What Disc To Cut Porcelain Stoneware With A Grinder Without Chips

Tile cutting disc What kind of disc to cut ceramic tiles. Description, tips for choosing? How to choose a disc for cutting tiles without chips, features of cutting tiles with a diamond disc.

Types of discs for cutting porcelain stoneware and ceramic tiles

Several types of grinder discs made of stone or diamond-coated metal are suitable for cutting tiles. In the line of diamond discs, several models are distinguished: solid, segmented, combined. They can be used not only for making simple cuts, but also for finer shaped processing of the product.

How to choose the right drive?

Depending on the modification of the disc, the grinder is capable of processing a wide variety of materials, metals, wood, porcelain stoneware, reinforced concrete, natural stone, etc.

Getting rid of dust

One of the disadvantages of the angle grinder is the large amount of dust generated during the sawing process. Here are some life hacks to help reduce dust:

- Do not cut through the entire thickness of the tile; just make a small groove and then simply break the tile along the cut line.

- Use wet cutting or water cooling to keep debris from flying around.

- Get a vacuum cleaner designed for construction needs.

You can use a vacuum cleaner without an assistant. Masters suggest building an impromptu hood from a container and a vacuum cleaner:

- Cut off the top of the plastic canister.

- Cut a round hole in the side for the vacuum cleaner hose.

- Place the workpiece and grinder over the container.

- Switch on the vacuum cleaner and make a cut over the hood.

Combined

Combination wheels combine dry and wet cutting capabilities. This nozzle is a cross between solid and segmented discs. In terms of cut quality, it is inferior to solid modifications, but outperforms segmented ones. As for the time of continuous operation, it requires breaks more often than segment, but less often than continuous.

Do not use water cooling on the combination disc. It does not withstand temperature extremes, it expands unevenly under the influence of liquid, which is fraught with rupture.

Segmented dry cutters

In segmented dry cutters, functional slots are provided along the perimeter, directed from the cutting edge to the center hole. Radial cutouts allow free expansion of heated metal and more efficient heat dissipation by air cooling. This allows to increase the time of continuous rotation of the grinder with a segmented disc can work for 1-1.5 minutes with a 20-second pause.

Stone discs

Discs made of stone have only one distinct advantage: affordable cost. But the disadvantages of this type of attachments are much more:

- Short service life;

- Rapid wear;

- Large cutting thickness.

Since it is impossible to cut tiles with stone discs, a lot of dust is generated during the work. The nozzle creates a number of restrictions in processing; it is used mainly for making simple straight cuts. But for thinner and curly sawing, such discs are not suitable.

Burr

Most often, the grout is done at 45º for joining tiles at 90º corners. But there can also be other degrees (bay window design, stair flights, etc.).

For the operation, a grinder with the ability to reduce the speed is recommended.

- Preparation of the required element in size. Regular right-angle cutting of tiles in any way.

- Neatly trims the desired angle. Removing the excess ceramic layer without touching the face layer. At the same time, try to leave a small layer of ceramic (up to 1 mm) in order to avoid damage to the surface coating. There is no preference for fixing the tiles. Most craftsmen hold tiles in their hands. It is more convenient to fix it to the workbench.

- Manual grinding and bringing the element to the required form.

Corner trimming followed by finishing by grinding.

Shaped cut (round holes)

Usually, the cutting of circular holes is distinguished. But the technique of cutting round holes with a grinder and any curly cuts is no different. The use of a grinder is justified for cutting large holes (over 50-100 mm). Smaller holes are drilled. A medium-sized grinder (discs under 125 mm) is unlikely to be able to cut a hole less than 100 mm.

Shape cut technology:

- The cut line is marked on both sides of the tile. It is recommended to cut the line leaving the line (up to 2 3 mm), unless of course a smooth cut without chips is required.

We mark the tiles on both sides.

Cuts across the entire mowing line from the front to a depth of 1 to 2 mm (depending on tile thickness, it may be necessary to cut deeper). It is cut in the same way from the back. At this stage, you should not pay special attention to the angularity of the cut.

It is cut along the entire contour on both sides of the tile. Segments are cut through. And unnecessary elements are broken off.

- Cut straight segments in the detachable part along the mowing line of the cut approximately every 2-3 cm. In the case of a circle, cut the mowing line in diameter. The segments are cut neatly until they touch the cutting line (partly farther from the cutting line through the cut).

- Nippers, pliers break out excess fragments.

- Operations 2, 3, 4 are alternated until all fragments are completely removed.

- At the final stage, the edges of the tiles are sanded.

Finish trimming and sanding.

For a curved cut, you will need a tool with a decrease in rotation speed.

Tile cutting

Before any operation, careful measurements are taken and mowing lines are applied to the material, along which it is necessary to cut off excess. It is recommended to use markers of a color other than tiles, as a simple pencil does not leave marks on the surface very well. It is even better to carefully scratch the line (for example, with a glass cutter), since a lot of dust is formed and when shaking off, you can simply erase the drawn line.

Straight cut

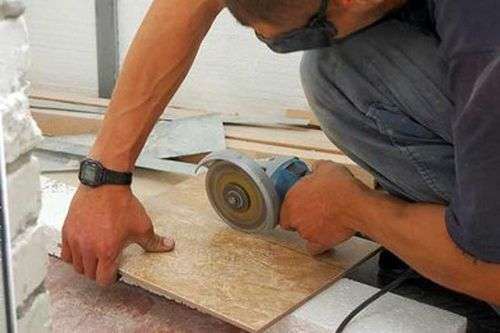

This is the easiest cut. It can be produced by a grinder of any kind, regardless of the material: porcelain stoneware, ceramics, tiles. At the same time, it is difficult to make a perfectly straight cut with a hand-held electric tool. Therefore, they resort to little tricks.

If the quality of the cut does not really matter (it will be covered with plinths, for example), then you can cut it by stepping on the tile or laying it on a rough surface (the tile’s own weight is quite enough so that it does not move during the operation). In any other case, a reliable fixation is required. For this, it is most convenient to use any clamps. A tile or fragment is attached with a clamp to the surface (table, piece of plywood, chipboard, etc.). For small cuts, you can use a workbench; for cutting along the entire length, a workbench is not very convenient.

Some techniques to improve cut quality:

- To obtain an accurate cut along the mowing line, a steel tape or steel angle is attached. You can fix it on the tile with the same clamps. Then it is cut right along the corner. The disc is led at a slight angle (10-15º) to the steel mount.

- The cut is made with an indent (up to 5 mm) from the mowing line. Then the workpiece is sanded manually or using the appropriate attachments with the same grinder.

- In order to reduce damage to the lining, a double cut is made. First, a pass is made along the front side to a minimum depth (the main thing is to cut through the front layer by 2 3 mm to reduce chips). Then cut from the back.

To obtain a straight cut, the tile is cut along the fixed metal corner.

If there are no peculiarities (something is in the way, the mowing line is not visible, etc.), then they always cut from themselves. If you do not have much experience with a grinder, then it is recommended to cut in several passes: the first shallow notch (1 5 mm) and the subsequent ones with approximately the same immersion.

Disk selection

Generally speaking, you can cut off in any circle. The question is different, how to cut with a given level of quality, minimum difficulty and cost. The first disc that comes to hand can leave too many chips, break tiles or quickly fail. But in case of extreme need and without claims for quality, you can cut it like that.

Smaller diamond discs are used in machine tools. When used with hand tools, the likelihood of impacts and jerks increases, which leads to damage to the lining and destruction of the disc.

There are several types of diamond-coated discs:

- Segmented. The disc surface is divided into equal segments. Diamond plated on the cutting edge. During operation, due to the slots, the disc is partially cooled. Note! This cooling only increases the continuous operation (up to a maximum of 1.5 minutes). Then you need to take the tool back and let the disc cool down (20-30 sec. At idle speed). The discs are designed for dry cutting;

- Solid. Full circle with diamond grit applied to the edge. Designed to work with water cooling. It is convenient to use such a disc to process the edge of a cut tile; segmented tiles are not suitable for this. The cut after such a disc turns out to be more accurate. For cooling, you can periodically wet the tile, use a spray bottle, or cool more often. The speed of work will be noticeably lower;

- Combined. Universal blades for dry and wet cutting. They lose in terms of cooling segmented, in terms of the quality of the cut solid.

Example of diamond cutting discs: segmented, solid, combined.

To reduce chipping, it is desirable that the height of the diamond spray is greater than the thickness of the material being cut.

When working, it is important to monitor the condition of the disk. At the slightest damage, the disc changes. Otherwise, working with a defective disc will lead to chips, destruction of tiles or to traumatic destruction of the disc itself. (As a variant of minor defects, the appearance of sparking during cutting. Sparking should not be, sparks mean that the metal base is touched, which means that either diamond dusting is emitted or a metal burr or shavings have formed. You can try to grind off the defect on stone, plaster, concrete. If sparking continues it is recommended to change the disk).

There are a lot of discs of different quality and different purposes. In addition to the types, thickness and height of deposition, the density of the deposition and the size of the deposited diamond particles are important. For cutting tiles with a grinder, such details may not greatly affect, but when cutting thick floor tiles, dense ceramics, especially porcelain stoneware, the choice of a disc can become critical. In these cases, it is recommended to try several discs on pieces of material and choose the best option.

Is it possible to cut porcelain stoneware with a grinder

Of course, an angle grinder can cut anything you want, with the possible exception of glass or particularly complex ceramic products. But it is not so easy to cut porcelain stoneware with a grinder so as to achieve a perfectly even cut line.

Of all the reasons that prevent high-quality cutting of porcelain stoneware, the most important are:

- The grinder is a hand tool, and often the material has to be cut, as they say, by weight, as a result, the disc deviates from the cutting plane, this leads to the formation of chips and sometimes cracking of porcelain stoneware;

- The cut-off wheel is not selected correctly. In the first experiments, beginners try to cut porcelain stoneware with cut-off vulcanite discs over stone and concrete. With this material, you can cut off a small part of the tile, but most often the result is negative;

- Incorrect cutting mode or no cooling of the cut line. The desire to cut faster leads to excessive pressure on the tool, as a result the circle and the tile itself breaks, not to mention the fact that the entire cutting line remains covered with chips and microcracks.

In theory, cutting porcelain stoneware is no more difficult than any other facing material, you just need to choose the right mode, cutting speed, pressing force and choose the right cutting tool.

If you cut with a grinder by weight, then chips must appear

Cutting with a grinder on weight is possible only for those who have strong enough hands. If you have to saw at least 20 cm in length, then even experienced and strong craftsmen get tired hands very quickly, the circle begins to deviate from the vertical plane, as a result, the seam begins to wag, and chips appear.

Sole-based cutting

Direct cutting of porcelain stoneware

It is considered correct to cut a porcelain stoneware slab on a table or workbench. The material is laid on the tabletop, fixed with clamps with rubber tips. The cut line should be outside the table surface. In this case, it is possible to cut porcelain stoneware with a very small angle of inclination, only 15-20 degrees. The master simply pulls the grinder towards himself, only lightly resting his hand on the stand.

Option for cutting with a grinder in pull mode

Why this method is good:

- The minimum load on the hands, if you need to cut a long enough seam, it will not be difficult to do this;

- The cutting line turns out to be even, it seems that the cutting was carried out not with a grinder, but with a tile cutter.

The only drawback of this method is that most of the dust escaping from under the disk falls on the floor, and the largest parts fall into the face and hands of the worker. Therefore, it is necessary to cut porcelain stoneware with protective goggles and using devices for collecting dust.

How to cut porcelain stoneware with a grinder without chips

There are two ways to cut porcelain stoneware tiles. The first is to mark a 1-2 mm deep line on the mowing line in a circle, and then split the granite into two halves as it is done on a tile cutter. The method is quite risky, it requires a good eye and accurate dosing of effort. The advantages include an order of magnitude higher cutting performance. The disadvantages include the unpredictability of the result and a large percentage of defects.

The second method is the classic cutting of porcelain stoneware to the full thickness of the tile. It turns out a lot of dust, the process takes a long time, but as a result, we get a very high-quality and fairly even cut.

In any case, when using a grinder, the seam is uneven. Visually, the line looks perfectly straight, but as soon as the cut plates are turned over and applied to the factory edge or metal ruler, all the irregularities will immediately become visible. An example of cutting porcelain stoneware with a grinder without chips is given on:

How to get rid of dust when cutting porcelain stoneware with a grinder

If the tiles are cut on a table, then, before starting work, a small piece of loose fabric must be pulled under the cutting line or a polypropylene bag must be hung. In this case, most of the dust flies down from the disc, so the amount of work on cleaning the room is reduced several times.

If you cut porcelain stoneware on a substrate directly on the floor, then the best solution would be to use a regular vacuum cleaner. The tip of the hose is attached along the mowing line of the movement of the grinder at a distance of 10-15 cm. It turns out not very convenient, since the pipe has to be rearranged, but the dust is removed quite effectively. Immediately after the end of the work, you need to blow out the grinder and collect part of the dust remaining on the surface of the porcelain stoneware.

How to cut correctly with a high-raised grinder

Most beginners and DIYers prefer to cut porcelain stoneware with a tool with a very large angle of inclination relative to the plane of the tile. The angle can be 45-60 degrees.

The tool can only be lifted high if there is a supporting surface on the cover

In this case, the grinder has to be held with both hands and at the same time perform small oscillatory movements with the cutting disc. It is as if the porcelain stoneware had to be cut with a hand saw. This is not very convenient, but the method really improves the quality of the cut and prevents the formation of chips.

On the one hand, with such a movement of the grinder, it is easier to control the cutting line, on the other hand, the tool is in an unstable position relative to the markings, which negatively affects the quality of the straightness of the seam.

Cutting porcelain stoneware with a grinder: how to saw off without chips

Anyone who has had a chance to cut faience, ceramics, porcelain stoneware with a cutting disc knows very well that the problem is not to cut. Such an operation is not particularly difficult. The problem is to learn how to cut porcelain stoneware with a grinder without chips. At the same time, control the process at any stage, otherwise the expensive material will go to scrap.

It is best to cut porcelain stoneware using a guide bar as a support for the grinder body