Miter Saw What Can You Do

How to make a miter saw with your own hands? How and from what is a do-it-yourself miter saw made with a broach? How to make trimming for wood and metal from manual circulars, with minimal financial investment?

Varieties

Cross-sections are divided into the following types:

- Pendulum;

- Combined;

- With a broach.

The base of the pendulum device is the bed. A table is also attached to it, which is based on a rotation mechanism with a ruler. This mechanism solves the problem of setting the cutting angle with its adjustment. The cutting angle can be adjusted by moving the table in relation to the base surface. The saw component is held in place by a handle and is spring loaded with a hinge. The pendulum moves the saw vertically.

In the combined modification, it is possible to change the cutting angle in two directions. The structure is the same as that of the pendulum facing, only one more hinge is added. In terms of changing the angle of cut in the horizontal surface, it can be changed in the horizontal direction, which is also opposite to the installed drive.

Facing with a broach allows you to translate the cutting component both along the circumference of the pivot axis and directly along the length of the cut. This is due to the existing guides.

Tool creation

It is possible to make a miter saw with your own hands, taking the available equipment as a basis.

From the grinder

Miter saws are capable of cutting wood, iron, plastics and other materials.

The most famous facing is based on the use of an angle grinder.

If you can do everything correctly, your device with a broach will have the following options:

- Disk rotation speed 4500 rpm;

- Cutting distance approximately 350 millimeters.

If necessary, trimming is dismantled from the unit and is practiced as an ordinary hand tool. A big plus is that the homemade device is versatile and can be easily disassembled.

Let’s consider how the manufacturing procedure takes place.

- Place the swivel mechanism of the angle grinder on the pivot of the implement wheel. Its fastening is made by means of a ball bearing. The recommended size is 150 millimeters, but larger ones will also work.

- Ears are welded on the outer side of the bearing. They are designed to secure the base of the unit. Install with M6 bolts.

- The holder should be covered with a protective cover so that chips do not fly on you during operation.

- The broaching problem is easy to solve. To create it, take shock absorbers from a truck. Even if they are not in working order, this is not a problem. Remove any lubricant from the shock absorbers, drill holes for ventilation and cover with a mesh to prevent chips and dust from entering the cavity.

- Install the soft start module. Thanks to it, you will not experience sudden jerks when starting the trimming.

- The final stage is the installation of the saw blade guard.

Depending on the supplied disc, the unit can be used for metal or wood, for facing pipes. But be aware that there may not be enough unit power to cut pipe ends. Decide on the specifications of your angle grinder to find out if the machine is capable of cutting pipes, or if it is only suitable for working with wood.

This design has two important drawbacks.

- To adjust the precision of the cut, wood residues are used first. Then the thrust is fixed, and you can start working.

- The unit makes a lot of noise when cutting pipes and working on iron.

Manufacturing of a complex unit

There is an option with a more complex and heavy construction. She will precisely cope with the facing of metal pipes. At the same time, a self-made device does not require the use of a circular as an element of the unit. But for specific moments of work, it is better to keep the circular at hand.

Based on the selected components, you have the opportunity to make a high-power unit. To create it you will need:

- An electric motor with a resource of about 900 W, and if you need constant cutting of pipes, you can take a more powerful electric motor;

- Sheet iron;

- Metal corners;

- Channel;

- Hinge groups;

- Angle grinder;

- Welding machine;

- File;

- Powerful spring.

When everything you need is ready, you can start assembling the end machine.

- The bed can be made using customizable supports, metal corners and bed racks.

- A sheet of strong iron is used as a working surface. It is necessary to make holes in it and file them with a file.

- For the manufacture of the pendulum rack, we use a channel and a welding machine. The structure is placed on an iron sheet. Approximate stand height 80 cm.

- The base for the electric motor is made of iron sheet as a stationary plate. The bed is necessarily mounted on hinges.

- A powerful spring will serve as a stabilizer for the electric motor of the miter saw. If you find one, then you can refuse from the swingarm and belts.

- The lifting bolt can be used to tension and adjust the belts. The pendulum can be made of steel to make the structure strong and reliable.

- The cutting tool will be a disc of the required diameter. For household tasks, a saw blade with a diameter of 400-420 millimeters is usually sufficient.

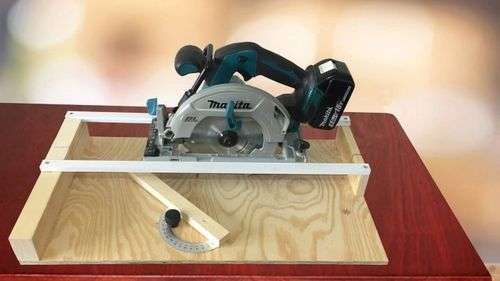

From a hand-held circular saw

The structure is common and acceptable for home construction. The body of the trimming unit is made of wood or iron. A base is constructed from plywood sheets (chipboard), on which a vertical rack is mounted, having previously cut holes in it to fix the facing. A pendulum-type device is made from a board and is attached to the base by means of a long bolt.

Having prepared a steel rod or corner, it is attached to the top of the pendulum so that the end sticks out. Then the spring is taken, one end of it is fixed to the rear shelf of the corner, and the other to the vertical rack. The tension is selected empirically, but it should be enough to easily hold the hand-held circular saw in the hanging position.

Having removed the handle from the equipment, it is fixed on the pendulum in a previously prepared hole. The wires are placed in the slots prepared for this, and the power supply is connected. A small slot is made in the table top, and side stops are fixed to it at an angle of 90. If they are made to rotate, then it will be possible to cut the blanks at a specific degree. The unit is assembled, it remains to be tested in operation. Using the drawings, you can make anything, even a very complicated apparatus.

How to make a miter saw with your own hands?

- Varieties

- Tool creation

- From a hand-held circular saw

- From the grinder

- Manufacturing of a complex unit

- Pros and cons

The miter saw is created by hand on the basis of the existing equipment of a hand-held circular saw, an angle grinder (grinder). And when mounting disks of a specific type, a home-made device can be used to cut a profile on a metal-plastic base, pipes, which will increase the area of its use.

Best miter saws

If you need to cut at a certain angle, both wooden blanks and thin metal, plastic, you cannot do without the best miter saw. But for it to give the desired results, the tool must be of high quality, safe, simple and convenient to use. Just taking into account such parameters, our rating was compiled, in which you will find budget models, middle and premium class options.

Which company miter saw is better to choose

- Hammer a brand of power tools for professionals with compact dimensions, high speed (about 5000 rotations per minute), low noise level and reliable protection against overheating. The devices can easily withstand heavy loads and are successfully used for different types of sawing. They are effective in working not only with wood, but also with thin aluminum surfaces.

- Bison budget manufacturer of power tools, among which there are saws. They are used for both simple and complex cutting of blades at different angles of inclination of the blade. The large entry depth of the working elements and their decent diameter guarantee the acceleration of the process. The products have a powerful motor that can handle even high loads.

- Caliber devices of the brand are suitable for processing workpieces not only made of wood, but also plastic and aluminum materials. They cope with a wide range of thicknesses with a large cutting disc and keep waste at an acceptable level. The company’s products are distinguished by a compact table, reliable stops and clamps, which guarantees a safer and more efficient use of miter saws for wood and other materials.

- Metabo manufacturer of professional electrical equipment, which features high build quality, good motor power, sharp discs. The company’s products are functional and reliably protected from premature failure. The diameter of the cutting elements ranges from 216 to 315 mm, depending on the specific model.

- Makita The company’s range is replete with miter saws, the average power of which is 1600 W. The instruments have discs with a diameter of about 20 cm, rotating at a speed of 3000-6000 revolutions per minute. Many of them are equipped with a comfortable table and a broaching mechanism for improved quality of work.

- Bosch German manufacturer of mainly premium products. Its saws have a compact size and adequate weight, equipped with a comfortable handle and durable stops. The company’s structures are distinguished by high-quality assembly and are made from durable materials. They have easy-to-replace cutting elements and intuitive operation.

- DeWALT The brand’s saws are appreciated for their good quality and high level of safety for the user. They keep the work surface clean when equipped with a dust collector. Most of the assortment is represented by network models powered by an outlet. The average power of the product is 1300 W, the cutting depth is about 3 cm, however, the tools weigh about 15 kg.

Rating of the best miter saws

Here are the other criteria used to compare the instruments:

- Power;

- Rotational speed;

- Cutting depth and width;

- Methods for processing canvases;

- The types of materials with which the tool works;

- Noise level;

- Power supply methods and cord length;

- Engine protection;

- Disc diameter and sharpness;

- Possibilities for table expansion;

- Dust box size;

- Weight;

- Equipment;

- Illumination of the working surface;

- Easy replacement of cutting elements.

Testimonial: Mac Allister Miter Saw MMSP1500WS. A good amateur tool for little money.

The saw looks very decent. Everything seems to be of normal quality, I did not see any jambs as materials. The frame and casing are made of aluminum alloy.

Out of the box, all moving parts are already lubricated. Moves along the runners easily and smoothly.

The saw blade is installed here on wood with a seat of 30 mm., 210 mm wide. And has 48 teeth. The engine rotates at 5000 rpm.

This miter saw has the ability to cut 45 degrees to either side. The corner is securely fixed with a spring-loaded handle.

There is a metal frame under the bed, when unfolded, an additional backgauge is obtained for the entire installation.

It is possible to supply additional extenders for long parts on both sides. The auxiliary clamp “third hand” is quite strong, made of metal and allows you to securely fix the part on the bed before cutting.

The saw also has the ability to make cuts at an inclination of up to 45 degrees to one side, for which there is a degree scale and a locking knob on the runner stand. Cuts can be made at the same time at an angle and at an angle. In this case, of course, the depth of a possible gash decreases.

Now the nuances that I discovered.

After reading the instructions, I found a lot of technical data that less conscientious manufacturers simply do not indicate. The manufacturer indicates that this miter saw is guaranteed for 2 years. But more interestingly, the service life of this saw is indicated at 32 hours. At first, this figure seems very small. But having estimated that it takes about five seconds to cut the part and the engine does not rotate at idle. The tool is not professional and therefore the lifespan in reality of this saw is practically unlimited.

Another parameter is power. Usually, most manufacturers indicate the maximum engine power, and the tool in life works at a little less. Here, everywhere in the characteristics of the saw, a power of 1500 W is indicated, but in fact this power is nominal, and the maximum is 1800 W.

Another point that confused me was the cutting depth indicated at 62 mm. In fact, I can easily cut an 80mm door frame at a 45 degree angle.

Sorry, the box was 76 mm. In the standard position, 80 mm does not cut a little. I installed a 216 disc from Metabo on this trim. In this case, the protective casing begins to touch the disc. Solved the problem by bore the hole for securing the casing with a bolt. The stops were also slightly shifted forward and only after that 80 mm became easy to saw.

You can make a deeper cut if you move the part away from the longitudinal stops by laying something 1-2 cm thick between them and the part to be sawn.I do not know what the manufacturer is based on indicating this maximum cutting depth, but I think this is more of a limitation on engine power and small diameter of the saw blade.

I really liked the miter saw, I can safely recommend it for purchase. With the help of it, I have already installed three interior doors with platbands in a country house, I am going to use it when laying laminate. Considering that I paid 10,000 for the installation of four doors in the apartment, this saw practically paid for itself. For this money, a very good offer. For domestic use, power and functionality is quite enough. Of the minuses, it can be indicated that the sawdust does not actually fall into the bag intended for this, but is sprayed over the entire surface. It is better to immediately connect the vacuum cleaner, although it does not help either. This is a specific flaw of the manufacturer. No laser pointer or backlight, but at this price point it would be too naive to expect. Over, I know from experience that the installed laser on budget models usually shines in the wrong direction and only interferes.

Einhell TC-SM 2131 Dual Feed Miter Saw

Subscribe to our channel “Club of Friends of a Good Instrument” on Youtube. There are a lot of great reviews, for example:

Miter saw 210mm with laser module Einhell TE-SM 2131 Dual. Miter saw 210mm with Scheppach SL 8 LXU / HM 80 Lxu broach. Miter saw for wood 210mm with Utool UMS-8L broach. Miter saw Stark MS-1820. End saw for wood 210mm Intertool DT-0621

What can you do with a miter saw

Hand, table or machine miter saw is a professional sawing power tool used for miter, longitudinal, transverse, oblique and oblique cuts. Its full name is a miter saw, this operating tool received for the ability to perform an ultra-precise and ultra-thin accurate sawing operation of the so-called mustache joint, when the joining of two parts with angled edges is as tight as possible (for example, two plinths in the corner of the room). In general, most often, in the everyday life of masters, a miter saw is simply called a miter saw.

Modern miter saws application

Modern trims can be used to cut wood and metal, as well as plastic and composite materials (chipboard, fiberboard, plywood, laminate, etc.). This makes this tool a popular equipment in wood and metal processing enterprises.

Before you understand what a miter saw is, how to use it in everyday life and in the carpentry industry, you should get acquainted with its main design features.

Like the closest relatives, circular saws, miter saws are equipped with a left and right tiltable saw head with a disc (smooth-edged or serrated). For the operator’s safety, the saw equipment is housed in a protective cover that automatically opens the saw blade when starting work.

The tool is started by the start button, which activates the operation of the gearbox with the electric motor. The tool can be purely manual, with a convenient bracket-shaped handle, it can have a table-top base, or it can be installed on a workbench with rubber-knob legs that prevent the machine from sliding on the floor.

In contrast to the circular, not only the saw head tilts at the trimming, but also the working surface of the table (bed). This provides a wide field for the joiner who can create different types of cuts in the workpiece by tilting both the saw head and the work table. That is why in the technical parameters of miter saws there can be several values of sections (width and depth of cut) with different positions of the head and bed.

Also, in contrast to the circular saw, in the trimming the saw head is fed to the workpiece, and in the circular saw the workpiece is moved to the fixed tool. The axis of the saw blade in the miter saw is located above the plane of the work table: to make a cut, the saw is lowered, crossing the workpiece and the surface on which the workpiece is fixed.

Miter saws are most in demand at factories for the manufacture of floor coverings, doors, furniture. Taking into account large-sized blanks in furniture production, in order to securely fix them to obtain the most accurate and accurate cut without chipping, bevels and burrs, a crosscut saw with a broach is used here.

What is a miter saw for?

The main task of trimming is to make a very accurate and perfectly even cut at a given angle. It can be a horizontal cut at 90 or at an angle of 30, 45, and so on. Most often, a miter saw is needed in woodworking and furniture enterprises, often its use in finishing work. She is an irreplaceable assistant in the manufacture of door and window openings, furniture. Cross-sections have also found their application wherever it is necessary to work with polymeric materials or soft non-ferrous metals. To do this, they replace the saw blade with a cutting blade for metal. Sometimes a miter saw is called a cutting saw because it is directly involved in the installation of something.

If you do not need frequent use of cross-cutting or the accuracy of the cut does not need to be so critically accurate, then we recommend that you pay attention to a cheaper and easier-to-use circular saw.

What you can do with a miter saw

What is a miter saw for? What can be done by trimming. What types of saws are there and how they fundamentally differ. The most popular miter saw manufacturers in the world.

In the household, you rarely find a miter saw due to the peculiarities of its scope. It is also worth noting that the cost of this construction device is quite high compared to the more common grinders. So let’s figure out why you need a miter saw and for what work it is bought.

Types of trims

First of all, I would like to divide the whole variety of types of miter saws by design into:

- Standard;

- Multifunctional.

In the multifunctional version, the saw has a movable cover or table that easily converts it into a miniature circular saw. This is a more professional type of instrument, which we do not recommend purchasing for home use because of the significantly (2.5-3 times) overpriced.

Secondly, miter saws can be divided according to functionality. The more advanced versions have a retraction, a very popular feature that allows ripping cuts to be made significantly wider than the saw blade diameter. Or the ability to cut at different angles. The most inexpensive miter cuts are usually only sawed perpendicularly.

Most popular manufacturers

- Metabo German quality speaks for itself. The company has been developing and supplying power tools worldwide for almost 100 years.

- Bosch is the second proven manufacturer from Germany, which has been known and loved by professional builders for almost 150 years.

- Makita Japanese quality, not inferior to German in anything. Than 160 countries use this manufacturer’s electric and gas powered tools.

- DeWalt is a North American manufacturer with factories on three continents.