The lawn mower flows gasoline from the damper. Adjustment of carburetor floats

The causes of breakdowns of gasoline and electric trimmers

Trammer for grass, both electric and with an internal combustion engine (ICE), is an indispensable tool in the summer and autumn period for owners of cottages and private houses. With its help, weeds, small shrubs are easily removed and the lawn is trimmed. But, like any technique, trimmers for grass fail at the most inopportune moment. To eliminate the malfunctions with your own hands, the user of this technique first needs to determine the reason for their appearance.

In the lawn mower and an electric trimmer for grass, if you do not consider breakdowns associated with the bar and the mowing head, the malfunctions mainly happen in the engine area.

Damage of gasoline trimmers

Typical breakdowns of a gasoline trimmer for grass, which are most often faced with the owners of this unit, are as follows:

- engine breakdown;

- problems with the carburetor;

- problems with the supply of fuel;

- muffler malfunction;

- gearal breakdown;

- The starter broke;

- Air filter problems;

- Broken a buckshot on a gas tank.

Malfunctions of electric trimmers

Since the device of an electric coser is much easier than a motirmer, then there are few reasons for its failure.

It should be noted that the elimination of some of them is best entrusted to the specialist.

Basically, the trimmer for the grass ceases to work normally in the following cases:

- Electric cable malfunction;

- The control button is faulty;

- burned engine winding;

- Contact joints break on the engine.

Why is the gasoline trimmer not starting for the grass

The reasons why the gasoline trimmer for the grass stopped starting is different, therefore, a phased diagnosis of the apparatus is required.

Fuel tank (fuel quality)

Remember that always before starting the unit, a check of the presence and quality of fuel is required. In this case, you should not be greedy and save, as well as “clever” about the amount of oil added. Everything must be done according to the management attached to the apparatus, since when the piston group fails, its replacement will cost about 70% of the total cost of the trimmer for the grass. Pour fuel due to the fact that you will fully conside it when performing work. After a while, the gasoline remaining in the tank loses its properties and can harm the engine. Therefore, do not prepare the mixture for the future and in large quantities. If the lawn mower starts poorly, try to drain the “old” fuel from the tank, and season it with a freshly prepared mixture.

Important! To refuel the device with fuel, the origin of which is unknown, fraught with negative consequences. Gasoline should be of high quality, bought at a gas station, and its brand should be not lower than AI-95.

Candle and candle channel

So, you changed the fuel, but nothing has changed, and the trimmer for the grass still does not start. In this case, it is worth checking the candle channel: whether it throws it with a combustible mixture. Often users transfer the air damper to the “OFF” position when starting, and when the engine started, they do not transfer it to the “ON” position, after which it stalls. Further, an attempt to start the internal combustion engine to again leads to the fact that it floods the candle with gasoline, and the start becomes impossible. To diagnose and eliminate the possible problem in this node, do the following.

- It is necessary to unscrew the spark plug, wipe it well and dry it. When installing a candle in the ICE cylinder, it should be dry.

- Draw from the combustion chamber the fuel accumulated there. This is done through the hole from which you twisted the candle.

- In the presence of soot on the electrodes of the candle, it must be removed either with a thin file or a nail file.

- Do not forget to put the gap between its electrodes before installing the parts in place. The gap on the candle should be 1 mm. As a probe to check the gap, you can use a coin.

- Next, collect the block, read the start instructions and try to start the engine again.

Honda Lawn Mower Repair – How to replace the Carburetor Float

If the engine does not start, then you will need to check the spark. For this:

- unscrew the candle;

- put on it a cap of a high.voltage wire;

- Touch its metal part to the cylinder body (to provide contact, you can insert a tubular key) as shown in the figure below;

- pull the launch cord so that several engine speeds occur.

Normally, with each piston roll between the electrodes, the candle should slip a spark. If there is a spark, then the reason that the internal combustion engine is not launched should be sought in other nodes of the device.

For a better understanding of the process, how to test the candle for the presence of a spark, you can use this video where the check is shown by the example of the Lawn Mushiel “Soyuz”.

If there is no spark, then in the beginning check the cable connecting the candle to the coil. perhaps the reason is in it. You can call it with a tester. In case of detection of the rupture of the chain, a high.voltage wire will require a replacement.

Also the reason that the spark has disappeared is a malfunction of the ignition coil (magneto). The figure below shows what the coil (magneto) looks like from the gasoline trimmer for Patriot grass (Patriot).

To exclude the malfunction, it will be necessary to use a tester to check the Magneto trimmer for the grass, namely, its primary and secondary winding. On the primary winding, the resistance should be in the range from 0.4 to 2.0 Ohms. If the device shows 0. this means that there is a short circuit in the winding, and if infinity is a clear sign of a chain break. The resistance on the secondary winding should be in the range from 6 to 8 kOhm.

On some coils, it can reach the value of 15 kOhm.

Air filter

If your lawn mower does not start well or stalls immediately after starting, you should pay attention to the air filter, since it can be clogged, as a result of which the air does not enter the combustion chamber, and fuel ignition does not occur. To check if the filter is the case, remove it and try to start the engine. If he earned, then the reason was found. The filter needs to be replaced or rinse well and dry before installation. In the case when you find the oil in an air filter, it must be washed with gasoline, squeezed well and dry at least 2 hours before installing in place.

If the unit does not start with an air filter, it is still recommended to check the fuel filter.

Fuel filter

This filter cleans fuel of possible pollution. If it is scored, then gasoline does not enter the cylinder, and, accordingly, the unit does not work or stalls after starting. The fuel filter is located at the end of the fence hose, which is located inside the fuel tank. To get to the filter, it is necessary to extract a cork with tubes emerging from it.

When extracting traffic jams, a fence hose can disconnect and stay in a tank. It is extracted with a tweezer.

Next, remove the old fuel filter from the hose and put on it a new, pre.acquired. You can also clean the fuel filter if you do not have new. The filter must be fixed on the hose using a spring latch.

Install the fence tube on the cork and insert the last into the tank.

Why does not apply gasoline in a gas.cocl

Adjusting the carburetor of the lawn mower

lawn mowers, as well as the entire gas tool for the garden, is not difficult to maintain equipment. Repair, configure without the help of others you can and necessary. For example, adjusting the carburetor of the lawn mower in artisanal conditions. it is 5 minutes.

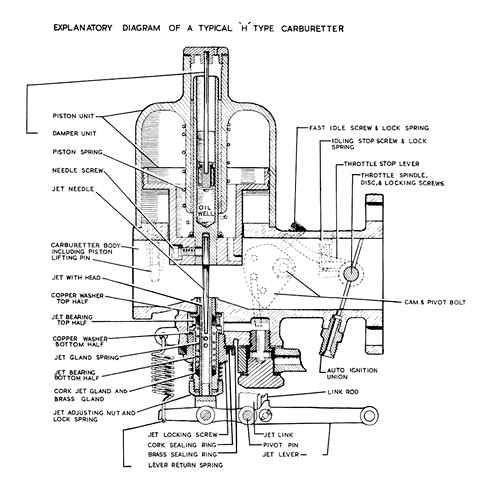

from the lawn mower. this is a node in the power system. In a personal computer, like all carburetors, there is a process of mixing air and fuel (gasoline) for the upcoming supply to the motor cylinders.

In this process, the main thing is the correct proportion of fuel and air, for what purpose the carburetor regulates.

The main problems and malfunctions of the carburetor.

Mesh filter. With this element, only two obstacles are more often:

To feel that the cause of the breakdown is unscrewed the fuel filter lid to extract a mesh filter. If he just accumulated mud, then flushing in gasoline or purging will help.

With visible damage on the mesh filter, it is necessary to put a new. There are also damage to the fuel supply pipe (when performing the repair, they practice checking this element).

The starting device of the carburetor almost always does not work due to blockages. Should be used for flushing acetone or the same petrol

- How to drill a with a pen without dust why the question is how to drill concrete? You bought a new mirror or decided to hang a shelf in the hallway? Or maybe your child draws talentedly, and you want to place all its parts in the frame and on the wall? Or there was another reason to nail the wall in the pan.

- How to breed oil into a benzotrimer

trimmer for grass, or bush. This is a tool that cannot be done in the household. At the same time, its reliability, efficiency and long service life depend on many factors. For example, fuel quality. This means that you need to choose the rules.

When spring comes, people often spend their free time in the country. With the onset of warm days, they try to save their territory from problems such as weeds and grass. It is difficult to do it manually, especially if the area is very large, so you remember.

The device of a homemade rotary mower from a chainsaw Ural 2 device of a homemade rotary mower from a chainsaw Urals 2 detailed overview with outlets and where the units are taken, I apologize for the mistake in the zoypniks 03.A detailed review.

Unine tractor MB-2M. This is a real workhorse. Reliable, undemanding, with a massive Lifan engine. an analogue of Honda. The main plus of this walk.behind tract is that all the equipment is suitable for it, which comes to our motorblocks. To pr.

Oil for lawn mowers: how to change it correctly and which liquid is better to pour a gasoline. A very useful thing for those who need to periodically mow grass on lawns and other land plots. However, when acquiring this tool, do not forget.

Purging parts of a carburetor with click of compressed air. permissible and comfortable repair practice.

The hull of throttles, the ligaments of the parts of the carburetor, the intake or graduation pipeline. what the listed parts can be made to our client is subject to depressurization. Probably check the option with a simple method. spread the problem area with soap foam.

The device of the carburetor of the lawn mower

The base of the carburetor of the lawn mower. the duralumin case. A diffuser is placed here (a hole with internal contours). Air is pumped through this hole. The speed of oxygen (air) is dependent on the cross.sectional (passage opening) of the diffuser.

Diffuser is equipped with fuel channels. There is a fuel when using the air flow is drawn there.

The principle of operation of the carburetor of the lawn mower

The throttle dashes determines the amount of air for supply, and for this reason the power of the motor directly depends.

Trammer for grass is not started, carburetor repair.

starts to do? Conduct an initial inspection and identify obvious malfunctions. Change the gasket.

- Air supply to the tube with an air septum (damper). The partition regulates the intensity of the air flow.

- The fuel supply system is certainly narrowed by the mixer in order to increase the flow rate.

- Petrolthrough the float chamber and nozzle with a narrowing pipe. The chamber with a float regulates the temporary volume of gasoline. In the float chamber, the pressure level is neutral, in the tube with narrowing is already small. Thanks to the pressure drop, fuel seeps through a jickler.

- Acceleration of the air flow contributes to the transfer of fuel (gasoline) and its spray. As a result, a fuel mixture of the desired proportion or density appears.

- The air-fuel mixture seeps into the cylinder of the motor through the fuel tube.

The level of air density in the system depends on the area of the open air damper. The more extensive the damper is open, the simply fuel consumption and power.

Simply put, adjusting the carburetor on a benzocos. creating a good fuel consistency due to the correct supply of air.

How to adjust a carburetor on a gas tank

Before adjustment, you need to painlessly clean the filters according to maintenance in the annotation.

The upcoming setting of the carburetor of the lawn mower is made by adjusting screws. There are three of them:

- How to disassemble a trimmer for grass gasoline Partner B250B Partner. Famous Swedish manufacturer with great history. He launches a huge assortment of garden products, equipment and heavy equipment. It was this company that introduced several innovations, including heated handles and chain brakes. AT…

- How to insert a drill into an electric screwdriver video

An indispensable power tool in a house with a name, a screwdriver is actively used in construction work. The most common procedure with this device is the replacement of the drill. Sometimes this process seems very complicated and almost impossible.

The vacuum valve does not hold

The reason why gasoline is outside the main path of its following can lie in a vacuum valve. The electronic valve prevents itself and excessive pressure of gasoline.

Fixing A 6.25EX Mower from surgingUp and DownUp and Down

To diagnose the malfunction, you need to turn off the valve from the main network and power it directly from the battery.

Important: first, the valve must be checked with a multimeter or a chain for the lack of short circuit. Otherwise, you can damage the battery and get an electrical injury.

On Chinese scooters are put non.combination vacuum valves. Repair is replaced by a failed component with a new. In more serious devices, a detachable case is used. In this case, the repair may be limited to a visual examination of the diaphragm with a decision to replace it.

Signs of unbalancing

Carburetor adjustment should be performed in the manufacture of the device. As a rule, the owners will learn about the need to self.regulation of fuel supply after serious failures, when correcting which the module was removed and, for example, cleaned.

Signs of a malfunction in the settings are as follows:

- It starts, but the engine stops immediately. Because the engine can only work when the supply of a certain amount of gasoline is supplied if the fuel is too “bad”, t.E. When the supply channel is blocked, the engine will stop;

- Too high fuel consumption, too many exhaust gases. The result of incomplete combustion of the mixture. In this case, on the contrary, there is too much fuel, and the mixture is too thick.

Do.it.yourself carburetor adjustment

The module configuration is not subject to repair and no spare parts are required. In this case, the repair kit of the carburetor for a gas trimmer for grass is not required.

- L. It is regulated in the first place, as it is responsible for the supply of fuel at low speeds;

- H. Is responsible for supplying gasoline at high speeds, as well as for fuel consumption and temperature;

- T. With its help, non.working configuration is carried out.

As a rule, there are options, it is a Chinese carburetor gasoline scraper, when only one screw for adjustment remains on the housing. To set the icy speed. This does not mean that the module is configured automatically. This means that it will be difficult to even perform such a type of repair as debugging. On the picture. Carburetor adjustment of the Chinese brush.

- The module is installed only when the engine is heated: the device first turns on for 10 minutes. If the braid rotates at idle, immediately start adjusting: turn the tint t counterclockwise until the rotation stops.

- Adjustment starts with a screw l. The screw rotates to the left and right until it finds its position in which the idle speed does not reach the maximum.

- Then turn the screw counterclockwise. It will be his work.

- The idle mode should be adjusted by turning counterclockwise to increase the speed and reduce clockwise. Its setting is to achieve a mode in which a sufficient number of revolutions are performed before the mower begins to rotate. In this case, the engine should work stably in different positions.

- The position of the screw L is determined by the last. At maximum speeds, a trimmer for grass should not work for more than 10 seconds. The throttle opens, the screw rotates clockwise, very slowly, until a decrease in speed is heard.

- Then the screw also slowly rotates counterclockwise until the engine starts to crawl with failures. Then the screw turns clockwise until the engine starts to work normally again.

Read How to install a trimmer for grass on a PVC boat

If you have a blood pressure monitor, and if the recommended speed is indicated in the product passport, the correction can be made more accurate, focusing not on the ear, but on the testimony of the device.

Adjustment of the carburetor of the bushrer in the video is performed by ear.

to the post “Adjusting and repairing the carburetor of a gasoline brush”

Please explain. In section 5 of the adjustment of the screw l. Error? Should the screw be read? Thanks

Tell me the initial position of the screws h l la

Tell me the initial position of the screws h l la

Thank you very much for the video about the accelerator, and I do not know, and the defect is very important and creates a huge problem that almost everyone is silent about. BRAVO….

It is possible that a tachometer. This is a speedometer, not a tonometer. Meter of blood pressure.

The heart of any chainsaw is a two.stroke internal combustion engine.

The trimmer for grass is not used for complex devices, so most of them are gender.

It is necessary to purchase reliable and accurate mechanical instructions.

The times of Soviet agro.industrial giantism have passed. They made a concert.

The same tractor. This is an economical version of the tractor for small jobs.

In order to make a nozzle like a harrow with your own hands, in addition to bodies.

Step.by.step instructions for repairing carburetor motorcosa

Dismantling the carburetor

Visual inspection of the carburetor will help to identify the leakage of the fuel of the air mortgage, but the main reasons for the refusal of the device lie inside. Therefore, in order to determine and most importantly, correct the breakdown of the carburetor must be disassembled.

To disassemble the carburetor, Motokos is not necessary for a lot of effort.

It is enough to unscrew the four screws on one side

And two on the other. This can be done using a regular crossbreed. Unscurately unscrew the screws and put it to the side. They may be needed when assembling. It is advisable to cover the table with a white cloth before disassembling, so that everything is visible, even the smallest details that may fall out during disassembly.

Step

We start disassembly from the fuel supply system.

We remove the primer. a bubble of swing, which is noteworthy, when assembling, installing parts of the carburetor is simply impossible. Products have characteristic castings and holes.

Step

Now remove the membrane. It is she who performs the function of pumping fuel to the carburetor.

With the vibration of the membrane, the other side exerts the pressure of the rocker of the mechanism and the needle rises, which, in turn, opens the hole and the fuel supply occurs.

Step

Remove the carburetor lid with the injection mechanism.

Step

Next, another membrane has been installed. We carefully remove it.

Step

Under the membrane there is another gasket. We also carefully remove it, in no case damage.

Step

Then we move on to the dismantling of parts from the back of the carburetor. As, earlier, we unscrew two bolts. This is already an air supply system.

There is a valve here, which, when the gas is added, opens and increases the air flow into the engine.

After its removal, the bare case remains in the hands. The carburetor is disassembled.

Determination of malfunctions and their elimination

Now it is worth paying attention to the problems that happen when the carburetor is operating and the methods of eliminating them.

Problem 1: Zaror of holes, channels and nozzles with mud

The first thing that happens is the holes and nozzles in the fuel supply system clogged with dirt. Filters installed in the tank and directly in the carburetor do not help. They still miss small particles, which cause motorcycles to fail.

Step

To do this, unscrew the bolt on the mechanism, holding it with a finger. The fact is, there is a spring and a careless action will lead to the fact that it will be lost.

Step

How to make a purge. The most effective way is the use of an ultrasound bath.

It is filled either with a special liquid or gasoline, a carburetor is placed there and under the influence of ultrasound, the so.called cavitation effect, the channels are cleaned from pollution.

The second cleaning option compressed air.

You can use the compressor available on the farm and clean the carburetor channels. However, this method is effective if the pollution is not very large.

If there is no ultrasonic bath or compressor at hand, then cleaning can be carried out in the third way using a special cylinder for cleaning the carburetor. They are sold in almost all car stores and supermarkets. The price is low and equals about 2-3, there is enough such a cylinder for 4 or 5 purges.

Step 0

Now we need to blow the channels in the case and the carburetor lid. See photo.

Step 1

Another particle of dirt can get stuck under the needle. Cm. a photo. This will also lead to the refusal of motorcycles.

Important! When cleaning the carburetor, in no case should not be used with needles, pins or wires. Even the slightest scratch will withdraw the carburetor from the system. It will have to be changed in its entirety.

Problem 2: Flaw clogging of thin cleaning

It is located on the cover of the carburetor and is a small metal mesh. Its pollution occurs very often. This is due to the precipitation of oil, additives, mud on it.

Step 2

Sometimes when disassembling the nets, a certain film is found. This carburetor lacks fuel and the lawn mower is either not starting or working with interruptions. The treatment methods are identical to the first reason: ultrasonic bath, compressor or spray can with a special solution. In addition, if the net is clogged thoroughly, you need to take a soft brush for watercolor paints, get wet into gasoline and rinse it carefully without damaging it.

Step 3

They have the ability to wear out during operation. From prolonged use, they are deformed, stretched, lose their elasticity, poor.quality fuel corrodes them, and can no longer perform their functions well. This also applies to the needle itself. The fact is that it is covered with a thin layer of rubber, which wear out during operation and can no longer enter the hole tightly. The lawn mower begins to work with interruptions. To eliminate such a breakdown, it is necessary to replace all worn parts. Where to get them?

How to properly adjust

Before setting up the carburetor trimmer for the grass, it is necessary to do the following:

- Rinse the engine;

- replace or clean the spark plug;

- change to a new one or clean the air filter (it is recommended to lay it out in warm, soap water, squeeze it out and let it dry well).

It is also necessary to install the cord of the right diameter in the trimmer coil or install knives-this is done so that in the process of configuration the engine has at least some load. After installing a cutting tool and starting a gasoline engine, let it warm up for 10 minutes.

If at the idle speed of the motor you noticed that the cutting tool rotates, then it is necessary to reduce engine speeds. This is done using the lower idle regulator, often marked with the letter “T”. The figure below shows the placement of regulators on the trimmer Husqvarna.

But, for example, on the STIHL trimmer, this screw may have a label “LA”.

So, turn the idle control regulator to the left, until the trimmer head is completely stopped.

To configure the carburetor, 3 regulators are used (screw).

- The right regulator L tunes the level of enrichment of the combustible mixture at low speeds. It needs to be adjusted by the first. Get a maximum of turnover at idle. This is done using the regulator L, turning it to the left and right. After finding the point of maximum revolutions, return the regulator for half a turn to the left (against h. Arrows).

- The lower regulator t (LA) is used to configure idle. Turning it to the left, the engine speed will begin to decline, and when the regulator is turned to the right, the revolutions will increase.

- Left regulator h is responsible for enriching the combustible mixture at high speeds. The enrichment configuration completes the adjustment of the carburetor. Also, using this regulator, you can configure maximum speed, fuel consumption and engine power.

Important! If you allow the engine to operate at full speed for more than 10 seconds, then it may fail.

To exclude this trouble, adjustment will be required. With the working motor, give a full gas, then turn the “h” regulator to the right until a reduction in revolutions begins. After that, the “h” regulator must slowly scroll to the left until you hear the uneven operation of the engine. Then the regulator “h” should be rotated to the right until the moment of flat operation of the motor is heard.

After conducting the above actions, the setting of the carburetor can be considered completed. After proper adjustment, the engine must confidently gain momentum, a little four at a maximum of revolutions, and when working, an idle cutting tool should not turn. This manual is suitable for adjusting carburetors on the Huter, Patriot and others benzocos.

There are also carburetors without a screw that is responsible for enriching the combustible mixture at low speeds. That is, they have only 2 adjusting screws: a idle regulator and a quality fuel mixture regulator at high speeds. How to configure a carburetor of this type, you can find out from this video.

Chinese lawn mower. The carburetor valve hung and fuel overflows.

Why do the gas mallicoline seals leave the system: Help: Privat: 4149439315000673 Webmoney WMZ: Z610102394928 WMU: U682580602704 If gasoline began to flow out of the air filter, know that the reason is the valve hanging. The traditional way to start the engine will not succeed. But there is a way to start it in an unconventional way, by turning off the carburetor. Recommended for viewing:

© 2005. 2022 “Catalog of websites No Follow”. In the catalog 84988 sites. The rights to all materials posted on this site belong to their authors. Hosting place advertising

Chinese lawn mower. The carburetor valve hung and fuel overflows.

Why do the gas mallicoline seals leave the system: Help: Privat: 4149439315000673 Webmoney WMZ: Z610102394928 WMU: U682580602704 If gasoline began to flow out of the air filter, know that the reason is the valve hanging. The traditional way to start the engine will not succeed. But there is a way to start it in an unconventional way, by turning off the carburetor. Recommended for viewing:

© 2005. 2022 “Catalog of websites No Follow”. In the catalog 84988 sites. The rights to all materials posted on this site belong to their authors. Hosting place advertising

A large assortment of gas.tools and components at affordable prices

The assortment of the Kosi Spit for Grass store has a huge selection of specialized products designed to perform work or support important functions of working tools. So, depending on the requests of the buyer, the online catalog offers to choose:

- Tools:

- Modern lawn mowers of grades GoodLuck, Baikal, Carpathians and other manufacturers;

- gasoline saws with the selection of power and sawing parameters.

- Spare parts:

- professional spare parts for the chainsaw of the Chinese release and the CIS countries;

- high.quality spare parts for benzos;

- Spare parts for electric saw and other assortment.

- Components:

- accessories for gasoline cos;

- original candles;

- guide tire for a chainsaw of the required length;

- knives for benzos;

- files for the chain;

- Lubrication for motorcycle and oil for nonsense of the desired consistency, depending on the nodes of use.

If necessary, a benzo.tool to buy online, each spare part is equipped with a link to the consumer basket, which simplifies the order process a lot. The manager’s phones that are able to answer questions are also available, to tell what spare parts are available now, how quickly the collection and delivery to the buyer are performed, and also help to choose the necessary elements and order them in the right amount. “Spit for grass” is a modern online store where you can buy spare parts for a chainsaw or lawn mower at an affordable cost.

floods the candle on a gas station

Probably garden tools are useful and effective, but there are times when the technique is abandoned to work. Among them, both a trimmer for grass, which have an option to dig a small clearing and large lawns, hit.

There are various prerequisites why the gasoline trimmer for the grass does not start:

- The most common breakdown occasion lies in the wrong choice of fuel. Often very economical users of the device pour something incomprehensible into the tank, but not fuel with an ordinary octane number. The bad fuel, which was kept in the plastic canister, has a terrifying effect. The device that has lost performance therefore sets off to the full bulkhead of the mechanism.

At high speeds

When a braid for grass stalls at high speeds, this is due to the following problems:

- clogging or clutching a valve located on the gas tank lid;

- The carburetor was diluted under the influence of vibrations arising during the operation of the mechanism;

- problems with the circulation of the fuel mixture;

- atmospheric air

- The hose intended for fuel fuel cracked or slightly connected.

The carburetor is regulated by relying on the operational instruction to the trimmer. For configuration, it is often enough to weaken the tightening of its body. If there are problematic issues with the circulation of the fuel mixture, then it can gradually enter the carburetor. After its production, the engine stalls at high speeds.

At idle

At single speeds, the common reasons for stopping a trimmer for grass are as follows:

- reducing the speed of the gearbox when heating it, which is a consequence of the use of inappropriate fuel mixture;

- clogging of the throttle;

If a carburetor is a problem place, then the technique will stop at the “cold” and with a “hot” launch.

The adjustment of the idle speed is considered to be correct when:

- The cool engine is stable at idle.

- The hot engine has not very high.speed stamping.

- Prior to the rotation of the trimmer head, sufficient speed dispers remains.

- The engine works steadily in any position (for example, with a sharp lowering knife).

Note: from the manufacturer (Husqvarna), the idle screw from one hundred percent twisted, was twisted at 8 full revolutions and “2 hours” (currently left). Husqvarna. 2 recommended idle speed.900 rpm. 3) Left screw h. regulates the enrichment of the consistency of large revolutions (is regulated last). It regulates the highest speed, motor power, temperature and fuel consumption.

Note: the Husqvarna engine should not work at full speed for more than 10 seconds!

- Open quite a throttle (give full gas) and slowly turn the left screw clockwise until the speed of the Husqvarna engine is reduced (by ear).

- Then turn the left screw very slowly counterclockwise until the engine starts to work uneven.

- Then turn the screw slowly back to an insignificant distance clockwise until the Husqvarna engine starts to work smoothly.

This is where the HUSQVARNA adjustment is completed.

Note: The recommended very high speed of the Husqvarna motor. 11.500 rpm. The largest output power of the Husqvarna 333R lawnie engine is 1.6 kW (2.1 l.With.) at 8.400 rpm.

Note: on the brand new trimmer Husqvarna from the manufacturer (Husqvarna), the left screw was unscrewed (at 0.5 turnover) and blocked (bay) with solid plastic, which I drilled after the guarantee period. At the moment, the left screw (like the right) looks at about 11 hours.

We check the correct settings of the Husqvarna carburetor

The engine is rapidly, evenly and confidently gaining momentum, and slightly four at the highest speed, the trimmer head of the T-35 should not spin at idle.

The suitable composition (quality) of the fuel.air consistency is adjusted (changes) by turning the screws for the adjustment of the fuel to the stream of sucked air (right and left). The number of the consistency of the throttle doses to the cylinder. If you turn them clockwise, then the mixture is impoverished in the cylinder (less fuel in the ratio of air/fuel) and the engine speed increases, with all this the Husqvarna engine works softer (it is weakly gaining speed) and the power is very much falling). Apart from that, having overstated speeds, it enters the cylinder in the depleted consistency with gasoline less oil (terrible lubrication) and so you can start the engine. Well, the trimmer for the grass will be bad to start. If the screws turn counterclockwise, then the mixture is sucked into the cylinder is enriched (more fuel in the ratio of air/fuel) and the revolutions of the motor decrease, with all this, more gasoline and oil falls at low speeds (better craving, better lubrication), but the engine Husqvarna “spins” poorly (poorly gaining momentum) and more soot is created in the cylinder!