Canadian Distributor of LOG BUILDING TOOLS for over 30 YEARS. Alaskan saw mill diy

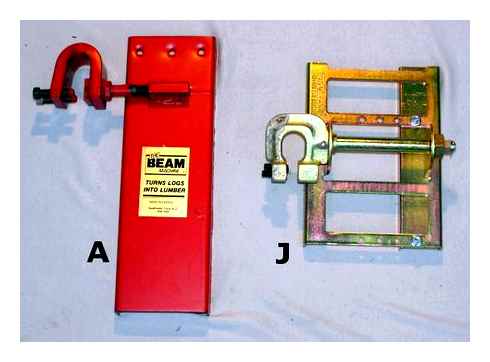

Lumbermaker Mill

This mil quickly attaches to a chain saw and by using a 2 x 4 or a 2 x 6 as a guide, will make lumber or square timbers. It is especially useful, however, in log construction for accurately cutting out door and window openings. It will also make mitre cuts by nailing guides at required angle.

| J-11-595 | Generic version of lumbermaker | |

| J-11-598 | Lumbermaker attachment. |

MICRO-MILL HI-PRECISION CHAIN SAW MILL

The Micro-mill mounts quickly and easily on any chain saw and it allows you with an almost non-existent learning curve to cut precision window and door openings and customize timbers and lumber with a skill and ease no other device can match. This mill is precision machined and its patented clamping system rotates 360˚ on sealed precision bearings. The most durable and accurate mill of its type. This mill uses a dressed 2 x 6 as a guide, but for even greater accuracy, the optional “High Precision Kit” is available which uses a 2 x 4 x ¼” aluminum channel as a guide.

| B-11-601 | Micro-mill chain saw mill. | |

| E-11-599 | no longer available | Micro-mill “High Precision Kit.” |

Mini Mill

This attachment quickly clamps to a chain saw bar, and by using a V-shaped guide rail mounted on a 2 x 6, it is especially popular for flattening or squaring timbers and even making smooth lumber from logs. It also is an ideal partner for the Alaskan Mark III by using it to square the log, then as an edger for the lumber. Made by Granberg.

ALASKAN SMALL LOG MILL

Clamps onto your chainsaw bar with no drilling required. Tighten pressure bolts on to chain bar to make cuts up to 18” wide and 1/2” to 13” deep. Lightweight and portable, enables user to mill lumber where the tree falls. No previous experience required! Ideal for making slabs, planks and beams.

| A-11-603 | Alaskan small log mill. Made by Granberg |

ALASKAN MARK IV MILL

An innovative attachment which clamps to your chain saw bar and converts your chainsaw into a highly portable sawmill. Safe and easy to use, this mill was designed to produce smooth dimensional lumber from rough logs at any job site. This tool comes in a variety of sizes for various bar lengths and consists of a parallel bar that adjusts in varying distances from the chain saw bar for the desired thickness of material. The first slab is taken off by following usually an H-style rail. All mills now are Mark IV with improved end brackets and clamp assemblies.

The Mark IV Mill is manufactured by Granberg.

C2 kit. Includes a 3rd bracket, a 2nd on / off bar and hardware.

Reinforces the mill and enables more accurate cuts when

slabbing a log. Recommended for mills 48″ and up in length.

Extended depth post 36” long to increase cutting depth of Mark IV mill from 16” to 36”

EZ-Rail System

The NEW 10Foot EZ-Rail System from Granberg! The best way to make a perfect first cut with a Granberg Mill, now even better! Comes in two 5′ sections. Makes for easy transport and increased versatility.

Aircraft-grade aluminum rails provide a stable surface that attaches in seconds and is easily leveled left to right, front and back. Cross members are adjustable along whole length of the EZ rails.

Longer cross member to widen EZ-Rail System from 12” to 24” wide. Recommended when using EZ-Rail System for mills 56” and longer and milling logs 48” diameter and larger. 4 cross members required for 10 ft EZ rail and 2 for 5 ft EZ-Rail

Alaskan Winch

The Alaskan Winch is a hand winch for the Alaskan Mill. The increased mechanical advantage of this tool makes milling easier and the cut smoother. It also has a unique lever arm anchor system that allows you to cut right to the end of the log. This light weight design attaches easily to the cross rails and is incredibly strong and durable.

The Alaskan Winch includes the Winch, 38ft of rope and the lever arm anchor system. Enables user to cut up to a 18 foot log!

Helper Handle

When sawing large logs a helper handle is used for two person milling. It is used with a roller for double-ended bars and without for sprocket nose bars. Sprocket nose must be drilled to use helper handle.

| D-11-607 | Helper handle without roller. Requires drilling 2 hols in sprocket nose bar. | |

| R-11-609 | Helper handle with roller and adjuster for double-ended bar. |

Slabbing Rail Brackets

Slabbing rail brackets are used to set up your H-style rail which is nailed to the round log and used as a guide for your Alaskan mill to cut your first slab.

DOUBLE-ENDED CANNON MILLING BARS

Can be used with two chain saw power units for more power and milling speed or with a helper handle. Generally used when milling large logs. Standard gauge is.063” and has bushings to make it a universal mount for most popular saws.

See for single ended bars in bar section of our website

OILER KIT

Provides a means for adding extra lubricating oil to your cutter bar and chain saw. Gives your bar and chain longer life for faster cutting. (no larger image available).

| G-11-618 | Oiler kit. |

RIPPING CHAIN

Semi chisel chain specially factory ground to 10˚ for making dimensional boards or planks from larger timbers by cutting parallel to the wood grain or “ripping”.

Granberg style ripping chain is made up of one set of scoring cutters and one set of clearing cutters. The scoring cutters (file at 20˚) cut a groove down each side of the kerf. The following two center clearing cutters (file at 0˚) remove the center ridge left by the scoring cutters. Depth gauges have to be lowered according to the power of your chain saw.

Oregon ripping chain. Available in.050”.058”.063” gauge and 3/8” pitch. Must specify gauge required. Also available in.325″, 3/8″ Low Pro.404″ pitch. 3/8″ pitch 3/8″ Low Pro.

Granberg ripping chain. Available in.050”.058”, and.063” gauge and 3/8” pitch. Must specify gauge required. Also available in.325″ and.404″ pitch. 3/8″pitch.325″ pitch

Granberg G1012XT precision grinder, c/w clamp-on guide 12 volt.

Granberg G912XT GRIND-N-JOINT, free-hand held, 12 volt.

Headcutter miter Attachment

This attachment clamps to any chain saw in seconds transforming it into a giant vertical cutting jigsaw. It is laterally angularly adjustable through 75˚ from vertical. It has a wide sturdy base plate which fully supports the weight of the saw through its angular range and provides excellent stability for accurate freehand cuts with a long cutting bar. By using the top cutting edge of the bar, the chain cutters throw wood chips away from the operator and cut area. This in combination with a large opening in the base plate and the U-shaped chain bar clamp located will behind the upper cutting edge of the chain bar provide an unobstructed view of the cutting chain as it is applied to the wood. With the HEADCUTTER the operator can easily guide the chain saw to follow a snap-line or scribed arc making it the perfect “framer’s” tool for gang cutting ganged lumber, beams placed on edge, structural insulated roof panels, etc. beyond the reach of most circulars.

| K-11-697 | HEADCUTTER Miter attachment: 75˚ range, 14″ x 20″ base with pusher handle; will accommodate chainsaws with wider bars | |

| K-11-698 | HEADCUTTER miter attachment; 75˚ range, 10″ x 16″ base |

MITER MILL ATTACHMENT

The MITER MILL is the latest elite edition of chain saw mills built with precision and quality only known to genuine products. Great for miter cuts up to 70˚ for gang milling beams, custom roof trusses, gable ends or any miter angle on structurally insulated panels. The MITER MILL is second to none in versatility, durability and accuracy /- ¼˚. The MITER MILL uses a patented clamping system which allows you to clamp anywhere on your cutting bar without drilling holes. The MITER MILL weighs only 10 lbs, fits chainsaw bars up to 20” and cuts angles 70˚ in one direction and 30˚ in the other. It is fully assembled and all components are hard anodized aluminum for increased wear quality and durability. An adjustable fence can be mounted in five different configurations – can run on edge or flip over to run on fence.

Its multi uses include gang cutting timber rafters, cutting birds mouths ganged or individual, pattern or template cutting, stopped cuts, valley “V” cuts on timbers, pitch cuts on timbers, stress skin panels – all cuts, truss construction, post beam construction, ripping cuts, curve cuts and miters.

| M-11-699 | MITER MILL attachment; 30˚/70˚ range. |

Log Wizard

This one-of-a-kind chain saw attachment turns your chain saw into an amazing new tool. The LOG WIZARD gives you the freedom of time and value of creation. It attaches to your chain saw bar by drilling two holes, comes supplied with 3/8 and.325 sprockets, weighs under 3 lbs and fits all chain saws. Its many uses include de-barker, planer, notcher, router, knot remover and post sharpener.

Cutterless chain to safely operate your LOG WIZARD. Only available in 3/8″ pitch. You need 7 extra links more than your bar normally takes We also give you extra connector in case you have to shorten chain. You also have plenty of adjustment when you mount your WIZARD on the bar in the two holes you drill.

Atom Drill

This attachment, by ATOM of Australia, quickly mounts on practically any chain saw and when fitted with a wood auger bit, will allow the operator to quickly drill up to 1 ½” holes in logs, beams, joists, timbers and what have you. One excellent feature on this unit is that it has an AUGER-STOP which switches the gear box into neutral if a sudden jamming occurs when drilling. Another feature allows the operator to then pull on the unit to automatically reverse the auger from the jammed position. Other features of this durable unit are tough re-enforced gear box construction, self-locking collar, 11 ball and roller bearings, forged steel machine cut hardened pinion gear, and protective chain and bar cover. When ordering, you must state make and model of your chain saw and pitch and number of chain you are running. Auger bits are sold separately.

| R-11-610 | ATOM drill attachment with AUGER-STOP and automatic reverse. |

LEWIS CHAIN SAW WINCH

This amazing little winch attaches quickly directly to your chain saw engine and has a straight line pull of 4000 lbs a up to 8000 lbs with an optional snatch block, with variable line speed of 60 to 80 ft/min. Fits all brands of chain saws and weighs only 22 lbs without cable. Safety features include a disconnect clutch to free-wheel the cable and a hand brake to control cable and load speed. Its many uses include log skidding, off-roading, hunting, boating, lifting and fence tensioning. Requires a minimum of maintenance.

| L-11-613 | LEWIS chain saw winch complete with 150’ of 3/16” aircraft cable and safety hook. |

How to build a Homemade Chainsaw Mill from Scratch. Step by step Build Instructions

Are you looking for a cost-effective and efficient way to produce lumber from logs? Look no further than this DIY chainsaw mill project!

In this step-by-step guide, we will show you how to build a portable and space-saving chainsaw mill using materials that are readily available at your local hardware store.

With this chainsaw mill, you’ll be able to turn your logs into lumber with ease and without breaking the bank.

STEP 1 : MATERIALS REQUIRED

To build this DIY chainsaw mill, you will need to gather a few materials from your local hardware store. The first material you will need is one by one square tubing, which will form the main frame of the mill.

You will also need half-inch square tubing, which will be used to support the chainsaw bar. Quarter-inch flat bar will be used to make the brackets that hold the chainsaw in place.

In addition to these materials, you will also need weld nuts, which will be welded onto the frame to allow for easy adjustment of the chainsaw’s height.

A bandsaw will be used to cut the metal tubing and flat bar to the desired lengths, and a welding unit will be needed to weld the pieces together. In this project, the Millermatic 212 auto-set mig welder will be used for welding.

Finally, you will need a chainsaw to complete the mill. For this project, the Homelite 1130g chainsaw will be used. This saw has a 28-inch bar, making it ideal for use with the chainsaw mill.

STEP 2 : DIMENSIONS OF THE SAW

In this project, we will be using a saw with specific measurements to ensure a smooth and precise cutting process. The saw will have a 12-inch deck, which will serve as the milling surface and slide across the log during operation.

The maximum width of the mill will be 26 inches, providing ample space for milling larger logs. Additionally, there will be 8-inch metal pieces on both sides of the saw to provide stability and support during the milling process.

These metal pieces will be designed to firmly hold the saw in place, ensuring a secure grip and preventing any unwanted movements.

For holding the saw in place, we will be using quarter-inch flat stocks. These flat stocks will be welded onto the metal pieces, providing a sturdy and reliable platform to mount the saw.

STEP 3 : MAKING THE RECTANGULAR GUIDE

The next step is to cut 26-inch pieces for the length and 12-inch pieces for the sides using a bandsaw or a handsaw.

Once you have the pieces cut to the correct length, you can start assembling them into a rectangular shape. Make sure the corners are square and the sides are even.

To ensure a strong and stable structure, it is recommended to use one by one square tubing for the length and half-inch square tubing for the sides.

This will provide enough strength to hold the weight of the saw and the logs being milled.

Once you have the pieces cut and assembled into a rectangle, it is time to weld them together using a MiG welder. Make sure the welds are strong and penetrate the metal properly.

You can also use clamps to hold the pieces together while you weld them.

After welding the pieces together, check the corners to ensure that they are square and the sides are even. This will ensure that the chainsaw mill is stable.

After assembling the rectangular guide plate, we need to add a center bar to provide additional support and prevent it from twisting.

This can be achieved by cutting a 12-inch piece of one by one square tubing and welding it to the center of the rectangle.

Before welding, ensure that the center bar is straight and centered along the length of the rectangular plate. Tack weld it into position and check for any misalignment.

Once you are satisfied with its placement, weld the center bar to the rectangular guide plate using a MIG welder.

This center bar will help to evenly distribute the weight of the logs being milled, ensuring a smooth and stable milling process. It also adds rigidity to the guide plate and prevents any twisting or warping.

STEP 4 : WELDING THE ADJUSTABLE GUIDE POSTS

To make the chainsaw mill more versatile and adjustable, two guideposts are welded onto the sides of the rectangular guide plate.

For this, two larger pipe sections of dimension one by one are cut to the same height as the rectangular plate. These guideposts will allow the chainsaw to slide within them and enable you to adjust the thickness of the slabs that you cut.

The guideposts also give you adjustability on the deck to move up and down. This will come in handy when you are cutting through logs of varying sizes.

The height of the guideposts can be adjusted by welding additional metal pieces onto them, which will allow you to change the depth of the cut.

Make sure to attach the guideposts securely to the rectangular guide plate by welding them firmly.

4 quarter-inch flat bars of length nine inches are cut. Two of them are bolted onto the bottom section of the rails that slides up and down on the guideposts.

The saw blade is placed securely between these bars. A small spacer block is welded onto the bars so that it doesn’t touch the saw blade.

Three-eighth-inch weld nuts are welded onto the side posts. Tightening with the bolts locks the adjustable rails in place.

To secure the saw blade in place, four quarter-inch flat bars, each with a length of nine inches, are cut. Out of these four bars, two are bolted onto the bottom section of the rails that slide up and down on the guideposts.

The saw blade is then placed securely between these two bars. To prevent the saw blade from touching the bars, a small spacer block is welded onto each of the bars.

Next, three-eighth-inch weld nuts are welded onto the side posts. These weld nuts act as a locking mechanism for the adjustable rails. By tightening the bolts on the bars attached to the rails, they can be locked securely in place.

STEP 5 : CROSSBAR WELD

To further improve the functionality and safety of the chainsaw mill, a crossbar is welded onto the guideposts. This crossbar serves a dual purpose – it pushes the chainsaw bar along when the mill is in operation, and it also provides a convenient place to grip the mill.

This additional distance from the chainsaw chain adds an extra layer of safety, as it keeps the operator’s hand further away from the cutting area.

To create the crossbar, a piece of one by one square tubing is cut to the desired length. This will depend on the size of the chainsaw mill and the preference of the operator. The tubing is then welded onto the top of the two guideposts, perpendicular to the direction of the rails.

During the welding process, care should be taken to ensure that the crossbar is level and securely attached to the guideposts. A level crossbar will help ensure smooth operation of the mill, while a secure attachment will prevent any wobbling or shaking during use.

Once the chainsaw mill frame is assembled and the guideposts are securely attached, it’s time to insert the chainsaw blade.

The first step is to place the blade between the flat brackets at the bottom of the frame. Make sure that the blade is centered and straight before proceeding.

Next, insert spacers between the blade and the flat brackets. These spacers will keep the blade from moving or vibrating during operation.

It is important to use spacers that are the same thickness to ensure that the blade is evenly spaced and secure.

Once the spacers are in place, use 3/8th inch bolts to tighten the brackets around the blade and spacers.

Before making the first cut, it’s important to ensure the chainsaw mill is securely fastened to the log. This can be done by attaching a flat plate to the top of the log using clamps or screws.

The height of the cut can be adjusted by moving the side rails up or down, depending on the thickness of the lumber required.

Once the chainsaw mill is securely fastened to the log, it’s time to start the saw. Ensure that the saw is properly lubricated and that the chain is tight before beginning the cut.

Place the chainsaw on top of the flat plate and slowly lower the bar into the log, being careful to maintain a straight line. As the saw cuts through the log, use the side rails to guide the saw and ensure a straight cut. Once the first cut is complete, the log can be rolled over and the process repeated on the other side.

A chainsaw mill converts rough logs into useful boards and beams right where the tree was felled.

We may earn revenue from the products available on this page and participate in affiliate programs.

Store-bought lumber is expensive, and it can vary in quality considerably. For those who have access to a supply of logs, DIY chainsaw milling will almost certainly help save money. It also provides complete control over beam and board sizes and allows for close monitoring of quality.

Chainsaw mills provide a versatile, portable, easy-to-use solution. Many mills are also very affordable, particularly for those who already own a suitable chainsaw for felling or cutting firewood. That said, chainsaw mills aren’t particularly common tools, so many people don’t understand which features are important.

This guide not only offers some helpful tips and suggestions but also takes a detailed look at some of the best chainsaw mills available. In-depth market analysis and thorough product vetting went into creating this list of top picks.

- BEST OVERALL:Granberg G778 36-Inch Alaskan MKIV Chainsaw Mill

- BEST BANG FOR THE BUCK:HiHydro 36-Inch Portable Chainsaw Mill

- BEST COMPACT:Carmyra 24-Inch Portable Chainsaw Mill

- BEST FOR BEGINNERS:Timber Tuff TMW-56 Lumber Cutting Guide

- BEST HEAVY-DUTY:Carmyra 48-Inch Chainsaw Mill

- HONORABLE MENTION:Granberg G777 Alaskan Small Log Mill

- ALSO CONSIDER:XRKJ 36-Inch Chainsaw Mill

How We Chose the Best Chainsaw Mills

As the owner of a large property, I have considerable experience with chainsaws. I am also an engineer by profession, so I have a good understanding of the structure and function of chainsaw mills. When selecting our top picks, I used the following criteria:

- Build quality: Chainsaw mills aren’t likely to be treated with a great deal of care, so a primary concern is how well they’re assembled. Each of the models chosen has the strength and durability to withstand a tough working environment.

- Brand: Many of our choices come from brands that have extended experience in the field and a recognized reputation. However, these units can come at a premium price, so I’ve also considered well-made tools from lesser-known manufacturers.

- Value: Most chainsaw mills are very affordable, particularly when weighing the potential savings over store-bought lumber. Nevertheless, we were careful to pick models with a range of to offer something for every budget.

Our Top Picks

Now, let’s apply this selection criteria to determining the best chainsaw mills currently available. Keep reading to learn more about some of the best chainsaw mills on today’s market.

Granberg G778 36-Inch Alaskan MKIV Chainsaw Mill

The Granberg Alaskan MKIV chainsaw mill takes top honors for its build quality, ease of use, and versatile functionality.

The sturdy construction combines heavy-duty zinc-plated steel and aircraft-grade aluminum. It takes around 30 minutes to assemble, but once assembled, clamping and adjustment are fast thanks to clearly marked depth scales. At only 20 pounds, it’s portable too.

The Granberg Alaskan MKIV chainsaw mill is designed to take a maximum 36-inch chainsaw, and the manufacturer recommends a motor capacity of 70 cubic centimeters (cc) or better. It can take smaller chainsaws, but if working with a smaller chainsaw, consider a lower-cost mill—the Granberg isn’t cheap. The bar clamp takes 3 to 4 inches from the cutting capacity, so using a 20-inch bar, for example, restricts the cut to around 16 inches.

- Bar size: 20 inches to 36 inches

- Cutting capacity: ½ inch to 13 inches thick; 32 inches wide

- Weight: 20 pounds

- A high-quality tool made in the United States that consistently tops independent reviews

- An excellent midrange model recognized for its consistent accuracy and renowned durability

- Can be set up for both left- and right-handed users

- Comes with a higher sticker price than many similarly sized competitors

- Assembly takes around 30 minutes, which some buyers found frustrating

Get the Granberg G778 chainsaw mill at Amazon, Northern Tool Equipment, or Acme Tools.

HiHydro 36-Inch Portable Chainsaw Mill

With a well-proven design constructed from high-quality steel and aluminum, the HiHydro is a premium chainsaw mill at a budget price. Unfortunately, the instructions are only fair, so assembling the mill can be frustrating. However, once put together, it has competitive capacities and should prove durable.

HiHydro claims a cutting width of 36 inches, but as with many competitors, this measurement doesn’t consider the clamp. While these always reduce capacity a bit, on the HiHydro, the loss is around 5 inches—fairly significant. Although the mill can take chainsaws as small as 14 inches, that only leaves a 9-inch cut, which is seldom practical. With this model, experts advise using a 30-inch or longer saw, which makes this an affordable option.

- Bar size: 14 inches to 36 inches

- Cutting capacity: ½ inch to 13 inches thick; 31 inches wide

- Weight: 8 pounds

- Uses a well-proven design and provides good value for money

- Aluminum and rust-resistant galvanized steel should result in good durability

- Light weight makes it equally convenient for home or on-site use

- While it is not difficult to assemble, many feel the instructions are poor

- A number of buyers have reported their packages had nuts and bolts missing

Get the HiHydro chainsaw mill at Amazon.

Carmyra 24-Inch Portable Chainsaw Mill

The Carmyra chainsaw mill uses the same popular and effective design as many competitors. The manufacturer uses a combination of steel and aluminum, resulting in a good balance between strength and portability.

This 24-inch model is particularly suitable for those who only need to mill small to medium-size logs. As is common, the clamp reduces the overall cutting width, in this case by approximately 4.5 inches. This results in a maximum cut of little more than 18 inches. While it’s smaller than many competitors, the Carmyra still produces planks that are useful for a wide variety of projects. For those who mill lumber infrequently or need relatively low lumber volumes, the 24-inch Carmyra is a good choice at a competitive price.

- Bar size: 14 inches to 24 inches

- Cutting capacity: ½ inch to 13 inches thick; 18½ inches wide

- Weight: 13 pounds

- Compact dimensions are ideal for many DIY users with smaller chainsaws

- Despite the relatively small size, it is capable of producing useful 18-inch wide boards

- Competitive price makes it a popular choice with low-volume users

- Many feel that instructions are poor (though helpful videos are available)

- Although welding or component failures are rare, they have happened

Get the Carmyra 24-inch chainsaw mill at Amazon.

Timber Tuff TMW-56 Lumber Cutting Guide

The Timber Tuff TMW-56 is called a cutting guide rather than a chainsaw mill because it operates slightly differently. Nevertheless, it produces similar results, and its cutting capacity is limited only by the size of the chainsaw used.

The heavy-duty steel guide is designed to run along a piece of store-bought lumber, such as a 2×2, 2×4, or 2×6. The user simply nails or screws the store-bought board to a log, bolts the chainsaw bar to the Timber Tuff, and runs the guide along the board. Cutting widths are defined by where users position the board for each cut.

While setting up each cut takes a little more time and care than other types of chainsaw mills, it is light, simple, effective, and comes at a very low cost.

- Made from heavy-duty steel and powder coated to resist corrosion

- Easy to use with standard store-bought lumber as a guide

- Costs considerably less than most competitors and can accept any size chainsaw

- With no preset depth guide, each cut takes a few minutes to set up

- Slow operation means it is not suited to high-productivity environments

Get the Timber Tuff chainsaw mill at Amazon, Lowe’s, Tractor Supply Co., Target, or Grainger.

Carmyra 48-Inch Chainsaw Mill

Those needing to saw large logs will want to take a closer look at this 48-inch Carmyra chainsaw mill. Even with some width loss due to the clamping mechanism, it can still saw boards up to an impressive 43½ inches wide. Like its smaller counterparts, it also has the versatility to mill thicknesses from just ½ inch up to 13 inches.

The design is popular and well proven. It uses a combination of steel for toughness and durability with aluminum to keep the weight manageable. Despite the heavy-duty nature of this chainsaw mill, it weighs only 16½ pounds.

Although rated for chainsaws as small as 14 inches, some bars are too narrow to accommodate the clamp. However, in reality, those with small chainsaws have no need for a mill this large.

- Bar size: 14 inches to 48 inches

- Cutting capacity: ½ inch to 13 inches thick; 43½ inches wide

- Weight: 16½ pounds

- Made from steel and aluminum, so it’s strong but manageable

- A well-proven design scaled up for heavy-duty milling capacities

- Capable of high productivity in hard-working environments yet remains very competitively priced

Get the Carmyra 48-inch chainsaw mill at Amazon.

Granberg G777 Alaskan Small Log Mill

Granberg classifies its G777 as a small-log chainsaw mill. While capacities aren’t equal to the Alaskan MKIV, the G777 is a quality tool that offers versatility in cutting depth. It’s also more compact and lighter than the Alaskan MKIV, making it ideal for field use when more modest log sizes are available.

The G777 tracks across the board’s surface like other horizontal mills, but it’s only supported on one side. As a result, users should take care when setting up the first cut. Subsequent cuts also require FOCUS to maintain accuracy, though most users should acclimate to the tool quickly.

- Bar size: 16 inches to 20 inches

- Cutting capacity: ½ inch to 13 inches thick; 18 inches wide

- Weight: 10 pounds

- A compact mill from a brand known for quality and durability

- Lightweight and portable, making it ideal for milling in the field

- Improved end brackets are stronger, easier to adjust, and more accurate

- Single-sided design lacks the stability of models with twin supports

- It is important to make the first cut carefully, as this impacts subsequent boards

Get the Granberg G777 chainsaw mill at Amazon, Northern Tool Equipment, or Acme Tools.

XRKJ 36-Inch Chainsaw Mill

Featuring a similar design to the Granberg Alaskan MKIV, the XRKJ is a low-cost horizontal chainsaw mill that’s constructed from quality materials. For the occasional user, it also offers good value for the money.

Steel and aluminum construction means that it’s not only strong but also lightweight. Unfortunately, build quality seems to vary, which might make assembly frustrating. Although the minimum bar size is listed as 12 inches, the resulting maximum cut is only around 8 inches. Additionally, chainsaws of that size are unlikely to provide sufficient power, so a 20-inch chainsaw is the smallest practical size.

- Bar size: 12 inches to 36 inches

- Cutting capacity: ½ inch to 13 inches thick; 32 inches wide

- Weight: 16 pounds

- A very affordable chainsaw mill that employs a well-proven design

- Offers competitive capacities and takes a wide range of chainsaw sizes

- A good choice for the user who is milling lumber infrequently

- Despite the capacity, this mill is not intended for regular, heavy-duty use

- Feedback from buyers tells us that build quality can vary considerably

Get the XRKJ chainsaw mill at Amazon.

What to Consider When Choosing a Chainsaw Mill

A chainsaw mill (also called a “chainsaw sawmill” or “Alaskan sawmill”) isn’t a particularly complicated device. However, chainsaw mills possess a number of key features that differentiate them, which has a big impact on choice.

Chainsaw Compatibility

Chainsaw mill compatibility can be considered in two ways: in terms of power requirement or whether a particular make or model of chainsaw will fit the device.

Cutting planks with a chainsaw mill requires a saw with considerable power. While a few cordless chainsaws offer comparable performance for tree felling or log cutting, milling takes a lot of energy and soon drains the battery. The challenge with even the best corded electric chainsaws is overheating. While a safety cutout usually prevents damage to the saw, it makes them impractical for milling.

That leaves gas-powered chainsaws as the only sensible choice. When describing compatibility with a chainsaw, chainsaw mill manufacturers often describe their tools as fitting “most types of chainsaw.” However, restrictions exist in bar length, so a minimum engine displacement (defined in cubic centimeters) is suggested. While some mills clamp the chainsaw bar, a few require it to be drilled to affix it, something many users would rather avoid.

Bar Capacity and Cutting Depth

Chainsaws are usually described by their bar length: 16 inches, 24 inches, etc. When considering chainsaw mills, bar size has a major impact on the maximum diameter of log that can be milled and, thus, the width of plank produced.

However, the stated dimensions can sometimes be misleading. If the mill clamps the bar end, as many do, it reduces the length available for cutting. While bar size is important for fitting the chainsaw to the mill, users will also want to check the mill’s cut size to determine its actual capacity.

Cutting depth is another key feature, and it depends on the type of chainsaw mill chosen. Some cut with the chainsaw held vertically (often called “edging mills”). These offer unlimited versatility, but repeatable accuracy is more challenging. Other mills cut with the chainsaw mounted horizontally, which can be set to a consistent thickness. Most run from ½ inch to 12 inches, though cuts as thin as ⅕ inch are possible. Some large-capacity models can exceed 15 inches.

Ease of Use

Small chainsaw mills frequently arrive ready to go right out of the box, but larger models generally require some assembly. Hardware is invariably included, and the tools may be, but the user may need to grab a couple of wrenches. These chainsaw mills are not complicated devices, but the quality of their instructions varies.

As mentioned, most chainsaw mills clamp the chainsaw bar. Some require drilling, which entails extra work. It’s probably best to avoid those models, as many options exist that don’t require drilling.

Chainsaw mills fall into two categories: edging mills and horizontal mills. Edging mills must be run on a board mounted to the log, and they’re generally used for squaring up logs for building purposes rather than for cutting multiple planks. Horizontal mills rest on top of the log and cut consistent plank thicknesses. Adjustment is usually straightforward via a couple of bolts.

Portability and Durability

One of the biggest advantages of a chainsaw mill is portability. They often weigh just 4 or 5 pounds; even the larger horizontal models seldom go over 20 pounds. Because they’re so lightweight, users can easily take the mill to the felled tree and work on-site. With only the cut lumber to move, a trailer or pickup truck often is sufficient to transfer the wood.

Construction materials are typically a mix of steel and aluminum. Steel offers great strength, so it’s used for the main structural components that hold things together. Chainsaw mills are often electroplated (usually with zinc, nickel, or chrome) to protect against rust. Aluminum is much lighter, so it’s generally used for guide rails. Look for a rugged build with consistent welds and metal with substantial thickness or cross section.

How to Use a Chainsaw Mill

Chainsaw mills are a reasonably simple tool to use, but always follow basic safety precautions. Also, take a couple of important steps when setting up the mill to ensure consistent, quality results.

- Ensure the log to be cut is stable. Use chocks underneath to prevent any chance of it rolling.

- Follow general chainsaw safety rules. Wear substantial footwear, gloves, a face shield, and ear protection. Chainsaw chaps are also a good idea.

- Check that the chainsaw chain is sharp. A blunt chain is not simply inefficient—it’s also more likely to bind or jump off the bar.

- The first cut is key. Used by itself, the mill rests on uneven bark and trimmed branches, which means making a clean, even cut is almost impossible. To remove that rough surface, some kind of guide is necessary.

- Edge mills usually run along a length of shop-bought or precut board that’s screwed to the log.

- For horizontal mills, a jig is affixed to the log. Some people rig up an ordinary aluminum ladder, but getting it level can be challenging. Purpose-built jigs are available that are much easier to adjust.

- Once the outer layer is removed, horizontal mills can rest on the now-flat surface. It’s not a complicated process, but users will want to take care when making the initial cut. It provides the surface for each consecutive cut.

FAQs

The sections above offer an in-depth look at the technical aspects of chainsaw mills, followed by real-world examples. Together, they give the mill buyer extensive information on the subject. However, in researching this article, a number of questions came up that benefit from separate answers.

Q. Should I purchase a chainsaw mill or a Band sawmill?

If you’re looking for an affordable, easily portable tool for sawing a modest number of logs per year, the chainsaw mill is probably the better choice, especially if you already own a suitable chainsaw. A bandsaw mill offers higher productivity and less waste, but most are a lot more expensive. They are more likely to appeal to those who are milling logs commercially.

Q. What’s the best size chainsaw to use with a chainsaw mill?

Each chainsaw mill has a maximum size chainsaw that will fit it. As this is one of those occasions when you can never have too much power, experts recommend using the biggest chainsaw possible within the specifications of the chosen mill.

Q. If I have a smaller bar, can I still use a larger mill?

Often you can, but it depends on the mill. Most chainsaw mills offer a degree of versatility; however, it’s important to check the minimum size. Usually, this is around 14 inches. That said, a chainsaw with a bar that short might not have the necessary power to cut effectively. Also, remember that a smaller bar length restricts the size of logs you can cut.

Q. How big of a chainsaw do I need for an Alaskan mill?

There are numerous models of Alaskan mills, ranging from the smallest, which can take a 12-inch chainsaw, to the largest, which can use a 60-inch chainsaw. It is important not to underestimate your needs. Choose a chainsaw that will comfortably cut the diameter of logs you use regularly. Remember that clamping the chainsaw bar will usually reduce the usable length by 3 or 4 inches.

Q. How long does it take to cut planks with a chainsaw mill?

Chainsaw milling is not a fast process. A lot depends on the log size and material density. Pine, for example, is easier to saw than oak. Knots or twisted grain will have an impact, as will the chain’s sharpness and power. With so many variables, it’s difficult to be precise, though most experts suggest between 10 and 20 minutes per cut as an average.

Q. How much power is necessary for a saw?

When it comes to chainsaw mill work, it is undoubtedly a case of the more power, the better. This is both for cutting speed and minimizing the stress on the chainsaw motor. Experts suggest a 50cc gas chainsaw as an absolute minimum, though 70cc and above is normally recommended. Granberg, for example, the manufacturer of our overall best chainsaw mill, suggests 70cc or bigger for their tool.

Q. What is a ripping chain?

A standard chainsaw chain is designed to cut across the tree trunk for felling or cutting logs for firewood. Effectively, this means you’re cutting across the grain. A ripping chain is designed to cut with the grain along the length of the trunk, so it’s better when using a chainsaw mill.

Q. What are a chainsaw mill’s limitations?

Each chainsaw mill has a maximum depth of cut and maximum width. How the mill clamps the chainsaw blade has an impact, so check the chainsaw mill’s specifications carefully.

Why Trust Bob Vila

Bob Vila has been America’s Handyman since 1979. As the host of beloved and groundbreaking TV series including “This Old House” and “Bob Vila’s Home Again,” he popularized and became synonymous with “do-it-yourself” home improvement.

Over the course of his decades-long career, Bob Vila has helped millions of people build, renovate, repair, and live better each day—a tradition that continues today with expert yet accessible home advice. The Bob Vila team distills need-to-know information into project tutorials, maintenance guides, tool 101s, and more. These home and garden experts then thoroughly research, vet, and recommend products that support homeowners, renters, DIYers, and professionals in their to-do lists.

Turning a Log into a Wood Pile with a Simple Alaskan Mill

Gareth Branwyn is a freelance writer and the former Editorial Director of Maker Media. He is the author or editor of over a dozen books on technology, DIY, and geek culture. He is currently a contributor to Boing Boing, Wink Books, and Wink Fun. And he has a new best-of writing collection and “lazy man’s memoir,” called Borg Like Me.

@garethb2

In this 30-minute video, wood sculptor David Groth runs through his process for breaking down a gorgeous redwood log into 4″ thick slabs that he plans to turn into some outdoor benches for his koi pond. The person videoing him asks a lot of basic and thoughtful questions and Groth is really informative with his answers, making this a very educational and interesting video for anyone [raises hand] who doesn’t know that much about the science of wood growth and the ins and outs of the lumber milling process.

In the video, Groth uses his handmade Alaskan mill to cut the log into perfect slabs. An Alaskan mill is a jig that attaches to a chain saw so that the saw can be suspended from the top of the log to a precise depth. Frequently, as in this video, a rail is attached to the top of the log at a level height and that’s what the mill is suspended from for the initial cut.

Here are a few of the things I learned from watching this video:

Negotiating a Heart Crack

Most boards have a “heart crack” that runs through the heart wood. When cutting a board, you need to determine where the crack is and how it moves through the tree. As Dave points out, this crack frequently twists through the log. In the video, he marks the crack on both ends and then rolls the log so as to minimize the exposure of the crack in the resulting milled lumber.

Removing the Sap Wood

Because this wood is going to be used outdoors, Groth removes all of the outer sap wood (seen here in the pale green outer ring). Outdoors, it would quickly rot. If his benches where going to be used indoors (or in other indoor applications), he would rip the entire width to gain the extra dimension in the lumber. The outside sap wood is cut off and stacked for drying and turning into firewood.

A Sharp Blade Cuts a Straight Line

Dave sharpens the teeth on the saw blade before removing the sap wood. Making sure the teeth are equally sharp and sharpened to the same angle helps to prevent the blade from traveling and producing a line that’s not straight.

A Careful Set-Up Helps Ensure a Perfect Cut

Taking the time to carefully mark a level cut-line on both ends, removing the top bark, and installing a top rail helps in milling out straight and level lumber. Removing the bark makes it easier to nail the rail securely to the log. Once the rail is installed and level, Dave measures down to his desired depth to make sure everything is level and square. If all goes well, when he gets to the end of the log, the blade should exit at the line he drew onto its end.

The Simplicity of the Alaskan Mill

Alaskan mills can get somewhat elaborate (and expensive). Groth’s mill is as simple as they get, a couple of threaded rods that attach to the saw bar, wooden spacers (at various thicknesses) to create the desired depth of the cut, and a top board that either runs along a rail or an already leveled-off and cut surface.

Shims Along the Way Prevent Chain Binding

As the cut is made down the log, shims are hammered in behind the mill to help prevent the cut top from pressing down on the saw bar and binding the chain.

Alaskan Mill Plans on Instructable

David Groth’s video provides most of the info you would need to make your own Alaskan mill. But if you’d like a somewhat fancier, sturdier metal-based mill, there’s an Instructable for building one out of 40mm X 40mm profile T-slot aluminum. Link: Chainsaw Mill Build, Use Tips n Tricks.

You can see David Groth’s chainsaw art on his website. And you can subscribe to his YouTube channel here.

Woodworker’s Guide To Sawmills

via merchant

Light, portable sawmills create a new perspective on lumber for furniture-making projects. Skip the lumberyard and mill the wood yourself.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.

In 2007 I got a call that changed my whole perspective on lumber. I’d been designing and building furniture for five years, buying wood from a great lumberyard. Then my pal from grade school called me. He had a healthy red oak that needed to come down and was wondering if I could use the wood for furniture.

Before then, I hadn’t thought of milling my own lumber from a tree. I had another friend who owned a small chainsaw sawmill, a one-person milling device he was happy to lend me for a week. I’d never used a sawmill before myself. But after a 30-minute introduction to the basics of its operation, I was ready to go. I’ll admit, the process was labor-intensive and exhausting. But each slice of the sawmill was like opening a birthday present.

What Is a Sawmill?

For most people, the term “sawmill” likely conjures images of a large factory that mass-produces lumber. In this case, a “sawmill” is a one- or two-person device for milling lumber, i.e. cutting timber into construction-quality wood.

These sawmills can be set up permanently, stowed in a car or towed behind a vehicle on a trailer. The smallest are barely larger than a chainsaw, and the largest sit on 24-foot-long trailers!

What is a Sawmill Used For?

A sawmill lets a furniture maker accurately slice a log into slabs or planks of wood. This article discusses portable sawmills, but you’ll see some are more portable than others.

How Does a Sawmill Work?

Sawmills feature a cutting blade, a mechanism for cutting accurate thicknesses, and a track for the blade to travel. Some have welded tables as a flat reference point; others use an extension ladder to register the first flat cut.

Operators roll or lift the log into a stable position and lock it in place with wedges. Then the user sets the blade for an initial cut on the front end to define a top, flat surface. The saw blade travels along the track the length of the log and slices a flat surface. The top piece, often waste, is removed, revealing a flat datum from which all other cuts will be aligned.

After each cut, the blade slides back to the front and is lowered to the correct height. The user must take into account the thickness of the blade when measuring. Depending on the size of the log and desired yield, the log may be cut into flat slabs or rotated if certain types of lumber are desired.

Types of Sawmills

Chainsaw mills

via merchant

As the name implies, this type employs an oil/gas chainsaw. These mills are designed for rough use but still require hourly maintenance. Bar lubricant must be topped off, and the proper oil/gas mix is essential for trustworthy cutting.

Chainsaw blades dull quickly. They must be sharpened every hour or replaced and sharpened professionally. When sawing lumber (as opposed to cutting down trees), a thinner ripping bar with a ripping chain is recommended, which still takes a hefty 3/16-in. kerf of wood.

Big chainsaws like the Husqvarna 395 XP and the STIHL 661 excel at powerful and efficient milling. Aftermarket bars as long as 42-in. can be mounted for larger capacity. Always be sure to use a chainsaw safely.

Alaskan style sawmill

via merchant

Designed by Elof Granberg in the 1960s, this style features a chainsaw attached to a lightweight aluminum frame. Users place it atop a log laying on the ground. Granberg makes a range of sizes, from 24-in. and all the way up to 84-in.

The Alaskan-style mill is among the least expensive ways to cut logs into planks, especially if you already own a large chainsaw. Alaskan mills can be loaded into the trunk of a car and brought deep into the woods to cut specific downed trees.

While not the most efficient, the Alaskan mill is the epitome of bringing the tool to the job and can mill the largest trees. One downside: You must always work on the ground. Milling an 18-in.-dia. tree usually requires the user to be on their knees or hunched over throughout.

Chainsaw mill with frame

via merchant

A more sophisticated take on the chainsaw mill, these models lift the chainsaw to waist height. Logosol F2 (1,900), made in Sweden, features a large, lightweight aluminum support frame with super strong log-lifters. The Logosol lifts the log up to 24-in., so most of the cutting happens at waist height or above.

Another option: The North American-built PortaMill PM14 (1,400), with a household aluminum extension ladder guiding the saw.

While the milling is more comfortable with these framed chainsaw mills, raising logs requires some real muscle! Logs can be rolled up ramps or stacked timbers, or ideally lifted by a tractor or skid steer. Cant hooks and other tools can assist in moving the logs to height. These models disassemble in about one hour and are easily transported.

Bandsaw mill

via merchant

Bandsaws drive a wide blade with coarse teeth that spins between two large wheels. Mounted horizontally, the blade slices a 1/8-in. kerf through the wood as it cuts. The blade must be properly tensioned and dulls instantly when it comes in contact with dirt, sand or any embedded fastener. Most are gas-powered.

Numerous reputable brands sell bandsaw mills in various sizes with features that can jack up the price. Embellishments include water-cooled blades, de-barking blades or pneumatic log lifting mechanisms.

Super-simple versions with a flat table like the LumberMan MN27 from Norwood (5,000) can handle a 12-foot-long log with a 23-inch cut capacity. This saw is nice because it sits low to the ground, but care must be taken to level the table for accurate cuts.

On the more expensive end, the Woodmizer LT50 Hydraulic Portable Sawmill (49,000) sits on a heavy-duty trailer and can handle a 36-in.-dia. log up to 21 feet log. A log this size weighs upwards of three tons, so this saw comes with pneumatic arms that lift the log onto the sawmill bed.

Mid-size saws like the TimberKing 1220CRZ (14,000) also sit on a trailer. It can handle a 33-in.-dia. log 17-ft. long. Instead of pneumatics, it features a winch system welded to the frame that helps get logs onto the bed of the saw.

One Last Thing

Logs are heavy! Utilizing an online log calculator, an eight-foot-long, 24-in.-dia. white oak log weighs in at more than 1,500 lbs.! Moving pieces this big requires muscle, lots of friends, or heavy machinery like a tractor or skid steer. Don’t underestimate the labor of moving logs around.

Where to Buy

You can purchase various types of sawmills through Saffords, Fox Forestry or Bailey’s.