What cable is needed for electric saw. The selection table of the cross -section of the wires (cable) in power and current

What cable is needed for electric saw

Electric extension cord or carrying are present in every house and office. The need for this simple electrical device arises when it is required to connect electrical equipment in the absence of a stationary outlet or power tool in an inaccessible place.

You can purchase a ready.made extension cord. But more reliable and cheaper to make it yourself.

In the presence of components and skills in working with the tool, the process will take 20 minutes. You will need: collapsible fork, wire of the required length and block of sockets.

Cable Size Calculation for Medium Voltage or 11kV Electrical Systems

Insulation of the veins for grounding yellow-green color

It is important to correctly connect it to the corresponding terminals

For safe use of the product, you need:

- The presence of grounding. Therefore, the cable select the three.wire, and the fork and sockets with grounding terminals.

- The presence of the appropriate degree of protection in sockets. For example, the design for the street and the bathroom should be moisture.proof, with a folding lid. In the carrying for computer technology, use a network filter. You can not use outdoor outlets, the back wall should be closed. It is recommended to connect a block of sockets consisting of at least three pieces

In the store you can buy a ready.made block for the assembly of extension cords.

- Clean the ends of the cable from insulation by 4-6 centimeters, and each core is 10 millimeters, neatly, without damaging.

- Disassemble and connect the fork on one side, sockets. on the other. Inside there are special terminals for the cable.

- Check the extension cord using a multimeter.

- Twist the screws, finish the assembly.

When connecting the wire and fork, the insulation should be tightly pressed with a special clamp. Otherwise, when pulling out the cord from the outlet, the load will regularly fall on the contacts. They will quickly weaken and begin to heat up.

To increase the reliability of the extension cord, you can make with a switch in the form of a button.

If the carrying wire is long, for example 20 meters, it should be wound on a special coil, which can also be done with your own hands.

This is interesting: the letter designation of the phase and zero on the Thermex boiler

Calculation of the cross.sectional area

Competent selection of wired cross section allows you to ensure the reliability and safety of electrical wiring. The main indicator on which the standard calculation of the area of the core or its section is based is the level of a long permissible current value.

The calculation of the cross.section of the wire in accordance with the load involves summing up the power of all connected electrical appliances with power expression in the same measurement units. W or kWh.

- 27 A and 220 V. the diameter of the copper conductor 2.26 mm with a section of 4.0 mm2;

- 15 A and 380 V. the diameter of a copper conductor 1.38 mm with a section of 1.5 mm2;

- 26 A and 220 V. the diameter of the aluminum conductor 2.76 mm with a section of 6.0 mm2;

- 16 A and 380 V. the diameter of the aluminum conductor 1.78 mm with a section of 2.5 mm2.

When choosing a section, it must be remembered that the inconsistency of the area of the core with current loads can provoke overheating, melting of insulation, close and fire hazardous situation.

Characteristic

The extension cable must have certain technical characteristics. Any wire cannot be used. Experts say that only copper cables are suitable for carrying.

They must have the necessary flexibility, elasticity and are protected by double isolation. If the first layer is damaged, the second will protect against an electricity blow.

One of these types is the PVS wire. It has insulation made of polyvinyl chloride resin and is more often used in everyday life than for industrial purposes. The cable hardens in severe frost and can crack in an aggressive environment, but under normal conditions it serves 6-10 years.

Most cables that can be used when assembling the extension cord are protected using PVC plastic. This is a wear.resistant material that is not afraid of high or low temperatures. The highest value is 40 degrees Celsius above zero, the lowest is 25 degrees of frost.

Frost.resistant extension cord can be used on the street or indoors where there is no heating.

Cables that are used in the manufacture of extension cords are divided into stamps. Each of them has certain technical characteristics, which will be discussed further in the article.

On sale you can find options that are designed for various temperature indicators. Frost.resistant views calmly tolerate low temperatures. Even at severe temperatures, they do not crack and retain elasticity.

It is worth noting the options that they are not afraid of overheating and long.term exposure to high temperatures. Modern manufacturers offer wires that can combine the features of both types. Separately make options for standard domestic use, not characterized by special physical characteristics.

Cables are divided into types and depending on the section. The minimum indicator for the extension wire is 1.5 mm in a square. When using it, carrying with a power of 3.5 kW will cope with the load on the network, which will reach 5 kW.

Mark size kg 3×1.5 is considered suitable for the line in 220 in.

Note: If you increase the length of the carrying, then reduced power can be restored with an increased section of the section.

Review of brands

On sale you can find various brands of cables that are wonderful for the extension cord. Each species has certain features that need to be taken into account before the choice.

This abbreviation is deciphered as a flexible cable. Recommended for use in open areas (construction locations, repair work in open air, etc. This option is highly resistant to bending. High.quality products withstands at least 30 cycles. While the wires are not afraid of constant intense and high temperatures.

The highest temperature indicator is 50 degrees Celsius, low. 40 degrees of frost. The service life has 4 years. European manufacturers use the abbreviation XYMM.

And also on sale you can find the option kg-x. It has all the characteristics described above, but has increased resistance to low temperatures. Such a cable can be constantly used in severe weather conditions.

This option is similar to the above, but has a reduced service life (instead of 4 years-two and a half years). And also a stored temperature regime was changed: from 50 degrees with a plus sign, up to 30 degrees with a minus sign.

Such a cable can be used in locations where it is permissible to get oils and other liquids, including aggressive chemical components. This brand needs protection against sunlight.

The main distinguishing characteristic of this type is to resist the direct sunlight. In this case, the cable performs all the necessary functions even at low temperatures.

The temperature range is as follows: from 25 degrees of frost to 40 degrees of heat. Experts recommend using the cable in the warm season. Serving life. 6 years. The number of bending is 30 thousand.

In this case, manufacturers use the following temperature range: from 40 degrees below zero to 40 degrees of heat. A cable of this type can be used both indoors and in the open air. European companies use the designation RN.

Popular brands

As mentioned above, modern saw oils are producing a large number of brands. Among them there are also little.known and very popular. If you decide to purchase high.quality and reliable oil for a saw, then you should familiarize yourself with the list of the most popular models.

Forest Plus

This oil is in enviable demand and has excellent adhesive properties. Forest Plus is characterized by the fact that it can be operated if the window is not lower than.15 degrees.

If all the storage and operation conditions of this product are observed, it may remain high.quality for 3 years.

Bio Plus

Firm products called Bio Plus are made on a plant basis. The oils of this company, when penetrating into the soil, very soon begin to decompose. Not all oil can boast of such a difference. Use this product is permissible at temperatures before.15 degrees, like the previous option.

Sunth Plus

This is no less popular oil based on synthetic components. It easily takes out quite serious equipment loads.

You can use it in more stringent conditions. the surrounding temperature can reach.25 degrees.

Because of this, the oil will not cease to act and enter the right nodes.

Champion

The adhesive type of Champion is customary to use for work with a rather large temperature range. This lubrication is sold in a container of 3 and 10 liters. The product is inexpensive, it is also convenient to use.

Husqvarna

The name of this world.famous brand is confident. Husqvarna saw oil is the most profitable and economical solution for missing the mechanism of an electric saw. Such products are characterized by moderate consumption and high efficiency.

Is it possible to use motor oil?

Is the use of motor oil as a lubricant for a saw is another common question of the owners of the tool.

In fact, transmission and motor compounds can be used to lubricate the chain of individual models, but it should be borne in mind that such mineral compositions are best avoided.

It should be borne in mind that such compounds are suitable exclusively for specific saw models. The fact that the tool can be lubricated with motor or transmission oils should be indicated in the technical documentation attached to the technique.

In no case do not lubricate the chain with such means, if there is no permission from the manufacturer. Do not forget that such compounds are not designed for the conditions of the circuit functioning. They simply cannot fully protect the equipment. Therefore, it is better not to take risks and not resort to the use of these types of oils.

Not suitable for missing the chain mechanism and ordinary vegetable oils. Of course, they will have a short lubricant effect, but it is worth remembering that such compounds have a characteristic property. they dry out. Subsequently, this can lead to the fact that the chain will move in the mechanism very poorly, with delays. Because of this, the work of the saw in general will noticeably deteriorate, therefore it is not recommended to experiment with vegetable oils in relation to this technique.

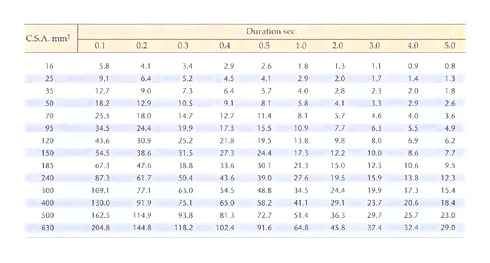

The selection of the cross.section of the cable (wire) in length

You should know that the length of the wire (cable) affects the voltage. The longer the fishing line for the trimmer, the greater the loss of voltage. To avoid this, you need to increase the cross section of the conductor. How to calculate all this?

You have certain electricity consumers in everyday life, in total they amount to 5000 W or 5 kW. The length to these consumers from the circuit breaker is 25 m. Since electricity flows one wire, and returns to another wire, the length doubles and is 50 m.

Then we need to find current strength (i). How to find you already know. You need to divide the power into voltage:

Using the current strength (a) or power (p) in table 2, we determine the cross section of the wire. According to the table, this is 1.5 mm² of copper wire.

Since the wire has its resistance (R), we calculate taking into account the following data by the formula:

From the formula: the value (p) is always a constant value. For copper it is 0.0175, and for aluminum. 0.0281.

Now you need to calculate the loss of voltage by the formula:

After this calculation, you need to find out the percentage ratio of voltage losses. If it is higher than 5 %, then the conductor should be selected for one position above referring to table 2.

Since the percentage of voltage losses is above 5%, the cross.section of the wire (cable) instead of 1.5 mm² select 2.5 mm².

As you can see, it’s not so difficult to do all this. Once it is worth counting and everything. After this calculation, you will be completely sure that the wires you selected will not let you down and last for many years.

Requirements

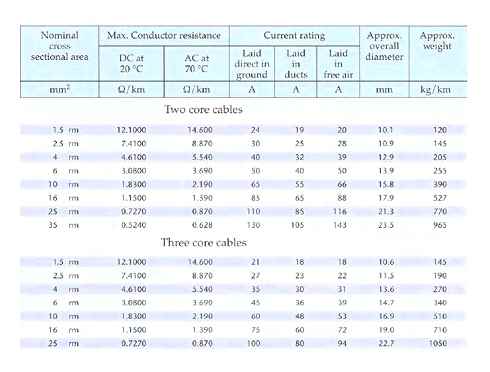

You can already understand that not every cable is suitable for connecting such a technique. This is logical, since with large overloads it will simply burn and can cause a breakdown of equipment or fire. Therefore, when choosing a cable for an electric stove, you should rely on such important characteristics:

- Rated voltage;

- material that serves as the basis for wired veins;

- cable section;

- Ease of connection to the device.

If we take the rated voltage for devices of well.known brands, then its indicator should be exactly no less than a regular power grid, where you need to connect the device. Now let’s say a little more about the described indicators.

Probably one of the most important aspects that will play the role is the material of the manufacture of cable cores. Best if they are copper. This metal itself can be soldered if necessary. And the copper power wire is more flexible than an aluminum analogue. But the cost of a copper decision will be higher. If the choice still fell on an aluminum analogue, then you need to understand that its installation should not be carried out in the materials that are burning. You can find out what the electric wire is made of, thanks to a special marking on the product itself.

Another important parameter will be the cross section. it must correspond to the load, which will be indicated in amperes. To conduct calculations of the current strength, the overall power indicator of all electrical appliances is necessary, which is connected to this network, divided into voltage.

Speaking directly about numbers, as a rule, most solutions from well.known brands (Samsung or Electrolux) are designed for electricity consumption slightly less than 4 kW. For this reason, the wire safety margins should be selected by power somewhere with a focus on such an indicator.

To make the operation of the device as safe as possible, you should also pay attention to the following points.

- Use the 3×6 PVS wire (3 veins with a cross section of 6 kV. mm each) or similar kg 3×6. In the vast majority of cases, these wires are suitable. This option will give the necessary supply in case of connecting some other household appliances.

BREAKER AND CABLE SIZES FOR ELECTRICAL CIRCUITS.

An important parameter is also the phase of connection. It will depend on the number of cores in the cable. The wire can be 3 or 5-burned. The number of cores will depend on the power supply network in the room. And it is either 1-phase or 3-phase. If the first option, then you will need to purchase a wire with three veins, and if the second is with five.

And also you should find out whether the acquired equipment supports the type of connection that was selected. For example, plates with a power of up to 5 kW are usually connected to a 1-phase network, and more powerful have 2 or 3-phase connection. The type of cable that can be used, but more than that below will be important.

In the case of the brand of the wire, the best solution will be the option of a PVS or kg. The first type is deciphered as a vinyl wire. This product has conductive copper veins, each of which is protected by insulation and all of them are in a white shell. Such a power wire withstands a voltage up to 450 V, and the insulation material does not burn, which allows the considered wire to be a heat.resistant.

It is also characterized by high strength and excellent resistance to bending. Can be used even in unheated and humid buildings, where it will last 6-10 years, depending on the operational conditions. Great for connecting electric stoves.

If we talk about a wire like kg, then its name is deciphered as a flexible cable. Its shell is made of a special type of rubber. In addition, the same shell protects the tinned veins made of copper. There is a special film between the wires that performs the protective function. It should not allow the veins due to heating as a result of use.

Typically, the KG wire contains from 1 to 5 cores. As you can understand, the living section determines the power that the cable can withstand. This cable is operated in the temperature range from.40 to 50 degrees. KG cable can withstand voltage up to 660 V. Typically, this wire has the following designation: kg 3x51x4. This means that there are 3-phase veins having a section of 5 kV. mm, and one garter lived with a section of 4 kV. mm.

Regardless of which wire will be selected to connect an electric stove, it should be bought with a margin of length so that you can move the product. In addition, the wiring going indoors and at the entrance to the apartment should be of high quality, which should also be checked before the connection.

How to choose?

If we talk about choosing a cable to connect an electric stove, then you should focus on the material from which it is made, power and cross section. Part of this information can only be found after the characteristics of the slab that will be purchased are analyzed. precisely, it will be necessary to know its power. And to make the choice correct, about 20 percent should be added to this indicator. It is better to always have a small supply in case of unforeseen circumstances. But it should be said that the power should not be higher than the one that has an introductory cable, otherwise the main load will be on it.

As a rule, many models of electric plates that are produced now are designed for power 380 V and have an average power indicator of 6 kW. But you can find models and more powerful. For such models, a cable made of copper for a voltage of 380 V and having a section of at least 1.5 kV is required. mm. This type of wire can withstand current strength of 16 amperes. If the device parameters are larger, it is better to take a cable with a section of 2.5 kV. mm.

For electric plates, which are powered by a single.phase cable network, such calculations should be carried out.

And also important will be the moment that all wires should have a double type isolation.

How to calculate the cross.section of the cable by current

You can choose the cross.section of the current on the current. In this case, we carry out the same work. we collect data on the connected load, but we look in the characteristics of the maximum current consumed. Having collected all the values, we summarize them. Then we use the same table. We just look for the nearest more value in the column signed by “current”. We look at the cross.section of the wire in the same line.

For example, you need to connect a hob with peak current consumption 16 a. We will lay a copper cable, so we look in the corresponding column. the third on the left. Since there is no value of exactly 16 A, we look in line 19 A. this is the closest more. Suitable section 2.0 mm 2. This will be the minimum cable section for this case.

When connecting powerful household electrical appliances from the shield, a separate fishing line is pulled for a power trimmer. In this case, the sequence of the cable section is somewhat simpler. only one power or current value is required

Not to pay attention to a line with a slightly smaller value. In this case, at the maximum load, the conductor will be very hot, which can lead to the fact that the isolation will melt. What could be next? The protection machine may work if it is installed. This is the most favorable option. Household appliances may fail or a fire start. Therefore, the choice of the cross.section of the cable always do it in greater value. In this case, it will be possible to install the equipment even a little more in power or consumed current without remaking the wiring later.

Calculation of the cable by power and length

If the fishing line for the power transmission is long. several tens or even hundreds of meters. in addition to the load or current consumed, it is necessary to take into account losses in the cable itself. Typically, large distances of power lines when entering electricity from a pillar into the house. Although all the data should be indicated in the project, you can reinsurance and check. To do this, you need to know the selected power to the house and the distance from the pillar to the house. Next, according to the table, you can choose the cross.section of the wire, taking into account losses on the length.

In general, when laying electrical wiring, it is better to always take a certain supply on the cross.section of the wires. Firstly, with a larger section, the conductor will heat less, and therefore isolation. Secondly, in our life there are more and more devices working from electricity. And no one can give a guarantee that in a few years you will not need to put a couple more new devices in addition to the old. If the supply exists, they can simply be turned on. If it is not, you will have to be wise. or change the wiring (again) or make sure that powerful electrical appliances do not turn on at the same time.

Cable brands for an extension cable

The cable is flexible, so the labeling of KG is deciphered, it has proven itself during operation in open spaces, including production and construction sites. Kg of racks to multiple bending (from 30 thousand. cycles), essential mechanical loads, including compression, tolerates the cold well (before.40 s) and heat (up to 50 s), but does not “love” direct sunlight. Passport period of service. 4 years. European analogue of this brand. XYMM cable.

The execution of KG-XL has similar technical parameters, but more steadfastly to the frost, before.60 p. At extronized temperatures, the brand does not “tumble” and retains its mechanical and electrical characteristics.

A product similar to kg, the KGN brand has a slightly shorter life, 2.5 years, and differs in terms of temperature regime:.30/50 p. The cable is permissible to use on environments in which it is possible to directly hit oils, aggressive chemicals or sparks. KGN brand also requires protection against sunlight.

Unlike KG and KGN, the PVS brand shows resistance to direct sunlight, but at low temperatures it behaves not in the best way. Therefore, despite the passport temperature range.25/40 s, this cable is best used in the warm season. Number of bonding cycles. 30 thousand., life time. 6 years.

This wire for the extension cord can be used to install lines indoors and structures, as well as in open spaces. Temperature regime from.40 to 40 s. In other characteristics, the brand is similar to the PVS. Similar brand from European manufacturers. Rn.

Cable section for an extension cable

The minimum cross section of the cable, which must be selected for the manufacture of the extension cable, is considered 1.5 mm2. In this case, carrying with a capacity of 3.5 kW will be able to maintain a total load on the network within 5 kW. Marko-size kg 3×1.5 will be optimal for 220 in lines, kg 4 (5) x1.5. For 380 centuries.

It is important to take into account that with an increase in the length of the carrying of power, loss of power can be compensated by a large indicator of the cross.section of the cable for the extension cable.

Topic: at what distance can I stretch the wire-carrier for the electric saw?

Not so long ago they gave her husband an electric saw in the service, a wonderful thing and already tested on firewood. But the problem, they brought firewood and dumped far enough from the place where you can connect to the outlet. There are several carrying shirts, but the question is: how far you can pull the wire, taking into account that the carrying of 10 meters and you will have to connect them.

Local registration 15.08.2012 Messages 1.000

(Registered visitors do not see this advertisement. registration )

Theoretically, you can pull it for as long as you like. That. There is a distance, within reasonable limits, does not play a role. Carefully clean the fork pins so that the excess resistance is not created. And all. the same, if possible, then pulling the carrier preferably from the nearest shield or outlet.

If we assume that the power of your electric saw is about 2 kW, then the current consumed by a saw is approximately 10 amperes. Choose such extension cords so that they allow the load current of 10 amperes, connect them sequentially and can be sawing up to a hundred meters. But? It will also take ten extensions? And they are expensive. Better buy a separate fork, outlet and copper wire of the required length and with a cross section of 0.5 mmmm and sawing for health. But, it is better to take 1.5 mmmm. There will be less voltage drop, and, accordingly, you can saw at a greater distance, up to 100 meters.

It really depends on the cross.section of your carrying. One and a half- two squares will be enough for your saw to work calmly at a great distance. If the extension cords are weak, then they will heat up and burn.

If each of these carrying and designed for heavy loads. There will be no problems. But if at least on any of them the section is small, then it will burn instantly. Buy you good cable and make a carry yourself