What are the main parts of a bench saw

Abstract lesson technology 6 grade

Subject: Metal cutting with a bench saw.

Goal: to teach students to use the bench saw, to familiarize themselves with the cutting process, to cultivate accuracy in work.

Equipment and tools: metalwork workbench, metalwork hacksaw, billets of long products.

Check readiness for the lesson. Entering students in the workshop.

Repetition of the passed material.

What are the main parts of the caliper?

How many measuring scales does a caliper have?

What measurements can be made with a caliper?

How many times is the accuracy with a caliper higher than the accuracy with a ruler?

List the rules for handling the caliper.

As a vernier caliper counts integers and tenths

What feature of the nonius allows measurements to be made with an accuracy of 0.1 mm?

3. The presentation of new program material.

When processing rolled metal, it is often necessary to manually cut the material into pieces. Sheet metal is cut with scissors, strip metal, thick sheet metal, as well as a bar, corner, etc., with a bench saw.

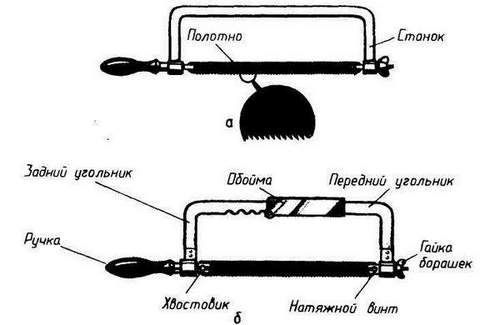

The hacksaw consists of two main parts: a hacksaw machine (frame) and a hacksaw blade. Figure 1, a shows a bench saw with a solid hacksaw. It can be fixed hacksaw blade of a certain length. In order for hacksaw blades of different lengths to be fixed in a hacksaw, the hacksaw is made sliding (Fig. 1, b).

The sliding machine consists of front and rear squares, interconnected by a clip. The distance between the shank and the tensioning screw can be changed due to the position of the rear elbow inserted into the clip. The deeper the square is inserted into the holder, the smaller this distance. In the rear corner of the hacksaw, a shank with a handle is installed. The shank has a slot and a pin hole. In the front corner there is a tension screw with a wing nut. The tensioning screw has the same slot and the same hole as the shank. The ends of the hacksaw blade are installed in the slot of the shank and the tension screw, which are fixed with the help of pins inserted into the holes. Rotation of the wing nut tightens the hacksaw blade.

The hacksaw blade is a thin and narrow steel plate with teeth on one of the ribs (see Fig. 1, a).

Fig. 1. Manual hacksaw: a. with a one-piece machine; b. the main parts of the sliding machine.

At the ends of the hacksaw blade there are holes for fixing it in a hacksaw. The length of the most common hacksaw blades is 250. 300 mm. Each tooth has a wedge shape and works like a cutter when cutting. When notching, the size of the teeth is chosen so that the resulting chips are placed between the teeth until they exit the cut. In order for the width of the cut made by a hacksaw to be slightly larger than the thickness of the blade, tooth alignment is done. every 2-3 adjacent teeth are slightly bent in different directions. This wiring is called corrugated.

It is noteworthy that the teeth should be directed in the opposite direction from the hand, and the tension of the blade should be such as not to cause damage to the blade.

The workpiece is firmly fixed in a vice and an incision is made in the place of cutting with a file.

The place of cutting is placed at a distance of 10. 15 mm from the edge of the jaws.

Video: What are the main parts of a bench saw

Fig. 2. Work with a hacksaw: a. position of the body; b. the position of the hands.

During the working stroke of the hacksaw (forward), the hacksaw is moved with light pressure, while at idle (back). without pressure.

If the thickness of the workpiece is a distance of 3 teeth of the blade, the workpiece is clamped between two wooden blocks.

If the workpiece has a large length and the frame abuts against its end, then the web is fixed as shown in Fig. 3.

Fig. 3. Hacksaw cutting:

a. without turning the canvas; b — with a turn of the canvas.

Preparing a hacksaw for work.

Preparing a hacksaw for work consists in installing a hacksaw blade in the machine and tensioning it.

First, the front and rear angles of the machine are pushed apart by the length of the hacksaw blade and in this position the machine is secured with a clip. Then the ends of the hacksaw blade are inserted into the slots of the tension screw and shank and their holes are combined with the holes in the hacksaw blade. At the same time, make sure that the teeth of the blade are directed in the direction opposite to the handle. After that, pins are inserted into the holes and the blade is pulled by rotation of the wing nut. The tension of the web should not be very strong, but sufficient so that it does not bend during operation. Strong web tension can cause it to break if there is the slightest distortion during operation. If the web is weakly tensioned, it1 will bend during operation, which can also lead to breakage.

Receptions of cutting. To cut the workpiece, it is securely fixed in a vise so that the place of the cut is not far from the edge of the jaws of the vise. In this position, the workpiece will not vibrate when cutting. At the site of the cut, a risk is indicated with a file. Then they take the necessary working position: stand half-turn to the vise (Fig. 4). The hacksaw handle is wrapped around with the fingers of the right hand: the end of the handle should rest against the middle of the palm

Fig. 4. The position of the body and legs with Fig. 5. The position of the hands with

work with a hacksaw. Work with a hacksaw.

Safety measures when working with a bench saw.

Work only with a serviceable hacksaw with a firmly fixed and properly stretched blade. A poorly fixed or slightly stretched web may pop out or break during operation, creating a hazard

The hacksaw handle must be firmly set and free of cracks.

Instead of pins, do not fix the hacksaw blade with nails or screws.

Do not use a hacksaw with broken teeth in its blade.

Sweep the sawdust from the workbench with a brush. Do not blow away or remove them with your bare hands.

Support the cut part of the workpiece so that it

did not fall or hurt her legs.

1. Mark the template blanks.

2. Cut the workpieces.

3. Check the dimensions according to the drawing.

4. Saw off the ends of the workpieces.

When working, use the entire length of the blade. This ensures uniform tooth wear and longer blade life.

To prevent the blade from heating up during operation, lubricate it with oil.

If the cut is large enough and during normal installation of the blade during cutting the machine interferes, the blade is rotated 90 ° (Fig. 3 b).

When cutting workpieces with ribs or sharp edges, observe the following rule: cutting should go from plane to edge so as not to break the teeth of the blade.

v. Fastening of the passed material.

What is the difference between sawing with a joiner’s hacksaw and cutting with a bench? What is their similarity?

List the safety rules when working with a bench saw.

What are the main parts of a bench saw?

For what purpose do they cut on a workpiece at the cutting site with a trihedral file?

Why is it necessary to loosen the pressure on the hacksaw at the end of cutting the workpiece?

How to cut a long workpiece?

Evaluate student work. Indicate errors.

Cleaning of workplaces and workshop premises.