Aluminum cutting in size. Advantages of laser cutting aluminum

Cutting aluminum

In addition to the implementation of high.quality aluminum rental, LLC SC Metopttreding carries out its processing. We make profiles according to the customer drawings, perform mechanical cutting and cutting of plates, strips and aluminum sheets. The use of modern high.tech equipment allows you to work with alloys of any brands and guarantees an excellent result. The resulting blanks retain the initial operational characteristics of the metal, and the quality of the cut meets the requirements and international standards.

Sheets, stripes and slabs up to 6 mm thick are cut on a scissors type guillotine, if their number is multiplying in pieces. The material with a thickness of more than 6 mm is processed on a band saw. Aluminum cutting is carried out in a straight line on square and rectangular blanks. The cost of the latter does not include the remains (waste) of the source rental. LLC “SC Metopttratreding” carries out high.quality cutting of aluminum sheets according to the customer drawings, as well as cutting plates and rods, including at an angle. By additional agreement, we provide the service packaging service in accordance with the requirements of GOST 9.510-93. The conditions and details of the order should be clarified by the managers of our company.

Advantages of mechanical cutting aluminum

Scissory guillotine. Is a machine designed to work with aluminum sheets. According to the principle of action, guillotine resembles the work of ordinary scissors: the main working elements are two cutting blades. The lower knife is located horizontally, the upper can have a small slope. In this case, the cutting force is not made over the entire width of the sheet, but in a small section. This allows you to cut the workpieces of greater thickness. With the horizontal position of the upper knife, the cut is carried out immediately over the entire width, but requires great efforts.

Br. The working element of such equipment is a metal gear strip closed in a ring. Features of its movement and design provide high performance, the accuracy of the cut, the smoothness of the resulting edge. The advantages of using tape saws include a small saw width and the possibility of cutting at an angle up to 60 °. Thanks to the use of coolant (lubricant-cooping fluid), the working area does not heat up and the aluminum workpiece retains the initial structure.

Features and advantages of technology

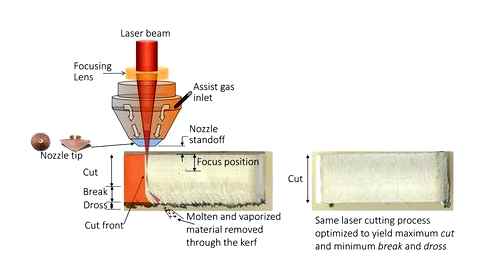

Aluminum is a material with high thermal conductivity, so its processing is complicated. Laser cutting of aluminum helps to avoid deformation, microscopic cracks and oxide film in the cutting area.

В основе метода лазерной резки лежит тепловое точечное воздействие на небольшой участок металлической поверхности.

Advantages of laser cutting of aluminum sheets:

- focused exposure to the laser beam;

- accurate positioning of laser equipment relative to the place of cutting;

- instant heating to melting temperature;

- In the process of cutting, the molten metal is immediately removed by a powerful stream of gas, which also cools the edge of the cut;

- The gas flow has a cross section of no more than 20 microns, which is thinner than any cutting tool;

- Neutral inert gases are used for blowing, which retain the cut smooth and even, as they prevent the formation of oxides;

- cutting is carried out by a computer program;

- lack of mechanical contact of the cutting tool with a metal surface;

- The additional finalization of the details is not needed, since there are no roughness, the cut is smooth and even;

- the amount of waste is minimal, the marriage is excluded.

In the company Moslavser, laser cutting of leaf aluminum is carried out on specialized equipment with the participation of experts in the industry. We make both single samples of details and large series.

We work economy without intermediaries, use only high.quality equipment and do not need additional processing. These three factors make the cost of laser cutting stainless steel more affordable than that of competitors.

Universality Laser Equipment allows you to work with details from various materials. An error of not more than 0.5 mm is allowed. The device can be configured depending on the type of material.

High performance developed and proven technology of cutting is highly processing. The quality of the cut remains ideal regardless of the complexity of the contour of the parts.

Лазерная резка применима во многих сферах: раскрой листов, изготовление наружной рекламы, упаковок, сувениров, для декора помещений, производства запчастей. Используя резку лазером, можно быстро обработать листовой материал, вырезать сложный контур или необходимую форму.

for laser cutting aluminum

Consider what the cost of laser cutting aluminum depends on:

- the thickness of the processed material;

- aluminum in the alloy in percent;

- urgency of the order;

- volume of work. with large orders we make a good discount;

- the size of aluminum blanks and the level of difficulty processing.

Below is a table with current prices. You can calculate the cost based on the volume and complexity of the work, by contacting the consultant of the Moslavser company.

Why should we contact us?

The democratic price of laser cutting aluminum and the most prompt execution of the order are important advantages of cooperation with Lazermetal. We support the production area in excellent working condition, provide maintenance and repair of machine tools. When ordering services in our company, you will gain the following advantages:

Laser Cut Aluminum plates for OX CNC

- an individual approach to setting up a machine for your purposes;

- creating technical documentation, if you do not have a current;

- optimization of the cutting process, recommendations from experienced masters;

- only qualified personnel, no mistakes in the work;

- efficiency, order can be sent to processing today.

We offer a full metal processing cycle, including polishing and other stages of work after cutting. Applying a modern machine, our company reaches the maximum accuracy of size, reducing the permissible error.

Features and advantages of technology

Due to its strength and lightness, aluminum replaces the basic design nodes of the units, which were previously made of steel. For technological cycles, the material can be produced in the form of blanks, rental or metal profiles. The massive use of aluminum alloys entailed the need to make cutting faster and more accurate. Due to the high plasticity of the material, it is possible to achieve this exclusively with the help of laser cutting.

Aluminum has high thermal conductivity, is subject to severe heating, oxidation and destruction during mechanical load. Compared to other metals, it requires a lot of power, which is due to its reflective and thermophysical properties. The technology of laser cutting of leaf aluminum material is based on a highly concentrated laser effect on a given area. It does not affect the neighboring zones, does not leave waste, while providing high cut quality and economical consumption.

The directed effect of the laser beam excludes strong deformation and structural change in the metal in the contact zone with the light bunch. A stream of molten gas acts pointily, quickly destroying the metal, but at the same time preserving its physical and mechanical characteristics. Cutting aluminum with a laser helps to get rid of microscopic cracks and oxide film in the cutting area.

for laser cutting aluminum

The price also depends on the complexity of processing and additional tasks, for example, the need to perform the refinement of the above technical specifications.

We consider each order individually, we try to find possible options for reducing the cost of work. You can familiarize yourself with the approximate of laser cutting of aluminum sheets in 1 meter in the price list, for a more detailed blast you need to provide a scan for each part in the DWG, DXF or SolidWorks format, indicating the thickness and number of details.

Advantages of laser cutting over other methods

These and other properties have made laser aluminum cutting one of the most popular methods of cutting the material.

Each industry uses its own specific alloy, which meets the technical requirements of the finished product and its field of operation. The processing of aluminum preparations depends on the scope of use. To work with sheet metal, cutting of the material using special industrial equipment is used. In modern conditions, the most optimal and convenient processing method is laser cutting, the technology of which is offered by LLC Promex.

The subtleties of the production cycle. Features of aluminum cutting

Despite the relatively fast result and high quality processing, laser cutting has its technical subtleties and nuances.

The main feature is that aluminum and its alloys do not absorb the heat ray poorly. This is due to the high reflective ability of the metal surface and its thermophysical properties. In view of this properties, aluminum is cut more difficult on laser installations than other metals.

A high power of the laser beam is required. The speed and quality of cutting depends on the percentage of aluminum in the alloy and the thickness of the workpiece.

The equipment where the specialists of the company Promex operate today allows you to perform complex technological cycles.

The machines of the German company Trumpf are equipped with a CNC system, due to which the entire cutting process is under constant control. High technological parameters of equipment allow you to operate machines in continuous or impulse mode. Due to this, the necessary speed of cutting and the quality of processing is achieved.

The main subtleties and features of aluminum processing:

- lack of mechanical contact of the cutting tool with the surface of the metal;

- Accurate focusing provides accurate positioning of the head in relation to the place of cutting;

- The gas flow has a section of 10-20 microns, thinner than any cutting tool.

Due to the creation of a low pressure zone in the area of exposure to the thermal beam, all melting products are spontaneously eliminated from the working edge.

To achieve good performance, aluminum cutting is carried out at low speeds. This avoids deformation of the material during processing.

Azot is used to work with aluminum in a laser burner as an active body.

To avoid even small roughnesses along the edges of aluminum products, laser cutting is accompanied by the use of nitrogen.

Advantages of laser cutting

In favor of such processing of metal sheets, the totality of the main characteristics is: high quality of the result at a favorable cost for work, accurate compliance with the agreed terms.

The basis of successful cooperation is the modern technical base. Production is carried out at the installation for laser cutting Lasercut Fo Professional (model 1000), which allows you to process the material, replace the sheets faster, without losing the final quality.

Equipment capabilities

The installation allows you to produce laser aluminum cutting with a microscopic error, for this cutting method it is less than 1/1000 mm. This will allow you to order details and blanks with a complex curly circuit, which is especially in demand in the design direction. In addition to aluminum cutting, our production carries out other types of metal processing.

With laser cutting aluminum, the installation shows the following possibilities:

For cutting metal, the customer drawings are accepted, a request for technical requirements for layouts can be made through the mail Client@Proflasermet.ru, by numbers 7 (495) 928-96-58 / 7 (495) 308-82-32.

Distinctive nuances of laser cutting aluminum

The extreme popularity of aluminum products requires the use of an operational and accurate method of cutting metal. The optimal result allows you to achieve the cutting of aluminum with a laser. This high.tech method is characterized.

A number of problems that have to be faced in the process of processing this metal have been known. In particular, it is subject to overheating and destruction in classical methods of processing. The use of the laser eliminates the deformation of the crystal lattice of the metal at the point of contact with the laser beam. There is an operational cutting with the preservation of the physicochemical characteristics of the edges of the edge.

Laser cutting of aluminum is based on the use of a high concentration beam. As a result, the work is carried out only on the microscopic area of the metal surface. Thanks to this, the excellent quality of aluminum processing and its maximum savings are ensured.

The advantages of laser cutting compared to other methods:

- Cutting does not take much time;

- economical metal consumption;

- ensuring the necessary characteristics of the edges of the cut;

- Unexpected equipment performance.

These and many other advantages allowed laser cutting to become the most optimal method for cutting aluminum.

| Aluminum sheet with a maximum sheet size 3000x1500mm | |||

| 36 | 42 | 56 | |

| 46 | 61 | 88 | |

| 66 | 81 | 118 | |

| 75 | 103 | 133 | |

| 85 | 125 | 148 | |

| 113 | 153 | 198 | |

| 143 | 198 | 278 | |

| 213 | 288 | 378 | |

| 327 | 418 | 478 | |

| 448 | 548 | 578 | |

| 498 | 598 | 678 |

Curly cutting aluminum with a laser

Of course, like any production process, laser cutting is distinguished by its characteristics. Due to poor absorption by aluminum of the thermal beam, this material is slightly worse processed on laser equipment compared to other metals. Mandatory installation with high intensity of thermal beam. Our company has just such equipment.

Modern production machines are equipped with a numerical control system system. As a result, cutting is constantly controlled by automation. This equipment can function in various modes. As a result, a good speed of cutting the material and a decent quality of metal processing are provided.

The following nuances of laser cutting aluminum can be noted:

- the exclusion of the direct contact of the cutting part with the material;

- high.precision position of the cutting tool in relation to the cutting area due to the presence of a focus system;

- Small gas flow diameter (up to 20 μm).

In the process of laser cutting, all products formed during melting are independently removed from the working area. No metal deformation occurs. In order to ensure the absence of even minor irregularities along the edge of the processed workpiece, as active heat during laser cutting, nitrogen is used. Thanks to the use of such equipment, figured aluminum cutting is possible.

Pros of technology

The highest accuracy is the main plus. The use of CNC during laser cutting of the metal excluded the human factor. A software drawing is laid on the machine computer, after which it performs operations automatically. This allows you to do the following:

- Hard alloys by laser;

- cut with a slight deviation of 0.05-0.2 mm;

- perform the most difficult details with patterns, bends even from thin sheets;

- save materials due to the information of waste to a minimum;

- exclude the appearance of chips and other defects when separating a metal blank;

- prepare large batches of goods in a minimum short time.

Another speed: the last parameter in the list remains for many partners key. Today we are contacted by customers who require the implementation of mass orders in uninterrupted mode. Not every company is able to guarantee stability, but thanks to constantly growing capacities, we accurately calculate the time of manufacture of serial parties. Even possible force majeure are taken into account, which in most cases are easily eliminated by reserve resources forces.

Plasma or laser cutting of sheet metal? The first type of processing is best suited for the manufacture of simple products from blanks with a thickness of more than 6 mm. In the case of processing a product of 20 mm, the plasma machine wins significantly. When it comes to mass production of complex structures, you should choose Laser even when working with thick sources. the absence of scale will exclude the need for subsequent cleaning of the goods, which will save time, labor costs, and therefore finance.

The advantages of the company

The achievement of our goals is facilitated by excellent quality and adequate price of laser cutting metal. Today we enter 15-20% of the capital of the capital with the lowest price. A constant flow of orders allowed to make a cheap service. 7 out of 10 customers are returned for the services again, so we do not need to worry about the lack of work and compensate for downtime by high cost.

Personnel with experience of 5 years, has the ability to accurately select configurations for the beam, providing you with a first.class result. Since the opening, we have not had a single complaint, not a single client had to wait for products longer than the agreed deadline. This is the best reliability indicator. Call us.