Choosing a Tile Cutter Manual Or Electric

When laying tiles, you need to cut it. There are many ways to do this. from scratching the furrow with a drill or glass cutter, to using stationary industrial equipment.

The choice of type of tile cutter depends on the amount of work, material (tile, ceramics, marble, porcelain tile). The tile cutter can be manual or electric, compact or stationary.

For the speed and convenience of work, you pay your money. We will help you make a choice, and tell you what options it makes sense to spend money on.

How to choose a manual tile cutter?

The tool involves the use of muscle strength. Performance is not so high, but you can save on the purchase.

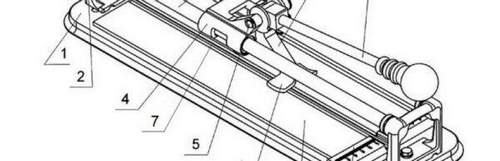

Consider the basic device:

- Base. The bed should be strong, not bent diagonally and not bend in length. The main parameter is the length of the desktop. For wall tiles, 40 cm is enough.

- Brackets for securing the guides. They must withstand the main load when the carriage moves.

- Guides. A carriage slides over them. Made in the form of steel pipes. The wall thickness of the pipe should be sufficient so as not to bend when the carriage moves.

- Carriage. It is made in the form of two bushings and a swivel mechanism. It is advisable to purchase a design with bearings in the bushings for smooth movement. This is the main indicator of the quality of work. If the carriage wedges, you will ruin the tile.

- Swivel mechanism. There should be no backlash. It is desirable that the axis is collapsible, in the form of a bolt. At the same time adjustment of a tightening, and dismantle for service is possible. A cutting roller is located on the movable part of the carriage (thrust rod).

Video: Choosing a Tile Cutter Manual Or Electric

Personal experience with various types of tile cutters. video

The choice of a manual tile cutter comes down to checking the quality of manufacturing the tool, and the presence of additional options.

We will dwell on the options in more detail:

Replaceable roller

If the bar with the roller can be dismantled. this gives additional opportunities. Having a set of rollers of different hardness and diameter, it will be easier for you to cut tiles from various materials. The replacement roller is easier to replace when worn.