Cutting furniture glass at home. Diamond disk

How to cut hardened glass at home. How to cut paved glass

Glass products have been very popular at all times: frescoes, dishes and many other things created from scraps of this material have always struck people with their grace and smoothness of lines. Looking at this splendor, it seems that in order to create it you need to be a real professional who has vast experience with glass and a lot of necessary tools, and for a simple “mortal” do not master this complex science. In fact, not everything is as sad as it seems at first glance, and everyone can get knowledge of how to cut glass at home.

The most ordinary sheet is called the hardened glass (the manufacturing temperature and the hardening temperature during the production of ordinary glass coincide and are approximately 660 O C), which is cooled very quickly, using blowing (cold air) on both sides of the finished sheet. Hardening (process) is due to very fast cooling. The glass hardened in this way has high mechanical strength, resistance to high temperatures and increased safety (in case of destruction, the glass breaks up into a large number of small and non.resistant pieces that will cause special harm to a person).

Tempered glass is used as a showcase.

The inhabitants of the former USSR are familiar with such glass. it was called “Stalinist”. This is due to the fact that with such cooling, in the crystal lattice of such glass, the residual compression voltage appears. Due to its three positive qualities, such glasses are widely used in the construction sector, in the production of dishes, they are used as windows of supermarkets, in various social institutions (schools, universities, hospitals, etc.D.), in the manufacture of cars and other machines.

The main drawback of such material is its vulnerability with mechanical shots to the ends. Even with a weak blow to the sheet edge, the glass is broken into a bunch of small fragments, and the whole sheet becomes unusable. However, even such a drawback found its application in everyday life. it is used if you need to create the effect of “broken glass” (in the design of furniture or dishes).

Most often you can find tables or cabinets with “broken glass”.

This effect is achieved through the use of 3 sheets at once: the upper. whole, the middle. broken, lower. whole.

Manufacturers of such leaf glasses do not recommend (and some even prohibit) cut such glass at home, since there is a high probability of leaf damage. And how then there is a cutting of hardened glass in domestic conditions?

Nuances when cutting at home

When considering the question of how to cut fisted glass at home, you need to pay attention to the choice of a more suitable tool. The following glass cutters were distributed:

- Diamonds today are used extremely often. Due to the use of durable and solid material, the tool can last for a long period. From time to time, it is necessary to sharpen the cutting edge when using a special sharpener stone.

- Roller. Cutting hardened glass at home is often carried out when using such a tool, since it is ideal for the work under consideration. There may be 6 videos that are often made from cobalt and tungsten. Due to the combination of a large number of rollers from durable and wear.resistant material, the task of cutting is significantly simplified.

- Oil is similar to the option with rollers, but at the same time the design has a special oil storage container. When performing work, lubricants are added to the cutting zone, due to which the cutting process is greatly simplified. That is why such a version of execution is used more often than others.

Before direct work, you need to check the degree of sharpening of the cutting edge. When using a worn tool, the processing quality is significantly reduced, there is a possibility that the created fishing line for the cutting trimmer will have insufficient depth.

Types of glasses

Before considering how to cut the glass, it is necessary to determine what types of it are, because further actions will depend on this. For example, cutting ordinary material should not cause almost any difficulties. It can be carried out both using glass cutter and with scissors. But cutting hardened glass at home is not recommended, because it will lose all its properties. It is best to cut it before hardening, and then entrust this process to professionals.

The corrugated glass is most often used for glazing doors or to create interesting interior elements. As well as ordinary material, it can be cut at home with the only difference that the incision must be done on the smooth side. It’s good if the roller glass cutter is at hand for processing such glass. You can cope with organic material without glass cutter, using a cutter, ordinary saw or other tools for cutting. With a glass, the thickness of which is no more than 2 millimeters to cope with a perfectly and stationery knife.

Preparatory work

First of all, before the harsh it is necessary to take care of your own safety, protecting the face and hands from fragments. After that, you need to prepare the material with your own hands. It’s enough to wipe the new glass, using a crumpled newspaper for this, for example, for this. With old material you need to work a little longer. First, it must be thoroughly washed with clean water, and also treated with a means of washing glasses, then degrease, for example, with alcohol or gasoline and dry well (see. video).

Wheak cutter will help us

The method of cutting the material using glass cutter is quite simple. The main thing is to choose the right tool. For example, you can choose a diamond device, such as, for example, in a photo, which has been the most popular for a long time, or glass cutter with a slightly beveled cutting edge. The latter can cut the material up to 10 kilometers, after which it must be sharpened in a special bar. The roller instrument can consist of 1-6 rollers that are made of cobalt-wolframa alloy. Oil windshields work almost in the same way as the roller, with the only difference being that its holder is built.in a tank with butter, which allows you to cut even rough material.

So, after choosing the tool, the glass is placed on a flat horizontal surface. It makes a corresponding markup on it, to create which you can use the usual ruler. After that, making the same efforts along the entire necessary length, a flat fishing line for a trimmer is made (see. video). This must be done the first time, since repeated manipulations will lead to cracking of the material.

Without glass cutter. and this happens.

You can cut the material with your own hands and using ordinary scissors. To do this, prepare the scissors themselves, as well as a vessel with hot water. Marking on the surface is done in advance. Further, the spicy side of the scissors is carried out according to the marking, creating a small crack, after which the glass is simply broken with his hands. Of course, this method of cutting will not be as ideal as the previous one, but can help out in an unforeseen situation.

Wood. the material is extremely grateful. Strong enough to be durable, hard enough to hold even a very thin shape, enough.

Cerambitus is a very specific weapon of near.battle, which became suddenly popular thanks to the game Call of Duty: Black Ops, as well as numerous.

Preparation for work. what tools are needed?

Often in the hands of newcomers, tempered material becomes unusable precisely because of haste and lack of experience. In such cases, the only right option can be called a laser, but not everyone can afford a In this regard, you will have to look for another way out. Many experts advise working as preliminary annealing. This will accurately cut the glass and use it for its intended purpose.

It is necessary to take into account the peculiarity that when cooling the excessive material, its outer side will cool much faster than the internal. If the surface has completely cooled down, then this does not mean that the inside is ready for cutting. Due to the fact that the glass is slowly cooling, the appearance of a large amount of voltage in it is prevented. Because of this, it is possible to get a better section. This should be taken into account every time you want to cut the material.

In order to do work correctly, you need to prepare the following tools and materials:

a piece of hot glass; warm clean water; stove; thermal regulator, however, if it is not, then you can cut the material without it; the square; marker; stone for grinding; glass cutter; wood rod with a diameter of not more than 6 mm; glasses for protection for protection.

Having prepared everything you need, get to work. In the process of cutting, adhere to safety rules so as not to damage the skin of the hands and face.

Preparation of material and desktop

To perform a high.quality cut, the glass surface must be cleaned well. If the glass is just acquired, it will be enough to wipe it with a newspaper, which leaves no divorces and villi behind.

Glass, which was used earlier, must be prepared more carefully. To do this, its surface is washed using special cleansing agents, then fat deposits are removed, for example, a rag saturated with the stispirite.

The preparatory stage also includes the calculation of the configuration of surface cutting. It will not work to completely avoid the appearance of waste, but the exact calculation can significantly reduce their number. The resulting scraps should not be thrown away, they can be used in the future. Carpet is a good base for cutting glass

The desktop should be even, without significant slopes. The surface of the countertop does not need to be made too hard, it is best made of wood.bearing plate and covered with soft textiles or other similar material for a more convenient cutting.

Learning to cut glass with your own hands

The transparent surface of the glass is well resisted by loads evenly distributed along the plane, but point attacks lead to its destruction. Microsemen in the structure of the material reduce its mechanical strength, therefore, the technology of cutting glass is based on the creation of scratches on its surface with a cutting tool and dividing it into parts with an effort with an effort attached to the weakened edges.

Before starting glass cutting, you must make sure that the factory sheet has the right straight angles. Then it is located on a flat flat surface, and a single incision is performed using a ruler and glass cutter. Next, the sheet with his own hands breaks with an effort to bend. If this did not work out the first time, the fishing line for the trimmer saw the saw is tapped with a hammer, and the attempt is repeated.

The mirror can also be cut with your own hands

It is convenient to work with a diamond glass cutter

A glass cutter in which a diamond head is used as a cutting element, it is very convenient to work. The handle of the tool must be held in the hand in the same way as a pencil, especially since it looks like it in shape. Next, a ruler is applied to the processed sheet or a pattern cut out according to the configuration, and a uniform scratch is neatly applied on the glass surface. In this case, the following rules must be followed:

- The tool must be placed at an angle to the sheet plane approximately the same as when performing a pattern with a pencil on paper.

- You can not add too much pressure force on the glass cutter handle. In this case, the fishing line for the trimmer of the saw will be replete with chips and bumps.

- Re.conducting the cutting part of the already marked scratch is unacceptable. If the sheet cannot be broken, you should step back a little and repeat the procedure.

- Work should be quickly and accurately. Time guidelines can serve two seconds when applying a scratch on a meter segment of the sheet.

Further, the fishing line for the trimmer of a qualitatively performed cut is combined with the edge of the desktop so that the part of the sheet going into the waste is on weight. The cut on the bottom is tapped with a glass cutter or a building hammer. When performing this manipulation, unnecessary fragments are easily separated and fall into the substitute box.

How to cut a roller tool correctly

Correct work with a tool in which carbide rollers are used as the cutting part, has its own characteristics. In this case, the glass cutter is not at an angle to the surface to be treated, but vertically.

Roller glass cutter should be crushed from the heart

In addition, it is necessary to attach a greater pressing force on the handle of this type of tool, otherwise a qualitative cut will not work. The video cuts glass well for the first three hundred meters, then it must be replaced with a new.

Working glass cutter is easier and more efficient

The principle of operation of the oil instrument is no different from the usual roller. Due to the lubrication of the processed surface, the process of performing the work is facilitated, and the service life of the glassus is increased.

How to cut a round hole

A round hole is cut out using a pre.made pattern of an appropriate configuration or glass cutter in the form of a circul. Using the latter is much more convenient, it consists of an adjustable tripod, suction cup and cutting element.

Cutting glass along the radius using suction cup

One end with the help of suction cups is strengthened in the center of the hole, its radius is exhibited on a tripod, the glass cutter quickly and smoothly outlines the circle. The accuracy and accuracy of manipulation helps to cut a fragment of the desired shape at home. You will find everything about drilling holes in the glass in the article “How to drill glass at home and provide an even hole”.

How to cut a mirror without glass cutter

The mirrors surrounding us: in a car, a bathroom or a female cosmetic bag, are in their structure an ordinary glass with a layer of metal on the back surface. Cutting glass with a mirror coating practically does not differ from the usual one and can be performed by a regular glass cutter or the methods given above. When there is no special tool at hand, the most effective device for cutting will be a file or a diamond disk. Let’s take a closer look at how to cut the mirror at home without glass cutter, using improvised means. First of all, it is necessary to prepare the processed surface: wash, degrease and dry. The mirror should be clean, without spots and strong stains. Otherwise, the fishing line for the trimmer cut can lead and the chip will be uneven. The working surface where cutting will be carried out should be even and not very stiff. You can lay a dense fabric or a piece of linoleum on the table.

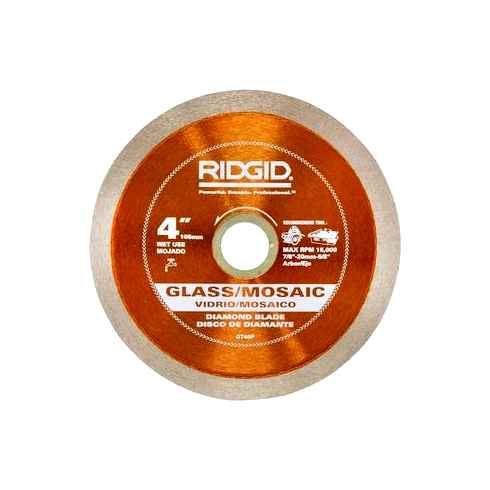

Having prepared the material and the workplace, we mark the fishing line for the trimmer of the future cut on the mirror. Straight lines are better to drive along a ruler or a rail with a height of at least 5 mm. So that the emphasis does not slide, to its lower part you can glue the strip of island. Next, take a file, corner grinder or other tool and make a cut along the marked line. A more detailed process of various cutting methods, scheduled above.

When the cut is ready, it remains to break the mirror in the right place. To do this, you can put a small item (match, pencil, nail) under the fishing line for a trimmer for a trimmer) and slightly press on two sides. You can put glass on the edge of the table or carefully tap from below a small metal object (drill or spoon). If the glass does not break, you do not need to crush very much. It is better to make a second cut in a couple of centimeters from the first.

Preparation of glass and cutting tools

The preparation process will depend on which product you will use for cutting. If the product is new, then it is enough to wipe it, using the old newspaper for this.

With the glass that has already been used, you have to tinker:

- It must be cleaned well. For this, a special cleaner for glasses is used.

- It must be degreased. For this, kerosene is used.

- It must be dried in a closed room.

In addition, it is necessary to prepare cutting for cutting. When working with such material, it is impossible to avoid non.waste production. Especially if you plan to cut out a figure of irregular shape. To minimize waste, it is necessary to make a workpiece and cut a figure on it. The resulting scraps do not need to be thrown away, they can be useful to create other products.

For cutting, you need to use special tools:

- Diamond glass cutter. Used at home, glass cutter with a beveled blade. It withstands up to 10 km of incisions. Such glass cutter often needs to be sharpened.

- Roller glass cutter. It is an element in which from 1 to 6 videos made of durable cobalt-wolframa alloy fit.

- Oil glass cutter. The structure is similar to a roller tool, differs with a capacity with oil. From the container, liquid is supplied to the surface. The tool is ideal for working with thick glass.

- Tool for cutting circles and ovals.

You can also cut the double.glazed window using scissors.

The above methods have the right to life and give out a good result with skillful handling of glass. Perhaps without experience in glass work, getting an even chip the first time does not work. Before proceeding with the processing of the main material, we recommend that you first fill your hand on unnecessary fragments. If you want to get high.quality cut without prolonged practice, it will be better to purchase roller or oil windows. Article from the heading rating

Hand.handed manual instruments and crafts

Save this page in your social. network and return to it at any time.

How to use glass cutter correctly

To qualitatively cut off the glass with your own hands, it is necessary to observe the technology and the sequence of actions.

note! The line should not be located along the cut line, but at a distance of several millimeters from it. This value corresponds to the distance between the tip of the glass cutter and its side surface.

- The cut is carried out smoothly, from beginning to end with one movement and with one effort. And only once. If you spend one place with glass cutter several times, then the glass just crackers.

- Produce chopped chop. To do this, a fishing line for a trimmer cut is combined with the edge of the table. They cause a crack, lightly tapping the cut with glass cutter, and then break off in one motion.

- If the chip is uneven, then the excess glass can be removed with pliers or use special cuts in the glass cutter handle. To avoid cracking, a fishing line for a cutting cut should be slightly moistened with turpentine or kerosene.

- At the final stage of the fishing line for the trimmer, the cut is treated with sandpaper, velvet file or sharpener.

How else can you cut off the glass

What to do if there is no glass cutter at hand? There are methods in which glass is cut by a non.standard tool. This operation can be carried out with a soldering iron, corner grinding, nichrome thread and even ordinary scissors! Find out how to cut glass with your own hands with each of these methods.

- With the help of a soldering iron. First, cuts are made by a file at the beginning and at the end of the cut line. Then, throughout the line, it is necessary to carefully draw a well.warmed soldering iron. Due to the difference in temperature on the sides of the surface, the glass will crack, after which it remains only to carefully break it off.

- corner grinder. This tool is in almost every house, so it is not surprising that it was adapted to work with glass. In order to cut off the glass with a corner grinder, you need a thin diamond disk. With its help, a thin groove is made along the entire cut line, according to which in the future there is a chip. But when cutting the corner grinding, it is necessary to ensure that the glass does not overheat, and be sure to use the coolant. A good tool is required, otherwise the glass will simply fly away from its vibration. Be sure to protect the respiratory organs and eyes when working with a corner grinder on the glass. Hit in them the smallest glass dust will not lead to anything good. Therefore, if you cut the glass sheet with a corner grinder, you need to stock up on glasses and a respirator.

- Using heating and cooling. A thread impregnated with a combustible substance is laid along the cutting line, and set fire to. Immediately after it goes out, the fishing line for the trimmer cut is cooled with water. The glass will crack from a sharp temperature difference. Another option is the heating of the glass with a nichrome thread through which an electric current passes. In this case, water is not required, the difference in temperature between the two surfaces of the sheet is enough.

- Scissors. Non.flower glass up to 3 mm is cut by conventional tailor scissors if this operation is carried out by plunging scissors and glass into a container with hot water. It feels like the process resembles a cut of thick cardboard.

Preparation for work

To obtain a piece of glass of the desired size with a flat edge without zazubrin and chips as a result, the surface should be prepared on which cutting will be carried out. Usually this is a table with a strong flat countertop and a sufficient area: the edges of the workpiece should not be on weight.

The tool should be of good quality. Roller glass cutter is convenient in that the culowning cutting wheel can easily be replaced by another.

The wheel is replaced as follows: the screw in the instrument head is weakened and another, which is spoiled by one turn, is put in place, which is then fixed by the same screw.

The surface of the glass sheet is cleaned of dust and garbage, since the slightest obstacle during cutting can ruin the result.

Be sure to prepare a ruler or a flat block of sufficient length.

Cut the glass

Many of this process also attribute to the preparatory stage, but we will single out it as an independent type of work. It is no secret that there is no absolutely non.waste production for this type of work, especially if the ultimate goal is to obtain a product with unusual geometric parameters. But if you pre.calculate and outline how to cut glass with glass cutter, you can minimize waste. Experts recommend combining the longest side of glass with a long edge of the workpiece. At the same time, the remaining scraps should not rush to throw away. they can be useful in the future.

Glass marking. On the opposite sides by the marker, the desired length is marked, and on the plane of the table, a straight line is drawn using the ruler.

Then combine the marked edges of the glass with a line on the table. The method is suitable, of course, only for transparent glasses.

The line or rail is laid parallel to the line of the future cut so that it does not interfere with the tip of the diamond cutter or the glass cutter freely move exactly along the intended line.

To make sure that the video is on the line, you can experimentally: by setting the ruler, apply glass cutter and visually evaluate the accuracy of the coincidence of the cutting tip or wheel with the intended line.

Clutching the ruler tightly, the strip is carried out at the mark of the strip.

It should be borne in mind that you should not press too much on the glass cutter to cut the glass correctly. Most importantly, it is a tool with the same click on the glass plane and unchanged speed. It is recommended to loosen the pressure in the edges of the glass. This will help to avoid Zazubrin and chips in these places.

Cutting wood, plywood, laminate using angular grinder

To cut a tree, plywood or laminate with a corner grinding machine, the corresponding discs are used. They are designed specifically for working at high speeds. But the best.suitable circles on sale are quite rare.

Cutting wood

A special wood disk has side teeth, increasing the size of the cut. In any case, it is necessary to cut wood carefully. The thickness of the boards should not exceed 4 cm.

Cutting wood with a corner grinder is a very unsafe occupation, during which you can easily get an injury. At the same time, it is strictly forbidden to use circles from the circular saw, because they are designed to work at a speed that does not exceed 3,000 rpm. If jamming occurs, then such circles may collapse. This is due to the fact that they make them from solid, but relatively fragile steel. Also, you should not use nozzles with large teeth, because the probability that the teeth will hook, and the circle will jam. In this case, the probability of pulling out the power tool from the hands increases repeatedly.

If, despite the increased danger, it is decided to saw boards with a corner grinding machine, then you must adhere to the following recommendations.

In order to best protect the workflow, the angular grinder should be used as a circular saw fixed in a stationary (motionless) position. In this case, the tool is fixed on a bed with guides. During sawing, the working material is served in the same way as on the circular.

The main disadvantage of this method of cutting lumber is the relative complexity of its implementation from a technical point of view.

Cutting laminate and plywood

To cut the laminate, use metal circles, concrete designed to cut ceramic tiles, as well as fine.tooth wood. When working, it is recommended to adhere to the following rules:

- The cut should be performed from the front part of the lamellas so as not to leave chips at the place of the cut;

- Due to the formation of a large amount of dust and the appearance of an unpleasant smell of burning material, you need to work in a well-ventilated room;

- To obtain an even cut, the lamella must be motionless.

To saw plywood, use wood discs. The cut is performed according to the previously marked line. At the same time, you should make sure that the circle does not jam the sawed fragment of the sheet before the end.

Cutting brick

Brick is a common material in construction. It is often required to fit in size, carrying out repair work in domestic conditions. At the same time, cutting bricks with a corner grinder is a very common operation. It will require, in addition to the working power tool with cutting disks, there are also such devices:

The whole process of cutting brick blocks is accompanied by significant dust formation, so you should take care of protecting the respiratory system and eye from dust. To do this, use glasses and a respirator or a continuous mask. Hands must be protected gloves.

To work with virtually no dust, it is necessary to regularly water the site of the cut with water.

The cutting process itself consists of several stages:

- applying with a chalk or pencil of the marking lines using a ruler or a square;

- Cutting bricks, in which the circle should pass near the applied line to provide the required size of the block fragment.

It is recommended to lay the board to the sawn brick so that it is more convenient to work and not damage the flooring. When cutting a brick unit, pressing on the power tool is not required. Simitable attachment of effort enough. When the work is carried out using the circles insufficient to fully saw the diameter, the cut is made along the marked perimeter. The excess is beaten off with a hammer, and then polished.

Labor efficiency and the quality of the final result can be increased by the use of a special bed. It allows you to reliably fix the angular grinder and brick block. At the same time, cutting a brick becomes possible not only along or down, but also at different angles. This installation is shown in the following photo.

To cut the brick immediately, without turning over, you should use circles with a 230 mm disk diameter. It is easier to process sections of the cut if the nozzle size is 125 mm. If you cut blocks in such a relatively small disk, then the quality of the result will be largely determined by the skill of the cutter. The work time will also increase, labor productivity will decrease.

Technology and principle of tools

Glass. fragile material, working with it is very problematic. Cutting such material requires a delicate attitude, and not everyone succeeds. To cut glass, to give it the necessary forms, today they use several types of glass cutters, but most often preference is given to the classic version. It leaves a neat scratched fishing line for a trimmer on the surface of the glass, and it remains only to break off the desired piece along the circuit.

The main knowledge of the glass is knowledge how to cut glass, so that the canvas of the required size and shape is obtained, as well as that the edges are even and without chips.

Previously, both glass and tools for processing were expensive and sharply glass were engaged only in masters with good skills, then in our time the situation has changed significantly. Nowadays, work with glass can be carried out by anyone.

Tool

A very good tool is needed to work with a glass canvas.

That’s why before buying glass and working with it, you need to start purchases with the tool.

But the first tool that came across should not be bought, because it may not be poor and will not be able to cut off the glass as it is necessary.

It is very important to determine which tool you need, because glass cutters come in several types:

Roller

A special video is built in a roller glass cutting for cutting glass, which is made of a very durable tungsten.baltic alloy. The usual diameter of the roller is 6.6 mm, such a diameter of the roller allows you to cut glass with a thickness of up to 4 mm.

Diamond

Diamond glass cutter is equipped with small diamond, this diamond cuts glass. The hardness of the diamond is well known and therefore it began to use it for a very long time to cut glass.

Nowadays, as before, diamond glass cutter is considered the best tool to cut off the glass.

Oil

Not so long ago, a glass of glass cutter was replenished with oil windshield.

This is essentially an improved roller instrument, in the handle of which a tank for supplying lubrication to the roller is built. This lubricant binds particles that formed when cutting glass while ensuring smooth movement. This glass cutter can cut glass up to 20 mm.

Workplace

Glass does not withstand local lateral loads. The pressure force from glass cutter just causes them. Therefore, the home master should work with glass only on a prepared clean and flat surface.

The coating of a solid sheet is well suited wood.fiber slab and similar materials. It is quite acceptable to set the usual table with a bedspread and cut it on it.

A little theory

Glass production is based on the melt with subsequent cooling of minerals of various compositions. After the end of the technological processes, a transparent, relatively strong structure is created. She normally withstands mechanical loads evenly attached to the entire plane, but does not resist local shock.

The usual cutting is based on the application of the scratch with hard sharp faces of the glass cutter. They reduce the strength of the surface and at the same time form microcracks, which, under the influence of operational loads, for example, gusts of wind, pressure of snow cover, lead to destruction during operation.

At the factory, when casting, a high.quality edge of the glass is created without defects that reduce the mechanical characteristics of the sheet. Consider how it is formed by a conventional construction glass cutter or its industrial automatic analogue.

Cutting heat.resistant glass

Necessary tools

As previously noted, the cutting of hot glass can only take place when using special equipment and tools. It is as follows:

- Special stove for processing hot glass.

- Thermoregulator.

- The square.

- Surface marking marker.

- Grinding stone.

- Special glass cutter.

- A rod with a diameter of 6 mm, made of wood.

- Eye. When cutting, shavings can form, which flies away from the cutting zone.

Using special equipment, you can cut hardened glass with accurate dimensions and high quality ends.

Basic pros and cons of hardened glass

Pros (dignity)

- Safety. In the case of destruction, it breaks up into small fragments that do not pose danger;

- Long service life;

- Mechanical strength. Fifetero large (204-up to 250 MPa) than ordinary glass strength for a break. Stability resistance. A bag with a fraction of lead weighing 45 kg when falling from a height of 1.2 m does not break the tempered glass with a thickness of 4 mm.

- Reliability;

- Attractive appearance;

- Excellent sound insulation;

- Resistance to vibrations and heating. Good resistance to high and low temperatures (their differences), which allows you to use it in glazing facades;

- The ability to create glass of different shapes and sizes;

With all the listed pluses and the optical properties of the glass of the past hardening remain unchanged.