Which is better than a grinder or tile cutter. Diamond disk

Industrial ventilation in Moscow construction installation in Podolsk

Performing facing work independently, a logical question arises: which of modern tools is best suited for this task? How to cut floor tiles?

Typically, tools such as tiles or a grinder are used for this.

How to cut tiles with a grinder

This tool allows you to process a huge amount of material, but it is considered traumatic, so it can be used if the master has extensive experience. Otherwise, you can ruin the tile.

- At the very beginning, it is necessary to fix the tile on the work surface.

- After that, you need to draw a line and take the device in order to start cutting the tile.

- For protection purposes, it is recommended to use a protective mask. Then the dust will not be able to get into the eyes and the respiratory system.

How to cut with a tile.Cutter manual

Those who do not know how to cut tiles with a tile cutter should carefully study the following information. Tiles cutter is considered the most suitable tool for cutting tiles. It can be manual and electric. Manual tiles is characterized by a large working surface and the presence of a lever.

- In order to start work, you need to take the handle as close as possible to yourself, and then install the blade on the rollers at the very beginning of the planned line.

- After that, you need to take the pressed handle forward and press.

- Now a hole will appear in the tile, after which it will split into several parts exactly along the line.

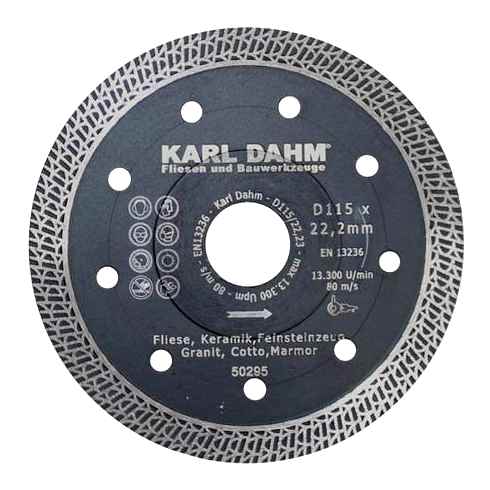

Electric tiles are arranged differently. He looks like a small circular saw. Its key element is a diamond disk.

Cutting sexual tiles is a time.Consuming and painstaking process, therefore, before starting work, you need to relax properly and then make sure that all the tools are about the serviceability.

Manual tile cutters

Their use is based on the use of the physical strength of the employee. Among these devices, glass cutters, pliers, forceps, etc. Can be distinguished.P. There is still manual glass cutter.

Best & worst Concrete saws & diamond blades from Makita, Hilti, Dewalt, Stihl, Echo and Husqvarna

He looks like a ballpoint pen with a video at the end. Hand glass cutters are different videos. They can be made from diamond or solid alloy. The most durable videos are made precisely from the diamond. To cut the tiles, you need to carry out a tool in a ruler. A furrow forms in place of the ruler, it needs to be broken.

Of the shortcomings of manual glass cutter, it should be distinguished that this device is suitable only for thin tiles. Also, with its help, you can cut only under the ruler, a curvilinear cut is impossible.

Using the nippers, it will be possible to cut the tile. Like glass cutter, nippers have a cutting roller. Therefore, the principle of cutting is as follows: the master must first draw a furrow, then hold the tiles between the sponges of the nippers and break it. Unlike the previous tool, it is possible to make a curvilinear cut with nippers.

How to choose the optimal power of an electric tile cutter?

In such devices, power primarily affects the torque (force when rotating the saw disk). That is, the more powerful the engine is in an electric tile, the easier it will be to cope with a dense thick tile, and the cutting depth will be larger. In fact, the more powerful the engine, the more with a large disk the device is capable of working. At the same time, excess power is not always good, as it affects the dimensions and cost of the unit. Conditionally, all tiles can be divided by power into three categories:

- Up to 1000 watts. Mainly stationary.Type tiles with the lower disk feed. The maximum disk diameter for them is 200 mm.

- From 1000 to 2000 watts. Portable and stationary with the upper drive of the disk. The maximum disk size is 300 mm.

- From 2000 watts. Mainly stationary with the upper drive of the disk. Over, most devices have a 400-mm disk.

Often, buyers prefer devices of the first category, since in most cases they meet the needs of consumers, but are relatively inexpensive. For repair in the house, a tile cutter with a capacity of 1000 watts with a lower disk feed may be enough. For example, many buyers with approval respond to the model Zubble EP-200-1000n with the lower disk feed and the ability to work with nozzles with a diameter of up to 200 mm.

Devices from the second category should be considered only if you need to make oblique cuts at an angle. Naturally, only some portable and stationary tiles with the upper drive of the disk can do such work.

The third category is intended for professionals who are launched marble and large.Sized porcelain. The price tag for such devices varies from 40,000 to 250,000 rubles. However, if your choice of tile cutter still fell on a device from the third category, then we recommend buying a model Einhell RT-SC 920 L 2200 watts with a 300 mm disk and effective water cooling.

How to choose a tile cut in an inexpensive cut depth? This indicator directly depends on the diameter of the saw disk. The larger the working disk, the greater the thickness of the tiles it is able to cut out (here much depends on the design features of the device). Simply put, first it is worth determining what thickness maximum you will need to cut the tile and then buy the appropriate device.

Naturally, the depth of the cut will be much smaller than the diameter of the disk. For example, consider a stationary tile cutter Elitech PE 800/62r. It works with discs with a diameter of 200 mm, but the cut depth is at an angle of 90 ° 36 mm, and at 45 ° 30 mm. This means that the device is suitable for laying facing ceramic tiles in the apartment, but it will not be able to cut the paving stones with a thickness of 40 mm or more.

It is also worth remembering that the concept of “cut depth” in devices with the lower and upper feed of the disk differs. If for units with the upper feed of the disk “cut depth”. This is really the value on which the disk lowers into the tile, then for the device with the lower presentation. This is the distance to which the disk peers out of the table. It was structurally so that with an equal diameter of the saw disk in devices with the upper feed, the cut depth will always be larger than that of devices with a lower presentation. Also, tiles with the upper drive of the disk allow you to cut niches and holes in the tile, which is useful if you need to put a square.Type switch or socket

Methods of cutting

Cutting with a grinder

If it was decided to use a grinder with a diamond disk, then it does not need to be drove sharply on the material, otherwise there is a risk of damaging the final part. Also, during work, you can not do without means of protection in the form of a mask and glasses.

Fragments and dust can cause significant damage to health. The tile needs to be firmly fixed and the stone from the near edge. It is necessary to make the stone go to the front side.

Cutting with an electrician

Unlike other tools, it is convenient to create curvilinear cuts with an electrician. To make a cut even, you do not need to buy additional devices: it will be enough to use the usual ruler.

Cutting with any pointed tool

Unlike other tools, this method only allows you to cut the upper part of the tile, and then it will have to be broken. If the facing layer is durable, then the finished result will be even.

However, if this layer turned out loose, then the layer will not be even. In this case, you will have to remove irregularities with the help of.

Is it possible to cut porcelain tiles with a grinder? Types of cutting ceramic products

In addition to ceramics, which is used in the improvement of bathrooms, there is also porcelain tiles, tiles made of natural stone. They differ in greater strength and reliability, therefore they are used for styling in public places, industrial premises, modern interiors of residential buildings.

These types of tiles are also processed using a grinder. The general principle of work will not change. The only difference is that due to higher strength it is recommended to use exclusively segmented metal discs with diamond spraying: due to better cooling, the probability of overheating is less. The wet way will help make the work more efficient and reduce the amount of dust.

The advantage of the grinder over the tile cutter is that the latter cuts only in a straight line. Ushm performs complex forms. What types of cutting will the master collide?

- Direct cut it is more convenient and faster to produce a tile cutter. But if you do not have it, then an angle grinding machine is suitable.

- Figure oval neckline. This is a complex variety. Used for decorative purposes.

- Rectangular hole.

- Round holes.

- At an angle of 45 °.

Straight cutting or straight cut

The standard, easiest way that we advise will initially master non.Professionals.

- Prepare the workpiece: for this we take a marker, ruler, draw a line on which we will make a cut.

- We have a workpiece on a straight surface, remove all the excess that can interfere. To ensure accuracy, we fix the workpiece with a vice.

- We start sawing. It is necessary not to saw ceramics through and through, but to make an incision 1-5 mm deep (depending on the thickness of your workpiece). We remember that when entering the material, the number of revolutions is reduced, later it can be increased. We conduct the tool smoothly, at the same speed, from ourselves. We do not drive back and forth along the intended line. We adhere to the intended trajectory as much as possible. When the cutting edge exits, we slow down again to avoid chips.

- We break the workpiece into two parts. If necessary, clean up at the cut place with the appropriate equipment.

Curly cutting or figured neckline

The most difficult, demanding on the skill of an employee is a variety. It is recommended to entrust its implementation to a professional if you do not consider yourself an experienced user. Unlike direct cut, a figured neckline will not work with a tile cutter: a grinder in this case is necessary.

- Make a marker marking on the workpiece.

- We fix the workpiece on a flat surface, fix it for the greatest reliability.

- We begin to work Ushm: you need to make short cuts, cutting off excess material.

- At the end of the saw, unevenness in the place of cut will remain. To finish curly cutting, change the cutting disk with an abrasive circle, process the scrap place until the result will be resisted.

Cutting rectangular holes in the tile

For this type of sawing, you will need a drill with a drill (recommended diameter. 5 mm) on the tile!

- We plan the contours of the figure that we will cut out.

- We fix the workpiece using a flat surface (this can be a large durable table or a special working workbench).

- Using a drilling tool, in the framework of the intended contours we create holes in the corners of the alleged rectangle.

- Using the Ushm, we cut the line, following the designated contour.

- We delete the inner part of the figure.

- If necessary, we finalize the resulting area with an abrasive.

Cutting circles (round holes)

Before cutting the circumference, prepare a drill, a carbide drill (3-4 mm. A suitable diameter), compass. Let’s start:

- Put a marker on the workpiece with a marker. It will be the central point of the circle.

- Using the compass, we draw the circle of the circle of the value you need.

- The drill create a hole in the place of the central point.

- The angle grinding is producing through slots from the inside of the circuit of our circle.

- We process irregularities using an abrasive or sandpaper.

Cutting at an angle of 45 °

This variety of cuts is considered complex. To improve the quality of the result, we advise you to perform work by a branded metal circle, fortified diamond spraying.

- We mark the place with a marker in the ruler.

- We have and, if possible, fix the blank.

- We place the blank with the outside to the bottom.

- Using an angle grinding machine, cut off the back of the blank at an angle.

- Following the designated line, we perform a repeated cut. This will achieve the most accurate and even result as possible.

- If necessary, bring the cut place.

Cutting tiles with a grinder

This video shows the general principle of operation by a grinder, including grinding the edges of the fault.

However, it is worth understanding: for such filigree work you need a good skill. In addition, quite often when cutting a disk. Both in a straight line and a curve. Chips occur. To cut the tiles with a grinder without chips and other problems, the masters recommend gluing masking tape along the cutting line and mark it on it. By the way, it is convenient to do it with a normal pencil.

To simplify the work, it is better to fix the tile or porcelain tile on the desktop.

It is convenient to do this with special clamps-beasts. At the same time, the depreciation of the support surfaces of the clamps and at least the minimum depreciation of the desktop is mandatory. This will help to avoid unwanted vibration leading to chips on the tiles and its uneven fault.

Cutting tiles with a diamond wheel and a MAKITA angle grinder

It is recommended to lay a foam, foamed polyethylene and other similar materials on the table.

Sometimes it does not go out to get an even section, in this case you can “choose” the material to a certain circuit with a grinder, and then smooth the edge with an abrasive.

If you need to make a rectangular neckline or cut the tile along the broken contour, straightforward cuts are performed.

Unfortunately, it is difficult to avoid cuts in the corners.

It is also convenient to grind the not entirely even edges of the tile after cutting. For this, special flexible abrasive circles are used.

What is required for the manufacture of a home.Made tool

The electric device is much more expensive in manufacturing than mechanical, but it is more convenient to work with it, and the quality of cutting tiles will be much higher. For its manufacture, the following will be needed:

- Table or workbench

- A grinder with a diamond disk;

- Metal platform;

- Two steel pipes;

- Fasteners;

- Clamps.

You can save on the equipment if you buy a cheap cutting element, but this is not recommended to do this, since the quality of the cut and productivity of the work depends on it.

Types of tiles

Knowing what tiles are, allows you to choose the optimal device for practical use. The tile cutting tool is divided into two main types:

Mechanical models by the method of action similar to glass cutters. Most electrical units resemble a circular saw, but there are also modifications similar to a strip.

Mechanical tools

Work with mechanical devices is carried out at the expense of the muscular power of man, They have no drive. Mechanical equipment is represented by several varieties:

Table mechanical products consist of the following structural parts:

- Table;

- Lever designed to break the cut material;

- Carriage;

- Cutting roller;

- Tiles.

To make markings, there are a ruler in many models of products.

Table models are used to cut in a straight line and cut glass or tile up to 1.5 cm thick in size. The whole process is as follows:

Label.Type stationary products are operated with strict consolidation to the table bolts (there are holes under them) or without fixing at all. The latter option is suitable only when cutting thin tiles or non.Flowering glass. The maximum size of the tile with which you can work depends on the length of the table.

A hand tool, in turn, is divided into 2 types:

Kusachki make figured cuts in the tile or glass (thick up to 8 mm), for example, under the baseboard or pipe. Their use requires the presence of skills of such work, otherwise you can easily damage the material.

Cutting roller You can work with glass or tiles up to 10 mm thick even by weight. With the help of this manual device, both direct and figure cuts are made.

Electrical equipment

The design of electrical equipment provides for the presence of the following components:

Electrical engineering is equipped Diamond discs.

In terms of mobility, the power tool is divided into the following groups:

Manual models of electric steamers Weigh 3-5 kg. They are very similar to circular saws. Their discs protected by the casing rotate at a speed of 11,000 to 13000 rpm. Such a power tool is equipped with a comfortable handle, adjusting the angle of cut and depth of deepening. The supporting soles of some models have rollers so that you can easily move the machine along the surface of the tile. A number of products are additionally equipped with parallel stops, which increases the convenience of their operation.

Cutting high-fired tiles – the right diamond cutting disc

With manual models you can work dry, connecting a vacuumber or vacuum cleaner to them, or wet method. In the second case, the tank under the liquid is located on top. For this reason, a manual.Type electric stump toss with a water supply by gravity will be possible only when performing work in a horizontal plane.

Table electric tile belongs to the toothy machinery equipment. A plain cutting machine operating on electricity, depending on the location of the saw head and electric motor is divided into models of such types:

The equipment with the upper location of the electric motor is divided into two varieties:

- Console, in which the saw head is fixed, and the table with the workpiece moves;

- Pavement, where the engine moves together with the disk.

Models with upper location provide accurate and high.Quality processing of materials. The cooler circulation is provided by the presence of a small pump.

Electric tiles Scheppach FS-4700

Units who have electric motor from below, usually have smaller weights and sizes, and they also cost cheaper than analogues with the upper drive placement. This type of tiles is designed for porcelain tiles, glass, ceramics. The working part of the disk protrudes from the table. Its cooling occurs due to immersion in the water located under it. The processed workpiece moves along the guides.

Electric tile cutter with a lower engine

Low.Produced varieties of equipment

In addition to the above varieties of equipment in organizations specializing in cutting different materials, you can find the following installations:

With the help of stonezerus, concrete, stone and other plates are treated, the thickness of which is from 60 cm.

Laser tile cutter use, if necessary, complex (curly) cutting, for example, to create mosaics from porcelain tiles. Such a tool can cut thick plates. For similar purposes, it is used and water tile. The principle of its functioning lies in the hydro.Carbonated method of cutting materials.

What materials cut these tools and where are used

It is better to stop your choice on a tile cutter:

- Teling cutter. A universal machine that performs a wide profile of work: cuts tiles of different types, stone and glass sheets;

- There is a different set of appropriate discs on sale;

- There is no huge dust accumulation in the work (has a vacuum cleaner), relatively safe in work, unlike a grinder;

- Allow you to save time cutting and make even neat cuts.

The minus of the tank cutter is the price, but many professionals know that you can perform homemade tiles from a grinder and do not spend extra means.

Which is better than a grinder or a tile cutter

When working with ceramic tiles, situations often arise that require it to cut it. However, cutting tiles is not easy, so it is best to use a special tool, t.E. Tile cutter.

The cutter for tiles, like any other construction tool, has its own varieties. The choice depends primarily on the characteristics of the tile itself. All existing mills can be divided into two large groups: manual and electric. Let’s analyze the most important features of both groups.

In that case, if we talk about the design of a hand tile cutter, this is quite primitive. Such a tool is equipped with a cutting element of titanium or diamond cutting, a convenient ruler for thin and acute cutting, a floating base for the convenience of chipping tiles, guiding, preventing the cutting part of cutting.

It is worth noting that from the entire assortment of manual tile cutters are very popular. Tile cutting. In appearance, they are somewhat similar to pliers. With their help, they first carefully cut the diamond disk on the enameled side, and then easily tear off the tile with a milling cutter. The cost of such a tool ranges from 120 to 600 UAH. It is easy to work with it; No special skills are required.

Hand cutters can be used if you have to cut the tile of a small thickness (that is, no more than 15 mm). In this case, the tools differ in length. For example, a cut for tiles with a length of not more than 400 mm is suitable for cutting wall tiles (about 8 mm thick).

Some manual nippers have a round mill (ballerina) necessary for cutting holes of different diameters in the tile. This allows you to get a hole with a diameter of up to 80 mm.

When choosing a hand cutting machine, you should pay attention to how the tool is held on the guides. Plastic rings can be used in the design. This is not good if you want to cut with high accuracy. In this case, it is better to use tile scissors in which the guide of the tool moves to self.Combatable seals or bearings.

When working with thick tiles or with a large number of work, power tools are required. Electric tiles are machines. The main technical indicators of the electric tile cutter are power (from 500 to 2200 W), circle diameter (180-200 mm), maximum cutting depth (30-40 mm), cutting length (up to 500 mm), table dimensions, continuous operation ( min), weight (from 10 kg). Estimated price range. From 800 to 8000 UAH.

There are two types of electric tiles: the lower motor and upper (rail). The lower mills cut the tiles of almost any size. In addition, the lower engine tools are compact and suitable for use in small areas. It is easier to work with rail cutters, and they also provide a more accurate cut of tiles.

All mills have a diamond.Cooled diamond disk. In the lower position of the engine, the water tank is located under the disk, and a small submersible pump is provided in the design of rail tile knives.

Electric mills have the opportunity to adjust the angle of inclination of the cutting plane relative to the material. Therefore, all electric carriers of tiles can cut the tile up to 45 degrees.

Practical question: is there still a machine for cutting tiles?

Some users use a corner grinding machine, that is, a tile grinding machine. Do not deny that it is possible. But at the same time:

Crama cutting products

To cut the tiles with a grinder, it is necessary to master the three directions of the cut.

Direct cut

It is not difficult to master it, at the same time the cut line is clean and without chips. When performing work, the tiles are securely fixed on a flat surface, marked with a pencil or felt.Tip pen. The cut part should freely hang from the table. The cutting tool is located at right angles To the workpiece. Carefully, without jerks, slowly lead the Ushm along the marked line. The tool should be moved to yourself in such a way that the marked line is visible.

At an angle 45 0

It is often necessary to dock, and this implies a cut of material at an angle of forty.Five degrees. Such an angle can only be obtained with a large training. But you can use this technique: first they cut off the workpiece in a straight line, and then gently disk, skark treat the edge at the right angle.

Figure neckline

Often there is a need to cut Round hole In tiles. You can do the work correctly with Ushm if there are certain skills. To do this, marry the hole on the workpiece and the line is circled by the felt.Tip pen, the center of the circle is noted. Begin to cut at a slight angle, slowly, on the inside of the line, gradually passing throughout the circumference. Then the sectors are cut out, they are taken out in turn, if necessary, cutting ceramics. Finally process the edges with a file, receiving a flat circle. This processing is called a dry cutter.

When performing figured processing of the workpiece, it is easiest to perform Rectangular cuts. In order for the sections to be even, without chips, it is necessary to regularly change the cut.Out circle. If you use segmented discs, then chips must appear on the cut line.

How to choose a tile cutter

In order for the tool to satisfy your needs and at the same time serve for a long time, it is worthwhile to outline the main criteria, on which the choice of a particular model will depend.

- Appointment. For home repair and small finishing work, a compact manual device with a mechanical principle of operation is suitable. For lining with tiles or stone of large halls or facade of the house, you already need a more reliable and powerful tool that will cope with a large volume of work faster. Such is electric tile cutter.

- Stanin and platform. The convenience of the operator, the accuracy of the location of the material and cutting will depend on the strength and reliability of the bed. Most often, tiles of tile cutters are made of dense metal alloys. The heavier the base, the more stable the device will be fixed on the table. For comfortable work with blanks of different sizes, it is advisable to purchase tiles with a wide platform and rubberized coating.

- Cutter. The cutting device of an electric tile cutter is a saw disk. It is important that it is well sharpened, has a smooth surface and the corresponding to the desired depth of the cut diameter. Hand units make cuts using a video or bearing (mechanical). The cutting element of the structure is made of metal with diamond spraying. The quality of work depends on the cutter to a greater extent, therefore, when chips appear or abrasion, it is recommended to replace it.

- The smoothness of the carriage. To perform a flat cut without depth changes, the uniformity of moving the carriage along the racks is important. The section is made once, so it will be impossible to correct the error of the first passage, and the material will be spoiled. Therefore, before buying, it is worthwhile to separately check the smoothness of the passage of bearings and roller.

- Lever arm. So that the tile cutter is effective when cutting dense blanks, the lever must have a reliable mount and a convenient design. A weak lever will not allow the cutting to the workpiece enough to press, and, therefore, the incision of the desired depth.

- Length and depth of cut. The size of the workpiece and the depth on which the video or disk are able to plunge into the material depends on these indicators. For roller mechanisms, the average indicator is a cut of 40 mm in length and 10 mm in depth. For electric models; 500 mm in length and 40 mm in depth.

- Power and speed. Parameters that are relevant for electrical models. The average indicators for tiles are a power of about 8 kW and the speed of the disk 3,000 rpm. Powerful models are able to work for a long time and saw the workpieces of a large thickness.

- Disk size. The larger the diameter of the disk, the more thick material it can cut. Most often, discs with a diameter of 100 to 700 mm are used for tile cutters.

Comparison of the grinder and tile cutter

These tools have a pair of common denominators, namely:

- They can Cut the slabs. Both Ushm and tiles are suitable for this. However, the degree of suitability varies from the view to the form.

- Grinding and tile cutters in general The same principle of work. A cut is made, shallow for a neat fault or full, literally cutting the tile.

The general ends on this, and the differences begin, which are not so few:

Which angle grinder blade / disk for concrete, plastic, tiles and metal

- Universality. The grinder can be used for its “profile” purpose. For grinding, but also for polishing, sharpening and cutting materials, tiles in particular. It is a practical and suitable tool for various tasks. The tiles are created only for cutting tiles and almost nothing more is good for anything. Only in extremely rare cases can it be used for cutting glass, but only when its thickness does not allow it to be treated with glass cutting.

- The size. Even the smallest tiles, designed for tiles of not more than 60 cm in width, will be much larger than any Ushm, which will entail the corresponding difficulties in its placement if it is necessary to work in limited spaces, as well as its storage.

- Cutting cutting tool. If in a grinder you can guaranteed to change the discs, then in some tile cutters, especially the roller type, this is not available. A video was blurred. Buy a new unit.

- The possibility of patterned cutting. A grinding machine has the possibilities for both curved cutting and cutting under an acute, and not just right angle. Most of the tiles are devoid of such functions if you do not purchase additional tools for them.

- Price. The price of more or less high-quality bells and tile cutters begins somewhere with 3-4 thousand. Rubles. At the same time, it is worth recalling that the grinding machine is a more universal and compact tool, with the changing disks, when the tiles cannot boast of this for the most part, and the purchase can become for use at a time.

- Convenience and working conditions. It is impossible not to take into account the working conditions that the tool sets on its own and here the tile cutting looks more attractive, since it has its working surface, albeit minimal, when the grinder needs a substrate or a large skill for cutting on weight. And it is also more convenient to moisten the disc disk due to built-in water supply devices, which minimizes the dust and heating of the cutting tool, not to mention the possibility of connecting a vacuum cleaner.

Based on the above, we can say that the Bulgarian is suitable for those who do not want to buy an additional highly specialized tool, the use of which can occur once in a life.

Ushm can quite successfully cut the tiles, without chips and torn edges, while non.Aggressed discs with diamond coating should be used, and wet cutting is recommended. In addition, a grinder can be made not only in a straight line and not only at 90 degrees. However, it should be remembered about safety and dust, providing yourself with protective equipment such as glasses and gloves, as well as a way of removing dust, whether it is a vacuum cleaner, moisturizing a disk or cutting on the street.

The tile cut is suitable for those who Professionally engaged in repair or specifically with the work with the plates. Because its main feature and dignity is that it was created for cutting tiles. And unlike the grinder. Tiles of large thickness are subject to mechanical tile cutters.

In addition, tile cutting is suitable for prolonged work with tiles Ushm is much better due to design features and a built-in cooling system, not to mention the best removal of dust and quality of work, since on the tile cutters a minimum number of torn edges and chips are obtained.

Summing up in one phrase, it should be said that you can cut the tiles, and with a grinder and a tile, it is better in domestic, inexpensive use definitely a grinder, and in a professional, frequent. Tile cutter.

Bulgarian (Ushm)

The old kind universal grinding machine, common in many households, having far from one use except directly grinding. In general, the Bulgarian is represented by a device in a small cylindrical case, which is convenient to hold with one hand, where at the end there is a mounting unit of the working disk.

Ushm are like household, So Professional, Basically, this difference is justified by the increased time of work working from the network and from the batteries, in the case of work in non.Electrified places, with various protective casings and handles for the second hand or their absence. The main characteristics are:

And the number of additional things includes such pleasant trifles as the function of smooth starting, adjusting and stabilizing the revolutions, the presence of a mechanism for balancing, the protection systems against jamming and re.Starting, fast.Seal clamping and spindle brakes.

Grinding is a truly universal tool with which you can not only grind, but also cut, sharpen and polish.

Which is useful when cutting tiles?

The straight line will make it easy, but with the unusual one. You will need to “play”. First you need to outline the cut line. Our advice: During cutting, do not forget to hold the tile, and use the tile cutter with the other hand. When cutting tiles, direct “on yourself” and hold at a right angle. After that, the cut tile should be put on any surface and hit with a palm or hammer with a soft rubber coating, the tile will split right along the line.

Electric tile cutter

It is considered the best option for cutting any tiles, porcelain tiles, paving slabs and clinker. It is equipped with a diamond disk and thanks to this the edges of the tiles are flat, and with smooth rounds.

Strongly marked in front of a sharp tile, put on the surface and carefully carried out with a blade. Must: the tile should be tightly pressed.

Important! Working with an electric tile cutter, you need to remember the safety. During operation, you need to use protective glasses, as well as observe the pallet in which the water is located. If the water is heated and clogged, it needs to be replaced. Also, if you use the device without water supply, it is recommended to work with a partner who will remove the dust formed during cutting with a construction vacuum cleaner

Electric tile cutter is considered the most modern and accurate method of cutting, close by the principle of action to large factory are used by experienced craftsmen and construction companies.

What to pay attention to when making a choice?

For the strength of the frame: the stronger it is, the longer the tiles will serve you. For the manufacture of the base, strong steel should be used: this minimizes the possibility of cracking tiles and shock absorption of the tool during operation.

If you plan to work with porcelain tiles, then you need to choose models with a long handle: this allows you to create a greater effort.

Its versatility depends on the length of the tool. A long model can be used for cutting both wall and floor tiles. The length of the tool directly affects its cost: the greater it, the more tiles are more expensive.

The quality of the work is also affected by the smoothness of the course, for models with bearings it is better than in those where they are not. To understand how smooth, it is necessary to carry out test cutting. The cut line should be even, and the work of the tool is smooth.

In order to be able to securely fix the tool, the base must be attached to the table, then it will not slip.

The presence of an angler will fasten the tile at different angles to the cutter, which also makes a tile cutter more convenient and universal in work.