Choosing a circular in a tablespoon. Hilti SCW 70, 1700 watts

All about how to choose a saw wooden disk for a circular saw, as well as a rating of the best

The most expensive and high.quality circular will saw poorly if you use a poor.quality, inappropriate or worn disk. And vice versa, any serviceable inexpensive circular saws well with a high.quality disk. The quality of the saw disk is crucial, since the circular only rotates and directs the disk, but as a result, it is it that.

To freely navigate when choosing saw discs, first of all, the value of marking should be studied. Today, discs are available to the buyer from manufacturers of the whole world, but different manufacturers have a different marking procedure, which at first can confuse the consumer a little.

In fact, there is nothing complicated in different markings, and on each disk and packaging all the necessary data are necessarily indicated. The buyer can find them and evaluate them.

Sometimes, instead of the thickness of the disk, the number of teeth is indicated.

Other markings are sometimes used. For example, a simple inscription 250 mm or with a “crossed zero” diameter icon 250.

Some manufacturers complement digital lines with pictures. For example, after line 335.64, 30/32, pictures with explanations are located. A disk with arrows indicating the external diameter and the number 335, teeth and digit 64, the inner diameter with the transition ring, which allows the use of the disk with a landing diameter of both 30 mm and 32 mm, is drawn.

The type of tool for which the disk is intended is a manual or stationary circular can depict.

The main parameters are worth paying attention to when choosing

These are characteristics, with non.compliance with which the disk simply does not fit a specific tool.

External diameter

On stationary circular, especially artisanal manufacturing, can be used discs with a large difference in diameter. Small for sawing thin blanks, large for bulky wood. At the same time, it is desirable to have a set of different disks.

Discure of large diameter to saw thin wood is irrational and inconvenient-unnecessary load loads due to a large lever of the disk, too thick drank, a large ledge of the disk over the workpiece, which reduces the safety of sawing.

The maximum diameter on stationary circular circus is limited to the size of the slot under the disk or casing, if there is one.

Minimum. sufficient protrusion over the desktop.

There is no such scatter in diameters on manual circular circus. a disk of the same diameter that was installed at the factory is used. In exceptional cases, a disc of smaller 3-5 mm of size may be approached, but an important characteristic will change-the depth of the cut. Too much the disk will simply not fit or will cling to the casing.

Landing diameter

In the days of the USSR, only two landing diameters were provided for stationary circulars and endings. 32 mm and 56 mm. Today, manufacturers around the world make landing shafts and disks of different sizes of 18 mm, 20 mm, 30 mm, etc.D.

However, the standards are preserved, although there are more of them. And this is understandable. no backlash is unacceptable here. The disk should sit on the shaft tightly, otherwise it will simply be impossible to work. Too small planting diameter will not make it possible to put the disk on the shaft, too large causes displacement, beating and vibrations incompatible with work.

Sometimes for compatibility of different diameters, transition rings or washers are used. For example, using a washer with an internal diameter of 32 mm and an external 56 mm, you can install a disk with a landing diameter of 56 mm for a 32 mm landing shaft with a diameter.

The transition ring 1 mm thick allows you to use a drive with a 32 mm landing in a shaft with a diameter of 30 mm, and T.D.

Thickness

The parameter matters. Thin discs have a number of advantages and disadvantages over thicker. Advantages:

The latter, especially important when sawing expensive wood. Sometimes only 2-3 mm determine how many, for example, bars will leave the board-5-6 with a saw with a thin disk or 4-5 with a thick cut.

A thin disk makes a 2-3 mm width. Thick-3-4 mm. Sometimes a large disc with a wide divorce of teeth can make a drink of 5-6 mm wide.

- prone to bends, so sometimes a drink can turn out to be wavy,

- they can quickly overheat, sometimes to the degree of “turning”, which can completely disable the disk. Overheated discs begin to “wag” with different amplitude, sometimes up to 10 mm or more.

Thicker and more massive discs work more slowly, but more stable.

Variety

Two fundamentally different types of disks are used:

The former belong to the outgoing type. Widely used in a time when there were no technologies of accurate and strong attack of carbide. However, a number of advantages have been preserved behind the monolithic discs:

- a very long service life, it is limited only by the fact that over time after many sharpening, the diameter of the disk decreases to critical sizes,

- Simplicity of sharpening and editing teeth,

- the possibility of changing the shape and angles of tooth sharpening,

- Lack of soldering, integral strength of the teeth.

Cons. require regular editing, sharpening and dilating, since they are inferior in strength to teeth of solid alloys.

It was expensive, since not only teeth, but the entire array are made of special instrumental steel.

In order to carry and hold cutting teeth from hard alloys, while not wagging, not overheating, other, cheaper steels are suitable. They are used today on disks with attacked teeth.

The quality of such a disk largely depends on the composition of solid alloys. Most manufacturers keep their compositions secretly. However, it is well known that the most durable were the old Soviet discs with the “victorious” teeth.

Today, the alloy is used in alloy carbide tungsten, cobalt and other elements. Simple, domestic discs do not differ in particular durability: they are painted, bounces rations, quickly erased to zero after several sharpening due to small size. But professional expensive discs from brands with a good reputation can serve for a long time and less often require sharpening.

The number of teeth

The cleanliness of the cut depends on the number of teeth first of all. It is important that not only the number of teeth differs, for example, by 10 cm of a circle, but the main thing is their size. If there are a lot of teeth, they are small in size. Small teeth saw more slowly and cleaner, less tear out the material.

Differences in the operation of the disk with a small number of large teeth and large. small ones are very significant.

- When working a large-legged disk is less than friction, the engine is easier.

- The disk is less hot.

- Large rare sawdusts are formed.

- The disk saws faster.

- At the exit, a large tooth can tear out pieces of material, especially on a plywood, a wood-based slab, etc.D.

- Circular stripes, traces of teeth can remain on the cut.

A disk with small teeth and their large quantities form small sawdust.

- It heats up stronger due to friction, wood can burn.

- Requires engine power, since the disk can slow down from friction.

- Small tooth at high speeds less tears the material at the output.

- Cut at high speeds it turns out without stripes, clean, similar to polished.

For simple fast sawing, wheels with rare large teeth are better suited. For a better saw, for sawing diagonally and across the fibers, a tooth with many small teeth is better suited.

Tooth geometry

On all modern discs, two forms of teeth are used:

The form of the first option is well verified, verified and designed. The cutting tip of the tooth thrown forward throws the sawdust. The void under the carbide tooth does not create friction, facilitates the course of the disk, reduces heating. Such discs are successfully used for longitudinal, diagonal and transverse cut.

Criteria for choosing disk saws for rating

Making our rating, first of all, we drew attention to the main characteristics of the tool. Economic work in their own site often does not imply large.scale work on the cut, so the saw for the house does not have to have a maximum power or depth of cut in 100 mm or more. Experienced business executives choose reliable, but light and convenient models that cope with the main tasks of landscaping.

- The depth and corner of the cut. The cut depth directly depends on the diameter of the disk. In various models, from 40 to 65 mm. The cut angle can be from 45 to 90 degrees.

- The power of the tool. The power of the house for the house varies from 800 to 2000 watts. This is one of the main indicators that buyers pay attention to. However, not always a more powerful saw is the best option for buying. It is worth evaluating the totality of all characteristics.

- Disk rotation speed. The speed of the disk rotation directly depends on the power. Household saw has this indicator at about 4500-6500 rpm.

- Pilage dimensions, its ergonomic indicators. For home use, small models with a convenient rubberized handle are suitable for home use. It is worth paying attention to the location of the handle itself: a straight hilt located in the front of the tool often causes inconvenience, preference should be given to a model that has a mushroom.shaped or bracket handle.

Currently on sale there are models of circular saws for left.handed. Convenience in using the tool directly affects the quality and performance of the work.

It is also necessary to evaluate how the outlet of sawdust is organized, where the input of the network cord is located, whether it falls under the cutting disc when operating. The length of the wire itself is also important. if it is short, there will be a constant need to connect through the extension cord.

In addition to the above characteristics, when compiling our rating, we decided to be guided not only by dry numbers and recommendations of specialists, but also by the real reviews of our customers, who in practice felt all the pros and cons of using a particular saw model. What could be more reliable?

TOP-10 best budget circular saws for the house

An important criterion for choosing is often the optimal ratio of price and quality of the tool. We present you the top 10 inexpensive, but, of course, high-quality disk saws for everyday life.

| Place | Name | Advantages | Grade |

| one | Bosch PKS 55, 1200 W | Assembly quality, thought out ergonomics, so it is convenient to work with a saw, a well.known brand and democratic | 4.7 |

| 2 | BlackDecker CS1550, 1500 W | The case is made of high.quality plastic, a good whole.lit sole, a medium.power engine. 1500 watts. | 4.7 |

| 3 | Interskol DP-190/1600M, 1600 W | Long cord. 4 meters, powerful engine. 1600 watts | 4.6 |

| four | Hyundai C 1400-185, 1300 watts | Good, well.known brand, positive reviews | 4.6 |

| 5 | Kolner KCS 160/1300, 1300 W | Small weight, only 3.5 kg, even with small engine speeds. 4800 rpm, gives a pure cut. | 4.3 |

| 6 | Hammer CRP 1300 D, 1300 W | Long cord. 3.5 meters, in the standard configuration, a high.quality disk that provides a pure cut. Good assembly quality, without gaps, without sharp edges. | 4.4 |

| 7 | Interskol DP-140/800, 800 W | Long cord. 4 meters, good assembly. | 4.4 |

| eight | Bort BHK-185U, 1250 W | High.rotary engine. 6000 rpm, good drinking depth. 64 mm. | 4.4 |

| 9 | Kolner KCS 210/2000, 2000 watts | Powerful engine. 2000 watts, large disk. 210 mm and, as a result, a good cut depth is 73.5 mm. Low | 4.7 |

| ten | Zubble PDP-65, 1600 W | Thoughtful ergonomics, using a saw is very convenient. Accurate and convenient scale for adjusting the angle and depth of drink. | 4.5 |

Next is a more detailed analysis of each tool, the main technical characteristics, pros and cons are given, as well as real reviews of owners from the Yandex marketplace.Market with whom we are sure to buy.

Reviews can be both positive and negative, but most of the reviews about all the tools observed in the article are positive.

And also after the reviews there are the best suggestions for the tool in your region, by which you can buy it for a couple of clicks with home delivery.

Bosch PKS 55, 1200 W

The compact Bosch PKS 55 disk saw is convenient to use, the market is one of the most inexpensive. A well.known brand causes the trust of buyers, which is subsequently justified by the working and uninterrupted work of the tool.

The photo shows that there is a high.quality parallel emphasis complete with the circular. It is a rarity.

In this model, using screw clamps, the angle of inclination of the disk is easily adjustable. If necessary, replacing the disk itself will not be difficult: this will require only a hexagonal key.

The handle is rubberized, very convenient when performing work, does not slip in the hand. Weight almost 4 kg. This is not the easiest option, but when performing short.term tasks will not become an obstacle.

In non.working state, the saw disk is reliably protected by a steel casing. All details are solidly adjusted to each other, made of high.quality durable material.

The cut depth allows you to cut thick floor boards or small bars.

The Bosch PKS 55 model with the letter A has a pitch nozzle in the marking, which is very convenient when performing work in the room. True, there is such a saw a little more.

Bort BHK-185U

Disco saw rating on wood begins the most budget option. But if the owner needs a tool that can easily cope with his direct responsibilities, then you need to pay attention to this model. For a home master more and does not need.

Refined disks with a diameter of up to 185 mm are suitable for the tool, which can be installed on a twenty.millimeter spindle. Despite the very low price, the model is equipped with a good 1250.watt electric motor. This allows you to get pretty decent speed.

At a speed of 5600 rpm, it is completely easy to cope even with large volumes of work. And in a short time. The convenience and speed of the process is also facilitated by the small mass of the tool. For a normal man, the weight of 4 kg will be practically invisible.

The device allows you to adjust the angles of inclination of the cutting tool. With a direct cut, you can delve into 64 mm. If you set a disk at an angle of 45 degrees, the cut can be done to a depth of 40 mm. The accuracy of the cut and the stable positioning of the saw is ensured by a set of parallel stops, which are included. But the measuring ruler on the device is absent.

All this makes the tool even more popular among home masters. And among reviews, in addition to the low price, you can often find words about high.quality crushing and solid assembly. And since no one expected more for such cost, they say little for the shortcomings.

Patriot CS 195

The saw has a rather strong electric motor. Its capacity of 2 kW allows you to promote the spindle up to 5500 rpmings per minute. Therefore, the tool easily copes with any wood. Even very hard varieties.

Dive depth. 65 mm. The cut angle with direct can be replaced by 45 degrees. over, the regulator is very convenient to use. Disk mills must be selected with a hole for planting with a spindle with a diameter of 24.5 mm.

The model on the sole has holes for reliable fasteners to the countertop. And fixation for the inpatient position of the tool is very simple and easy to perform in a short time. There is also a connector in which a vacuum cleaning hose is connected. The device allows the saw work in complete comfort. Without dust and chips scattered throughout the room.

Users also note the convenience of an ergonomic handle covered with rubber. This allows you to use more confidently not quite a light manual saw. The weight of the device is given by a strong electric motor. Therefore, the manufacturer tried, where it is possible to facilitate the design. For example, used a sole from aluminum alloys.

Ergonomics

When constructing a disk saw, manufacturers try to put up all the nodes so that the tool is as convenient as possible in work. For some manufacturers it turns out better, others are worse.

To evaluate convenience, just pick up several different models. Even with an unemployed engine, the difference in weight, layout in the center of gravity will immediately be noticeable.

Everything matters. how conveniently the handle lies in her hand, what is the coating, the total weight of the tool, whether the saw hangs freely in a horizontal position, or you have to make efforts to leve it to the working position.

Especially for left.handed people there are models made in a mirror location.

The accessibility of the viewing of the guns of sawing in front of the platform is also important. They are guided by them to make a flat drink on marking.

The removal of sawdust in all models is organized through the pipe. If desired, you can fix the bag to collect sawdust or a vacuum cleaner hose so as not to clog the workspace.

The vacuum cleaner is connected quite rarely. But without it, some budget models already show a disadvantage during operation. the challenge pipe can constantly be clogged with sawdust, especially when sawing raw wood. often this happens if the pipe of a small diameter and complex shape.

Equipment

Almost all circular, regardless of the brand, are sold with standard configuration:

- The key for unscrewing the disk (plus the key for fixing the shaft, if the design of the spindle is not provided in the design).

- Parallel sawing.

- Sawdock bag or adapter for a vacuum cleaner hose.

The guide tire has a large length and is rarely offered in the standard configuration. And you need to pay money for it, but someone does not need it. Why overpay? When it is required, you can purchase it separately.

Thus, the difference in configuration practically does not affect the purchase price.

An example of a standard set of a wood saw saw. one. Saw. 2. Box. 3. Adapter for installation in the table. four. Parallel emphasis. 5. Disk change.

The main selection criteria

Power, speed, disk diameter, cut depth

The diameter of the cutting disk (external, not the size of the landing hole). it can be said without exaggeration that this is the main parameter of the circular. Based on it, manufacturers are forced to arrange a specific model. The larger the disk, the more powerful the engine should be to promote it to the desired speed, the more torque will be required to maintain this speed and there is no jamming, the more technologically the stabilization system should be so that there is no beat, vibrations and noise, the harder it is. more overall, it will be more expensive to saw. But on the other hand, large equipment allows you to saw more massive blanks, material of greater thickness.

However, it is not enough just to pay attention to the size of the circle, it is much more important to have an accurate idea of the maximum depth of cut. The developers almost always indicate these parameters in passports, and for both perpendicular and for a mowing cut. There is some conditional separation:

- Light class (40-50 mm). sheet materials, work “in place”.

- Middle class (50–65 mm). the most common, universal.

- Heavy class (65-140 mm). these are massive, purely professional machines.

The convention is that many companies give out their special classification (Makitians, for example, do not release the kids at all and move a little in this matter). It turns out that we, ordinary users, can only listen to our needs, choose priority in the ratio of “maneuverability/universality/strength” based on the specifics of the alleged work. For example, Hitachi C13U (weight 13 kg, 335 mm disk, 2000 watts) and Hitachi C6MFA (weight 3.4 kg, 165 mm disk, 1010 watts). The ratio of the depth of direct cut for these models: 128 mm to 57 mm, respectively.

Left: Hitachi C13U, right: Hitachi C6mfa

I would also like to note that in the case of emergency need, it is possible to cut a very voluminous part by making a drink on both sides (yes, for the correct work, the disk does not have to go through the workpiece through).

What else gives a power supply? If there is a need to compare the two circulars with the same depth. then a stronger motor of one of them will provide better frequency stability, more continuous operation, and will allow more dense material to quickly cut. The watts under the hood traditionally correlate with the diameter of the equipment and, again conditionally, the units are credited to one of the three corresponding classes:

Makita 5143r

Disk rotation speed. what it gives, except for the speed itself? There are two main nuances. The first thing the shaft moves faster, the cleaner the cut (however, cleanliness more depends on the type of disk. the quantity and shape of the teeth). The second, high speed is the opposite of the torque. The third, high speed is high temperature, and some plastics may begin to melt during sawing. If the frequency has become a stumbling block (read the “choice”), then you need to compare saws with the same diameter of the cutting disk. Even better, find a model with idle frequency adjustment.

Electronics guarding order

Advanced circular are stuffed with electronic systems for the eyeballs. This is quite predictable, since this tool is powerful and dangerous. the user needs to help so that the mission is not impossible. If there is a financial opportunity, you should not refuse additional options, there are no unnecessary trifles for the performance and safety.

For the benefit of the correct speed regime, a system for maintaining a constant speed of spindle rotation under load is working, the so.called constant electronics (Dewalt DWS520K). A special controller constantly reads the speed with a local speed fall (for example, when the supply accelerates or when the equipment gets into the compacted material zone), it is stabilized by automatic increase in the outgoing power. The probability of jamming the disk is almost zero, but the cut quality only improves. Obviously, this requires a certain power reserve (this is a prerogative of relatively large machines). Another point is the idle speed adjustment, pre.installation. It is needed for manual selection of process parameters for materials with various physical characteristics (Metabo KSE 68 Plus). Not all models can boast of such an option. And, by the way, the possibility of pre.installation is not a prerequisite for the presence of constant electronics, the only affordable frequency can be stabilized.

Metabo KSE 68 Plus

In order not to overload the network when the tool is turned on, since the starting currents, albeit in a short period of time, significantly exceeds their value-almost all more or less powerful circular launches have a smooth start system. The equipment does not accelerate immediately, which eliminates the leap of the tool and protects the parts of the gearbox from unnecessary shock loads, the aggregate lives much longer (“Fiolent” PD 3–70E).

If the operator is in a hurry to complete what he has begun and does not listen to the “well.being” of the disc saw, then the system of protection against overloads will receive a signal from overheated engine windings or react to a sharp difference in power consumption and turn off the power, maintaining the performance of an expensive tool.

The electrodynamic brake sharply stops the disk after the release of the starter (AEG BKS 18). The system is designed to protect the operator from a possible injury, a part from damage, and the machine from the reverse blow.

AEG BKS 18

Mechanical features

With a deaf jamming of equipment, the motor can fail very quickly, there is a chance of a reverse blow. To protect against such trouble, sliding clutch is used. The working shaft of the motor will continue to rotate even with a fixed disk. Do not worry, the system does not work unnecessarily.

Features of choice

Among the whole variety of machines for wood work most suitable for the ordinary layman will be the saw circular electric table. This is a more practical option than a manual model that has the advantages relevant to any home master.

To be satisfied with a satisfied choice, we advise you to very carefully approach the issue of choosing a desktop circuit. You can make the right decision if, when studying various models, you take into account the following nuances:

Appearance

Knowing about the existence of such models of circulars as Makita, special scales 2000 and others from well.known manufacturers, even a person far from the woodworking sphere can easily choose a suitable model of circular saw.

However, dozens of other circulars who deserve attention can be found in the market. And each of them is distinguished by its technical and operational characteristics.

First of all, you need to most carefully examine the appearance of the machine. We advise you to pay attention to the following points:

- In what condition is the working surface, from which material it is made.

- Whether disk elements are reliable, as well as other important nodes of the machine.

- What power indicators are given on the device.

- Is the fastening of disk units conveniently made, how easy it is to change the disk yourself.

- Try to determine the weight of the car, for this you need to pick it up. A good table machine must be heavy, otherwise it will not be able to solve serious problems. Otherwise, already during the sawing process, you can be very upset by a perfect purchase.

- Ease of use. Try to at least approximately understand whether it will be convenient for you to saw such a machine workpiece. Table models can be made in a variety of configuration options: some buyers can calculate them convenient, but it will be difficult for others to understand the first time to which side to approach the cars.

- Availability of discs. When buying consumables from Italian and German manufacturers, you can not doubt their quality and reliability. However, the disks can differ in terms of availability. We advise you to find out in advance whether you will have problems with the purchase of a disk. Sometimes there are such models for which it becomes very problematic to get the desired disk for wood, metal or metal.

Functionality

Table disk saws belong to the category of machines that can be used not only for woodworking. Therefore, we recommend that before buying, you can familiarize yourself with the capabilities of the model that interests you so that you can use all the potential available to it.

Circulars from such well.known manufacturers as Makita, special and others are supplied with interchangeable disks that support work with materials such as:

Аккумуляторная циркулярная пила Hilti SCW 22-A. Подробный обзор и тест циркулярной пилы Хилти

Solving the issue with the equipment for the circular, you will have to purchase several different disk elements. Keep in mind that each disk can only be used to work with specific material. Therefore, when choosing the disk you need, be sure to consider this moment.

Safety elements

Each master must comply with certain safety rules while working on the circular. However, even in this case, one cannot be sure that he will not be injured. It is necessary that the circular machine itself meets certain safety requirements. For this, the corresponding elements of protection are responsible in modern machines.

To be sure of your own safety, we advise you to find out when choosing a circular, what kind of protective devices it is equipped with. On machines from such well.known manufacturers as special, Makita, the following components are necessarily present:

- overheating protection device;

- protection system in the case of sawing saw;

- emergency shutdown mechanism;

- electronic control systems;

- buttons for protection against random inclusion;

- nozzles;

- restrictive framework.

In no case do we recommend saving to the detriment of security. This should be remembered even if you buy a tool for home use. Today you can buy a circular can be at least 20 tons. R. In stores you can have more expensive models designed for use in private workshops.

For time.tested installations from Makita, you will have to lay out about 33 tons. R., and buying no less popular special cars will cost you 10 tons. R.

Repairs

In the case of the failure of the circular machine, many people think for a long time before doing the repair of the unit with their own hands. Regardless of the complexity of the device, we advise you not to take on this business, but to entrust the repair to specialists:

- It is very difficult for a beginner master to understand the level of complexity of the upcoming repair, unlike a more experienced professional.

- A specialist can easily determine the scale of the breakdown and the chances of returning the tool to working condition only by looking at the device of the machine, as well as knowing the features of its manufacture and other important characteristics.

- If you have failed a desktop saw, which has not yet expired, then we do not advise repairing it on your own. It is best to give it to the service center, where you will be repaired without any fee with high quality.

- If the warranty does not work on your machine, or in your case there is an event that does not fall under warranty repairs, then you can contact a friend of the experienced master and agree with him about the repair of the saw. It is not worth doing this business independently, nevertheless, not everyone can cope with this task.

Description of the Interskol saw

This desktop power tool is perfect for sawing oak blanks. The unit has a working capacity of 3.1 kW. The design system of overload protection is not provided. Has a high rotation speed, which is 3200 rpm. In the back of the case is the power regulator.

This is the perfect solution for sawing pine boards. In the model, the teeth are located at an angle of 35 degrees. The system of protection against overheating of the shaft is not provided. The unit has a carriage of 8.4 cm wide. There are ventilation holes near the handle.

As you can judge from customer reviews, the tool is equipped with a fairly high.quality brake. The rotor functions. For a more accurate setting of the tool frequency, there is a regulator. In stores, you can purchase an Interskol table circular saw for 18 tons. R.

Technical characteristics of circular saws

When choosing a circular home, first of all, pay attention to the technical characteristics that are given below.

The power of the electric motor

Power affects the performance of the tool. The higher this indicator, the more thick products can be cut with a saw.

In the carpentry, there are 3 classes of circulars, depending on the power:

- Up to 1000 watts. light and compact devices designed for cutting plywood or thin boards.

- 1000. 1500 W. semi.professional saws for use at a small construction site. Suitable for cutting small bars, logs or thick boards. If used at home, then such a saw will last longer than low.power.

- From 1500 W. a professional tool with a large engine resource allows you to work up to 6 hours a day with interruptions.

Disk rotation frequency

Characteristic affecting the speed of work. Most often this indicator directly depends on the engine power. When processing solid wood at high speeds, the risk of jamming the working body from the resistance of the material is reduced. Semi.professional models have a rotation frequency of 5200. 6000 rpm. this is a good indicator for purchase.

The depth of the cut

One of the main criteria for choosing a circular is the depth of cutting of the material. Characteristic directly depending on the power and diameter of the cutting disk. When buying a household saw, the maximum depth of cutting does not exceed 55 mm, and a professional tool will easily produce wood with a thickness of 80 mm or more.

- From 40 to 46 mm, which is considered low depth, and a tool that satisfies this parameter is everyday.

- From 50 to 55 mm. the saw is able to cut thick floor boards or small bars.

- From 65 to 70 mm. using the tool, you can cut the unnecessary elements of the frame of a wooden house.

- From 65 to 140 mm. a professional saw, which can quickly produce small bars, or several boards at the same time.

Work at an angle

This characteristic is more likely to the basis of the device than the saw itself. The bed on some hand saws has runners and a stopped mechanism for the possibility of setting an angle of inclination, which is convenient when working with doors, skirting boards or furniture.

Which sole (platform) is better?

All experts write that a cast sole is best. But saws with a good cast sole are expensive.

The main thing is to look at the quality of the sole, and not at the production method. Even if the sole is forged, but thick and stiff, then such a sole is not almost worse than a cast.

Circular at a price of up to 5000 mainly flimsy stamped sole.

Daws with a price of 5000-10000-cast or stamped, but thick and hard!

Type of battery

Wireless devices operating from batteries allow you to cut wood in any inaccessible place. Although it sounds like an advertising slogan, it is really a useful type of tool. If you are dealing with saws once every half a year, then the battery saw you do not need anything, this category of saw is more suitable for professional use.

There are two main types of batteries for household power tools:

- Lithium-ion (Li-Ion)-modern batteries that do not lose the capacity after energy replenishment at any level of residual charge. Of the minuses. low frost resistance. the battery loses its effectiveness during operation at negative temperatures (this is in theory). In practice, people calmly work them in the cold and in the heat.

- Nickel-cadmium (Ni-CD)-obsolete, but still widespread batteries. To replenish the tank, they require complete discharge, but at the same time, convenient when working in extreme conditions. It is better not to buy such batteries, and there are not many of them left on the market.

Battery voltage. 3 main types are found on sale. 10.8 V, 12 V, 18 V. As a rule, the higher the voltage created inside the battery, the more powerful the tool. The best batteries in the market are the products of brands such as Metabo and Bosch. Before buying a new nutrition element, it is necessary to study what kind of voltage range a specific device is designed.

Whether the level is needed, or a laser pointer?

This option allows you to accurately adhere to the saw trajectory during the operation of the tool, as the beam indicates the direction of movement of the saw. However, the presence of such equipment does not guarantee the perfect result, since its achievement depends on the experience of the master and the firmness of his hands during work.

Do you need speed adjustment?

An important function in professional work with wood, as it allows you to set the desired mode for cutting a specific type of material. The speed indicator also depends on the width, the size of the teeth and other characteristics of the cutting disk.

Do you need a smooth start?

Also a convenient option, because a gradual set of engine power without jerking does not overload the power grid and prevents the rapid wear of the motor. Of course, with frequent turning on and off cycles, the time for processing the material increases due to prolonged acceleration of the disk, but the engine will be saved from sharp voltage jumps. But such an option is found only on expensive circular saws.

The technical characteristics of the circular saw directly affect its cost. So, the cheapest model will work at low speeds with low useful power, which is why problems are possible, and an expensive professional tool will cope with almost any specialized task.

Which circular saw to choose for a home or cottage

The acquisition of a new circular saw can be a real problem for a beginner, taking into account a large selection, dispersion of the price and parameters of the product at the outlet. When choosing the most suitable tool, it is necessary to be guided by the following principles:

- In the event that the country or at home constantly requires a tool for performing standard construction or finishing work, a circular saw with an average capacity of 1500 W and a cut depth of at least 55 mm is suitable. If you need to dissolve the board along, then power is needed from 1600 watts.

- If thin pine boards, for example, a lining, as well as a laminate or plywood are subject to open, then the power of up to 1000 watts with a cut depth of up to 40. 45 mm will be enough.

- If you need to make a cut in hard.to.reach places where you need to keep the device on weight, the best solution will be to buy a battery tool with a small diameter of a saw disk.

- When it comes to the construction of a wooden house and prolonged use, it is better to opt for professional equipment with a capacity of 1.9. 2.2 kW.

- If you need to arrange an opening under the sink or hob in the countertop of the kitchen set, you should use an electrician.

- If it is necessary to constant wood harvesting for large construction or for sale, you should consider the purchase of a stationary disk saw.

The final decision on the purchase depends on the type of upcoming operation and kind of master’s activities. If the work is associated with woodworking, in most cases, only a professional tool is suitable, and with domestic use 1. 2 times a month, it is worth choosing a choice on budgetary inexpensive models.

How to choose the right desktop sawing machine?

By and large, all such devices have a similar design, but often they can have additional elements that allow largely expand the functional side of the tool, increase the safety of handling it. The product is placed in a metal or plastic case with one or two handles. Due to a high number of revolutions for safety, the saw disk is closed with a special protective casing, which opens only when the tool is brought to the workpiece.

There is still a platform that helps to keep the disk in a given position. Included with the product, a crumbling knife is supplied. with its help it will be possible to free the canvas if it gets bogged down in the material. The required number of revolutions is achieved using an electric motor, on which a disk is installed using bolts. One of the main features of circular saws is the ability to saw the material exclusively in a straight line, arc cutting is not provided here.

Depending on the depth of sawing, the tool can be divided into several groups: small ones (they are able to drink material to a depth of 46 mm), medium (up to 55 mm), large (up to 70 mm) and professional, in which this parameter can reach 140 mm. It is most convenient to use desktop zirular saws. When they are used, the tool is stationary, only the sawing material moves. If necessary, you can cut the workpiece at different angles in the longitudinal or in the transverse direction. One of the key advantages of this tool is a small mass and high mobility level. With it, you can work with blanks whose width exceeds 60 cm. However, the device vibrates quite strongly in the process of work, which can negatively affect the final quality of the cut.

When choosing the device, you should definitely pay attention to the engine power. In this regard, the devices can be divided into three groups: low.power tools have an engine whose power does not exceed 800 watts. With their help, it will be possible to cope with light products. Universal products are equipped with an engine from 800 to 1200 watts. Professional constructions have a capacity of over 1200 watts.

When choosing models to include the best desktop sawing machines in our rating, we took into account all the above factors, and also paid attention to user reviews and the ratio of price and quality. In the review, you will not find very expensive products, since we tried to include here only products of acceptable cost so that each of our readers could choose the device for himself. Now is the time to start the analysis of the operational characteristics of specific models.

Ten best models of desktop sawing machines

Dewalt DW745

Despite the low level of power of the electric motor, these products can be used not only in domestic conditions, but also in the framework of a small production. The largest width of the workpiece is 315 mm on the left side and 610 with the right. If you saw at a right angle, then the maximum saw depth can reach 77 mm. If you do it under an inclination of 45 degrees, this parameter is reduced to 57 mm. Rubbed legs largely reduce the level of vibration of the tool during operation, which positively affects the accuracy of the tool. When developing the apparatus, engineers established reliable protection against overheating and overload here. If the disc is stuck in the material, then the protection system that will turn off the engine will work and will not allow it to burn out.

The technique is placed in a steel frame, which reliably protects the tool from various kinds of physical damage, inevitable during construction and repair work. In addition, a reliable dust removal system is provided, thanks to which the fishing line for the cutting trimmer will always be visible. The mass of the device is 22 kg. The overall dimensions of the tool. 577x742x425 mm, table area. 630×570 mm. Here it will be possible to use a cutting disk with a maximum diameter of 250 mm, the number of revolutions reaches 3800 per minute. The angle of inclination of the disk is adjustable from.3 to 48 degrees.

- Quite accurate emphasis that provides high accuracy of work;

- Power is quite enough for use at home;

- There are legs that allow you to extinguish excessive vibration;

- There was no schedule on the shaft of a disk.

METABO TKHS 315 M DNB

This is a professional tool for increased accuracy, however, you can work with it exclusively in the workshop, since it operates only from three.phase current. The device is equipped with high.power electric motor. 3100 watts. The maximum diameter of the saw disk can reach 315 mm, which provides a high level of performance. Parallel and angular stops are supplied with the tool, the height of the saw canvas can be adjusted depending on the specific needs. The maximum speed of the saw disk is 2990 revolutions per minute. The highest cut depth at right angle of the canvas is 85 mm, if the cut is led 45 degrees, then the parameter is reduced to 53 mm. The developers’ tools turned out to be quite heavy. 77 kg, and the size of the site is 800×600 mm.

The unit case is made of sheet steel of increased strength, which is painted with powder paints, the countertop is made of galvanized materials. There is a mechanism that allows you to lengthen the work surface if there is a need to work with wide blanks. Well thought out a sawdust removal system. For comfortable transportation, the machine has wheels and handles.

- You can saw rather large blanks;

- Suitable for both rough and accurate sawing;

- The highest quality of manufacture and assembly;

- There is everything you need for comfortable work.

Bosch AdvancedTablecut 52

Multifunctional universal products, designed for both straight and long.term and even angular sawing of blanks made of wood of various breeds, starting the most soft and ending with the most gesture. The tool is perfect for home use and for the workshop. It occupies a minimum amount of free space, in addition, with its help you can dissolve various woody and chips. The vertical angle of the saw is adjustable from 0 to 45 degrees. The original possibility is to adjust the horizontal angles of sawing from.60 to 60 degrees. Changing this parameter is carried out due to a special pulling lever and rotary handle.

Saw canvases do not require special service during operation. there is no need to lubricate them or tighten them. Sprinking is carried out without vibration through the use of the latest nanoblade technology. Using the SDS system, you can replace the saw canvas manually, without using the key. The device has a rather long period of warranty service. 3 years. At right angles, the maximum cut depth is 52 mm, with an angle of inclination of 45 degrees. up to 35 mm. The mass of the device is not very large. 8.5 kg. The product is equipped with an electric motor, the power of which is 550 W. A universal shield is delivered in the kit that does not allow the chips and sawdust into the eyes of the operator, there are pushers and supports that protect their hands when sawing any blanks.

- The device allows you to cope with almost any household tasks;

- It is possible to adjust the angle of inclination with an accuracy to a degree;

- The sawing canvas does not need to be maintained;

- There are protective tools that ensure the security of the operator;

- Long operation;

- High quality manufacturing and assembly.

Metabo Tkhs 315 C DNB

The model was developed to work with wood and building and finishing materials made on its basis. Can be used both in domestic conditions and on the construction site. Engine power is 2800 watts. Its performance indicators allow you to solve even quite complex problems. The set of parallel emphasis is supplied, providing an accurate and straightforward cut. The diameter of the saw disc is 315 mm. much higher than the average indicator. It provides a sawing fairly thick boards. It is possible to expand the base for blanks, so that you can comfortably and easily work with wide products.

TOP-20 of the best circular saw for home

We will talk about each device in detail, indicating the main technical indicators, advantages and disadvantages, prices. You can also familiarize yourself with the opinion of users who have already purchased these power tools.

Interskol DP-190/1600M

-

With the Interskol DP-190/1600m circular saw, you quickly and smoothly saw parquet, sex boards, laminate, plywood and other building materials in the right sizes. In addition, the design of the power tool allows you to adjust the cutting depth, and you can also connect a regular vacuum cleaner to collect sawdust so that the workplace always remains clean. Safety is ensured by a reliable protection system against random inclusion. Characteristics

- long cord (4 m);

- smooth start;

- deep cut (65 mm);

- It is convenient to regulate the height of the cut;

- reliable design;

- functionality.

Bort BHK-185U

An inexpensive, but good model of a disk saw, has a fairly high power, opens a review. 1250 W is enough to easily and quickly cut even a hard, order of dry wood. It’s nice that the saw is equipped with an additional set of brushes. The weight is only 4.1 kg, which greatly simplifies the transportation process, doing the work really easy and comfortable. The speed of rotation of the disk reaches 5600 rpm, so that even a large number of boards, bars and other lumber can be cut in the very short time. The diameter of the disk is 185 mm, which provides a cut height of 64 mm. In total, all this makes the tool a very successful acquisition. At least if this is not the best budget model of a disc saw, then, definitely, it is one of those.

Elitech PD1255P14

A device for accurate work is suitable. The configuration has a guide canvas, as well as fixers. All this will allow the tool to work on the processed surface. It will also be possible to cut in the intended area. All this is especially useful in the case of symmetrical work.

In size. this is a compact device. The handle is length. Due to this, the unit can be used using 1 hand. Part of the device from the upper part is covered with stripes with a rubber surface. Also in the presence of the second supportive handle.

The engine is equipped. In terms of power characteristics, it is 1200 watts. This is enough to cope with different types of materials. There is a special discharge where you can connect a vacuum cleaner.

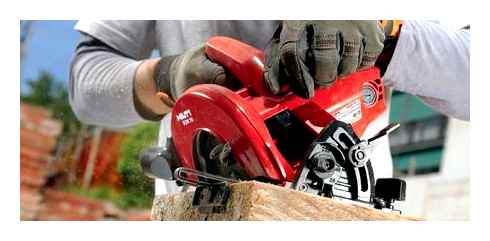

Циркулярная пила Hilti SCW 70

- The casing is made of durable metal;

- The diameter of the drive is 160 mm, which is enough to perform cuts in a depth of 55 mm and 41 mm with angle;

- the backlash in the places of the main attachment are not seen;

- shafts in the area of bearings rotate;

- The case is compact in size;

- The size of the disk occurs on the market often, if necessary, it can be easily replaced;

- 5500 revolutions at 1 minute enough to do the work.

- high;

- There is no rubber coating on the second handle;

- weight 4.8 kg, which is uncomfortable with prolonged work;

- there is no brake disk;

- Drinking tires can find a gap that needs ending;

- 2 m cord, which is uncomfortable when moving in work;

- revolutions are floating if you change the type of load;

- lack of smooth launch;

- An uneven sole comes across.

Bosch Universalcirc 12 0

Before you, of course, is the best battery saw of the rating. Its mass is only 1.4 kg, which allows you to work for a long time, not knowing tired and performing a large amount of work. A disc with a diameter of 85 mm provides a saw 26 mm with a depth. for small work it is quite enough. Drank very even and neat due to the speed of rotation of 1400 rpm. Important additional functions are the connection of the vacuum cleaner, locking spindle and backlight. With all this, the noise level during work is small. about 80 dB. With all this, this saw is one of the best in reliability, after all, Bosch is a really serious company.

Bosch GKS 190

This model of the device is popular thanks to a good ratio of price. quality. Of course, it is expensive, however, the quality of the tool is on top. Great assembly quality provides a long service life, and therefore you will not regret the purchase. A fairly high power of the device with small weight allows you to work comfortably and with pleasure, which contributes to and blowing the working area from sawdust. The function of blocking random inclusion makes the device as safe as possible.

- neatly drank;

- excellent assembly;

- convenient in operation;

- long cable (4 m);

- solid cut depth (70 mm);

- Good power.

Bosch GKS 12 V-Li

Professional saw, which will be required by the master, which is engaged in the processing of the floor. Using the device, you can cut off laminate, plywood, parquet or PVC plates. The saw was made in accordance with the pistol.shaped form. The handle is rubberized. Management is carried out at the expense of one hand. This is quite convenient, because the apparatus is 1.4 kg.

The design is compact. It is easy to perform different manipulations, even if the space is limited. Changing the angle of inclination of the supporting plate is possible due to the screw from the end part. Sawed in depth will be 26 mm.

Safety precautions when using

Before you start working with a power tool, be sure to study the safety rules that are described in detail in the instructions attached to the device. We, in turn, will remind you the main points:

- The sawed material must be securely fixed on a stable (non.staggering) horizontal surface at a convenient height to you.

- Under no circumstances can the work of the saw turn the disk up.

- The disks used must fully comply with the nature of the material with which you work.

- You can not use less diameter discs than provided by the manufacturer to avoid the formation of a dangerous gap between a rotating disk and a protective casing.

- You can not bypass (shunt) the shutdown button or by mechanical ways to clamp the start button in the “Inclusive” position.

- You need to work with a saw only in special glasses that protect the eyes from flying sawdust and dust.

- Any manipulations with a power tool need to be carried out in the off state.