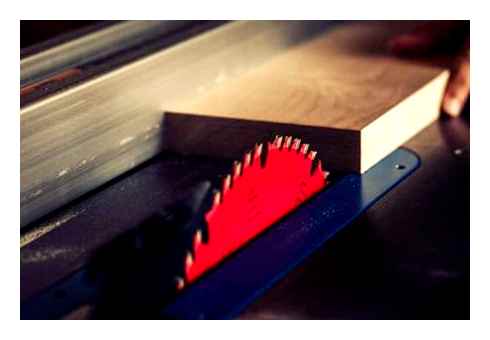

Anti kick back device for table saws. Table saw anti kickback

Blade Height and Kickback

Kickback on the table saw can be caused by a number of factors, blade height being just one. Miss-alignment of the blade and/or fence to the miter slot, a dull blade, loss of control of the wood, removal of the splitter and/or riving knife assembly, cutting small pieces and poor operator technique are common factors that may contribute to kickback. Frequently, more than one of these factors is involved but each can initiate a kickback on its own.

I have looked at table saw alignment in other stories on NewWoodworker.com and suggest you read those, listed in the Resources section below. For our purposes here, we will assume your saw is properly set up and aligned as part of your regular maintenance.

Blade Height

There are some that are convinced that raising the blade high above the top surface of the wood helps prevent kickback. The idea is that because the teeth are coming down onto the wood at the front of the blade more vertically, they apply downward force on the wood as they cut, pushing the wood down onto the table. If we could make the back of the blade disappear this might be true. However, with the blade high the teeth at the back of that blade are emerging from the table nearly straight up. Because the blade is so high, the front and back edge are much further apart which increases the leverage. If the wood turns into the back of the blade just a little bit, it wants to rise and when that happen a kickback is likely milliseconds away.

I know there are some who think that running the blade very high will prevent kickbacks, or lessen the chance. Wrong! With the blade low as prescribed by the blades manufacturer the up and down forces (left) are closer together and not nearly as pronounced as with the blade high. Raise the same blade much higher (right) and those up and down points of leverage are not only enhanced by the wider distance, they are also much closer to straight up in the back and straight down in the front. Click images to enlarge

Think of this as Newton’s third law, once removed. If the blade and fence are perfectly aligned, the wood has no inherent stress trying to close the kerf (even a little), the operator pushes the wood in a perfectly straight line and the splitter and anti-kickback pawls are in place, the rear edge of the blade may not be as big of a factor. In the real world though, given the number of variables, you are pushing your luck on the best of days. If the wood turns just a little, or the kerf begins to close up from stress within it, you could be on your way to a true demonstration of how fast and powerfully things can go wrong on a table saw. I have been in front of a piece that turned into the back of the blade slightly, I saw that but before it truly registered I had already heard the Bang! and felt the pain of the wood hitting my side. If I would have had the blade higher that piece may well have hit me higher, raising the potential for major injury even more.

All this and we haven’t talked about the liabilities of so much blade exposure and how close that puts your fingers even with a push stick or handle. Here again, if you work in a perfect world, fear not, all will be fine. If you consider yourself mortal it is time to rethink your table saw habits.

Real World Defense

The best defense against kickback is to keep your table saw properly aligned, including blade and fence parallelism and the miter gauge square to the miter slot. Employing proper technique, including the use of a good push handle (with an extended forward edge) is also important. Keeping the blade guard, splitter and anti-kickback assembly or riving knife properly installed and aligned should be a no-brainer. However, the frequency with which we hear of kickbacks shows that way too many of us are not using our brains enough.

Kickbacks tend to start at the rear of the blade where it comes up out of the table. Raising the blade just makes that worse. The piece in my hand (left) is my only major kickback and it started at the back of the blade, without the guard or a riving knife when the piece turned into the blade slightly. If I would have had a riving knife and used a good push handle (right) I probably would not of had that kickback. Click images to enlarge

Cutting small pieces on the table saw has always been a good way to have problems. When faced with having to cut a piece under 12”-long, I look to the Band saw or try to rip the piece from a longer piece of stock and then cross cut it to the final size.

The most common blade height setting suggested by the blade manufacturers I have talked with is having the bottom of the gullets at the top edge of the wood. Some suggest having the bottom of the gullets just below the surface of the wood, some just above it. The idea is that exposing the gullets increases dust ejection and introduces air into the cut that helps mitigate temperature build-up.

Another important factor is keeping the blade clean. Built-up pitch and other wood-related contaminates increases the friction between the blade and wood. Like the moment arm, friction magnifies the forces (up and down) the blade applies to the wood.

Conclusions

Nothing can totally eliminate the possibility of experiencing a kickback. However, keeping your saw properly aligned, using good technique and safety equipment (See Saw-Aid in the Resources section below) drastically reduces the chance of a kickback starting. The splitter and anti-kickback assembly or riving knife can substantially reduce the severity of a kickback should one try to start.

Video Tutor

I believe that raising the blade high above the wood both increases some of the common factors that support a kickback and expose the operator unnecessarily to more of the spinning blade. Consequently, I always set my blade height so that the bottoms of the gullets, at their highest point, are even with the top of the wood being cut.

In a little over 40 years of woodworking I have had exactly one serious kickback, caused by my poor technique combined with disregarding a few of the above cautions. Since then, I have developed a much better maintenance program that includes cleaning my blades frequently along with checking the alignment of my blade, fence and miter gauge. I also use push handles or push blocks. My blade guard and splitter assembly or my riving knife is also in place. Simple, common-sense solutions that make my table saw use far safer.

Resources

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner. Privacy Statement

Anti kick back device for table saws

I’m surprised no one has mounted an anti kick back device on their fence for ripping. Ripping is when kick back happens. Radial arm saws have an anti kick back device that is a toothed crescent of metal on the end of a rod placed at the outfeed end of the saw carriage. The teeth glide across the wood as you push the wood through the blade. The metal crescent digs into the wood when the blade wants to kick back. It would be pretty easy to devise a similar setup for table saws. This would be quite effective when ripping narrow strips.

LeChuck

Most recent table saws, and not so recent, have anti kickback pawls. Good safety device. Unfortunately on my saw, they leave a mark that is a real pain to sand off (since it’s dug in), and that’s not always very visible until you put some finish on it, even after sanding. I wonder if I should take a file to the bottom of the pawls to make them less sharp.

PurpLev

anti kick-back pawls have been on tables saws for AGES… since the days of the splitter/blade guard and before the inclusion of riving knives.

pintodeluxe

Featherboards and Board Buddy rollers are other options instead of the kickback pawls. They will not mar your workpiece.

CharlesA

“Man is the only animal which devours his own, for I can apply no milder term to the general prey of the rich on the poor.” ~Thomas Jefferson

CharlesA

“Man is the only animal which devours his own, for I can apply no milder term to the general prey of the rich on the poor.” ~Thomas Jefferson

basswood

I use both fence and table mounted feather boards that both hold stock tight to the table and fence.

These both improve rip quality and reduce the likelihood of kick back.

Also friendlier to the wood than aggressive pawls.

BillWhite

I use pawls and Board Buddies when the work will allow. I’m a weenie when it comes to kick back. Bill

nicholasrhall

I’ve never seen board buddies before. That’s pretty slick.

It doesn’t seem as though they would be very effective on narrow cuts. It looks like the narrowest cut they could make is about 2.5″. Is that the case, or is a way to set them up for narrower cuts? If so, how narrow can they go?

It does seem like a fence mounted cam style pawl would be able provide antikickback in narrower stock, for example when you’re cutting 1″ spindles for craftsman style furniture. Does such a thing exist?

Outside of a dog, a book is a man’s best friend. Inside of a dog, it’s too dark to readGroucho Marx

OggieOglethorpe

I’m good with a properly installed riving knife, and properly face and edge jointed stock.

Pawls and Board Buddies annoy me, and in my opinion, don’t add anything to a properly installed knife. If the kerf can’t close, and the stock can’t get pushed against rising teeth, the board can’t kick back. If your blade is raised at least to the bottom of the gullets, and the knife is close to the back (rising) teeth, there is no way for a board to climb on top of the blade.

Setting a blade too low can create a kickback situation, even with safety measures installed.

On my previous saw, I used to install white oak splitters to my zero clearance inserts, less than 1/4″ behind the blade. I kept inserts handy that matched a bunch of blade heights. The planed to match blade thickness splitter grain was oriented vertically, securely glued in place, and the leading edge was rounded and waxed. It was a shop-made version of the Micro Jig splitter, but it could be installed much closer to the blade, built to varying heights, and it couldn’t unintentionally come out. They worked great, unless the blade was tilted…

To me, the real riving knife made a bunch of stuff invented before it’s introduction obsolete.

nicholasrhall

I imagine there are a lot of us out there that would love to have a real riving knife!

Unfortunately, it seems like they have really only been available (except for an infinitesimal minority) in US for the past 5 years or so. Even now, I would guess that less than 1% of saws owned by Lumberjocks have a real riving knife.

The Grizzly 1023 that I work on doesn’t have one, but wired for 220V, it does have an enormous amount of power. As a result, I’m always keen to learn what other folks do to minimize the risk of kick-back. Pawls and board buddies may be a pain, but their not nearly as painful as fingers in a 20 tooth rip-cut blade at 8000 rpm!

CessnaPilotBarry: Your point about properly face and edge jointed stock is well taken, I’ve seen people try to “square the edge” of a wany edged rough cut board on a tablesaw in order to “save the jointer blades”. All the equipment in the world is worthless if you don’t at least square the edge on the jointer. It’s the kind of shortcut that can lead to long recovery times and physical therapy. I think that there are a lot of folks that make the transition to rough cut lumber that don’t understand that the jointer is one of the best pieces of safety equipment in the shop.

Outside of a dog, a book is a man’s best friend. Inside of a dog, it’s too dark to readGroucho Marx

Anti Kickback Pawls: Causes How To Prevent

That’s why it’s important to invest in anti kickback pawls, which reduce kickback while operating a saw. They also help prevent equipment damage that could cost you thousands of dollars.

This article describes how to use the anti-kickback device and prevent it from jumping back.

Read this article to know about how does anti-kickback pawl works, why we need anti-kickback system in table saw and other similar things.

What is Kick Back?

Kickback is a violent motion in which you rapidly move your hands and arms back.

This is used to describe the action of an individual who has suddenly become scared during work in power saw.

What Causes Kickback on Table Saw?

Kickback is a common occurrence when using a table saw and can be caused by several factors.

In general, kickback happens when the workpiece being cut is suddenly propelled backward towards the operator, often with great force.

This can be extremely dangerous and can result in serious injury or even death.

Understanding the causes of kickback on a table saw can help you avoid it and stay safe while using the saw.

Improperly Aligned Blade

One of the primary causes of kickback on a table saw is an improperly aligned blade.

If the blade is not parallel to the miter slot, it can cause the wood to bind and twist, resulting in kickback.

It’s important to check the alignment of the blade regularly and adjust it as necessary to prevent kickback.

Dull blade

A dull blade can also cause kickback on a table saw. A dull blade will have a harder time cutting through the wood, and as a result, it may cause the wood to bind or twist.

This can lead to kickback. It’s important to keep the blade sharp and in good condition to prevent kickback.

Incorrect blade height

Another factor that can cause kickback on a table saw is an incorrect blade height.

If the blade is too high, it can cause the wood to lift up off the table and bind, resulting in kickback.

It’s important to adjust the blade height correctly for the thickness of the wood being cut.

Pushing the wood too fast

Pushing the wood through the blade too quickly can also cause kickback on a table saw.

When you push the wood too fast, it can cause the blade to bind and twist the wood, leading to kickback.

It’s important to feed the wood through the blade at a steady pace and avoid rushing the cut.

Incorrect fence positioning

The fence on a table saw is used to guide the wood through the blade.

If the fence is not positioned correctly, it can cause the wood to bind and twist, resulting in kickback.

It’s important to ensure that the fence is parallel to the blade and properly positioned for the cut being made.

Knots or defects in the wood

Finally, knots or defects in the wood can also cause kickback on a table saw.

These imperfections can cause the wood to bind and twist, leading to kickback.

It’s important to inspect the wood for knots or defects before making the cut and avoid using wood with significant imperfections.

By properly aligning the blade, keeping it sharp, adjusting the blade height, feeding the wood through at a steady pace, positioning the fence correctly, and inspecting the wood for defects, you can minimize the risk of kickback and work with confidence on your table saw.

What Are Anti Kickback Pawls?

Anti-kickback pawls are small metal teeth or hooks that protrude from the top of a saw’s guide bar.

They’re designed to grip the wood being cut and prevent the saw from being pushed back towards the user in the event of kickback.

Anti-kickback pawls are typically found on chainsaws, circular saws, and table saws.

A kickback pawl is a part of the clutch mechanism of a power tool. It locks the drive shaft and prevents it from moving when you release your grip on the handle.

The anti-kickback pawls of a saw are like minuscule, tiny versions of the teeth on your mouth.

They hang behind in order to prevent large chunks from coming back at you when feeding wood through it.

Why Anti-Kickback Pawl is Important

Anti-kickback pawls are an essential safety feature in power saws, designed to protect the user from injury.

Kickback is a common hazard that can occur when the saw blade binds in the wood or encounters a knot, causing the saw to jump back towards the user.

This can cause serious injury or even death. Anti-kickback pawls help prevent kickback by gripping the wood and stopping the saw from moving backward.

This makes power saws safer and easier to use, especially for beginners or those working with large or difficult-to-cut materials.

People who don’t wear seatbelts are putting themselves in harm’s way. Similarly, people who use table saws without anti-kickback pawls risk being harmed by the blade coming back to them if it kicks out of its cut.

Use and Working Mechanism of Anti Kickback Pawl

Anti-kickback pawls are an important safety feature found on many table saws.

They work by preventing the workpiece from being thrown back towards the operator in the event of a kickback.

The anti-kickback pawls are two small arms located on either side of the blade, near the top of the blade guard.

They are attached to a spring-loaded bracket that allows them to move up and down as the workpiece is fed through the blade.

When the blade rotates in a forward motion, the pawls move freely across the surface of the wood.

However, if the wood tries to move backwards, the pawls dig into the surface of the wood, preventing it from being kicked back.

The mechanism that enables the pawls to move up and down is called the riving knife. The riving knife is a small, vertical projection located behind the blade.

It is mounted on a bracket that allows it to move up and down with the blade.

As the blade cuts through the wood, the riving knife holds the wood open, preventing it from binding against the back of the blade.

Anti Kickback Theory & Safe Demonstration. Table Saw & Radial Arm Saw

This helps to prevent kickback by keeping the wood moving forward smoothly and without any sudden stops.

When kickback occurs, the anti-kickback pawls engage with the surface of the wood and prevent it from being thrown back towards the operator.

The pawls dig into the wood and grip it tightly, stopping it from moving backwards.

This helps to keep the operator safe by preventing them from being struck by the workpiece or the blade.

It’s important to note that while anti-kickback pawls are effective at preventing kickback, they are not foolproof.

It’s still important to follow proper safety procedures when operating a table saw, such as using a splitter, featherboard, and push stick, and maintaining a clean work area.

By using these safety features in conjunction with the anti-kickback pawls, you can significantly reduce the risk of kickback and operate your table saw safely and effectively.

How to Prevent from Table Saw Kickback Happening?

Preventing kickback on a table saw is essential for maintaining safety in the workshop.

Here are some steps you can take to prevent kickback from happening:

Use a splitter

A splitter is a small vertical projection located behind the blade that helps to prevent the wood from pinching the blade and causing kickback.

Many table saws come with a splitter, but if yours does not, it’s worth investing in one. You can also purchase a riving knife, which is a type of splitter that moves up and down with the blade.

Use a featherboard

A featherboard is a device that attaches to the fence and applies pressure to the wood to keep it from moving during the cut.

It helps to prevent kickback by keeping the wood in contact with the table and fence.

Use a push stick

A push stick is a tool that is used to push the wood through the blade. It keeps your hands away from the blade and allows you to apply pressure to the wood without risking injury.

Using a push stick helps to prevent kickback by allowing you to guide the wood through the blade safely and effectively.

Keep the blade sharp

A dull blade is more likely to cause kickback because it has a harder time cutting through the wood. It’s important to keep the blade sharp so that it can make clean cuts without binding or twisting the wood.

Use proper technique – Proper technique is crucial for preventing kickback.

Make sure you’re feeding the wood through the blade at a steady pace, using the right blade height for the thickness of the wood, and positioning the fence correctly.

You should also avoid pushing the wood through the blade too quickly or applying too much pressure.

Use high-quality wood

Knots, warps, and other defects in the wood can cause kickback. To minimize the risk, use high-quality wood that is straight and free of defects.

Maintain a clean work area

Sawdust and debris can cause the wood to bind and twist, leading to kickback.

Keep your work area clean and free of sawdust, and regularly clean the table saw and its components to prevent debris from interfering with your cuts.

By following these steps and taking proper safety precautions, you can significantly reduce the risk of kickback on your table saw.

Remember to always prioritize safety when working with power tools and seek professional help or instruction if needed.

FAQs about Anti-Kickback Pawls

Do all power saws have anti-kickback pawls?

No, not all power saws have anti-kickback pawls. However, they’re a common safety feature in chainsaws, circular saws, and table saws.

Can I use a power saw without anti-kickback pawls?

It’s not recommended to use a power saw without anti-kickback pawls.

Kickback is a common hazard that can cause serious injury or even death, and anti-kickback pawls are designed to prevent it. Using a power saw without anti-kickback pawls increases the risk of injury.

Do anti-kickback pawls require maintenance?

Yes, anti-kickback pawls should be checked and maintained regularly to ensure they’re working properly.

They should be cleaned of debris and checked for wear or damage before each use. If the pawls are damaged or worn, they should be replaced immediately.

In conclusion, anti-kickback pawls are an essential safety feature in power saws, designed to prevent kickback and protect the user from injury.

They work by gripping the wood being cut and preventing the saw from moving backward in the event of kickback.

By understanding how anti-kickback pawls work and why they’re important, you can use power saws safely and with confidence.

ANTI-KICKBACK RIP BLADES

This anti-kickback rip blade features an alternate top bevel grind which is a great choice for solid wood, (both hard- and softwood), plywood, lumber and other non coated panel products. While anti-kickback blade geometry reduces the risk of material kickback, it does not eliminate it!

Description

This general purpose blade features an alternate top bevel grind which is a great choice for solid wood, (both hard- and softwood), plywood, lumber and other non coated panel products.

You may also like…

with high quality, precision cutting tools

We are using cookies to give you the best experience on our website.

You can find out more about which cookies we are using or switch them off in settings.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Everything You Need to Know About Table Saw Kickback

A table saw is arguably the most versatile tool to own if your projects involve woodworking.

But it does come with its fair share of safety hazards that must be considered before you make each cut.

Your typical woodwork routine involves gently pushing the lumber forward into the downward spinning teeth at the front of the blade.

As the piece of lumber reaches the rising rear teeth of the saw, its knots get caught up in the blade and hurled forwards at breakneck speeds.

Most blades move at roughly 3000 rpm and create enormous kinetic energy that could harm you.

Worse still is when your hand gets pulled into the spinning blades, causing grave injuries.

Yet, for every horror story out there, one or more safety mechanism was left ignored.

It pays to understand what causes kickback on a table saw in times like these.

What Causes Table Saw Kickback?

When you cut into the board, you create tension. The higher the tension, the greater your chances of kickback.

As the lumber goes halfway through the blades, the resulting kerf starts to pinch the rear teeth of the saw.

Most saws may end up slowing down or stop moving entirely, which is significant from a safety point of view.

However, if your table saw is relatively powerful, it can flip the board and send it hurling right in your face instead.

1) Not Enough Pressure Against the Fence

As the lumber gets pushed into the blade, it begins to lose pressure against the rip fence and starts to veer off sideways.

When this happens, the rising teeth catch the wood before getting thrown off at frightening speeds.

Sometimes, the fence gets “toed-in” towards the blade, which means that the distance from the blade to the fence is less at the rear of the saw than at the front.

This presses the lumber against the rising rear teeth causing kickback.

2) No Riving Knife or Splitters

A riving knife is one of the best safety devices that can be installed on the table saw.

It is mounted behind the saw to prevent the woodwork from pinching inward into the blades.

Riving knives also firmly keep the woodwork against the fence to prevent it from rising up against the rear of the saw.

The second best tool is a splitter that works precisely like a riving knife with the exception that it does not rise, fall, or tilt along with the table saw.

Another difference is the arched shape of the knife, designed to mimic the blade’s curvature; this is a great safety mechanism.

Since a splitter does not rise and fall with the blade, lowering the blade to cut thinner stock increases the gap between the splitter and the blade.

This increases the potential for the blade to catch the board before the kerf reaches the splitter.

Make sure to remove the splitter to make non-through cuts and grooves.

3) The Riving Knife Isn’t Properly Mounted

One of the primary functions of the riving knife is to act as a form of rearguard to the lumber.

However, for the rear guard to properly work, it must be properly aligned with the blade kerf to prevent off-cuts.

If the riving knife isn’t correctly mounted or aligned with the kerf, the knots in your woodwork may get pinched at the back of the blade and violently thrown towards you.

4) Using an Older Table Saw

Not all table saws are equipped with safety accessories like a riving knife or cutter.

Retrofitting one without substantially modifying the table saw isn’t advisable, especially when working with an older model.

This is an accident just waiting to happen because your woodwork will eventually catch you by surprise with a table saw kickbacks.

One effective solution is to buy anti-kickback safety rollers. These are mounted on your fence with a track instead of being mounted on the rail.

Not only do anti-kickback safety rollers hold the lumber against the table, but they also keep them snug against the fence.

5) You Don’t Have a Plan for Your Cuts

Before you make any cut, you should always have a plan for where your hands and body will be positioned throughout the cut.

You never want to be halfway through the cut only to realize that you don’t have a plan for getting the board all the way through.

Don’t ever stop midway, because this will definitely result in a major kickback.

6) Making Freehand Cuts

Freehand cuts with a spinning blade are one of the biggest mistakes that a beginner can make.

Always use a fence to support the piece and keep it square against the blade.

You should always never stand directly behind the woodwork when making a cut, even if you’ve implemented all the possible safety measures.

All these safety measures will only minimize the chances of a kickback, never completely eliminating it.

Instead, you should stand off to the side. In this case, if kickback does occur, you’re always out of the way of a vengeful block of lumber.

Using the Wrong Dimensions

The distance from the blade to the fence should never exceed the length of the wood that is against the fence.

This is because when you start making a cut, the table saw blade would create tremendous forward torque compared to the small amount of wood held up against the fence, it will create a turn.

If the board starts to spin, it will climb up against the back of the plate. At this point, the board gets caught up by the plate and spins into you.

Tools to Prevent Table Saw Kickback

Snap-in Splitter

- Popular aftermarket table saw splitter for preventing kickback on table saws (for Thin Kerf Saw Blades Only)

- Voted Best Tool by Popular Woodworking (2004) for Table Saw Safety!

- Installs directly to wood or plastic Zero Clearance Inserts (Throatplates)

- Mini-featherboard technology keeps the workpiece against the fence and prevents burning

- Simple instructions and installation drill guide included

Snap-in splitters are specifically designed to reduce dangerous table saw kickback.

They instantly snap on any DeWALT table saw and are easy to remove.

Snap-in splitters will slip into a bracket that can be easily mounted to the rear of the table saw.

Zero Clearance Throat Plate

- Allows for use of stacked dado cutters

- Can be used with DWE7490 and DWE7491 versions

- For woodworking and building

- Package Weight: 0.372 kilograms

This relatively simple upgrade minimizes the size of the blade’s kerf as it is being cut into by the table saw.

They make your woodwork projects safer and yield better cutting results with little hassle.

Table Saw Kickbacks

Most people use a dedicated zero clearance throat plate for each operation – including regular cuts, dado cuts, thin kerf cuts, and even angled cuts.