Smooth Start Angle Grinder

angle grinder or angle grinder is a very useful tool in the household when working with various surfaces. Such a tool dramatically facilitates many tedious processes. It can be used to process, sand or trim metal, wood, stone or plastic materials. Most modern grinders are initially equipped with a "soft start" function. What is the use of this function?

Features and purpose

What is the soft start function for? The reason is that when you turn on the angle grinder, a large voltage is suddenly applied to its engine. This extremely negatively affects the electronics of the instrument, and also wears out the wiring. It is sharp surges of voltage that most often disable the angle grinder. In addition, with a sharp start, it is quite difficult to hold the tool in your hands, because it starts to shake and lead to the side. All this can lead not only to a breakdown of the tool, but also to injuries. That is why most manufacturers have provided their models with a soft start function and speed control.

The speed adjustment function is useful in that such an angle grinder can carry out various types of work. The disk rotation speed is selected depending on what the angle grinder needs to be done. to grind, polish or trim the material. The speed of rotation of the discs may affect the quality of surface cutting. For example, for hard surfaces, a higher speed of rotation of the disk is required, and for softer, on the contrary, a low speed is required. Grinding work is very difficult without a wheel speed controller.

It is imperative to remember safety when working with an angle grinder. This is a traumatic device, therefore negligence in handling it is unacceptable. It is necessary to work in a protective mask, gloves and hold the grinder firmly with both hands so that it does not slip off the work surface.

Soft starter

On modern grinders, the soft start function has already been installed, but some masters independently supply their angle grinder with a soft start device. In principle, setting a limiter is not so difficult.

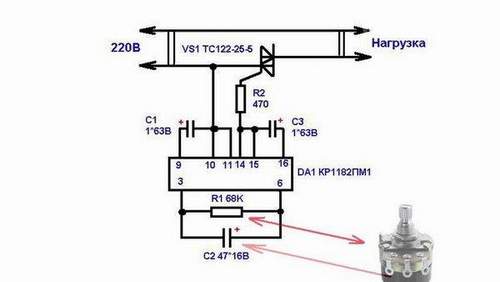

You can purchase ready-made devices for a soft start, or you can make such a device yourself. Below is one of the most famous schemes of the device soft start tool.

So, for the manufacture of a soft start system you will need:

- microcircuit. КР1182ПМ1;

- R1. 470 Ohm R2. 68;

- C1 and C2. 1 microfarad. 10 volts;

- C3. 47 microfarads. 10 volts.

The essence of the work of such an apparatus is the following characteristics.

- When the device turns on, the voltage from the network begins to flow to the chip (DA1).

- Then the control capacitor begins to charge gradually. After which the device reaches the desired voltage indicator. For this reason, the thyristors open in the microcircuit with a slight delay. The period of such a delay depends on the time it takes for the capacitor to fully charge.

- Triac VS1 will also open gradually. This is because it is also controlled by thyristors.

These processes are carried out in periods that gradually become smaller. And for this reason, the voltage that is supplied to the engine by an angle grinder does not grow abruptly, but gradually. Thanks to this, the angle grinder turns on smoothly.

The capacitance of the capacitor C2 directly affects the time during which the engine starts to work completely. The capacitor, which has a capacitance of 47 microfarads, starts the device in about 2-3 seconds. And at the moment when the angle grinder turns off, the discharge of the capacitor C1 is carried out using a resistor R1 of 60 kOhm. This happens in about the same time as inclusion. Then the tool can be run again for further work.

Video: Smooth Start Angle Grinder

This unit can easily be connected to any device that is designed for a voltage of 220 V. The basis of this device is a chip and triac. The main thing is that the minimum current strength of the triac is 25 A, and its maximum voltage is 400 V. Such a circuit is assembled on a printed circuit board. The board should be wired as compact as possible.

Selection tips

How to choose the right angle grinder? For this, it is worth using several basic criteria.

To select a suitable tool, it is worth deciding on the specific type of work to be performed by this tool. angle grinder can be of different types: network, with batteries, gasoline and pneumatic.

Network models are perhaps the most common. Such an angle grinder works from a home network, that is, from a simple outlet. Such models of the tool have high power, compactness and high speed of rotation of the cutting discs.

But the limitation in working with such an angle grinder is due to the dependence on the mains. For example, when working on the street, there is not always a power outlet nearby and you have to use various extension cords.

Battery devices are devoid of this minus. They have a special mount for power supplies that are charged from the mains. After charging, you can work with such a tool without any wires. Typically, such an angle grinder has compact dimensions and small diameters of the cutting discs. As a rule, such models are more expensive than standard tools. Also, the period of their work is limited by the capacity of the power supply.

Petrol models of grinders are not common. Such devices are large in size, because they need a fuel tank, as well as an internal combustion engine. Among the advantages, it is worth highlighting the high power of these models, a wide range of drive selection and autonomy. Negative aspects include their weight and volume, high noise level and, of course, the additional fuel costs for the operation of the device.

Pneumatic models of angle grinder are often used for production purposes. and very rare for domestic work. This is an unusual angle grinder that works from a stream of compressed air, and needs a special compressor. In such models, the problem of overheating is completely eliminated, and the period of work can be limited only by the human factor. Also, such models are the lightest and most silent.

For simple work on the processing and grinding of surfaces, light models of grinding machines with a small diameter of the cutting wheel are suitable. For work on cutting durable materials, it is worth choosing more powerful and, accordingly, bulky equipment with a large diameter of the disks. The diameters of the discs can be from 125 (minimum size) to 230 (maximum size) mm. that is, the size range is quite wide. The universal blade diameter is 180 mm. In this way, you can also process surfaces and cut material.

When choosing a disk, you should conduct a careful visual inspection. Even minor damage and chips can lead to extremely sad consequences. By the way, almost 90% of accidents when working with an angle grinder occur due to a fault on the cutting discs.

Another important selection criterion is usability. The angle grinder should be equipped with convenient handles, should not slip out of the palm of your hand and be heavy. Many angle grinders have an electronic relay to protect against power surges and overloads. This is a useful feature, so you should choose a tool with such a fuse.

It is recommended that you select models with a soft start function. This will help the tool to serve a much longer time, and using an angle grinder with such a function is much more convenient and safer.

How to connect?

If you need to connect the soft start function to the angle grinder with your own hands, you need to do this through the adapter. The input contacts of the conductor must be connected to the rectifier unit. An important role in this is played by the correct determination of the zero phase. The device contacts are fixed using a blowtorch. In order to check the operability of the device, you must use a special tester.

Among other things, the speed regulator of the grinder can actually be placed immediately in the outlet. From it the tool will work. To connect, you need a junction box, a socket and a regular network cable. A hole must be made in the junction box (can be drilled) to insert an AC regulator into it. The board is placed inside the box, and the socket is attached to it. This regulator is applicable not only to the grinder, but also to any device that will be connected to this outlet.

It is important to remember that these works are associated with high voltage. Therefore it is extremely important to observe safety measures in order to avoid accidents.

So, above it was examined for what purpose in the angle grinders there is a soft start function and a speed control of the cutting wheel. Usually, these functions are already built into modern tools, but if they are not available, if you so desire, you can install them and connect them yourself.