Cock the wood-brown stove to the full version. Programs for cutting

How to saw laminated wood-brown slab and wood-fiber slab without chips? Rules and options for cutting

Laminated wood-bearing plates (laminated woody stove)-easy to process, durable and inexpensive material for furniture production. You can cut a laminated wood-bruise plate without chips at home and you can do it yourself. However, first you need to figure out what rules and nuances exist. Since the wrong cut can cause cracks, chips and faults.

For the saw, the laminated woody plate will require the following tools:

And also for cutting you will need additional devices:

The cutting laminated wood-brown slab is performed in the following order:

- Marking material. To mark the blanks, the ruler and pencil will be needed to apply points to the sheet of material from the end. Then the points must be smooth into one fishing line for a trimmer and glued a painting tape on top. A good way to saw a laminated wood-brown stove without chips using the tape, t. to. It helps to reduce the number of cracks in sheet material that occurs due to elevated temperature and strong pressure. Cutting laminated woody stove.

- Next, a laminated wood-bruise plate occurs. Choose how to cut the woody stove, and put the tool at the required angle so that the cut edges of the sheet are even. The laminated wood-brown slab and wood-fiber slab should be cut very carefully and how much it is smooth.

- Processing of the slab. If the cutting wood-brown slab at home are uneven from the ends, along which cutting was carried out, they are treated using tape grinder. In some cases, it is better to immediately contact the company that provide services for the manufacture of furniture parts to order according to the size of the customer and cut the laminated wood-piece stove on special equipment. To paste the part of the part, use a special gluttine end edge for processing.

Cutting methods of laminated wood-bruise without chips

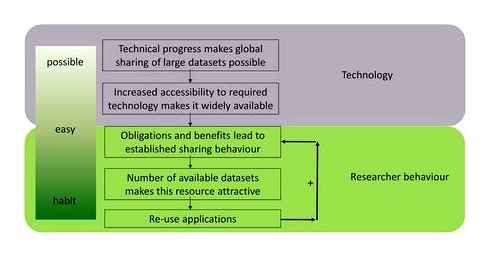

Speaking laminated wood-based stove at large enterprises in woodworking is carried out on a special format-sprinkle machine. Small workshops producing furniture also acquire this, but it is expensive, therefore, as a home tool is inappropriate. If the question arises of how to cut a laminated wood-bruise plate without chips, then as alternative methods for cutting, you can choose sawing using a hacksaw, circular, milling cutters for laminated woody plate or electrician.

Using a hacksaw

Drinking a wood-brown stove without chips with a hand hacksaw is not easy to also saw a laminated wood-brown plate with a jigsaw. Although this is a cheap and affordable way.

First you need to cut a fishing line for a trimmer with a knife, draw with a nail or awl, and then stick the masking tape, to protect the upper laminated layer. Then at an angle of 30 degrees carefully, without pressing, cut the material. The selected hacksaw saw should be with small teeth so that the cut is as even as possible.

The hacksaw can leave damage, which is eliminated using a tape grinder, exhibited perpendicular to the subsequent outskirts.

At the final stage, it is worth treating the sections with sandpaper with a flexible profile.

Electric

Often for cutting, laminated wood-based plate is used by an electrolobian. The main condition to carefully cut off the stove. small teeth.

The electrolobian saw will not be able to replace the disk saw, t. to. It is mainly used as a cutting tool for small sections of plates. They need to work without strong pressure, smoothly and not too fast. If the cutter of the laminated wood-brown plate has no experience, then small chips may appear on the back, but with practice the quality and appearance of the saw will improve.

Circular saw

If the question arises, how to cut the wood-based slab and which tool to choose, then the circular is quite suitable. It is also often called a disk saw. This is a disk tool mounted on the table. Many are interested in which disk for the circular saw to use. The circular disc is needed with small teeth. Cutting is better than when using a jigsaw.

For greater accuracy, you should mark the guides, and also not work at too large speeds.

With the help of a cutter

The milling cutter is used not only to cut the plates, but also when drilling holes, cutting grooves, creating edges, etc. P. With it, you can perform a figured cut. The tool is used with the jigsaw. The plate is first sawn with a jigsaw, and then a milling cutter with a bearing is used, giving a cut the necessary depth. How to drill, cut and saw slabs with a milling cape are known to professional sawing men. Using this tool, the cut is absolutely even and neat. However, this is very time.consuming, requiring increased attention and special skills (for example, setting a template for a cutter to a drilled or other surface), the process that without experience is better not to take such work, and order the sawing to specialists. In some workshops, such a service is provided. The main supplier of wood mills is Topvoltage, ordering their tools from them, you can do this with delivery.

Cut formatically cutting machine

The use of the sawing machine guarantees the accuracy of the saw and the complete absence of chips. Such machines are used in production and are considered specialized equipment.

- Carriage. Allows the movement of the mobile table, but the plate is fixed in the right position.

- Saw node. It has two flat metal disks: the first makes preliminary cutting, the second. drains completely through.

- Stanin. The mechanism is fully relied on on it. Eliminates vibration and adds stability, which is important for the quality of the cut.

Three desktops: 1st: location of the knot. 2nd (mobile): supply of plates for sawing. 3rd: maintaining sawn parts.

Types of sawing machines depend on the time of continuous work:

When setting up the machine, they matter: the depth of the cut; plate position; The corner of the cut.

- The plate is motionless to the table (mobile carriage);

- The workpiece is positioned according to the size ruler and the saw node is launched;

- когда диск наберёт нужную скорость, стол будет двигаться вперед вместе с плитой-заготовкой и попадать на него.

The use of format-sprouting machines is advisable for mass production, and not for isolated cases. For a one.time independent use, you will quite select the tool easier or order a cut to specialists.

Drinking with cutting

- Tire. the ruler is fixed to the plate using a clamp on the marking line;

- along the line, a cut is preliminarily made on one side with a depth of about 0.1-0.3 cm;

- Further on the other hand, the plate is cut completely through and through.

If everything is done carefully, then no chips will appear.

Speaking using a scratched marking line

Carefully cut the laminated woody stove, without the appearance of cracks and chips on its surface, is possible thanks to the application of scratches. To do this, you need to take a ruler and with the help of a nail or an awl, scratch the necessary marking on the laminated coating.

Then the laminated wood-brown plate should be cut strictly along the scratched line. In this case, the edges of the teeth of the saw used should fall into the place of scratches. This method can quite successfully, without any excesses, perform a cutting laminated wood-bearing plate using a jigsaw or ordinary hand hacksaw.

Application of an electrician

For a neat sawing laminated woody stove, you can use an electrician. At the same time, it should be noted that this tool is preferable to use for cutting small areas on wood. Also, when using an electrician, you should select a file with a small size of the teeth.

When sawing a laminated coating, the power tool should be moved smoothly, without strong pressure. During the drainage of the sawing laminated wood-based slab using a jigsaw, it is recommended to set the power tool for small speeds.

Materials and tools

In the conditions of a woodworking enterprise, a special equipment is used for sawing a sheet of laminated woody plate, which is called a format-sprinkle machine. Some private furniture workshops acquire such a machine, but it is hardly advisable to install it at home due to a high cost. Homemade power tools will be able to replace such equipment-sawing a wood-and-steering plate can be made with a disk saw or hacksaw. The process of sawing will take a lot of time and effort, but from an economic point of view it will be quite justified.

Electric jigsaw

In order to perform a flat drink without damage to the laminated layer, you will need to take a file for a jigsaw, in which the size of the cloves will be the most minimal. It is advisable to use an electrician for sawing small in size of the plots of laminated wood-based slab. Jerks and excess pressure during work should be avoided. The speed of feeding the cutting canvas from the tool should be chosen by the minimum.

This device is quite capable of performing an even and high.quality cut without chips of a laminated surface.

Manual hacksaw

This manual tool is used in combination with the canvas for metal, since it has the smallest cloves. Before working at the cut site, it is necessary to stick a paper sticky tape that protects the layer of lamination from damage. The canvas of a hand hacksaw must be kept at an angle of 30–35 °, this position reduces the likelihood of chipping on the material. The movements of the hacksaw should be smooth, without pressure on the canvas.

After the cut is made, the edges of the cut are required to be treated with a file and fine.grained sandpaper paper.

Circular saw

This power tool consists of a small desktop and a rotating gear. The disk saw makes a slice on the wood-based panel much faster and better than an electric jigsaw. Performing the cutting process, the saw is included at small speeds. In this case, chips can appear on the opposite side of the saws of the saw.

To prevent this situation, before starting sawing into place the cut, glue a paper adhesive tape.

Electrofreing

This is a manual type of power tool that is used for sawing and drilling woody plate. Before starting work in a laminated wood-based slab, a small cut is made using a manual jigsaw, retreating from the marking circuit by 3-4 mm. In the process of sawing, several cutters knives and its bearing device are used, which regulates the depth of cut. It is not so simple to use the cutter, so for cutting the slab you need to have a certain skill of working with this tool. The movement of the cutter is quite fast, and there is a chance to make an uneven saw.

But with the help of a milling cutter you can get a perfectly smooth section of the material. the appearance of chips and cracks when using this device can be very rare.

The use of manual tools is advisable in the manufacture of single products from laminated woody stove. For mass production, it is advisable to purchase format-sprinkle equipment.

How to cut it correctly?

To cut a laminated wood-brown stove without chips at home is quite possible with your own hands. Significantly simplifies the task of preliminary creation by an sharp object of the groove in the area of the saw. Once in this place, the canvas of the cutting tool goes along a given path and it turns out to be much easier. Right-in-law cuts on a laminated wood-based slab are much easier to make than cut a sheet of figure.

It is extremely difficult to perform curved configurations using home devices, this can only be done using an electrophresis. This tool performs a quality cut and has a lot of additional functions.

The price of the electrophrease depends on the manufacturer, so you can choose a budget model with good technical parameters.

For cutting a leaf of a laminated wood-based slab using an electrophrease, the following actions must be performed:

- On the surface of a conventional wood and steering plate, all contours of the future workpiece are marked;

- Using an electric jigsaw, the workpiece is cut, retreating from the intended circuit by 1-2 mm;

- The finished sawn template is cleaned with a file or sandpaper;

- A prepared stencil is applied to the laminated wood-based stove and fix it with carpentry clamps so that it is in a stationary position;

- along the contour of the stencil with an electrophreze equipped with a bearing mechanism, the blank contours are cut, cutting off the edge exactly along the intended line;

- After the work, the end sides are cleaned and treated with a decorative edge.

The use of electrophrease allows you to perform a figured cut of laminated wood-bearing plate without chips and cracking of the material.

Electrophrees knives should completely capture the entire thickness of the workpiece material. the only way you can get a quality product.

You can find out about four methods of sawing a laminated wood-bruise slab without chips from the video below.

Cutting methods of laminated wood-bruise without chips

You need to saw a laminated board with a special machine (formato-sprinkler). But it), if we are talking about use at home. The alternative can be budget options (hacksaw, jigsaw, etc.D.) that will take more time when cutting, but will require less monetary investments.

Using a hacksaw

It is difficult to saw a hacksaw at home is quite difficult. First you need to cut a fishing line for a trimmer for measurement and glue the tape along it. This will protect the upper layer from damage. The tool is directed at an angle of 30 degrees. Gently, without strong pressure, move the hacksaw forward and backward. To cut the laminated wood-brown stove without chips with a hacksaw at home, choose devices with the smallest teeth. In case of damage, the cut place must be passed by a file, directing it from the edge to the center. In the end, rub with sandpaper (fine.grained) and hide defects under a flexible profile.

Electric

To flatterly sawn down the wood-bruise plate without chips, you need to choose a device with a minimum size of teeth. It is used for small areas of tiles, smooth movements without pressure with low speed. If you use a jigsaw for the first time, then a little crack may appear on the back of the plate. With further use, the quality of the saw will improve.

Circular saw

The tool is a table with a gear disk for a wood-piece stove. Among the masters he is called a disc saw. Cuts the tree better in comparison with the jigsaw. A good result without chips is possible when sketching guide lines and fixing the circular saw on the board. Chips should not appear at the place of cutting saw into the stove. But the opposite side can be sawn with fragments.

With the help of a cutter

Fraser. power tool for manual wood processing. Suitable for cutting grooves, curly processing, edges and drilling. Before using it, a tree sheet is sawn with a jigsaw, retreating 3 mm from marking. It is necessary to cut the milling cutter along with the bearing, which form the cut depth to the required level. This is a laborious process, only experienced specialists can do. High probability of crookedly cut off the board.

Cut a format-sprinkle machine

The workpiece is installed on the table and fixed in a stationary state. The necessary markings on the sheet are made and the saw node includes. When the disk reaches sufficient speed, the table moves forward with wooden slabs and gets to the disk.

Wood-and-based cutting machines are divided into 3 types:

- Stanin. a mount on which the entire mechanism is based. A heavy bed will add stability to the device and eliminate vibrations. This is important for high.quality sawing.

- Saw node. consists of 2 flat metal disks. The first preliminarily cuts the stove, and the second finally cuts it through through.

- Working tables. Three at once take part in the process. The first is for the location of the node, the second. for the supply of drunk plates (mobile), the third. to maintain sawed parts.

- Carriage. allows you to move the moving table. In this case, the workpiece is fixed using the emphasis and the rulers in the necessary position.

Drinking with cutting

For the process, a tire is needed. a stubborn ruler. It is fixed on the board with clamps. Trimming is carried out according to the markings. The tire is installed along the line, and the gap is made by 10 mm deep. The second cut is done through and through. With this method, there will be no chips on both sides, since the laminate is already cut on the bottom.

Some elements used in design ideas are cut not straightforwardly, but curvoline. In this case, the mixed type of cutting wood slab is used.

What can not be sawn

Due to the combined structure, it is difficult to cut the laminate without chips. But with the proper approach, this is possible at home with improvised means.

With a large amount of work, some masters saw laminated boards with a greenhouse. Nozzles for wood are selected. To facilitate the cut, the bar is installed along the cutting line. Laminated plates are not recommended to saw a corner grinding or an angle grinding machine, as you can get hurt.

Cut the laminated wood-brown stove on its own is not difficult to conduct. This is a very profitable lesson, as the cutting service is very popular. Many construction shops and furniture workshops offer cutting a wood-cutting plate according to the markings and fragments. This saves time and effort.

Features and recommendations

Experts and experts advise doing this kind of work with the help of electrical jigsaws already because the usual manual hacksaw is too rude. It does not allow cutting the material quite evenly. The correct sequence of steps is as follows:

preparation of tools (ruler, electrolobesian, measuring roulette, awl or other acute device for drawing along the wood-based stove);

the addition of these tools (if necessary) by a square for laying straight angles;

measurement of the desired part (with a reserve of 0.2 cm so that you can fit);

Actually, the cut along the laid line;

finalization of the place of sawnut with sandpaper;

With very poor quality end-wiping it with small, similar in tonality to a wood-based slab.

What else you need to know?

When it is planned to saw off everything without chips on the one hand, it is permissible to use files with the upper and lower arrangement of the teeth. Most masters prefer small files with straight teeth. Such devices are less than the material, but at the same time they work quite decently. After the saw, it is best to process the ends stretched on even bars with a sandpaper. If there is no ready.made fine of suitable coloring, you can mix different crayons, like paints in the artist’s palette, and get a new color.

To cut without errors and, moreover, you must always take into account branded marking. There is no compulsory designation standard yet, but almost all firms strictly follow the classification Bosch specialists. Or at least indicate it along with their own contractions and terms. For cutting wood and products based on it, CV format files are good (sometimes designated as HCS).

Hardwood files are designed to process laminated panels (they are also useful, note, and when processing hard wood).

Some inscriptions indicate in which mode the tool works optimally:

Basic. a simple canvas that allows you to make pure high.quality cut;

Speed - a device whose teeth are divorced (this allows you to saw faster);

Clean is a canvas that was not bred (usually gives the cleanest incision).

If the workpiece is relatively thick, preferably a sawing canvas with large incisors that did not bred, then the departure from the vertical will be minimal. Longitudinal (in relation to fibers) incision most often make braids. For a transverse, a straight canvas is better suited. When it is planned to make a blank for furniture, it is advisable to choose a less productive, but a more accurate tool. Since most of the files produced now cuts the material when drawing, the workpiece will need to be processed from the inside.

Tools and equipment for sawing

Depending on the volume of upcoming works and the saw configuration, they use:

Not every tool can get details of the required form.

Formato-sprinkle machine

If the exact sizes are known by which the sheet should be cut, it is more correct to entrust the work to professionals. Almost all sellers. bases and building materials. provide such an option. Often the sawing service is free, the customer pays only the cost of a wood-piece plate.

For cutting, format-sprouting machines of various designs are used.

Sprinkle the wood-brown slab without chips allow various additional devices. For example, some models have two sawing disks: the first, small diameter, drinks a surface laminated layer, and the main carries the full cut.

CNC format-sprouting machines operate in a semi-automatic mode, excluding the operator’s errors, which allows you to get ready-made parts with an exact size of up to 1 mm. This is important in the manufacture of cabinet furniture.

Lobby

A sheet is cut by an electric jigsaw on straight and curly lines.

- Availability. Most masters have a jigsaw, and the new one costs inexpensively;

- On sale there are special files for a wood-piece plate, laminated wood-bearing plate and laminate;

- You can cut circles with a small radius;

- Suitable for the manufacture of through holes for hatches or electrical products.

To obtain a rectilinear cut, you must have experience working with a tool or just use the guide tire.

Parquet

A manual disk saw, sometimes called a “parquet”, is used if there is a large amount of work on the cutting of the wood-piece stove along the even lines.

Acquire wheels with carbide tips of teeth.

To simplify and accelerate the work, they choose a parquet, complete with a guide tire or buy an accessory separately.

You can do without additional details if you lead a cut along the guide from the corner or plaster rule.

The main drawback of the method is the inability to make a curved incision.

Milling mill

To qualitatively saw off the wood-making slab using a milling cutter, the master needs extensive experience.

A flat, impeccable edge is obtained only when using diamond mills, the price of which is large.

At home, a milling mill is often used to finish the edges of the laminated wood-based slab. In these cases, the sheet is sawn with a hacksaw, a jigsaw or a disk saw, and then the cut is treated with a milling cutter. It is important to provide a stock of 1.5–2 mm, which will be removed by the milling.

Hacksaw

The cutting of hand hacksaws takes a lot of time and requires a large cost of physical strength.

Hand saws with a large and medium tooth are suitable only for sawing a conventional wood-based slab (without a laminated layer). The result will always be accompanied. The appearance of the edge can only be fixed by decorative lining.

A small cutting volume is performed with a hacksaw with small teeth. To reduce the number of chips, launch tape is glued over the sheet, mark the fishing line for the cutting trimmer and only then begin to work.

Despite the fact that the seats of the saw wheels for parquet and an angle grinding machine may coincide, cut the wood-boring plate and a tree with a corner grinder is strictly prohibited. The torque of even a weak machine will tear out the tool from the hands, and the disk will cause injury. The danger is that rotation cannot be stopped instantly.

Stages of work

Using an electric jigsaw is the most common option for sawing a wood-brown stove at home, due to the availability of tools, universalism and simplicity of circulation.

Requirements for used files:

In the assortment of most tool manufacturers there are special products for sawing wood stove. Files for laminate are also suitable for work.

The process of sawing consists in the sequential performance of three operations: marking sheets, sawing and processing the edge if necessary.

Cutting out the material

When homework, it is important to correctly carry out the cutting of the material in order to minimize the amount of waste. Particular attention is paid to the “layout” if the laminated wood-brown plate has a clearly pronounced pattern, which must be taken into account.

It is recommended to plan the location of the parts on a sheet of paper. On the Internet, it is easy to find calculators and programs that automatically plan the optimal location of parts.

Before starting work, it is necessary to lay the sheet on a solid basis, taking into account that the site of the cut is needed a supply of free space for the progress of the file.

Further, the cutting algorithm consists in the sticker of the painting tape and the drawing of the sawing lines with a permanent marker.

Having glued the masking tape of the required width, it is possible to exclude scratches from the steel sole of the electrician, reduce the likelihood of chips of the laminating layer.

If it was not possible to find special files for the wood-cutting stove, the sawing is carried out on the back, so that the teeth “work” towards the surface.

The process of sawing

It is recommended to saw with the help of guides with even lines.

The work algorithm is as follows:

- A layer of laminate is cut through a sharp knife or a special tool. The operation reduces the number of chips.

- With clamps, the guide is fixed, about which the sole of the jigsaw will be based on a direct cut. You can do without device if the quality of the edge is not decisive or with extensive experience. The location is chosen based on the width of the supporting plate of the jigsaw.

- Set the average rotation of the electric motor, remove the rolling mode.

- Start drinking from edge to center. The instrument pressure is excluded, since in this case the file will definitely take aside or the cut will pass at an angle in the plane of the sheet.

- If necessary, they carry out finishing, bypassing the workbench.

- At the end of the drink, the sheet is excluded under its own weight.

Only high.quality files allow you to work for a long time. The Economy Class tool will ensure cutting out no more than 5-10 linear meters of laminated woody stove, after which the teeth dull chips, the jigsaw leads to the side.

If you need to cut the inner hole under the hatch, installing electric sockets or switches, first mark the marking. Next, drill a wood-boom slab with a drill 1-2 mm exceeding the width of the file. Having set the file in the formed hole, the sawing is carried out.

Processing after trimming

If you use hard profiles, = just remove dust. Playing is carried out with carpentry glue.

The end of the end of the end is carried out with films of different material:

An important condition-before glitting, it is necessary to align the end surface of the wood-bearing plate.

For processing, use a milling mill, file or a grinder.

Self-adhesive films are pressed by any even bar. After gluing, the protruding parts of the end tape are cut off.

How to cut a wood-piece plate without chips at home?

There are several ways to avoid chips when cutting a leaf of a laminated woody boat:

1) For non.real details, it is enough to glue the masking tape on the back of the cut. it will hold the laminate. it will be smaller before the cut.

2) Put another piece of black woody plate under the part and cut both parts together, tightly pressed to each other. On this principle, the work of machine tools is based, cutting several sheets of laminated wood-based stove at the same time.

3) when cutting with a jigsaw, leave the allowance of about 3 mm (if the saw leaves chips more than 3 mm. most likely it is dumb). and polish it with a tape grinding machine called the “tank”. Also, this grinding machine will help to accurately adjust the details to the irregularities of the walls. This method is most often used by professional installers of built.in furniture.

Sofa Cum Bed: Fabric Alfonso Convertible Sofa Online @ Wooden Street

4) when cutting with a jigsaw, leave the allowance of about 3 mm. and finish it using a milling cutter. In the production, curved parts are made precisely by milling by, but it should be borne in mind that the laminate has very high hardness, and ordinary cutters will quickly dull, which, again, leads to chips on the surface of a laminated wood-based stove. It is better to use professional machines for sawing. Professional cut of the wood-based slab Read more

Check how to indicate the sizes of parts: taking into account the edge or without? The filler holes for the hinges, grooves and quarters simply indicate in the order form or you need a drawing for each detail?

Order form and instructions for filling it out here: http: // www.DSPKOMPLEKT.ru/dostavka.HTML

We can make details according to your sketches on the day of circulation. You can pick them up after complete gluing the edge with the end of the wood-based part of the part. Otherwise, claims on the quality of the manufactured parts will not be accepted. Other parts of the furniture, for example, an aluminum profile for a cape doors can be sawed in one day.

Basic Rules

A feature of the laminated wood-brown plate is that the material has a solid protective coating, which is a multilayer-layer-made film of paper with a resin, compressed under the influence of high temperature and pressure. The thickness of the laminated layer in the laminated wood-bearing plate is small, but it reliably protects the material from the effects of moisture and mechanical damage. Speaking a laminated wood-brown slab is a complexity associated with the fact that under the influence of a cutting tool a laminated layer is cracking, thereby a worsening aesthetic appearance of the sheet. The width of the chips is small, but it is not always possible to eliminate them.

The laminated wood-based cutting can be performed using an electrician, a disk saw or a conventional hand saw with rare small teeth.

In order for the cutting of the material to be done carefully and efficiently, it is necessary to adhere to the following rules:

- so that the teeth of the saw do not damage the laminated layer of the material, glue the adhesive mounting tape on the cutting line for the trimmer;

- To facilitate the process of sawing with a sharp knife blade, it is necessary to scratch the layer of lamination until a layer of chips reaches, while the direction of the blade should take place along the tangent, relative to the surface of the material;

- The saw canvas in the process of sawing is important to keep at an acute angle of 30 degrees relative to the surface of the workpiece;

- When using the power tool, work is performed at low speeds;

- On the finished part, it is necessary to make a cut of the thin layer of the laminated part at an angle of 45 °;

- After the cut of the edge, the blanks are treated with a file in the direction from the periphery to the middle;

- After the edge of the cut is treated with a file, it is closed with a self.adhesive overhead with a melamine strip, or it can be a kant in the form of a letter C or t.

Introducing VinylMaster XPT, DSR, PRO, LTR and CUT

What may be needed?

At furniture enterprises, sawing laminated wood-based slab is performed on special equipment-usually it is a CNC machine, on the table of which a sheet of material is laid. The circular saw of such a machine makes a clean cut without chips. Format cutting of workpieces occurs in mass quantities, and in addition to sawing in the production process, additional devices and materials are used for processing furniture parts. Most trading companies provide the population with services for cutting purchased furniture shields, but some masters prefer to do this work on their own. DIY laminated wood-boring stove at home is much more difficult. A manual saw will require a master of caution and the presence of a specific tool.

It is most convenient to carry out a cut of laminated woody stove with a milling cutter or an electrician. The most productive cutting is performed using a circular saw, but the correct choice of disk for pure cut is quite complicated.

In addition, a laminated wood-based slab will require a special desktop with guide edges to work on the processing.

When performing work by an ordinary electrician in the absence of experience on the material, chips are often formed, since using this tool to make the perfect cut quite problematic. The sawing process can be facilitated if the bimetallic peel for laminate, the teeth in which are sharpened in the inner direction on the jigsaw. The work by an electrician is performed at low speeds of supplying a sawing canvas, this is done so that cracks do not appear when working on a laminated surface.

Another way to cut the laminated sheet wood-bearing plate is the use of a hacksaw cloth. For work, a hacksaw for metal is suitable, in which the teeth are very small. To work, the canvas will have to be prepared, that is, to make dentitions by 0.5 in thickness of the canvas. The canvas itself should be made of hardened steel brand. Not every power tool is suitable for working with laminated material. This furniture stove cannot be sawed qualitatively with an angle.grinding tool called a corner grinder. The speed of the disk rotation of this tool is very high and chips on a laminated wood-based slab will be inevitable, especially if the circular disk with a large size is used to work.

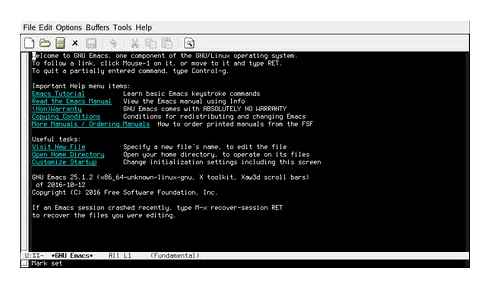

Expand download the program

The program allows you to create a leaf.type cutting plan at furniture production enterprises. The program is easy to use on any computer.

- Using the program, you can quickly make roller and sheet materials;

- The program is designed to work user with any experience with a computer;

- There is a cutting function with the removal of extra pieces of sheet;

- Windows OS is supported, starting with version XP and completing version 10.

The user can indicate the appropriate dimensions, make calculations, create and save projects. Additional convenience is created by adding all the information about ordering to the database. In the course of work, you can enter information about the details, material and readiness of the order. When deciding parameters by the User, the program reports on the correctness of the data. Drawings can be applied to wood, glass and metal, excluding unnecessary costs of the material.

All information is stored in the database, so all not processed material is on secondary use.

The features of the program are as follows:

- Each detail has a symbolic name;

- It is possible to add an additional set of sheets to the main one in the following processing;

- When calculating, you can combine orders for saving consumables;

- For each material there is a database. When choosing the necessary material, the program is proposed to the sheet parameters.

The user cutting program can download for free. At the beginning of the work, it is necessary to set the parameters of the parts that will be cut out. The program at the same time selects the necessary parameters to prevent the formation of a large number of excess material.

All cuts that are made during operation are horizontally or vertically. When calculating cutting, the program automatically keeps records of a certain material.

The program is equipped with a convenient integration in Russian, easy to use for any user. This program will significantly save time and help to make various project calculations. At any stage, there is the possibility of making changes to the parameters, which significantly optimizes the process of cutting the material. With the program, the probability of making any errors is significantly reduced. For firms involved in cutting glass, wood and other material, such a program is simply necessary.