig. 1, there is shown an embodiment of the prior art. A thermionic vacuum tube I0, which in this instance is illustrated as a triode, has connected to the control grid thereof three parallel circuits which are shunted across 35 the control grid-cathode path of the tube. The

rst comprises a resistor I5 and source of positive biasing potential I6 connected serially each to the other. A condenser II is connected in shunt with the resistor I5 in the source of bias- 40 ing potential I6, and the third shunt circuit is a coupling coil I2 connected serially with a rectier I3. vThe anode circuit of the tube is connected serially With a coil I4 which is inductively coupled With the coil I2, and the circuit is completed through source of energizing potential indicated, the negative side of the source of potential being connected to the cathode of the tube.

To more clearly explain the operation of an organization as illustrated in Fig. 1, the assumption shall be made vthat at the condenser Il prevails a strong charge Withgthe terminal thereof directly connected to the coil I2 being negative. The said charge shall be supposed to be so high that the tube as a result is biased to a point below the bottom knee of its plate current grid voltage characteristic. The coil I4 in the plate circuit of tube I0 as a result carries no current, and hence, no potential exists across the coil I2. ‘The rectifier I3 is subject tovoltage action in its backward sense. The condenser II is then charged through the resistance I5 from the D. C. voltage source I6, the potential at the upper condenser coat being such as indicated by.curve K in Fig. 2. Over the zero line which corresponds to the iilament potential of tube I0 there is plotted in Fig. 2 the potential of the D. C. voltage source I 6 indicated by the straight line G in addition to the potential at the upper condenser coat. Graph K obeys an e function, with the straight line G being the asymptote. When the curve K intersects the dotted (dash) line C Which corresponds to the bottom knee of the plate current-grid voltage characteristic of tube Ill, a rise of current is initiated in the plate circuit of this tube Which is indicated by I in Fig. 2. To this rising current in the Winding I4 corresponds a constant voltage across the coil I2, the latter to have by assumption a polarity such that the terminal thereof connected directly to. condenser II has a positive polarity. 1 This lastrmentioned potential is designated by S, in Fig. 2. It is also a blocking potential-for the rectifier I3. When graph K crosses the zero line, the potential at condenser II is reversed, with the result that the condenser voltage now has a sign so that the rectier I3 is acted upon in its for- Ward direction. The voltage `at the condenser I I must then rise to a level which lies above the voltage to occasion incipient current flow in the rectifier I3. However, as the rectifier I3 con? ducts current again, the voltage at the condenser II diminishes again because of the discharge through the rectifier, and simultaneously with the decline of the plate current of tube I0 a voltage reversal will happen across the coil I2. Incidentally, the magnetic energy of the coil I4 will be discharged through the rectier I3 and re-appears in the form of an electric charge at the condenser II of= a polarity such that the terminal thereof directly connected to the inductance coil I2 has a negative polarity.

Under practical operating conditions, the process as hereinbefore outlined is not exactly as described on the ground that a grid current begins the coil I2, that is, vin a sense so that the polarity thereof is such that the terminal connected directly to the condenser I I has a positive polarity, While the size thereof diminishes. The instant of incipient current flow in rectifier I3, as Will be seen, is governed by the instant at which the line exhibiting a flatter rise than curve K, Fig. ‘2, has assumed a greater amplitude than the reduced voltage across the coil I2. This flat intersection of the curve which represents the potential actually prevailing at the upper condenser coat across the horizontal line which corresponds to the altered potential at the coil I2 is attended With a serious uncertainty of the time of initiation of the short stroke of the sawtooth Wave. For one has to figure With the chance that a certain noise or disturbing (stray) voltage level prevails at the control grid of the tube I0, which has this consequence that the incipiency of the saw-tooth return or iiyback stroke, comparatively speaking, may happen far earlier or later, according to the noise voltage level.

Hence, it is here suggested to insert a resistance Il in series with the control grid of the tube lo as shown in Fig. 3. The result and action of the said resistance is two-fold, namely, the curve K after crossing the zero line O Will continue to rise With practically unvaried slope or rate. over, the grid potential of the tube I0 because oil incipient grid current flow, Will now stay practically constant and stable. As a consequence, however, the voltage across the coil I2 disappears, so that, as soon as the condenser has assumed a small charge of such polarity that the terminal thereof connected directly to the inductance coil I2 has a positive polarity, the rectifier I3 is rendered conducting so that the return stroke is caused to commence. As will be noticed, the noise level will then have far less chance to cause a shift in the time of initiation of the saw-tooth return stroke inasmuch as the curve K and the graph giving the potential shape as a function of the `time at the coil I2 nov longer intersect at a comparatively sharp angle.

Referring to Fig. 3, there is shown an embodiment of my invention in which similar reference numerals refer to similar parts as explained hereinbefore With respect to Fig. 1. In this case, the cathode of tube Ill is grounded and the anode of tube i0 is connected to ground through a coupling coil I4 and source of energizing potential indicated, the negative terminal of the source of energizing potential being grounded. The control grid is connected serially to a resistor I’I, the terminal of the resistor I1 remote from the termination thereof connected to the control grid of tube I0 being electrically connected to the cathode of the tube through the three parallel circuits referred to in regard to Fig. l. These circuits compriser a serially connected resistor I5 and source of energizing potential I8, condenser II connected in shunt with said resistor and source of energizing potential, and a series circuit comprising coil I2 which is inductively coupled to coil I4 and rectifier I3 connected in series therewith, the combination of the inductance I2 and the rectifier I3 being connected in shunt with condenser II and resistor I5 and source of potential I6.

In an arrangement of circuits according to the invention a saw-tooth voltage wave is obtained at the condenser II, While moreover, if desired, a saw-tooth current Wave may be obtained from the plate circuit of tube IU, that is, when the bottom point of curve K is made to coincide with the incipient flow of plate current of tube I0. The coil I4 may be used directly as the deector coil in a cathode-ray tube.

It is, moreover, readily feasible tol synchronize a saw-tooth wave generator according to the invention by impulses. These impulses, to the said end in View, must be made to act upon the plate current of tube I0 in a sense to cause a reduction thereof, and this is accomplishable, for instance, by a further control grid of tube I0. For television purposes, therefore, a sawtooth wave generator according to the present disclosure may be readily controlled with line or lineseries impulses.

It is also to be emphasized that the invention is useful not only with generators for which potential feedback is eifected by a transformer, but that the invention is useful also with sawtooth wave generators comprising any desired regeneration scheme which furnishes a potential of suitable phase such as is insured, for instance, by a reversing tube or a device presenting negative slope.

l. A saw-tooth Wave generator comprising a thermionic vacuum tube comprising anode, cathode and at least one control electrode, a parallel resonant circuit comprising an inductance and a condenser connected in the control electrodecathode path of said tube, a uni-directional conductor connected serially With said inductance and condenser comprising the parallel resonant circuit, a series circuit comprising a resistor and source of potential connected substantially in shunt with said parallel resonant circuit, resistive means connected to said control electrode and connected serially to said parallel resonant circuit, means for feeding back a portion of the anode-cathode circuit energy to said parallel resonant circuit.

A saw-tooth wave generator comprising a thermionic vacuumv tube having anode, cathode and at least one control electrode, a rst in ductive member, a uni-directional conductor, condenser means, said first inductive member and said uni-directional conducting means being serially connected each With the other and connected in parallel with said condenser means, source of fixed potential, an impedance means, said source of fixed potential and said impedance means being serially connected each with the other and connected in shunt with said condenser means, said condenser means being connected in the control electrode-cathode circuit lof said thermionic tube, impedance means connected serially With said control electrode and said condenser means, and a second inductive member coupled tosaid rst inductive member and connected in the anode-cathode path of said thermionic tube.

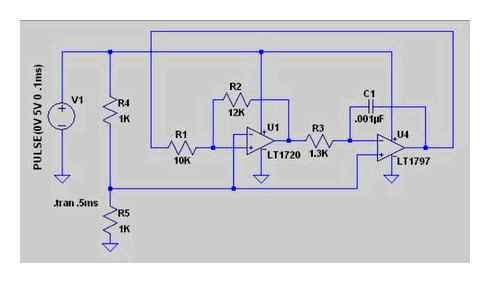

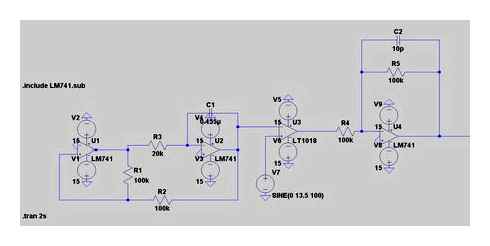

LTspice: Generating Triangular Sawtooth Waveforms

Some of the most common waveforms needed in simulating voltage and current sources are sine, square, triangular and sawtooth shapes.

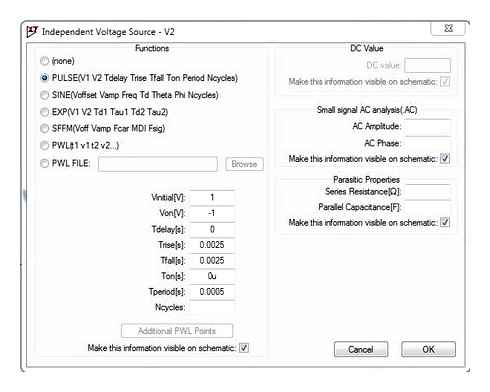

LTspice simulation software has a built-in pulse, sine, exponential, single frequency FM and an arbitrary piece-wise linear functions available in the source component editor. Although it may not look like it, LTspice does have a triangular and sawtooth functions available but they need to be created from either a PULSE or PWL function.

PULSE fuction is often used in transient circuit simulation where we want the source to behave like a square wave. You can omit Ncycles if you need a free-running square waveform.

PULSE(Voff Von Tdelay Trise Tfall Ton Tperiod Ncycles)

A simple approach to creating a triangular and sawtooth waveform is using the PULSE fuction using the source component editor shown above. For the triangular waveform you can set the rise and fall time equal to 1/2 of your desired period in your pulse function. Likewise, to create a sawtooth fuction you cab set the rise time equal to the period and the fall time to zero. The PULSE function can be further modify to best match your simulation needs. Waveforms for these two fuctions are show on the top of the page.

For any arbitrary or complex waveform, you can always rely on the piece-wise linear function. The arbitrary piece-wise linear fuction is defined by a sequence of time and voltage pairs.

This specifies that for time before t1, the voltage is v1. For times between t1 and t2, the voltage varies linearly between v1 and v2. There can be any number of time, voltage points given and for times after the last time, the voltage is the last voltage.

To implement a triangular or sawtooth waveform you could use the following piece-wise linear functions. Waveforms for these two fuctions are show on the top of the page.

These two examples use an undocumented repeat feature of PWL function. To explore these features you will need to directly edit by right-clicking on the source symbol’s text in the schematic editor rather than using the source component editor.

Here are some highlights of the undocumented features for the PWL fuction:

PWL REPEAT FOREVER (0 0.5 1 1 0) ENDREPEAT

PWL TIME_SCALE_FACTOR=0.5 VALUE_SCALE_FACTOR=2 (0 0.5 1 1 0)

information on the pulse, sine, exponential, single frequency FM and an arbitrary piece-wise linear functions is available in the LTspice help file (F1). An example LTspice simulation is also provided below for your reference.

Author

Gabino Alonso is currently the director of strategic marketing for the Power by Linear Group. Prior to joining ADI, Gabino held various positions in marketing, engineering, operations, and education at Linear Technology, Texas Instruments, and California Polytechnic State University. He holds a Master of Science degree in electrical and computer engineering from University of California, Santa Barbara.

Resources

Cookie Consent

By clicking “Accept All”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Visitors have the right to withdraw their consent. For additional information you may view the cookie details. Read more about our privacy policy.

Analog Devices is in the process of updating our website. After we finish updating our website, you will be able to set your cookie preferences.

Strictly Necessary Cookies: (Always Active) These cookies are necessary for the website to function and cannot be switched off in our systems. They are usually only set in response to actions made by you which amount to a request for services, such as setting your privacy preferences, logging in or filling in forms. You can set your browser to block or alert you about these cookies, but some parts of the site will not then work. These cookies do not store any personally identifiable information. Functional Cookies: These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third party providers whose services we have added to our pages. If you do not allow these cookies then some or all of these services may not function properly. Performance Cookies: These cookies allow us to count visits and traffic sources so we can measure and improve the performance of our site. They help us to know which pages are the most and least popular and see how visitors move around the site. All information these cookies collect is aggregated and therefore anonymous. If you do not allow these cookies we will not know when you have visited our site, and will not be able to monitor its performance. Targeting Cookies: These cookies may be set through our site by Analog Devices and our service providers. They may be used by Analog Devices to build a profile of your interests and show you relevant content on our site. They do not store directly personal information, but are based on uniquely identifying your browser and internet device. If you do not allow these cookies, you will experience reduced relevant content. Decline cookies

Saw tooth graph

I usually browse the ‘Crawl stats’ into ‘Google Search Console’ to check that the ‘Average response time’ is ok. As you can see in the attached graph, I try to keep this value around 100-120 ms.

However, starting on Dec 29, these figures have begun to show a sawtooth graph ranging from 90 ms to 240 ms. This does not make sense for me. Should I worry about this more-than-100% changes?

I’ve been checking some issues to be sure about the origin of this matter:. My web hosting claims that there are no network incidents or no SSD issues in the server. I have not changed my PHP code in the last few weeks. I use CloudFlare (Pro Plan), I do not see nothing relevant in the stats (honestly, I wouldn’t be able to detect a CloudFlare incident either). According to the ‘Crawl stats’ of GSC, there was a significant increase in 404 errors starting on Dec 29 (an error writing the sitemap), but I fixed it, and on Jan 9 there were almost no 404 errors in the ‘Crawl stats’ Almost no 5XX or ‘Page could not be reached’ errors in the ‘Crawl stats’.

Any similar experience is welcome. Thank you.

Dimitri

i never bother with this, so. by curiosity I looked, and I observe the exact same thing as you!

Until Dec 29, I have a flat line at ~ 90-100ms, then all of a sudden very irregular values.

I wouldn’t worry. Also, this is Google’s crawler stats, it doesn‘t mean visitor are facing the same changes. 240ms, is twice more than what you used to have, but it’s still a good value, in my opinion.

Design of Sawtooth wave generator using opamp

This shouldn’t have an impact on your indexing and ranking.

I understand that Google is taking in consideration the speed of your site, when viewed in Chrome, (by humans), and still, this account for very little in the ranking.

Sgt_Kickaxe

The tooth you need to look for is a sudden huge spike in googlebot crawl activity. It typically preceeds a major update and site re-evaluation

robzilla

Had some trouble finding the Crawl Stats report in GSC, apparently it’s now buried under Settings.

Since Dimitri noticed a similar change around Dec 29, it’s possible that there’s been a change on Google’s end. For example, if they used to crawl mostly from the West Coast and have shifted east, moving further away from your server, that can have an effect on the average response time reported. For that reason, response time as measured by Googlebot is unlikely to be used in rankings, so don’t worry about that. Unless the response times are consistently problematic, of course. But then we’re probably talking 5-10 seconds consistently.

A higher than usual response time can affect your crawl rate, because it signals that generating the page may be very resource intensive, the server is overloaded, network conditions are poor (e.g. self-hosted), etc. So then they may take a step back and crawl a little less frequently, so as not to cause any trouble.

But 90-240 ms is not bad at all, even 1000ms is probably still fine (but, as noted, may affect crawl rate). Looks like mine usually jumps around between 70 and 150. Analytics reports an average response time of 100 ms for US traffic, so that’s pretty similar. That’s probably the first thing I’d check if I were worried about a change in response times.

I don’t see a change around Dec 29, but I have servers in various locations in the US. You use CloudFlare, but it’s probably not caching your dynamic content?

guarriman3

Hi @Sgt_Kickaxe, thank you for your nice answer.

The tooth you need to look for is a sudden huge spike in googlebot crawl activity. It typically preceeds a major update and site re-evaluation

Precisely, as of January 21st, the Googlebot’s crawl requests of my site jumped from an average of 30-40k/day to a peak of 300k/day. This week the rate is abnormally low, 2-3 k/day. I hope that the site re-evaluation is for the better 🙂

On another note, as of January 13, the Average Response Time (according to GSC) the response time returned to normal levels (100-120 ms), after four peaks of 240-250 ms.

LTSPICE #14: Simulating Various Waveforms (Squarewaves, Sinewaves, Triangles And Sawtooths)

Understanding Saw Tooth Geometry

My recent saw sharpening video where I demonstrated the Veritas Saw File Holder has generated a lot of emails with questions about saw tooth geometry. I take this as a good sign that lots of people are actually thinking about sharpening their own saws. Not only that but the introduction of filing guides like the Veritas and the Rakemaker II by Blackburn Toolworks (a great site to check our for more info on this subject) have people thinking in detail about what tooth geometry is best for their work. These little guides open up a level of filing accuracy only previously attempted by saw filing experts. Of course with this comes questions about how this saw tooth geometry actually works. What degree of rake and fleam are best for me?

This is a tough question to answer. Like any sharpening related topic there are many, many opinions and solid justification for each of those opinions. Usually any sharpening discussion is to be entered at your own risk and histrionics should be expected with much wailing and beating of the breast. So here is my sidestepping disclaimer: the numbers I detail below are but one option within the mellifluous multiverse of saw tooth geometry. I give ranges of numbers knowing full well that there are too many variables at play to state one degree of rake and/or fleam is better than another. From body mechanics and stature, to type of wood and degree of seasoning. Don’t forget the phase of the moon and astrological sign either! These are my humble opinions won through hours of sawing with a fair dose of standing on the backs of giants like Herman, Harrell, Wenzloff, and Smith.

Elements of Saw Tooth Geometry

This is a great PDF provided by Tools for Working Wood, go download it!

Pitch, Rake, Fleam, and Set are the elements we should consider. I think that really only rake, fleam, and set are the primary elements and pitch a secondary element. Pitch, the number of points per inch or PPI, plays a role in determining how deep your gullets are and therefore how efficiently the saw carries saw dust away from the kerf. This in turn relates to the speed and the cleanliness of the cut but not nearly as much as the rake and fleam can effect these outcomes. As such I think we can set pitch aside for this discussion since it will be rare that we are actually changing this pitch unless you are making a saw from scratch or restoring a really really beat up and well used saw.

Rake determines the aggressiveness of your cut. This is the angle of the cutting face of the tooth. At 0 degrees, the tooth is vertical and cut very aggressively. One can actually lean the tooth forward to create a positive rake and a very aggressive cut, but also one that is hard to push and start while leaving the undercut tooth a bit weaker. You will find a positive rake on some Japanese saws but the pulling motion and much harder steel adds in some variables that ameliorate the negative effects of positive rake. The more you relax the rake, or increase the angle the tooth slants away from the cut the easier the saw is to push. The teeth can now skate over the wood more easily. This makes starting the cut easier but also it slows down the cut as the teeth have a tendency to lift up and away from the cut. A low rake angle cuts fast but can feel grabbier and also make take more experience to handle. Changing this angle will help you adjust to harder and softer wood as well.

Fleam is the angle across the face of the tooth or perpendicular to the tooth line. By adding fleam you turn the teeth into little knives that slice the grain instead of chop it like a chisel. The more fleam the cleaner the cut you get but the weaker you make the teeth. As the fleam angle increases you get a smaller tooth front and the steel becomes brittle. As such high fleam saws should be used in softer woods that won’t push back so much on the more fragile teeth. The converse to this is a saw tooth with little to no fleam will leave a rougher cut and require more effort to move through the wood. The slicing action that is inherent with fleam is what makes a well tuned crosscut saw do its job without splintering and tearing across the grain.

Set is the amount of offset the teeth have to either side of the tooth line. When we set the teeth we are bending them away from the saw plate to widen the kerf and allow the saw to run without binding. Like the other elements this is a good thing but too much goes wrong very fast. The wider the kerf the more wood you remove and therefore the more work required to push the saw. Likewise the wider the kerf the sloppier the action as the saw plate can now wiggle about in the wider kerf and throw off a precise cut. This is why joinery saws always have less set than rough work hand saws. Also why softer and/or wetter woods need more set because the spongy and sticky saw dust won’t clear as readily from the kerf and more room is needed for the saw to run. If the kerf gets tight not only will the saw bind, but it can deflect in the kerf as it tries to find a way around the build up dust, thus making your saw not run true.

None of these elements should be considering singly. They all relate to one another and should be considered as a whole to create the best tooth geometry for the task at hand. This is very useful as you can compensate, augment, or offset the positive and negative effects of one element by tweaking another.

For example,

If I want my saw to cut fast I will reduce the rake. If I want it to start easily yet still cut fast I will increase the fleam a bit to make the teeth slice more (like skewing a hand plane). This also have the happy effect of making a smoother cut surface. I can also reduce the set to create a cleaner cut since a more uniform tooth line won’t present as jagged an edge to the wood. This allows me to reduce the fleam to make a stronger tooth. The beauty is that by altering all 3 of these in concert can produce the perfect experience. Each one plays a role and tooth geometry should rely on all 3 to do the job.

So what does this mean to you? What degrees should I use for my saws? What follows are some general numbers to use as a guide. Now that you know what changing these numbers will do you can tweak them one way or another to create a saw that performs well in a specific situation or over a wider range of applications.

Set

This is not as cut and dried to the point where I can put a numerical range on it. The reality is that set is measured in thousandths of an inch and most of us don’t have the capacity to even measure this. Professional saw filers have much more accurate setting techniques and a heck of a lot of muscle memory to aid them. For the average woodworker with a pistol grip saw set, it comes down to feel. Most set has a pitch guideline on them that you can adjust to match the saw. The finer the pitch, the smaller the set. My recommendation is to set this adjustment to a pitch that is finer than the actual pitch of the saw you are working on. Sometimes several times finer in fact. set can be added and set can be removed but I find it easier to add more than take it away. Often times the setting process is helpful in adjusting a saw that isn’t running true too so the best thing is to skew to the finer set and then make several test cuts altering the set to get the right feel. With each test cut make sure you saw enough to let friction heat up the saw plate causing it to expand. You may think you have it right only to find the saw plate expands in the middle of a cut and starts to bind.

I find that once I have a saw set, I don’t need to reset it until I have sharpened the saw at least once more. In other words, every 3rd sharpening is a good rule of thumb. So while set is a little more touchy feely than rake and fleam, remember that it is also part of the geometry that effect how the saw cuts. Don neglect to alter the set in order to tune a saw. I have certainly been guilty of just relying on rake and fleam to solve all my problems. Though if I’m being honest usually the adjustments I make in set entail reducing the amount rather than increasing it.

Hopefully this treatise will help you wrap your head around these concepts. Don’t over analyze it but rather relish in our ability to be able to finely tune our hand saws. For the average hobbyist, pitch a number in the middle of the above ranges and you will do just fine. If you are more adventurous and looking for that “perfect” saw, consider each and every task as an equation to be solved with a little creative tooth geometry. Is it any wonder why masters of the saw like Ron Herman have so many saws? Once you solve one of these geometry equations you will find yourself getting more saws and tuning them to specific tasks. Careful this is a slippery slope and soon you will be talking about witchcraft like sloping gullets and progressive rake and fleam.