Which side to put a knife on a lawn mower.

How to remove a knife from a lawn mower?

The lawn mower greatly simplifies the care of the lawn. The tool carefully cuts the grass at the same distance from the ground, leaving behind a neat, well.groomed surface. Garden technique has a complex structure. The cutting mechanism is responsible directly for cutting vegetation. Lawn braids are equipped, as a rule, knives. This is a consumable element that is blunting, damaged, breaks down. To restore the full functionality of the tool, you must first familiarize yourself with how to remove the knife from the lawn mower.

The main function of knives for the lawn mower is to cut the grass. For one working cycle, the tool is able to process a large territory and collect an average of 10 kg of grass. Some models are equipped with a mulching mechanism. Such tools install additional knives designed to grind cut vegetation. Knife elements for the lawn mower have a specific device. Their blades create an ascending traction, thanks to which the cut grass is fond of the grass collector.

The following requirements are advanced to the lawn mowers:

For the manufacture of cutters, high.quality stainless steel is used with a hardness indicator of at least 55 on the Rockwell scale. If this value is lower, the knife is quickly swollen, especially when cutting shrubs and weeds. To protect the elements from corrosion, steel is improved using special additives (chromium, zinc). This gives knives resistance to rust. If you do not cover the part with a protective composition, after the first session a brown coating is formed on its surface.

How to remove a knife from a tool and why do it?

Experts recommend changing the knife on the lawn mower at least once a season. Removing the cutter is required if it is necessary to sharpen or replace the cutting element. Consider how to remove a knife from a lawn mower.

- If the tool works, stop it. It’s easier to turn off the electric device, just press the button, remove the network cable or remove the battery. Basin lawn mowers are disconnected from the key. After you need to drain the remaining fuel mixture.

- Remove a container for collecting grass from the lawn mower.

- Clean the cutting elements and protective casing from adhering grass mass.

- Remove the visor. This element is responsible for the delay of grass, which in the process of mowing is scattered in different directions.

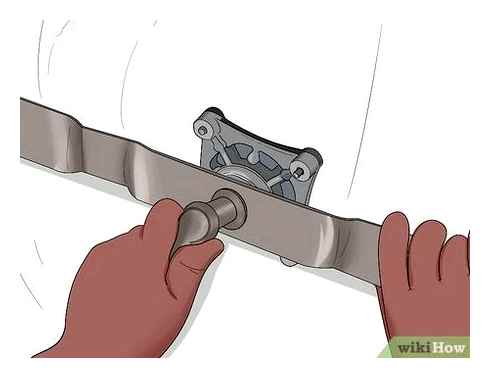

- Using a wrench or head, unscrew the mounting bolt. A cutting element is installed on the apron. Before you remove the knife, be sure to put on dense gloves to protect your hands from cuts.

- Put a new knife. Tighten the bolts.

The last step is to check the mounts. If the bolts are weakened, the tool begins to vibrate greatly during operation. This can even lead to spontaneous loss of the blade from the seat. It is advisable to install the same consumables. When buying a new knife, choose products of the same brand and with the same characteristics as the old cutter.

How electric lawn mowers are arranged

The general layout of electric lawn mowers is the same.

An electric motor is installed on the wheel chassis, directly or through the belt gear, a rotating cutting tool that cuts the grass at a certain height.

However, despite the general principle of work, all braids are divided into types of:

Type of chassis

Most lawn mowers are equipped with a four.wheeled chassis with a rigidly fixed axis of the front wheels, so for rotation, especially during the mowing of grass, it is necessary to press a little on the handle to tear the front wheels from the ground.

Indeed, during the turn, the direction of movement of the apparatus and the direction of rotation of the wheels do not coincide, which is why the latter resist the side movement, and the cooler the turn, the stronger they resist the movement.

Some models are equipped with front piano wheels, the axis of which does not have rigid fixation, so that the axis of their rotation clearly follows the trajectory of the lawn mowing, therefore, regardless of the steepness of the turn, they never move sideways.

Almost all three.wheeled lawn mowers are equipped with front piano wheels, so it is much easier to control them than four.wheeled. However, the most maneuverable are two.wheeled models, because regardless of the steepness of the rotation of their wheels never move sideways.

engine’s type

Collector and asynchronous motors of alternating current are installed on electric lawn mowers.

The former have somewhat smaller efficiency, but it is much easier to perceive high loads or overloads, the latter more effectively turn electrical energy into rotation of the shaft, but greatly increase the cost of the apparatus.

This is caused by both the highest cost of collector engines, and the need to protect them using belt transmission. The main difference between collector engines is the presence of contacts (collectors), therefore they are sometimes called collector engines, confusing with direct current motors.

Devices with a collector engine are well suited for mowing lawns and other territories planted with cultural vegetation, however, their use in areas overgrown with wild grass, especially tall and thick, is undesirable.

After all, such vegetation sharply increases the load on the engine windings and the brushes of collectors, as well as on the details of the belt transmission, all this leads to a rapid decrease in their resource. Asynchronous engines are deprived of this drawback, however, when working with them, it is necessary to use different methods of mowing well.groomed and high grass.

Type of cutting tools

The vast majority of the devices are equipped with a rotary cutting tool, that is, knives mounted on the engine shaft, which rotating, cut the grass and throw it through the side or rear window. During the rotation, such a knife is created by a vertically directed air flow that raises crushed grass and provides an even surface after mowing.

To some extent, the rotor cutting mechanisms can also be attributed to fox, which are installed on wheeled trimmers for the grass, only instead of a metal knife they cut the grass dispersed to huge speeds with a fishing line.

The main drawback of the knives of the rotary mechanisms is their vulnerability before solid obstacles, because rotating at high speed, they stock up enormous kinetic energy. Therefore, in a collision with an obstacle, not only defects of the cutting edge appear, but also the shape of the knife is often disturbed, due to which an imbalance appears, leading to strong vibration during engine operation.

Part of the lawn mower is equipped with a drum cutting mechanism, which is a hollow drum of steel plates, as well as a sharply.mounted knife operating on the principle of scissors.

The rotating drum captures the grass and leads it to the knife, which cuts vegetation, so such a mechanism is deprived of the main lack of rotary analogues. After all, the speed of rotation of the drum is much lower, which means that the energy accumulated in it is not enough to damage the plates, in addition, the knife does not contact obstacles at all, so defects do not appear on its cutting edge.

Method of ejection and processing of grass

The knife rotating at high speed not only cuts off the grass, but also gives it acceleration, so that the centrifugal force presses the cut vegetation to the deck, so it flies through the rear or side window, depending on the configuration and the operating mode of the mower.

If both holes are closed, then the cut grass passes between the ends of the knife and the walls of the deck, after which it falls down.

When working in this mode, falling fragments are quite large, comparable to those that fly through the windows provided for this.

If, together with a regular knife, set additional (mulching), then the size of the grass falling to the ground will be reduced several times, so this mode of operation is called mulching. All rotary braids can not only throw the grass back, but also collect it in the grass collector, this mode is in demand where for any reason you can not leave mowed vegetation on the site.

Drum mowers work a little differently. rotating, the drum accelerates the fragments of cut vegetation inside it, which are pressed to the tightly adjacent gas mowing housing. Therefore, at the time of passage through the output window, they fly out under the influence of centrifugal force.

All drum braids are equipped only with the rear emission, however, part of them includes a grass collector, so such models can be used not only for haircuts, but also to remove mowed grass from the site.

Way to travel

All electric lawns, regardless of the type of cutting mechanism, are divided into self.propelled and non.self.propelled. The former is equipped with a clutch and belt transmission, as well as a gearbox that lower the speed of rotation of the engine to the optimal level for wheels.

How to use electric lawn mowers correctly?

The use of these devices implies not only the mowing of grass, but also the maintenance carried out before and after the mowing.

In addition, for new devices, the correct assembly is also needed, because most of them are delivered in the form of individual nodes located in a common box.

Since the assembly methodology of each model is individual, we recommend that you carefully read the corresponding section of the instructions for the operation of the device, which is also often called the user manual.

Preparation for work

Preparation for work begin the external inspection of the device, paying special attention to the integrity of the insulation of the wires, including extension cords, in addition, do not forget to check all threaded joints. In addition, carefully inspect the mowing housing, if cracks or dents are found on it, then you can’t use such a device, first it must be disassembled and the condition of the internal parts and mechanisms is checked.

If everything is in order, then install the device on a flat surface, connect via extension cord to the outlet and turn on the engine. the mitch should work without knocking or vibration. After 10–20 seconds, if the smell of smoke does not appear, turn off the engine and disconnect the extension cords from the network.

then first eliminate their causes and only after that, having completed another check, proceed to the mowing of grass. In addition, do not forget to check the condition of the cutting edge of the knife, turning off the device from the outlet and waiting for the end of the rotation of the engine shaft.

If the knife is stupid or damaged, then replace it with a new one or sharpen it with subsequent balancing.

In drum mowers, check the condition of the drum plates and sharpening the knife, if the knife is stupid, then sharpen it, strictly following the operating instructions.

If you are planning to work with the grass collector, then check its condition and install it on the lawn mower to make sure that it adjacent.

Having discovered a loose fit of the traumatic collector, remove and eliminate the reason that is most often noticed during cleaning the grass.

Also check the ease of rotation of the wheels, if one or more of them rotate tightly, then check the condition of the bushings or bearings, if necessary, cleaning them from the grass.

If it is recommended to lubricate bushings or bearings in the operating instructions, then do this by finding the slightest resistance to rotation.

In addition, remove any solid items from the site, including:

The mowing of the lawn

Let’s move on to the question of how to mow grass properly. Start the mowing of the grass by unwinding the extension cord and laying it with large loops to exclude twisting when removing the mower from the outlet. Can be laid with a snake or in any other way, the main thing is that during the removal of the mowing he does not get confused and does not be in the way of moving the mower.

Then set the optimal section for this section, then first connect the cable to the outlet, then the lawn mower to the cable.

For ease of work, fix the cable using special mounts to exclude disconnecting the plug of the lawn mower from the cable socket.

On the vast majority of models, the engine is turned on using a button and lever, this is described in more detail in the operating instructions. Having turned on the motor, move the mower in the direction of the outlet, the non.self.propelled model smoothly push you in front of you due to your physical strength, activate the self.propelled drive using a special lever.

The speed of movement should be such that even a meeting with thick grass does not lead to a decrease in engine speed (they are controlled by ear). If the revolutions have fallen and the sound of the mower has changed, then stop moving forward and hand it a little, then continue moving forward, but already at a lower speed.

When working in the rear emission mode, including with an installed grass collector, a snake is the optimal trajectory of movement along the area of the optimal trajectory.

To do this, first, on the edge of the site, remove to the maximum distance, then unfold the mower and shift to the width of the mowing sideways, then move the device towards the outlet.

If the turn is right, then the extension cord should be to the left of the mower, if left, then on the right. To reduce the likelihood of a wire fall under the knife, it can be thrown through the elbow of the corresponding arm. That is, when turning to the right to throw through the left elbow, and when turning left, through the right.

When working in the side emission mode, the cable should always be on the opposite side, and to reduce the likelihood of falling under the knife, it can also be thrown through the elbow.

When working with the grass collector, follow not only the indicator of its filling, but also the sound that the lawn mower produces. If the sound has changed, but there is no section with thicker grass, then the grass collector is full, so it is necessary to stop the engine and remove the mowed grass.

What clothes to use

The choice of clothing affects the safety and efficiency of mowing grass.

A dangling sleeve can hook and block the lever of the knife or wheel drive, and the probability of falling when working in shoes on slippery soles is very high.

Therefore, to work with a lawn mower, you need:

- shirt with long fastening sleeves;

- long pants made of dense fabric;

- foot covering the leg on strong corrugated soles;

- protective glasses or mask;

- Hat or cap (on a hot sunny day).

How long can you use?

The optimal operating mode for each model is described in the operation manual for the lawn mower.

If this document is not available for some reason, then adhere to the Rules 15/10, that is, mow the grass for 15 minutes, then wait 10 minutes until the engine cools down.

The process of removing the descents

This is the name of the site on the canvas of the knife. the border between the base of the working part and the surface of the tip. If the cutter has not been sharpened for a long time, chips appear on it. By removing the edge of the blade at the same angle over its entire surface, it will be possible to get rid of the defects that have appeared. To do this, take an electric sharpener or small file. It is important to remove the metal evenly from both blades. This can be achieved by applying the same efforts and roughly calculating the number of passages.

The more evenly the descent of the descents will be carried out, the greater the resource of the blade will be.

Sharpening

This manipulation can be performed using an emery bar with a granularity indicator of 400-600. In the process, the device should be periodically wetted in soapy water. The sharpening itself is made on grain with the length of the bar from the center of the processed zone to the edge.

To increase the productivity of the process, you should use a drill with an adapter. On its cartridge, a sharpener should be fixed. a stone or a circle. After turning on, it is necessary to start with a jagged.to.end. It is convenient if it is possible to fix the drill, and move the knife along the edge of the grinding circle.

In the process of processing, you should not attach excess pressure. Movements should be smooth. It is necessary to prevent overheating and try to hold the angle of sharpening in one position.

How to replace a knife on a lawn mower

Today we will talk about how to replace a knife on a lawn mower. A sharp and well.balanced knife is important for the correct haircut of the grass and the efficient operation of the lawn mower.

How to Change A Lawn Mower Blade: A Guide For Girls

A sharp knife gives a clean and even cut, and stupidly tears the grass and makes it vulnerable to diseases and damage. Replacing or sharpening a knife should become part of the service procedure. Fortunately, the lamp of the lawn mower is easy to replace.

This simple procedure, which practically does not require special knowledge or experience. Just be careful when handling the blade itself, and everything should be smooth. Before replacement, drain fuel from the gas tank. This will prevent fuel leakage at the replacement stages.

CAREFULLY! Before the launch, operation or maintenance of the engine or equipment, study the operating manual to avoid injuries or damage to property. Contact the authorized workshop if you are not sure of any procedure or have additional questions.

You’ll need:

- Key for 19, 17 or 15 depending on the model (see the user guide);

- A stop for a lash of a lawn mower (we did not have) or a wooden bar;

- Good strong working gloves, best leather (required);

Step 1

- Turn the lawn mowed to the side so that the air filter is at the top.

- For a lawn mower with a seat (rider), use a jack or remove the cutting deck to get access to the knife.

How to sharpen a lawn mowing knife

When it comes to sharpening a knife, there are several effective methods, so it will depend on your personal preferences or, possibly, on the tools that you have at home.

The first option is to use a small sharpened circle that attaches to your drill. It can be bought at your local shopping store, they are inexpensive.

Another option is a file or a grinding disk. I prefer a grinding circle. Usually, one or two passes are enough to expose the metal and create a sharp line. As soon as your blade has a bevel and sharpness you need, you will need to turn it over and do the same with the other side.

Balance the knife and collect again

The last step is to balance the knife. I use a metal crutch and a stand. You can use any device that suits you. The main thing is that the effect of a swing is created.

Place the knife evenly. Pay attention to which side seems heavy and easy. The side that sides more will require more grinding to ensure the correct balance. As soon as this balance is reached, paint the knife with a spray and install again on the lawn mower.

Now that your knife is sharpened and cleaned, it’s time to test it! You notice the difference when cutting the lawn? That is great!

How to change the disk on the trimmer and for which motorcycle they are used

Trammers for grass differ in the method of engine operation. Electric and gasoline options are released. The latter. have a much more capacity of their competitors.

For miniature trimmers, plastic knives or light metal elements are traditionally used. For mowels of greater power, you can even use a winning disk for a trimmer for grass. But the restrictions affected not only the power of the devices.

The second principle is the mechanism: hard or gear. In the first. rotation is transmitted based on the shaft, and in the second. a steel cable. A flexible cable does not work with large discs, as it quickly becomes unusable. Therefore, for a flexible transmission, use a reel with a fishing line instead of knives. The type of device should be found out before the purchase, so as not to be with a quick breakdown.

Which knife for a trimmer for grass is better to choose? Review of possible options

Manufacturers produce several varieties of cutting elements for motorcycle. It all depends on the type of device. It is customary to distinguish between consumables:

What material for a trimmer knife is better

The purpose of the consumable determines the material: iron or plastic. The choice of one or another option is determined by several factors:

Important: metal mills are never installed on network braids. The power of the device is not enough for a full torque. Therefore, he appeared an alternative. plastic. Features of the design of the electric format motokos simply do not allow metal knives to work adequately:

Plastic blades are used only on devices with flexible hoses. Plastic copes with fine grass, dry areas and burdocks. If the wrong disk was accidentally installed, look further: how to change the disk to the reel on the trimmer.

Metal cutters. It is used for mowing thick, dense grass, small trees. The properties of a disc trimmer for grass allow you to install it in the fight against shrubs.

Technical and external characteristics that indicate that you need exactly an iron tip:

- straight bar, respectively. the length of the device itself increases;

- comfortable handles for control of a scythe;

- Setting a smooth turnover of the blade.

Tip: for mowing a large territory with different types of grass and shrubs, gasoline units are well suited. They need to install a metal disk with sharp knives on them.

How many blades should be

The form does not affect the efficiency of the blade as their total number. For example, for the future hay it is worth taking a mill for 6-8 blades. With an amount of 2-4, the grass is mowing “into the meat”, and you will not fall any drows. For young trees, blades with many small teeth are great (look in stores with winning elements. also a great option).

Labric mushroom knives are Natural in different ways: on one or both sides. Dumb or spent option increases fuel consumption and works inefficiently.

Important: try not to work with blades in areas with stones, brick. The only hit of the blade on the solid edge can break it can break it. Worse, if part of the pebble flies away in your direction. Be carefull!

How to change the nozzle for a trimmer for grass? The element should be selected on the basis of dimensions, material and design. Also focus on the format of work and the area that you will mow. The instructions from the tool will help you partially. Manufacturers indicate which knife what territory your equipment will process. Well, we go to how to put a knife on a trimmer for grass correctly.

Landing diameter and external size

For trimmers, disc cutting tools with three landing diameters are suitable:

A larger.diameter disk is possible over an electrocos or a benzotrimer with a smaller landing diameter, for this, central rings are sold in spare parts stores.

If you have acquired a cutting tool, the landing diameter of which is less than that of your device, then it is physically impossible to install it there, so the best option will be to return it to the store and take it more suitable.

The disc cutting tool with a 26 mm landing hole is designed for professional bushes, so if you do not know the diameter of the landing hole of your device, then purchase a circle with a landing diameter of 25.4 mm.

He is the most popular. And just in case, take the center ring to him.

Given that the central ring is easy to lose, we recommend that before visiting the store, measure the landing diameter of your device and purchase a disk for it precisely for it.

Never Install a Push Mower Blade UPSIDE DOWN Again (Don’t make this mistake with your lawn mower)

In addition, take into account that the outer diameter of the trimmer discs is 20–25 cm, but the specific value for each model depends on its power and the number of disk teeth. the smaller the teeth, the usually the diameter is larger.

After all, the more teeth, the higher the load on the engine, and the diameter increase means an increase in the lever shoulder, in other words, the larger the diameter of the disk, the more the tooth loads the power unit stronger.

How to install it correctly?

We will tell you step by step how to properly install a disk, how to wear it.

Regardless of the time you want to attach a gear circle instead of a trimmer head or knife, the general procedure is the same:

- Turn off the machine engine and wait for the end of rotation of the cutting tool. If you have an electric kos, then disconnect from the cable-unit to exclude random start.

- Any convenient item, for example, with a standard player key, fix the shaft of a trimmer for grass.

- Unscrew the nut that fixes the cutting tool, or the tool itself. Remember that the thread can be either right and left, so twist to the side corresponding to the thread of the gearbox shaft of your trimmer for grass.

- Remove the coil or knife.

- Remove the gearbox protective washer.

- Clean the protective washer and the gearbox cavity from the remnants of the grass.

- Take the gearbox, if it is hot, then lay a new grease in it.

- Put a protective puck in place by combining holes for fixing the shaft.

- Put the disk by placing it so that the teeth are directed towards the rotation of the gear shaft. If the disk is intended for your model of the apparatus, for example, it was included with it, then find on it the arrow indicating the direction of rotation, and put it so that it is on the far from the ground. If the gear circle is intended for another model that differs in the direction of rotation, then focus on the teeth so that they are directed towards rotation of the engine shaft. If you do not know which direction the gear shaft rotates, then focus on the direction of twisting the nut. it is delayed in the opposite direction.

- Put one or two clamping washers onto the disk (depending on the model of the device).

- Twist the nut, then tighten with a regular key, creating an effort only with a brush.

- If before that you mowed a coil, then replace the protective casing or remove the “beard” from it, that is, the inspection that increases its height.

Necessary tools for sharpening

The first thing you should pay attention to is how the knife is removed correctly. In no case should the lawn mower with a gasoline engine be turned upside down and a protective casing, since oil and burning remaining in the cylinders will get into the carburetor area.

Turn the mower to one side, and towards the control handles. If possible, it is desirable not to do this, but use the overpass. In extreme cases, the lawn mower is simply placed on 2 stools, and even then the knife itself is removed. To do this, it must be blocked (for example, with a crowbar or a wooden beam) and alternately unscrew 2-3 bolts from below. Should be neat, since the washers will also be removed.

After extracting the knife, it should be carefully examined for the presence of chips and burrs, which are obtained when the lawn mowers get on a stone or another solid subject. If there are such, you need to remove them with stiffing. The easiest option. Spend the whole edge. However, if this is done on one side of the blade, you will have to grind as much on the other, regardless of whether there are chips there. All this is done due to the correct balancing. Further the sharpening of knives for lawn mowers begins further.

For editing and turning the cutting edge, you will need:

- corner grinder;

- vise;

- Drill with adapter for grinding paper (discs);

- file;

- skin (sandpaper) for about 250 grait.

It is necessary to start by leveling the cutting edge (if it was not performed). For this purpose, an angular grinder with a grinding circle or a sharpener with large grain (up to 400 grait) is suitable for this purpose.

The standard angle of sharpening is 30 ° (conducted only on one side).

However, it is recommended to clarify this information in the operation of the lawn mower. Some manufacturers of the edge on the lamp for the lawn mower are made under 20-25 °. Thus, a lot of sharpness is achieved, but the permissible wear is reduced to repeated sharpening.

How to sharpen a knife

The easiest and most effective method is how to sharpen knives for a lawn mower. This is a drill with an adapter for grinding wheels. It is not worth counting on “factory sharpening”, since it is performed using a diamond disk, but you can restore the cutting edge with this method in 5-10 minutes.

The disk is selected with fine granularity, in the range of 800-1500 Grit. To sharpen a traditional knife, 4-5 such skins will be required. During the grinding of the edge, it is necessary to monitor the balancing. To do this, just hang the knife on the rope, passing the one through the central hole for fastening. If he will not deviate in any of the sides, everything is in order. Otherwise, you need to slightly walk again with a skin on the opposite side to level weight.

After sharpening with the help of the disk, it remains only to perform the final eyeliner of the cutting side of the blade. Experts recommend using sharpeners with very fine grainness for this, from 1.5 to 4 thousand Grit.

You will have to spend at least 15 minutes on each side of the knife, clearly withstanding the angle of 30 °. To achieve the best results, the upper part of the blade is made rounded. It must be borne in mind that with a final eyeliner, the angle changes to larger 2-3 times. First, the transition is made from 30 to 35 °, then. up to 40 °. Literally 2 passes after the shift will be more than enough. This form of the blade is made for greater resistance to the appearance of burrs.

A knife for a trimmer for grass (meaning a model of a lawn mower with an electric drive) is sharpened in a slightly different way. There you have to use only a file or diamond sharpener. Perfect option. grinder. where the disk with diamond spray is wearing. But as a rule, the sharpening of a knife for an electric lawn mower with your own hands is not performed. This is done by qualified masters when using special equipment (laser sipping the edge is performed).

In this section, we prepared video videos in which it is shown how to change the coil from fishing line to a knife or disk (mill) on various trimmers.

How to redo the cutting mechanism from fishing line to a knife:

How to change the coil in the gearbox Motokos:

And one more video instruction on how to install knives or disk, if you decide to replace a coil with a fishing line with them:

A knife and a disk are regular cutting tools of trimmers with an upper engine location and a straight bar.

With a mowing of low spite of herbs, they are less effective than a fishing line for a trimmer, but ideal for cutting high thick vegetation, including young shrubs or trees, as well as thickets of various weeds.

Now you know how to put them on your trimmer for grass and what to do if you get an apparatus without details necessary for installing a knife or disk.