Chopper of branches from a circular saw with their own hands

Types of homemade garden devices

All self-made machines can be divided into 3 types:

Chippers are designed for shredding branches and fully dried coarse green mass, that is, thick stems.

They are not well suited for processing and shredding fresh or slightly dried green material, i.e:

often the chipper is made in the form of a rotary chipper. About how this unit is set up, its principle of work, and how to make it yourself, we told and showed on the video in these articles:

Self-made machine of this type effectively grinds branches of a certain thickness, turning them into fine chips, which can be used as:

- decorative and agro-technical mulching of the garden plot;

- dye and flavoring when infusing alcohol;

- fuel for smoking various products;

- animal and bird supplements;

- fuel for boilers and stoves.

Shredder is designed for shredding fresh and dried green mass, but is not suitable for processing dry haulm and any branches. Its base is a fishing line cutting module, which we told you about here.

Shredder is designed for rough grinding of branches, so the finished chips are used only for heating.

Industrial shredders have the ability to produce a normal-sized chip, but in homemade devices, the most important quality is considered the simplicity of design and ease of manufacture, which becomes the reason for the increased size of the chip.

What a wood chipper consists of

Gasoline and electric engines have their pros and cons. Gasoline engines are more powerful, allow you to work away from the electricity grid, but are much heavier than electric, make more noise, emit more exhaust, require fuel.

Electric. are environmentally friendly, lightweight, do not require refueling, but are tied to a power source.

The engine is the most expensive part of our design. It can, of course, be bought, but in this case the cost of our homemade machine will not be small. You can use parts of the old angle grinder, gasoline and electric trimmers, drills and peorators, chainsaws, but their power (1.5. 2.3 kW) is small.

The resulting chipper will only be able to handle 1. 1.5 cm branches. If we want to make a tool with higher efficiency, we need something more powerful.

Chip cutter with a 4. 7.5 kW motor can cope with the branches of 50 mm. Will suit, for example, the engine from an old circular saw, motors from the machines of woodworking enterprises (drilling, milling).

You can help us by picking up scrap metal or companies with their own fleet of vehicles, which periodically carry out repairs.

We can also find there the automobile leaf springs we need for our work, 3 to 15 mm thick sheet metal, angle bars, or channel bars.

In addition to the motor power it is important the RPM. If the speed of the motor shaft can be 3000 rpm, then the rotation of the cutting unit shaft 1500 rpm is the right value. If there are more of them, productivity will increase, of course, but the chip will be too small.

The second part of our preparatory work is to decide what type of cutting unit we can make.

Materials and tools for work

Many components for the shredder can be selected from parts lying around at home in the household. If you take the frame, it is perfectly formed from iron corners, pipes and channel bars.

An electric motor is often bought or borrowed from a small tractor. The cutter used must have large teeth, and circular saws must have d: 100-200 mm.

When the work is related to the shaft, then a couple of pieces of gears, shafts, and also pulleys are purchased. Blades can be made from car springs on a milling machine.

As a toolkit you need to take: an angle grinder, peorator, keys for nuts, a welding machine and a set of fasteners.

The main components of the machine

There are many types of mechanisms and the price of models varies, but both factory and homemade consist of the same components, the only difference is the size and layout:

- The basis is a metal supporting frame, often it is made from either a corner or a profile tube;

- The heart of any machine is the power plant. Here it is an electric or gasoline engine, less often a diesel is used;

- The most important part is the cutting part;

- Depending on the design, there may be a transmission mechanism. Most often it is belt-driven, but chain and gear transmissions can be found on powerful units;

- Throat for feeding the material;

- Hopper for the collection of chips;

- Protective equipment and guards.

The general design of all chippers is similar.

It is unrealistic to dissect all the nodes, so I will talk about the main ones, that is, the types of power units and the cutting unit.

Types of power units

The main and only advantage of shredders with internal combustion engines is their autonomy. The price of such machines is much higher, plus these engines are quite bulky and heavy. When installing with their own hands, most often the drive for a power tiller is used.

The power of the internal combustion engine for the shredder must be at least 6 horsepower.

The shedder with internal combustion engine is fully autonomous.

It is much more convenient to make shredders on the basis of electric motors. The range of this product is now huge, and you can almost always find an ownerless motor at home. The most powerful semi-stationary shredders are usually made from a circular saw, and if you are interested in a lightweight device for grass and small branches, then make it from an angle grinder.

The electric motor for a home shredder is selected by power.

When choosing an electric motor for a homemade shredder, you should consider its power, here it all depends on what branches you are going to shred.

- If on your site the diameter of branches does not exceed 2 cm, then feel free to take a motor for 1.3-1.5 kW. Broken drill, vacuum cleaner or angle grinder may well become donors;

- For a young garden, where the thickness of the material up to 4 cm already have to look for a motor of the order of 3-4 kW. Here you usually take a circular saw, by the way and the bed can also be used from it;

- To shred serious branches up to 15 cm thick, the power of the power unit must be at least 6 kW. In the domestic sector such machines are rarely used, this equipment is closer to professional.

Cutting block types

It is the device of the cutting unit that determines the diameter of branches that can be shredded on the shredder. There are 3 types of designs used in traditional factory machines.

You can make such a block with your own hands, the instructions are available, but it needs a good gear reducer, and it is expensive, so this design is rarely used.

The shredder can only shred dry branches, otherwise the shaft is clogged with raw fibers.

These 2 types of cutting units are similar. These designs are considered versatile, with proper motor power they can cut any wood.

Chopper varieties

The basic design of all types of shredders is the same. They only differ in terms of motor power and blade varieties.

Gasoline engine in some models, electric motor in others. The first is more powerful, is engaged in shredding large branches. Independent of power supply. mobility. The electric is weaker in power and the remoteness of the work depends on the length of the cable. But it is mobile because of its lightness.

- Up to 1.5 kW electric motor. Capable of shredding branches up to 2 cm in diameter. Mainly recycling in small areas.

- 3. 4 kW. Can cut up to 4 cm of wood. Use in a small garden or dacha.

- 6 kW and more. Works on large farms. Can handle up to 10-15 cm in diameter trunks.

As a rule, the homemade machine is equipped with a 4 kW motor. It does not make sense to use more than that, because it will consume a lot of electricity. To perform work on shredding of branches on a summer cottage site, such costs are not required.

Engine speed does not make much difference. The kniveshaft has a final speed of 1500 rpm. It is adjusted by the diameters of the pulleys.

Torque transmission by chain, belt or by mounting the cutting tool directly on the motor shaft.

Depending on the cutting tool, branch chippers are divided into:

- The twin-shaft type. This is a powerful unit that can shred large branches. than one blade is mounted on the shaft. The degree of wood shredding depends on their number.

- Installation with a cutting disk. If the engine power is 3 kW or more, the knife is attached directly to its shaft. For weaker machines, a gear train is used.

- With circular saws from a circular saw. Relates to the simplest designs.

Shredder from an angle grinder

The simplest home-made grinder can easily be made from an angle grinder. It is better to get a tool with 3000 watts.

Construction examples

The frame is shaped like a kitchen stool and is welded from a 35 × 35 mm metal angle bar. From the bottom of the shaft to the top of the grinder is attached to it. Working tank is made of a bucket, tank, gas cylinder.

To prevent chips from flying out, a tin pipe is slanted to the side slit. On the shaft of the grinder attach a two-, three-blade knife from a lawnmower or a disc from a brush cutter.

Assembly drawing

If there is sheet steel, rebar, angle, welding, then the drawing of the compact device for grinding plants will come in handy. Assembly sequence:

- From a sheet of steel cut 2 plates, one for fixing blades, tools, the second for the hopper cover;

- In the center of the first plate is drilled a hole, welded washer, the edges of the angle welded, welded on the sides of 2 studs;

- On the outside weld mounts for the grinder;

- At the top of the second plate cut a hole, welded obliquely or horizontally a piece of pipe;

- finished hopper lid is fastened with nuts on the studs;

- make the legs from the armature;

- angle grinder is attached, a knife is put on the shaft.

Grass and branch chopper for dacha with their own hands, made according to this drawing, will come in handy in the household.

Gardeners on a note: a machine for shredding branches from circular saws

From time to time a large amount of vegetable waste (branches, grass) appears on the garden plot. It is worth noting that from such waste can be made a quality natural fertilizer, simply recycling them. The process of such processing involves shredding the solid waste into small chips. This task is perfectly performed by the most simple shredders, which are used during the work in the garden or on the homestead.

The modern market is represented by a variety of models from a variety of manufacturers, garden shredders (shredder). However you can make such a device yourself at home, thereby saving a lot of money. As a rule, homemade garden shredders perfectly perform such basic tasks as shredding grass and small, non-thick branches of trees, as well as bushes.

Variety

The output of garden shredders varies greatly. Light models can cut branches and limbs up to 25 mm in diameter, medium models up to 40 mm and heavy models up to 50 mm.

Output is determined by engine power and the size of the tools. Factory-made shredders have a branch diameter limiter in the shredder head, which calibrates the branches and prevents too thick branches from getting to the cutting part.

Types of power tools

Gasoline four-stroke engines are used most often in shredders. Two-stroke or diesel engines are used less frequently.

Their advantage is autonomy. no need to pull the cable.

For stable operation, the motor power starts at 5 liters.с.

Shredders with electric drive are much more convenient.

For branches from bushes up to 20 mm thick, 1200-1500 watts is enough. If you plan to crush the shoots with a diameter of up to 40 mm, you will need 2,500-4,000 watts.

On garden plots rarely encounter shredders for branches thicker than 50 mm, it is usually a professional installation, they cope with branches up to 150 mm and consumes more than 10 kW

Cutting block types

The working body of the device, its size and design largely determines the diameter of the branches with which it can cope.

- Disc block. Several cutting blades, e.g. from a circular saw, are mounted on one shaft. Such devices are not difficult to make yourself, but the thickness of branches is limited to 20 mm.

- Cutter drum. productive system, with sufficient motor power can shred branches up to 80 mm. Requires a gear reducer on gears, quite difficult to manufacture.

- Auger drum. Versatile and powerful device. Production requires special steel and industrial equipment and machines, which are not available in the domestic workshop.

Drawings of different designs of garden shredders

Let’s look at several shredder designs that you can assemble yourself.

Drawing of the hammer shredder

Hammer chipper can crush branches, straw, corn stalks, grain.

1 hopper feeder (sheet δ1 mm); 2 edging of the hopper neck (25×25 angle piece); 3 shutter/flap valve (sheet metal, 3 pcs δ1 mm); 4 M6 bolt for tie rod (8 pcs.); 5 Framing of charging hole in the housing (equal-ribbed angle of 25 mm); 6 M8 stud bolt (8 pcs.); 7 outer drum of the body (pipe Ø 270×6); 8 Stator with grooves (tube Ø 258×6); 9 and 20 hammers and spacers (sheet δ3 mm, hardened to the hardness of HRC 4547, 72 pcs. and 70 pcs. respectively); 10 stud bolt Ø 3 (4 pcs.); 11 M20 nut with spring washer; 12 hammer shaft (circle Ø 22, 4 pcs.); 13, 14 pipes strapping (equal-ribbed 25 mm angle); 15, 19 spacers (rubber, sheet δ3 mm); 16 Nut M8 fixing the flange (8 pcs.); 17 Hammer rotor; 18 Flange (sheet of rubber); 13 δ5 mm, 2 pcs.); 21 clamp; 22 drive shaft

Cutting tool circular saw package

1530 circular blades set on the shaft one of the chopper‘s cutting system variants. Some masters point out that the saw teeth quickly get clogged with plant matter. Others say that they reached the good work of the tool empirically by the different alignment of teeth relative to the neighboring saws. Since the carbide teeth are thicker than the disk itself, thin spacers of metal (such as washers) or plastic must be installed between the saws, and the entire package is clamped with nuts.

Package of 15 circular saws on shaft

You can use a single-axle tractor with little power as a drive, pulleys and bearings used parts from VAZ car. The hopper’s mouth is a truncated pyramid with a small outlet opening to keep out a man’s hand. It is better to make the frame under the shredder higher in order to remove the shredded material less frequently.

A set of saws on the M20 stud

Side view

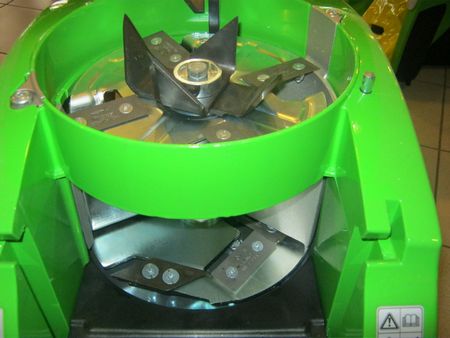

Double roll shredder

This chopper cuts branches into 2 to 8 cm long pieces, suitable for heating the sauna or the wood heating boiler. It is designed as two shafts with 34 knives per shaft, rigidly bolted together. The blades can be made of KamAZ or MAZ leaf springs. If you can find a bulldozer blade, that will work, too. The shafts are mounted on solid plates in parallel, with enough distance between them so that the blades cut the branch but don’t cling to each other. Free rotation of the shafts is ensured by bearings, and their synchronization is achieved by means of a gear clutch moving by means of a belt (chain) from the engine. To drive this shredder, it is advisable to use a motor of high power, but lower revolutions.

If you want to build a mobile shredder, the frame must be provided with mounts for the wheels.

Frame element

Axle and shaft

Assembling shafts

mounting the shafts on the crankcase

Shafts made of square billet for 4 knives

The video shows the chopper with gears: the idler gears from the MTZ shank, matched to the right size, the driving gear (the gear for transmitting torque to the shafts) was found by fitting.