Best Hacksaw – Top Picks, Reviews & Guide. Hacksaw for cutting metal

Can a Hacksaw Cut Through a Chain

A hacksaw is a tool that is typically used to cut through metal. However, can a hacksaw cut through a chain? The answer is yes, but it depends on the type of chain and the size of the hacksaw blade.

If the chain is made of softer metals, such as aluminum, then the hacksaw will have an easier time cutting through it. However, if the chain is made of harder metals, such as steel, then the hacksaw will have a more difficult time cutting through it.

Cutting Chain with a Hacksaw

If you’ve ever tried to cut through a chain with a hacksaw, you know it’s not an easy task. The teeth on a hacksaw are designed for cutting metal, but they’re not strong enough to cut through the hardened steel of a chain. So, what can you do if you need to cut through a chain?

There are a few different options. You could use a power tool like an angle grinder or cutoff saw, which will make quick work of the job. Or, you could use a file to slowly grind away at the chain until it’s severed.

Whichever method you choose, be sure to wear safety gear and take care not to damage the surrounding area.

How to Cut Hardened Steel Chain

If you’re looking to cut a hardened steel chain, there are a few things you’ll need to take into account. First, hardened steel is much harder than regular steel, so you’ll need a saw with carbide teeth or discs.

How to Cut a Chain Without Bolt Cutters

If you don’t have a bolt cutter handy, there are still ways to cut through a chain. With a little patience and the right tools, you can cut through even the thickest chain. First, start by using a hacksaw to make a cut in the middle of one of the links.

Then, use a hammer and chisel to chip away at the link until it is weakened enough to snap. Repeat this process on as many links as necessary until the chain is severed. For thicker chains, you may need to use an angle grinder or power saw instead of a hacksaw.

Be careful when using power tools near the chain, as they can easily damage it beyond repair. If possible, clamp the chain down before starting to cut. With a little effort, you can easily cut through even the toughest chains without resorting to bolt cutters.

Just be patient and take your time so you don’t damage either your tools or the chain itself.

How to Cut a Metal Chain Without Bolt Cutters

If you’re in a pinch and need to cut a metal chain without bolt cutters, there are a few methods you can try. First, see if you can find something sharp to use as a makeshift cutter, like a hacksaw blade or an old knife. If that doesn’t work, you can try using a pair of pliers to twist the chain apart.

Finally, if all else fails, you can try heating up the chain with a blow torch until it’s hot enough to snap apart. Whichever method you choose, be sure to exercise caution and take your time to avoid injuring yourself.

Conclusion

If you’re in a bind and need to cut through a chain, a hacksaw can do the job. It’s not the ideal tool for the task, but it will work in a pinch. Just be sure to use plenty of lubricants to prevent the blade from getting damaged or stuck.

Leave a Comment Cancel Reply

report this ad John Carry

Hi, I’m john, I, ve spent my time helping people to successfully do their DIY projects.I’m a professional saw expert for over 10 years. I’m working with every type of saw and always try to find out which is best for my project. See more report this ad

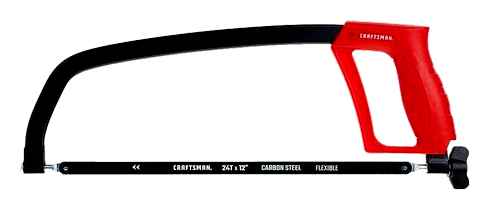

Best Hacksaw – Top Picks, Reviews Guide

Hacksaws were originally designed to cut metal, but are just as widely used for cutting plastic pipes and conduit for your DIY electrical and plumbing jobs. A hacksaw is something that every man should have handy in his tool box, as these make great additions to your repertoire as a DIY-er.

Hacksaws can be used to cut wood, although it would be better to use a handsaw for this. The cool thing about a hacksaw, is that you can hold it perpendicular or parallel to the frame you are using and cut the metal, plastic or wood you are working with. Don’t forget to checkout our review on All Hand Saw Types

Best Hacksaw. Intro

The most commonly used hacksaws come with standard 10″ or 12″ blades. Junior hacksaws also come with a standard 6″ blade, and this allows for much more precise cutting than a standard-sized hacksaw. Powered hacksaws come in a variety of sizes and all hacksaw blades typically come either in carbon steel or high speed steel. Let’s learn a little about a few specific hacksaws, so that you can see which is the best hacksaw for your specific needs.

Hacksaws come in a variety of sizes as far as blades are concerned, and some are adjustable so that they fit multiple-sized blades. Depending on what kind of cut you’re looking for, hacksaws come in 14, 18, 24, or 32 teeth per inch (tpi). The fewer tpi, the bigger the object you should be cutting.

Frame:

- M ateria l: the best type of hacksaw, the one that will last you a lifetime, is made of steel. Frames do come in aluminum, but finding a lightweight steel frame is better for the money and for quality.

- Weight : You want to pick a hacksaw that is light weight so that you don’t get pooped out just working that hacksaw back and forth. You’re sure to get tired just by sawing the metal or pvc pipe, but having a heavy hacksaw tires you out much more quickly.

- Length : The frame length varies, but the most common lightweight yet sturdy frame is a 10-inch frame. It wouldn’t hurt to have multiple hacksaws in your tool box, but if you have to choose just one, a 10-inch is best.

- Mounting Pins : Having two rows of mounting pins allows you to tilt the hacksaw and get a much better, bigger cut. Although the hacksaw is at an angle, the cut is still straight and goes much further than one with only one set of two mounting pins.

Blade:

- Type of metal:

- High-carbon steel.These are commonly used and work well when sharp. However, because these blades aren’t heat resistant, the teeth dull more quickly.

- Bi-meta l- The teeth of these are made of high-speed steel and bonded to a back of spring steel, which helps keep cost down, but these blades last a long time.

- Length: Whatever length the frame is, that’s the length of blade you need to purchase for it. A 10-inch frame should have a 10-inch blade.

- TPI (# of teeth-per-inch) : The more teeth per inch, the thinner the material you can cut. (i.e. if you have to cut a thick, 1-inch piece of steel, you want the lowest number of tpi possible.

- 18 tpi: minimum thickness of material to cut is 5/32 in. or 4 mm

- 24 tpi: minimum thickness of material to cut is 1/8 in. or 3 mm

- 32 tpi: minimum thickness of material to cut is 3/32 in. or 2.5 mm

How to Use a Hacksaw

Before you use the hacksaw for the first time, you must be sure that the blade is well-tensioned. You don’t want to break the blade right out of the gate.

When you purchase a hacksaw, the standard blade may come already set in the saw. However, you’ll need to learn very quickly how to change out the blade or how to install different blades into the saw yourself. You’ll need to first turn the adjustor on the saw handle or frame. Every hacksaw is different when it comes to replacing the blade.

The teeth on a hacksaw are meant to cut only on the forward stroke, the push stroke. This means that when you are pushing, you need to add pressure so you’ll cut the material. However, when drawing the hacksaw back, you will want to let up on the pressure. If you don’t let up on the pressure when drawing back, you’re not cutting anything, but you are definitely dulling the teeth more quickly. You want your blades to last as long as possible.

How you hold a hacksaw is very important to your success in cutting whatever material you’re working with. When getting ready to cut, the hand in the rear should be in a pistol-grip with your pointer finger pointing along the blade. Your front hand should be on the front of the frame. This allows you initially to put more pressure down to cut.Once you have established the cut, both hands can be moved to the back of the frame, which allows the most pressure and direction.

The final thing that you should care about is how you are going to hold the material you plan to cut. You have to be sure that you don’t waste any energy by allowing your material or your work bench to move one iota. How will you be sure it’s all 100% secure? The most successful way to do this is by having a vice that is mounted securely to your work bench. If you can’t afford a vice, you have to at least get some sturdy clamps to make sure your material is securely placed on the work bench before you begin cutting.

What happens if your cut begins to move away from where you want it to be? The hacksaw allows you to correct your cut simply by turning the frame slightly in one direction or another. It’s actually pretty simple. This twists the flexible blade, which causes the blade to cut more on one side than on the other.

How to Choose the Right Hacksaw Blade

A 24 TPI hacksaw blade offers the most range. It’s good for cutting aluminum, steel rods and plates, and more.

A 18 TPI hacksaw blades is perfect for cutting wood, PVC pipes, as well as hardened steel and general workshop cutting.

Good quality 14 TPI hacksaw blade that’s great for cutting thick metals like aluminum, copper and even stainless steel.

A 24 TPI hacksaw blade offers the most range. It’s good for cutting aluminum, steel rods and plates, and more.

A 18 TPI hacksaw blades is perfect for cutting wood, PVC pipes, as well as hardened steel and general workshop cutting.

Good quality 14 TPI hacksaw blade that’s great for cutting thick metals like aluminum, copper and even stainless steel.

A hacksaw blade is available in different TPI (teeth per inch) to best cut a specific range of material thicknesses. Hacksaw blades are usually meant to cut metals, but in very specific rare cases they are used to cut wood.

The higher the TPI, the finer the cut will be. The lower the TPI, the coarser the cut is going to be.

The lower the TPI…the larger the gap between teeth…and the longer the tooth. This allows more material removal and clean-out with each saw stroke, thus saving cutting time.

The higher the TPI…the smaller the gap between teeth…and the shorter the tooth. This allows the blade to cut thinner material thicknesses without getting hung up in the material.

Hacksaws at Last Best Tool: The Good, the Bad, and the Outdated

| WOOD AND THICK METAL USE | 14 | 1/8″ – 1/2″ |

| HEAVY METAL USE | 18 | 1/8″ – 1/2″ |

| MEDIUM METAL USE | 24 | 3/32″ – 5/16″ |

| THIN METAL USE | 32 | less than 1/8″ |

| GLASS, CERAMICS, MARBLE, FIBERGLASS, AND STEEL | Carbide Rod | – |

The values provided on this chart are a general guideline. Blade TPI recommendations can be found on each manufacturer’s product packaging. Read the entirety of the article for more details.

Material thickness – not diameter – relates to blade TPI.

An economical and easy method to measure material thickness is to use a rule.

If you’re looking for the best high-tension hacksaws, check out our recommendations.

Best Hacksaw Blade for Mild Steel: 14-TPI Hacksaw Blade Overview

Use a 14-TPI blade to cut thick metal (over 1/8″) will speed up cutting compared to an 18-TPI blade.

| 1/8″ STEEL U-CHANNEL | 27 sec. | 30 sec. |

| 1/2″ REBAR | 24 sec. | 26 sec. |

Speed tests are an estimation based on hand cutting. New Lenox hacksaw blades were used for consistency.

Note 1: I am not sure why Lenox suggests using a 14-TPI blade for cutting wood. After several thick wood cutting tests (softwood and hardwood), I discovered a 14-TPI hacksaw blade is hopeless at cutting wood; the blade constantly gets hung up in the material. I also tried a Morse 14-TPI blade and had the same ineffectiveness.

I find that a 18-24 TPI blade works best for cutting wood, or switch to a dedicated wood cutting hand saw for better performance.

Note 2: A Lenox 14-TPI blade has a minimum thickness rating of 1/8″, whereas a Morse 14-TPI blade has a minimum thickness rating of 3/16″. We tested both brands of blades to find the truth in these guidelines.

- The Lenox 14-TPI blade effectively cuts 1/8″ thick material, as stated.

- The Morse 14-TPI blade struggled to cut below 3/16″ and is ineffective in cutting 1/8″ thick material.

- Used to cut pipe, tubing solids, wood, plastic or any machinable metal

- Increased heat and wear resistance for long life

- Flexible to prevent shattering during use

- 10 blades per pack

Note 3: Finding 14-TPI blades at local home improvement stores may not be possible, and many of the hacksaw blade brands don’t offer a 14-TPI model. Don’t worry, a 14-TPI blade isn’t needed for homeowner projects. However, a tradesman that cuts heavy metal regularly may want to experiment with a 14-TPI blade compared to using a 18-TPI blade.

Best Hacksaw Blade for PVC Pipes, and Steel Rods: 18-TPI Hacksaw Blade Overview

A 18-TPI blade gives you many of the same cutting abilities as a 14-TPI blade, but with less effort and smoother cutting.

Cut a wide range of wood thicknesses. A hacksaw isn’t the ideal choice for cutting wood, but for random projects where precision cutting isn’t needed, a hacksaw will get the job done, e.g. cutting a tree limb, demoing a small wall or building structure.

A hacksaw is very effective for plumbing projects that use PVC. A 18-TPI blade cuts through PVC tubing, whether trying to cut and remove existing plumbing, or cutting new PVC to length for a plumbing project. E.g. replacing a garbage disposal, sump pump, or an outdoor drainage project. A heavy-duty utility knife works well to deburr the PVC after each cut.

- T2 Technology provides a long hacksaw blade life

- Shatter-resistant, bi-metal construction allows saw blades to bend and flex without breaking

- Saw blades cut through black pipe, Unistrut, copper pipe, hardened steel, threaded rod and rebar

- 18 TPI

- 12″ L x 1/2″ W

Note: A DeWALT 18-TPI blade has a material thickness rating of 1/4″ – 1/2″. Most other 18-TPI blades have a minimal material thickness rating of 1/8″, which the DeWALT 18-TPI blade cut effectively too. A confusing discrepancy in DeWALT’s 18-TPI nominal material thickness recommendation.

- Model Number: DWHT20558

- Item Package Length: 13.8582677024″

- Item Package Width: 8.0314960548″

- Item Package Height: 0.2362204722″

Best Hacksaw Blade for Cutting Aluminum, Steel, and more: 24-TPI Hacksaw Blade Overview

A 24-TPI comes standard on hacksaws and from our tests offers the most range. The tooth count and size isn’t too small nor too large.

Note 1: Lenox rates their 24-TPI blade to cut 3/32″ thru 5/16″ for hardened materials, but a wider range of softer materials can be cut.

- The LENOX hacksaw uses an I-beam construction, allowing the blade to tension up to 50,000 psi

- Rubberized handles allow for confident handling, even in wet and cold environments

- Hacksaw accepts any LENOX reciprocating saw blade to be used as a jab saw

- LENOX hacksaw stores up to 5 extra 12-inch hacksaw blades in the I-beam

- All hacksaw come with one 12-inch, 24 TPI hacksaw blade

How to Cut Metal using a Hacksaw – A Complete Guide

Cutting Metal with a hacksaw may seem intimidating, but it doesn’t have to be. With the right tools and a little know-how, anyone can learn how to cut Metal with a hacksaw in just a few simple steps. Read on for our beginner’s guide on using a hacksaw to cut Metal.

Gather Your Tools and Materials

Before you start cutting Metal, ensure you have all the necessary tools and materials. You’ll need an appropriate hacksaw frame, at least one blade for your saw, safety goggles or glasses, gloves for protection, and clamps to secure the Metal firmly. It’s also a good idea to have some masking tape handy—you’ll see why later!

Prepare Your Work Space

Safety is always important when working with tools and materials, so you must prepare your work space first. Make sure there are no flammable materials nearby, as sparks may occur during the cutting process; clear away any clutter that could get in the way; set up any clamps or other devices needed to keep your material steady while you work; and ensure that your workspace is well-ventilated. Once you’ve prepped your work area, wear safety glasses and gloves before proceeding.

Cutting Metal With A Hacksaw

Now it’s time for the actual cutting! Place the Metal between two clamps so that it is steady while you’re sawing away at it. Position the blade of your hacksaw against the Metal so that it is aligned parallel with where you want the cut to be made—this will help ensure an even cut. Then begin sawing back and forth slowly and steadily until you’ve reached your desired length or thickness of Metal. If possible, use masking tape around where you want the cut made: this gives extra protection from flying sparks and helps keep things clean by catching any small pieces of shavings generated during cutting.

Conclusion:

With these steps in mind—and with plenty of practice—you should soon be able to master cutting metal with a hacksaw like a pro! Just remember:

- Always wear proper protective gear when working with any tool.

- Never try to rush through cuts.

- Use clamps or other devices whenever possible to hold material still while sawing.

- Use masking tape around each cut line if possible for extra safety (and cleanliness)

Pipingmart is a B2B portal that specializes in metal, industrial and piping items. Additionally, we share the latest information and information about materials, products and various types of grades to assist businesses that are involved in this business.

Best Hacksaw Blades In 2023 [A List Of Top 6 Picks]

METAL CUTTING

The bar stocks, rods, tubes, iron flats, metal sheets etc. are always required in desired lengths in a fitting shop. Hacksaw is the common tool which is used in the fitting shop to cut the job in required or desired length.

Parts of Hacksaw

It consists of a metal frame, fitted with a wooden handle. The blade fits over two pegs which project from the pins sliding in the ends of the frame. The wing nut at the front end to the frame is for tensioning the blade.

TYPES OF FRAMES:

The frame of the hacksaw can be either FIXED TYPE, which can accommodate the same length of the blades always, or can be ADJUSTABLE TYPE, which is capable of accommodating different lengths of blades.

TYPES OF BLADES:

Hacksaw Blade is the main part. They are manufactured in two different categories ALL HARD and FLEXIBLE. All Hard blades are hardened all over while the Flexible Blades are hardened only along the teeth and the remaining portion is tempered to make it tough and comparatively softer.

PUSH TYPE BLADES:

PUSH TYPE BLADES are those which cut in forward stroke only. In these, the teeth always point away from the operator.

PULL TYPE BLADES:

PULL TYPE BLADES are those which cut in backward stroke only. In these, the teeth always point towards the operator. The blades are specified by its length and the pitch. The length of the blade is the distance between the outside edges of the holes which fit over the pins. The most usual blade for hand work is 250 mm long and 12.5 mm wide. The pitch is measured by the number of teeth per 25 mm length.

The points of the teeth are bent to cut a wide groove and prevents the body of the blade form rubbing or jamming in the saw cut. This bending of the teeth to the sides is called setting of the teeth. Usually alternate teeth are set to right and left, every third or fifth tooth left straight to break up the chips and help the teeth to clear themselves. The fine toothed blades for cutting thin metal are sometimes made with a wavy set minimize stripping of the teeth from the blade.

The choice of the blade for any particular class of work depends upon the pitch of the teeth and at least two or three teeth should be in contact with the surface being sawn. If this is not attained, the teeth will be stripped from the blade and sawing too sharply over a corner will also result in teeth being torn off.

The blades in common use are generally 0.7 m thick, 12.7 mm wide and 20 to 30 cm long. About 5 to 7 teeth form per cm length of blade form the COARSE GROUP and 8 to 12 teeth per cm form the FINE GROUP of teeth.

APPLICATIONS:

For general cutting in most of the metals like steel, cast iron, aluminum, Babbitt metal and all other general cutting work

For medium sections of metal sheets, pipes and metals likes brass and copper etc.

For thin sections of metals sheets, tubes and conduits etc.