Cutting Solutions. Table saw crosscut

Cutting Solutions

THE ORIGINAL DUBBY SLEDFrom standard 4 sided panel cutting to the absolutely stunning heptagon frame you will be completely accurate with the angles on your mitered projects with the Dubby Sled. The Dubby will allow you to make perfect cuts the first time you do them and keep your creative juices flowing with idea after idea. It is ideal for making frames but it also works very well for the cutting of tiny pieces while keeping your fingers out of harms way. See more product details

Dubby Cutoff Sled

From standard 4 sided panel cutting to the absolutely stunning heptagon frame you will be completely accurate with the angles on your mitered projects with the Dubby Sled. The Dubby will allow you to make perfect cuts the first time you do them and keep your creative juices flowing with idea after idea. It is ideal for making frames but it also works very well for the cutting of tiny pieces while keeping your fingers out of harms way.Please Note: The Dubby WILL NOT work on most JOBSITE style table saws.

WORKING WITH LARGE PANELS The Dubby has the capacity to crosscut panels up to 24″ wide x 52″ long, and allows you to do them safely. Since the panels don’t make contact with the table saw top, “walking” of the material is virtually eliminated. This will allow you to cut perfectly square panels for your furniture and cabinet making projects quickly, easily and accurately.

WORKING WITH ANGLES The Dubby angle scale is the simplest, most accurate and easiest to read scale available. Being about 15-20 times more accurate than the average miter gauge, the scale has pre-determined lines for any shape (from 4 to 16 sides) you want to cut. This means no calculations, no hassles, and best of all, no test cuts for perfect results

WORKING WITH SMALL PIECES No miter gauge on the market can offer you the margin of safety provided by the Dubby Sled. The versatile hold-down clamp included with every Dubby will give you an extremely safe way to cut small pieces, and will easily pivot out of the way when you don’t need it. With 35lbs. of hold down pressure, the clamp will hold small pieces all the while keeping your hands and fingers out of harms way.

Will the DUBBY Fit Your Saw? The Dubby sled is compatible with most cabinet and contractor table saws. However, your table saw should fall within the following specs for a proper fit. The Miter Slot should be a ¾” wide x 3/8″ deep slot. Your saw must measure at least 27″ from the front of the saw to the back. The miter slot must be 4″ to 5 ¾” from the installed table saw blade. Read Info

The Original Dubby Table Saw Cut Off Sled System

If you are looking for a product that will allow you to work more accurately with your table saw, we hope that we may be of some assistance in your search. Our objectiveis to provide you with information that will allow you to determine if the Dubby is a tool that will be useful in your shop, and also help you determine if you would want a “Single Dubby” or the “Double Dubby” to meet your needs. There have been a lot of new after-market miter products invented since we introduced the Dubby back in the mid ’80s, but none of them has been able to offer the versatility, accuracy, simplicity, safety, and just plain fun of this outstanding product. From panel cutting to absolutely accurate angles on your mitered projects, the Dubby will allow you to make perfect cuts the first time you do them.

Dubby precision everytime

From repetitive cuts to one and done cuts, with the Dubby you’ll be able to cut your angles accurately each and every single time you use. The Dubby is simple unmatched when it comes to simplicity and consistent precision.

So easy to adjust

As with the rest of the Dubby, your angle set up is a breeze. Simply loosen the lock knob and adjust the fence to your required angle on the etched metal scale and lock it in place. That’s it! Its that simple and that quick!

Large or Small

The Dubby wasn’t just designed for one type of woodworking project. It is designed to assist you with your day to day woodworking projects. From larger panels to small moldings, the Dubby is ready to help make the perfect cut

It really is simple to use

The Dubby’s no nonsense approach has served itself and its many loyal users over the years very very well. From the easy to adjust fence to the easy to handle hold down toggle for small parts, the Dubby is perfect for any woodworker. It doesn’t matter if your just starting out or are an experienced woodworker, the Dubby is a must for every workshop!

Micro Adjsutable

Precision is important in some instances, and when its needed, the Dubby delivers. The adjustable stop not only allows you to make precise repeatable cuts, but it allows you to micro adjust the exact location to stop you stop piece. Talk about precise!

Select a side below to view compatibility chart

A. Depth of table saw top:

B. Distance from the saw blade to the edge of the extension:

This measurement should be at least 19″. You must insure that the Dubby platform will not overhang the outside edge of the extension.

C. Width and depth of miter groove:

The miter grooves on the saw should be 3/4″ wide and 3/8″ deep. The grooves may be slightly undersize or oversize, as our adjustable/self-adjusting bar will accommodate these variations.

D. Distance from the miter groove to the blade:

For Dubby orders this measurement should be between 4″ and 5 3/4″.

- Work With Large PanelsThe Dubby has the capacity to crosscut panels up to 24″ wide x 52″ long.

- Work With AnglesThe Dubby angle scale is the simplest, most accurate and easiest to read scale available.

- Work With Small PiecesThe versatile hold-down clamp included with every Dubby will give you an extremely safe way to cut small pieces, and will easily pivot out of the way when you don’t need it.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Note: Designed for Full Size Saws

Dubby Replacement Parts

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

DIY Table Saw Crosscut Sled Kit

DIY Table Saw Crosscut Sled Kit

If you own a table saw, you probably have come across a situation or two where you need to make smaller cuts or make cross cuts. You may also have had the need to make repetitive cuts of the same length. Making small cuts, cross cuts and repetitive length cuts is where table saw crosscut sleds excel. Crosscut sleds help stabilize the work piece and are very accurate since they are essentially calibrated to your saw during the sled building process. See more product details

×

DIY Table Saw Crosscut Sled Kit

If you own a table saw, you probably have come across a situation or two where you need to make smaller cuts or make cross cuts. You may also have had the need to make repetitive cuts of the same length. Making small cuts, cross cuts and repetitive length cuts is where table saw crosscut sleds excel. Crosscut sleds help stabilize the work piece and are very accurate since they are essentially calibrated to your saw during the sled building process. Some time ago we noticed a lot of companies had UHMW bars available for purchase. While we as a woodworking company know exactly what they are used for, many novice or non-woodworkers do not. That’s when we decided to create this package with pre-cut UHMW bars, pre-cut aluminum track, a knob and bolt and an easy to understand how to guide booklet so you can create your very own, custom crosscut sled to fit your table saw!

Why Make it Complicated

This kit has been put together with one main theme in mind. Keep it simple. From the hardware included, to the “How To” Guide Booklet, we made the crosscut sled building process a breeze. Sure, you can spend more money other kits to try and build a sled, but most of those kits and manufacturers assume you already have it all figured out. We chose the opposite approach and prepared everything for you and included everything but the wood material in this kit. Its as simple as taking the supplied hardware, choosing your size, then build your sled to your specifications!

Please Note: Wood and other building materials are NOT included with this kit.

Whats a Cross Cut Sled You Ask?

Crosscut sleds have a basic singular purpose and that is to crosscut smaller stock pieces on your table saw. Thats the basic function of a crosscut or cutoff sled. However, crosscut sleds are excellent for not only small stock pieces but mid size cuts as well. Not only that, these sleds can be used for making repetitive cuts at the same length when a stop block is employed. Crosscut sleds typically become one of the most commonly used jigs in your workshop.

Please Note: Wood and other building materials are NOT included with this kit.

High Quality Parts

From the UHMW bars to the Anodized Aluminum Tracks, this kit is made for the task and not to mention made in the USA! The track and UHMW bars are the perfect hardware to help you create and build the ideal crosscut sled.

Please Note: Wood and other building materials are NOT included with this kit.

Full Color, Full Detail How To Guide Included

When putting this kit together we wanted to make sure that we covered all the bases. The final piece of the puzzle was the How To Build Your Own Crosscut Table Sled guide booklet. We took the time to map out how to build your very own sled, but left the dimensions up to you so you can adapt the sled to your particular table saw.

Please Note: Wood and other building materials are NOT included with this kit.

Your Saw. Your Size

The size of the sled can be any basic size you require based on the size of your table saw. While most contractor and consumer level cabinet saws are 27″ long from front to back, many job site saws are considerably smaller. The one thing you must make sure of is that the UHMW bars will fit into your slot. This kit includes 3/4″ x 3/8″ UHMW for standard 3/4″ x 3/8″ miter slots.

Please Note: Wood and other building materials are NOT included with this kit.

Please Note: Wood and other building materials are NOT included with this kit.

Made in the USA

Made in the USA so you know you’re getting a high quality kit to help you with your next workshop project!

UHMW bars are most commonly used as runners for crosscut sleds since they don’t produce as much friction as wood does. Another advantage is that UHMW won’t expand or contract like wood does during drastic weather changes. Each bar is approximately 3/4″ x 3/8″ which fits most standard table saw slots. UHMW bars are also slick and won’t leave any residue, dust or shavings behind like wooden bars tend to do. The tracks that are included in this kit are made from solid extruded aluminum and are Made in the USA. Each track is cut to length for the perfect sub-fence on the crosscut sled. The included knob and bolt is for making a simple stop block which when finished, can slide the length of either track along the sub-fence. The stop block will allow you to make repetitive cuts without having to constantly move and measure the fence distance each time you make a cut.

We have also included a full color and detailed how to guide book to help you with the crosscut sled building process. Each kit comes with 2 each 19″ long by 3/4″ by 3/8″ UHMW bars, 2 each 12″ long mini tracks, 1 each knob, 1 each 1/4″ by 20 tpi bolt and a how to build your own crosscut sled guide book. Make your crosscut sled to the size you want or need for your table saw and your specific cutting needs.

Please Note, the bars do NOT FIT RYOBI table saw track slots.

- Build your own crosscut sled

- Make crosscuts quicker and easier

- UHMW Runners

- The tracks that are included in this kit are made from solid extruded aluminum

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Make an Ultra-Square Crosscut Sled (5 Cut Method Calculator Included)

The first thing any table saw owner should build is a crosscut sled. They make using a table saw safer, easier, and they skyrocket the repeatability and accuracy of your woodworking. There’s a million and one guides to building this essential jig — some with all the bells and whistles. That’s not what you’ll find here. This guide explains how to build a simple and solid crosscut sled that’ll give you dead-nuts accurate cuts time and time again… Meaning you can build it in a couple hours — and move on to making the fun stuff. We’ve also created a 5 Cut Method Calculator you can use to dial in your sled to perfection (without having to do any math at all).

WHY YOU NEED A CROSSCUT SLED

Why build a crosscut sled when you already have the miter gauge that came with your table saw?

SAFETY

Most miter gauges aren’t big enough to support a board very well. And with the friction of the board moving over the table, it’s even harder to keep it steady.

This increases the chances of kickback — especially with bigger boards.

With a good crosscut sled, the board is fully supported and there’s virtually no risk of kickback.

ACCURACY

Since crosscut sleds keep boards steady as they pass through the blade, cuts stay right on your line.

The cut in the base of the sled (which is exactly the kerf of your table saw blade) also makes aligning cuts a breeze. Just slide your marking line up to the kerf cut and you’re set.

REPEATABILITY

Crosscut sleds allow you to use stop blocks — meaning you can cut multiple pieces to the same length without measuring.

A stop block can be as simple as a square piece of scrap and a clamp. But for real accuracy and efficiency, I recommend the Katz-Moses No Deflection Stop Block.

No deflection means it doesn’t budge once it’s locked down — even if you’re slamming 8/4 boards up against it.

CLEANER CUTS

A crosscut sled that extends past both sides of your table saw blade supports your stock on both sides of a cut.

That support reduces tearout on your workpiece and offcut, saving you from extra cleanup or wasted wood.

A FEW TIPS FOR SUCCESS

The more care you take building your sled, the longer it’ll serve you.

Take the time to make sure your pieces come out square, straight, and flat.

Before cutting anything, make sure your table saw blade is at exactly 90°.

And be modest with the size of your sled.

I once made an enormous crosscut sled I thought would be great — but it was way too heavy and the long fence changed shape over time.

Modify the size to your needs. But I recommend matching your sled to the dimensions of your table saw top.

HOW TO BUILD A CROSSCUT SLED

You don’t have to follow these instructions in this exact order, but I find it to be the most efficient process (accounting for glue dry time).

ROUGH CUT YOUR PIECES

I cut my base to about 24 x 38 inches to fit my table saw top.

Since the fences will stand on their edges, the width of the pieces equal the fence height.

If you’re planning to use my stop block, plan to make your fence a hair over 2 ¾”, 3”, 3 ¼”, or 3 ½” tall. This ensures the stop block can reach the base of your sled.

Cut your fence pieces oversized at first. You’ll trim them down to their final dimensions later.

The back fence (furthest from the user) just holds the two sides of the base together, so length isn’t too important.

For the front fence (closest to the user), I generally make it as long as the base.

I like to make my fences with 3 pieces of plywood. It creates a big bottom that guarantees the fence will sit at a perfect 90° to the base.

SAFETY TIP: Unless you know exactly what you’re doing, I don’t recommend taking a 4×8 sheet of plywood straight to your table saw.

It’s too heavy and unwieldy, and can easily lead to a kickback.

Use a track saw or circular saw with a straight edge to cut your board into more manageable pieces. Then trim them up on the table saw.

GLUE UP THE FENCES

What matters here is that your fences dry flat.

Look down the length of your plywood pieces. If they bend a certain direction, alternate how you glue them up so their opposing forces pull them flat.

You can also clamp the pieces against a sturdy level as they dry (thanks, Tamar).

Make sure the faces have glue from corner to corner and edge to edge, and clean up any squeeze out with a wet rag as soon as it’s clamped up.

MAKE THE RUNNERS

The runners should be snug but slide easily in the miter slots.

Once you add paste wax they’ll run more freely, so err on the tight side

Use a pair of calipers to measure the exact width of your miter slots. Cut two strips of hardwood a hair wider than that measurement and dial them in with a planer or hand plane.

They should sit around 1/10 inch lower than the table top when resting in the miter slots.

This doesn’t need to be exact. You just don’t want them dragging on the bottom when attached to the base.

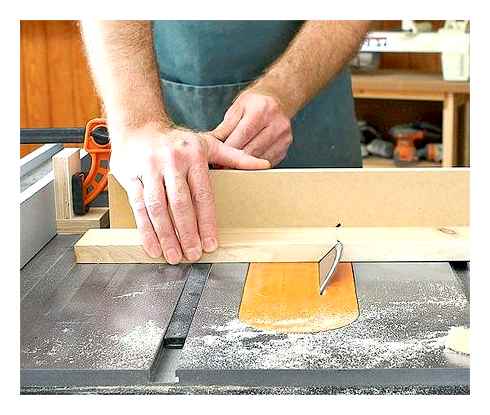

ATTACH THE RUNNERS TO THE BASE

Lay down a line of 5 or 6 coins or washers in the bottom of each miter slot, then lay the runners on top of them.

I run a line of wood glue along the tops of the runners and spread it evenly. You don’t need to use wood glue — but it will increase the longevity of your sled.

Then run a bead of CA glue over the runners (it’ll still work on wood glue).

TIP :This trick makes sure your sled has almost zero play — even if your runners aren’t perfect.

Use a sliver of wood or paper to shim both runners either away from or towards each other.

This pushes the runners tight against the miter slot walls before you lay down the base.

Use the table saw fence as a reference for laying down the base onto the runners.

Then put something heavy on the base over the runners until the CA glue dries. About 5 minutes should do. Make sure there’s weight on the ends as well.

Once the glue’s dry, flip the sled over with the runners facing up. Lift straight up so you don’t snap them off with the miter slots.

I put 5 to 6 screws through the runners to make sure they never budge. And make sure to drill pilot holes and countersink the screws.

Trim off any excess that extends past the base and you’re good to go.

FINISH UP THE FENCES

Now that the fences have dried, it’s time to clean them up.

Rip a thin strip off one side to get a clean edge. Then flip the fence over and rip it down to its final height (I do about 3 ½ inches).

TIP: If the edges are too uneven or covered with dried glue to rip safely (I told you to clean it up), tape a straight edge to the top and ride that along the table saw fence.

Make the thin rip on one side, then use that as a reference edge for the other side.

Just make sure your straight edge won’t go into the blade and stand clear in case of kickback.

Now cut your two fences to their final length.

If you like, use a block plane to put a small chamfer on the front bottom edge of the front fence. This keeps sawdust from getting in the way of your stock while you’re making cuts.

ADD T-TRACK FOR THE STOP BLOCK

I seriously recommend adding t-track for a good stop block to your fence.

It simplifies making accurate, repeatable cuts — and is quicker and more reliable than clamping a piece of wood.

Use a dado stack or router to cut a groove through the top of the fence. Make it around ½ inch from the front, and just a hair deeper than the height of the t-track.

Once the grooves cut, lay in the t-track and mark where to cut.

You can cut aluminum on pretty much any woodworking tool. I use an angle grinder myself, then file down the rough edges.

SawStop NOTE: If you’re using a SawStop table saw, make sure you put it in bypass mode before cutting aluminum.

Fasten the t-track in the grooves with screws. You can also add some 5 minute epoxy for extra bonding strength.

ATTACH THE FENCES

Attach the back fence to the base by screwing through the bottom of the sled. Make sure to countersink the screws so you don’t scratch up your table.

The placement isn’t critical as long as it reaches past both sides of the blade.

Now this is where things start to matter.

ATTACHING THE FRONT FENCE

You’re only going to use two screws to attach the front fence at first:

A pivot screw on one end (which will NEVER MOVE) and a second screw somewhere on the other side (which will move).

TIP: Measure from where you’ll place the pivot screw to the opposite side of the fence. Use a square to mark a few alignment lines to get it right.

Write down this distance. It’s a variable in the 5 cut method equation — and doing it now is a lot easier than trying to measure from the bottom of the sled later.

Pull the sled back and raise the blade to just higher than the base. Turn on the table saw and run the sled through the blade.

SQUARING YOUR SLED: THE 5 CUT METHOD

Congratulations, you’ve built a crosscut sled. But it won’t give you dead-nuts square cuts right off the bat.

That’s where the 5 cut method comes in. It can seem intimidating, but I promise it’s actually really easy.

And to make it even easier, check out our 5 Cut Method Calculator that tells you exactly how much to adjust your fence to bring it into square.

WHAT IS THE 5 CUT METHOD?

The five cut method is a formula that helps you calculate the error per inch of your crosscut sled.

It uses one piece of wood to compound the error of your sled — and help you get that error down to a tiny fraction of an inch.

HOW TO USE THE 5 CUT METHOD

Grab a scrap board that has one flat-ish side. Anything semi-rectangular will do.

The dimensions don’t matter. It just needs to fit in your crosscut sled and not be so small that you can’t make significant cuts.

Rest the board on your crosscut sled with one side resting against the fence.

For the sake of clarity, let’s say it’s on the right side of the crosscut sled (meaning the left edge will be cut from the user’s perspective).

Label the top left corner (furthest from you and closest to the blade) with an A. Label the bottom left corner (closest to you and closest to the blade) with a B.

You can also number each side clockwise from 1 to 4 for clarity — side 1 being the left side closest to the blade (labeled with an A and B), and side 4 resting against the fence.

Rotate the board counter-clockwise so the freshly cut edge is resting against the fence and make a similar cut on side 2. Repeat this process for sides 3 and 4.

After you cut side 4, rotate it counter-clockwise one last time so side 4’s against the fence like how you started.

You’ll now take a final 5th cut off the side marked with an A and B. Make this offcut about ½ inch. It doesn’t have to be exact — you just don’t want it too thin.

SAVE THIS OFFCUT — it’ll give you the variables for the 5 cut method formula.

Just make sure you know which is the A side (furthest from user) and B side (closest to user).

THE 5 CUT METHOD FORMULA

Use a pair of digital calipers to measure the width of side A and side B, then measure the length of the offcut. Try to get precise measurements — down to 2 or 3 decimal places is good.

- [(A–B) ÷ 4] ÷ Length of 5th offcut = Error per inch (EPI)

- EPI x Distance from pivot screw to end of fence = Distance to move fence

- If result is positive, move fence away from user (forward)

- If result is negative, move fence towards user (backwards)

Let’s say you get the following variables (in inches):

- Width of side A: 0.59

- Width of side B: 0.52

- Length of 5th offcut: 5.73

- Distance from pivot screw to end of fence: 20

First, you’d subtract side B from side A:

Divide the result by 4 (for the 4 sides of the board):

Then divide by the length of the 5th offcut:

Your error per inch is 0.003 inches. It doesn’t sound like a lot — but I promise you can do better.

Now to calculate how much to move the fence, multiply the EPI by the distance from the pivot screw to the end of the fence.

Since this number is positive, you’d move the end of your fence furthest from the pivot screw away from you 0.061 inches.

If the result were negative, you’d move it the opposite way towards you.

But how can you reliably adjust the fence by such a small amount?

ADJUSTING YOUR FENCE WITH THE 5 CUT METHOD

You’ll need a piece of scrap wood, a couple clamps, and a feeler gauge.

If you don’t have a feeler gauge, cut several small strips of paper. Use your digital calipers to figure out how big a stack will get you close to your adjustment number (0.061 in our example).

To move your fence forward, place your feeler gauge or paper stack against the end of the fence — and I mean the end.

Move the scrap wood up against the feeler gauge and clamp it in place. Use just the corner of the scrap right at the end of the fence to get super exact.

Clamp the piece of scrap down securely. You don’t want it to shift.

Take out the second screw holding your fence in place (NOT THE PIVOT SCREW), remove the feeler gauge, and push the fence forward until it touches the piece of scrap.

Clamp the fence down in this position, then drill a new hole for the second screw and fasten the fence in place.

NOTE: Don’t reuse any of these “second screw” holes. If you do, it’ll just pull your fence back into the wrong position.

Mark previous holes so you don’t accidentally use them again. Yes, I’ve messed this up before.

If you need to move your fence back towards the user, first clamp the scrap wood in place with the edge against the fence.

Then remove the second screw, insert your feeler gauge between them, and push the fence against both so the feeler gauge (or paper) is held tight. This is where you’ll refasten the fence.

Now repeat the 5 cut method again. Done properly, you should only have to do it 2 or 3 times.

WHAT’S GOOD ENOUGH?

Woodworking isn’t machining. You want your crosscut sled to cut square — but it doesn’t have to be precise enough to send billionaires to space.

If the final number to adjust your fence gets into the triple digits (i.e. 0.007 inches), take it and run.

You can even just cut a piece of scrap wood on the sled and test it with a good square.

If there’s no light between the edge and the square blade, it’s time to start building.

FINISHING TOUCHES

Once your fence is squared up, throw a few more screws in the bottom to secure it in place. 4 to 30 should do the job.

Break the top corners of the fence with a block plane to make it kinder to your hands.

Then just lightly sand all your surfaces and slather them down with some Katz-Moses goo.

Rub the bottom of the sled and runners with paste wax so it slides easily and doesn’t scratch up the table, and you’re good to go.

HOW TO STORE YOUR SLED

Your crosscut sled can basically live on your table saw and be moved to the floor or table when not in use.

It’s best to lay it down flat so it doesn’t warp over time (avoid leaning against anything for a long period of time).

You can also drill a hole in one side and hang it from a wall.

AN ESSENTIAL WOODSHOP JIG

A good crosscut sled will quickly become the most-used jig in your shop.

And even though this is a simple version — it’ll be an absolute workhorse for you.

Afterall, there’s elegance in simplicity.

Have you souped up your crosscut sled with other modifications? Tell us how in the Комментарии и мнения владельцев below!

And as always, STAY SAFE IN THE SHOP!

Continue reading

6 Комментарии и мнения владельцев

Finished my first sled with this build. I was convinced I wasn’t doing something right. After the VERY FIRST 5cut calculation, I had002!! Is that mind blowing to anyone else? Never moved the fence! I still can’t believe it. Had to share that here, my wife just rolls her eyes…

Finished my first sled with this build. I was convinced I wasn’t doing something right. After the VERY FIRST 5cut calculation, I had002!! Is that mind blowing to anyone else? Never moved the fence! I still can’t believe it. Had to share that here, my wife just rolls her eyes…

A simpler version of Fred’s method uses a 3-4-5 triangle rather than a right angle and requires no calculation. By measuring 3 units along one edge (A unit could be 1cm, 10cm, 4in etc) and 4 units along the other (edge 1 might be the kerf, edge 2 the guide) the resulting hypotenuse should be 5 units long. If not… adjust. The other Комментарии и мнения владельцев regarding this method still apply. Personally I would attempt to trace a perpendicular using basic geometry and then screw my guide provisionally to this line. Then the 5 cut method can be used to verify the accuracy and adjust if necessary.

A simpler version of Fred’s method uses a 3-4-5 triangle rather than a right angle and requires no calculation. By measuring 3 units along one edge (A unit could be 1cm, 10cm, 4in etc) and 4 units along the other (edge 1 might be the kerf, edge 2 the guide) the resulting hypotenuse should be 5 units long. If not… adjust. The other Комментарии и мнения владельцев regarding this method still apply. Personally I would attempt to trace a perpendicular using basic geometry and then screw my guide provisionally to this line. Then the 5 cut method can be used to verify the accuracy and adjust if necessary.

PS. I should have said if you get 84.70 you will have to move the fence AWAY from the blade until you get 84.84.

PS. I should have said if you get 84.70 you will have to move the fence AWAY from the blade until you get 84.84.

Caution: I’m thinking there might be a few flaws in Fred’s geometry method. 1) If the pivot screw in the right side is inserted firmly but the fence can still be moved, it might move slightly on that first cut. Probably not a big deal but it could happen. 2) If the pivot screw is at the right end of the fence as instructed above and the sled is centered on the blade, then your geometry will be thrown off. Using Fred’s numbers, measure 60 cm from the fence along the kerf and 60 cm along the fence. Unless your diagonal ends up exactly 84.84 cm on first measurement you’ll have a geometry problem. Say you get 84.70. Now you have to move the fence toward the blade until you get 84.84, but when do the 60 cm along the kerf is no longer 60 cm. It is shorter (because the pivot point is 25 cm to the right of that line).

The only way this method can work correctly as described is if the pivot screw is exactly at the point where the two 60 cm lines meet, right on the edge of the fence where it meets the left.

Finally, Fred is happy with 1 mm accuracy, which equals ~0.0394 inches. The author mentions getting that number down to 0.007 inches. I’d give the 5 cut method a try.

Caution: I’m thinking there might be a few flaws in Fred’s geometry method. 1) If the pivot screw in the right side is inserted firmly but the fence can still be moved, it might move slightly on that first cut. Probably not a big deal but it could happen. 2) If the pivot screw is at the right end of the fence as instructed above and the sled is centered on the blade, then your geometry will be thrown off. Using Fred’s numbers, measure 60 cm from the fence along the kerf and 60 cm along the fence. Unless your diagonal ends up exactly 84.84 cm on first measurement you’ll have a geometry problem. Say you get 84.70. Now you have to move the fence toward the blade until you get 84.84, but when do the 60 cm along the kerf is no longer 60 cm. It is shorter (because the pivot point is 25 cm to the right of that line).

The only way this method can work correctly as described is if the pivot screw is exactly at the point where the two 60 cm lines meet, right on the edge of the fence where it meets the left.

Finally, Fred is happy with 1 mm accuracy, which equals ~0.0394 inches. The author mentions getting that number down to 0.007 inches. I’d give the 5 cut method a try.

For the pivot screw in the front fence, I drilled the fence bottom and placed a 1/4” threaded brass insert in the fence being careful to get it perfectly perpendicular by use of a drill press Then I drilled and countersank a 1/4” hole in the base to fit a 1/4” Allen head machine screw. This made repeated loosening and tightening of the pivot screw a breeze and the pivot never moved or loosened.

For the pivot screw in the front fence, I drilled the fence bottom and placed a 1/4” threaded brass insert in the fence being careful to get it perfectly perpendicular by use of a drill press Then I drilled and countersank a 1/4” hole in the base to fit a 1/4” Allen head machine screw. This made repeated loosening and tightening of the pivot screw a breeze and the pivot never moved or loosened.

A much easier way to set your fence than the 5-cut method is just to use one simple calculation from geometry. Fix the right side of the fence as close to square as possible firmly but so it can still be moved. Then, push the unadjusted sled through the saw the first time. Mark and measure along the left side of the cut from the fence to as close to the far end as possible. Use centimeters as accurately as you can measure, usually to the mm. Lay out the same distance along the fence to the left and mark that with a point. The distance between the points must be 1.414 the length of the first measurement to set the fence to precisely 45 degrees. Adjust the fence to make this so and fasten. Using this method to make my sled results in cuts the full depth of my sled to within a mm of square. I used this for a miter sled too. Perfect. Example: First measurement is 60.0cm, about two feet. Mark the fence to the same 60.0 cm. The calculation is simple: 1.414 × 60 = 84.84. Set the distance between the points as accurately as you can to 84.84 then fasten the fence. Done. If the fence is too short to mark the second distance, mark the farthest point you can to the left along the fence and transfer that same measurement to the left side of the cut. You can use multiples of a 3-4-5 triangle to do the same thing. Very easy using centimeters.

A much easier way to set your fence than the 5-cut method is just to use one simple calculation from geometry. Fix the right side of the fence as close to square as possible firmly but so it can still be moved. Then, push the unadjusted sled through the saw the first time. Mark and measure along the left side of the cut from the fence to as close to the far end as possible. Use centimeters as accurately as you can measure, usually to the mm. Lay out the same distance along the fence to the left and mark that with a point. The distance between the points must be 1.414 the length of the first measurement to set the fence to precisely 45 degrees. Adjust the fence to make this so and fasten. Using this method to make my sled results in cuts the full depth of my sled to within a mm of square. I used this for a miter sled too. Perfect. Example: First measurement is 60.0cm, about two feet. Mark the fence to the same 60.0 cm. The calculation is simple: 1.414 × 60 = 84.84. Set the distance between the points as accurately as you can to 84.84 then fasten the fence. Done. If the fence is too short to mark the second distance, mark the farthest point you can to the left along the fence and transfer that same measurement to the left side of the cut. You can use multiples of a 3-4-5 triangle to do the same thing. Very easy using centimeters.

Table Saw – How to Build a Crosscut Sled for A Table Saw?

The table saw crosscut sled is every woodworker’s dream. This dream is not just because of the speed associated with getting things done but also the precision. There are a lot of technical ways you can go about making a crosscut table saw sled.

This article presents all you need to know about building a crosscut sled for the table saw. It will present several factors you must consider and the steps you must follow.

So, as we move through each section, open your mind to making a practical DIY crosscut sled.

Table of Contents

- 2.1 What is a crosscut sled?

- 2.2 What can the table saw crosscut sled do?

- 3.1 There is no friction between the crosscut sled and the table saw.

- 3.2 Crosscut sled fences can prevent hurting.

- 3.3 Table saw crosscut sled can make repeat cutting:

- 3.4 Crosscut sled can accurately cut at an angle.

- 4.1 Structure

- 4.2 Tools and Supplies

- 4.3 Gather materials and cut the pieces

- 4.4 Cut and assemble the runners and the base

- 4.5 Add the stiffener and square the fence.

- 4.6 Test the fence for square

- 4.7 Add stop blocks

- Create First Cut Series

- 4.8 Check accuracy (5-cut Method)

- 5.1 Magic miter sled

- 5.2 How it works

- 5.3 How to build a table saw sled for 45-degree miter cuts?

Section 2: About table saw crosscut sled.

2.1 What is a crosscut sled?

A crosscut sled is a device you can use to make crosscuts. However, there are different intricacies in creating a crosscut sled.

Crosscut sleds are not just a modern time tool, as different generations have different applications and modifications of the tool.

The different variations of the crosscut sled available today require sufficient insight before making a choice.

2.2 What can the table saw crosscut sled do?

As a modern woodworking tool, the crosscut sled has quite some functionalities that you must know:

The crosscut sled makes safe and repeatable crosscuts on a table saw.

Crosscut sleds are also renowned for their accuracy and are very helpful in making complex cuts.

With a 90-degree position design, it also possesses zero-clearance kerf.

They are also very versatile in adding accessories like stomps and clamps to improve functionality.

Speed is one of the finest attributes of the table saw. The speed allows the crosscut sled to cut through multiple parts easily.

Tablesaw crosscut sleds also come with a single or double miter track design for improved accuracy.

crosscut sled

Section 3: Why do we need the table saw crosscut sled?

3.1 There is no friction between the crosscut sled and the table saw.

Friction is a major concern whenever you carry out activities that involve motion. Likewise, for the table crosscut sled, friction affects its motion.

This frictional concern occurs because they are mostly flat as you cut your ply or hardwood. This positioning, along with the movement from the workpiece against the blade, causes friction.

Your grip on the workpiece must be firm to get an accurate cut. This step can prove to be trickier at times when you have to cut slippery materials.

In a nutshell, as your workpiece gets larger or more complex, they increase friction. Some woodworkers prefer miter gauges at such times, but the crosscut sled can be more effective.

Miter gauges may not be effective in cutting materials of such sizes. The crosscut sled’s design makes for a larger base that prevents contact of the workpiece with the saw table.

The absence of this contact makes the crosscut sled a much better option for reducing friction.

3.2 Crosscut sled fences can prevent hurting.

Due to the increasing sizes of materials and complexity, the miter gauge fails to meet accuracy and speed. Using the miter gauge will leave you open to accidents from the blade.

For this reason, the crosscut sled edges the miter gauge with its design configuration. This configuration includes accessories that improve its safety worthiness.

A crosscut sled is particularly useful in preventing injuries or causing fatalities. The crosscut sled’s tailgate provides a clamping surface, thereby preventing accidents.

3.3 Table saw crosscut sled can make repeat cutting:

The crosscut sled device is your best option if you are a woodworker. This device allows you to carry out repeated cutting during woodworking.

With its adjustable stop feature, the table saw crosscut sled is a perfect tool for repeat cutting.

All you need to do is to input the parameters of the sled that mark the dimensions you need. The sled operates more like a basic control system.

Some sleds, however, don’t come with this feature. You can easily attach a scrap block to the fence, and you are good to go with the feature.

3.4 Crosscut sled can accurately cut at an angle.

The crosscut sled is a gem for making cuts at impossible angles. With its zero-clearance feature, the sled combines accuracy and acute functionality.

Section 4: How to build a crosscut sled for your table saw?

4.1 Structure

The design and structure of this sled restrict the number of resources you have available. In addition to the design is the factor that allows you to borrow concepts from earlier and other manufacturers.

Invariably, you are not building from scratch. It is just a combination of different techniques and methods of building a crosscut sled.

4.2 Tools and Supplies

- Tri-Square

- Drill Bit

- Countersink Bit

- Calipers

- Miter Saw Stand

- Plywood

- Hardwood scrap (straight)

- Earmuffs

- Wood glue

- Feeler Gauges

- Router Bit Set

- Kreg Mini Track

As a side note, you must calibrate your table saw before making any cuts to prevent errors in cutting dimensions.

Tri-square

4.3 Gather materials and cut the pieces

Get yourself a ½” plywood, then mark and cut a 36 inches width along with a 26 inches depth dimension. This dimensioning will make for a suitable table saw sled base.

For creating your fences, use a double stack of ¾” plywood. You can use offcut plywood for this purpose. You should create strips with 37 inches and 23 inches for the back and front fence, respectively.

Glue your strips together to make for a compact fence that is very straight.

Finally, let the glue dry for 8-10 hours before cleaning up the faces with a jointer.

Cutting pieces

4.4 Cut and assemble the runners and the base

- When assembling the runners and the blade, cut your back fence square. After this, you mark your workpiece using a table saw sled base.

- You can cover all exposed edges using a round rover. Then dimension the plywood to make cuts at necessary points.

- Cut your runners using maple wood according to your dimensions for width.

- Adjust the fence to ⅜”, flip your runners and run them through.

- Drill countersunk holes in each runner.

- Next, use the miter slots to position the runners.

- Create slots on your plywood and put two washers along with the slot

- Drop in the runners to move them up from the table surface.

- Secure your runners to the base with permanent screws

- Cut your runners in correspondence to the length of your sled base.

- Finally, give the runners a trial test.

4.5 Add the stiffener and square the fence.

- Before setting up your fences, make sure to add stiffeners at the respective table saw sled ends.

- Next is to make marks on the sled on your router table. These marks will indicate the track length from beginning to end on both sides of the table.

- Mark the width of the cut

- Make a plunge cut on the backside.

- Move your router fence back to allow for maximum width groove.

- Use a chisel for each slot to give it a polished clean look.

4.6 Test the fence for square

- Smoothen your track edges to keep it from catching on anything, then test.

- Put your front fence to hold the sled after cutting.

- Adjust your fence to the end of the sled the drill in with 1-½” screws.

- Raise your blade to cut through from the fence till you get to about 3 inches to the back fence.

- Drill your back fence edge with a countersink bit

- Clamp the fence firmly and square with a chisel.

4.7 Add stop blocks

- Cut a small scrap block and spline, then adjust with sandpaper to fit your sled track. The stop block is a basic block design that acts as a safety measure. The block has a spline to keep the block from rotating with the blade when you lock down the crosscut sled.

- Position your block to about ⅛” to create an allowance for sawdust and minor kickbacks. Subsequently, attach the stop block to the table saw crosscut sled.

- Cut two other sled blocks of sizes 4×3 inches.

- Glue them together and around sled edges.

Create First Cut Series

- Adjust your fence using the popular 5-cut method series.

- Firstly, assign numbers to a fresh 1818 plywood on all sides.

- Create a strip from each side, with the first strip having a higher dimension.

- Measure both sides of the strip using a caliper.

- Secure all countersunk hole locations to increase rigidity.

4.8 Check accuracy (5-cut Method)

- Repeat your 5-cut method process to take the error percentage.

- Your error should reduce drastically with up to 80% error reduction.

- Clamp a level to your fence for rigidity, then screw the fence in place.

- You can also create further assurance by securing all countersunk hole locations with omission to the first hole.

Section 5: Can I make a table saw sled for 45-degree miter cuts?

5.1 Magic miter sled

The Magic Miter is a woodworker’s go-to tool to measure and cut the ideal markings on your workpiece. Magic miters prove to be integral equipment for handling the versatility that comes with different projects.

5.2 How it works

Using the magic miter, you begin by placing a measuring tool at the points you want to measure. Subsequently, changing the different sides’ miter would be best to lay the level against the wall or plane.

Place the Magic Miter in line with the measuring tool. Change the Magic Miter arms by pushing the middle support forward or reverse.

Continue pushing this support until the arms sit at a similar point as the measuring tool’s point.

Press the point measuring tool down onto the Magic Miter and lock it into a spot to set the point. Add the wood (or other material) you wish to cut into the Magic Miter.

Next, supplement the material on the left arm of the Magic Miter. This procedure does cut a point facing left or right.

Next, add the sharp edge to the Magic Mitre’s middle groove before working on the wood. Hold the wood set up with your non-cutting hand.

Saw the wood until it was carved entirely through before removing it from the Magic Miter. Press the point estimating device down onto the Magic Miter and lock it into a spot to set the point.

Supplement the material on the Magic Miter’s left arm. It allows you to cut a point facing the left or the correct arm to cut an angle.

5.3 How to build a table saw sled for 45-degree miter cuts?

The first step to making a 45-degree miter cut is to attach your runners. To do this attachment, you will tape the top of the runner on both sides. Next is to align your fence to the base with your runners.

Following that, you must attach your sled base to the tape and check to see if it runs smoothly. Then drill holes through your runners into the base and create tap threads into those holes.

Subsequently, fasten with a countersink drill bit. One of the simple tasks during this construction is attaching the fence. All you have to do is place it on the sled, so it flushes with the edge.

Next, you must carefully slide the fence over the fence and take the biggest square. Once you are sure you have taken the biggest square, set it. After setting the square, all that remains is to screw the screws in the corners.

Conclusion

Crosscutting is popular among professionals, skilled users, and unskilled operators. Making a crosscut sled can be tricky, especially if it is a DIY sled.

This article outlays a systematic approach to making your table saw crosscut sled. In conclusion, therefore, as you continue to look out for helpful tips to help make your table saw crosscut sled, look no further.

NCCuttingtools has got you covered. We have the best products and professionals to meet your table saw needs. Contact us today.

What is a table saw sled and why you should use it?

Woodworking often involves making jigs that increase accuracy, safety, and speed of using power tools. A table saw sled is one of those essential jigs for a woodworking workshop. The jig is simple to make and provides several benefits to your woodworking experience.

I have used a table saw sled for a while now, and it has helped improve my crosscuts on the table saw. Building a table saw sled is a fun project that I would suggest to any woodworker, no matter their skill level.

Why Use A Table Saw Sled?

Increases safety while cutting

Most table saws come with a miter gauge. It keeps your workpiece aligned while you cut, but it also provides the support needed to crosscut wood safely.

A table saw sled provides extra support with a longer backstop that is also taller. The sled supports the workpiece and the excess material after passing the blade, helping prevent debris from being kicked back towards you. It also supports larger pieces better than a miter gauge can.

A table saw sled keeps your fingers away from the saw blade. That is important when you are crosscutting smaller pieces of stock. Finally, a table saw sled reduces slipping from finger pressure or resistance from the tabletop.

Prevents shifting while feeding

One of the benefits that woodworkers appreciate from using a table saw sled is the reduction in slipping I just discussed. You have to press down towards the table and against the fence of a miter gauge to keep the workpiece from sliding as you move. A sled, however, supports the wood from the bottom, which reduces the finger pressure you need to maintain.

Less finger pressure will result in fewer movements, including on smooth surfaces you are cutting. The sled’s bottom support also eliminates friction between the workpiece and the tabletop. Alignment maintains throughout the cut due to the sled riding in the miter gauge slots.

Improves crosscut accuracy

For most woodworkers, this is the benefit that encourages them to make a table saw sled. The rigid support and alignment provided by the sled keep your wood positioned for a precise crosscut.

Again, your wood sits on the bottom of the sled and not the tabletop of your saw. Friction will not pull it one way or the other as you slide it through the cut.

The larger backstop of the sled provides more support for the workpiece to press against while crosscutting. That prevents the wood from rocking at the start of the cut, especially on smaller pieces.

The bottom support and larger backstop are appreciated when working with wood hard to control due to length, weight, or width.

Allows you to work faster

Quick alignment is one trick that experienced woodworkers use when operating their table saw sled. You can use the groove cut into the bottom of the sled to line up your cutline instead of the saw blade.

Making several of the same cuts is faster when using a table saw sled equipped with a stop. You can also secure the workpiece onto a sled faster with accessories like a clamp.

You can crosscut small components without having to create elaborate jigs on the spot to hold them. Boards that are long, heavy, or wide can be fed faster on a sled than using a miter gauge alone.

Makes repetitive cuts easy

Using a table saw sled allows you to make several of the same cuts quickly. You can purchase an aftermarket stop that acts as a block that the end of your workpiece touches. You can also make a stop out of scrap wood and a clamp.

The stop sits so that each pass across the saw blade cuts pieces to the desired length. You butt the wood against the stop block and cut. The process repeats until you have the desired number of identical boards.

Produces more accurate miter cuts

A table saw sled can cut boards at an angle. You can create a backstop that sits at a predetermined angle. The lumber rests on the backstop, and the miter cuts as you move the sled across the saw blade.

A protractor-style backstop that adjusts can also produce accurate miter cuts. The sled provides a larger surface for marking degrees of an angle, allowing you to set finite angles smaller than a degree.

Its bottom and backstop support prevent the wood from slipping as the saw blade cuts into the fibers at an angle. The result is cleaner and at the correct angle across the entire end of the board. Once you set the mitered angle on the table saw sled, you can make several repeat cuts quickly.

Simple and cheap to make

A table saw sled is easy to make. Its major components are the runners for the miter gauge track, the sled bottom, and the backstop. You can upgrade your design to include a front stop, angled supports, or an adjustable mitered backstop.

Prefabricated table saw accessories can be quite expensive. Another feature of the table saw sled is that you can make it from wood in your shop. Framing lumber and plywood are the most popular materials and are purchased cheaply at most big-box stores.

Glue and a handful of fasteners are the only extras beyond the wood. You can buy accessories like clamps, rulers, or stops to customize your table saw sled to fit your shop’s needs.

Sledding All-Year-Long

A table saw sled improves your woodworking and increases safe usage of your table saw. It can increase your enjoyment of the hobby, making it an accessory that you will use whenever you have to crosscut on the table saw.

Woodsmith Table Saw Crosscut Sled Plan

Standard cross cut sleds have one major drawback – the weight. The design of this sled helps reduce weight and make it small and easy-to-use. Its simple construction is easy to build and the aluminum fence and stop block make cross cuts accurate and repeatable. The plans walk you through building this sled, and are a great way to improve accuracy in your shop.

We offer the Woodsmith Table Saw Crosscut Sled plan as a downloadable PDF or a printed format that we ship to you.

Big results in a small package. Reach for this lightweight sled and make perfect crosscuts every time.

Step-by-step instructions, exploded views, materials list, and more—these plans have everything you need to build your own Table Saw Crosscut Sled.

What you get (Downloadable PDFs):

- 8.5” x 11” PDF of 9 printable (digital) pages of step-by-step instructions

- 45 full-color photos illustrations and exploded views

- Retail source for project supplies

What you get (Printed Shipped):

- 9 pages of step-by-step instructions

- 45 full-color photos illustrations and exploded views

- Retail source for project supplies

- 8.5” x 11” print shipped to you

Woodpeckers LLC

Woodpeckers LLC 13700 Prospect Road Strongsville, OH 44149 1-800-752-0725

Quick Links

- About Us

- Advanced Search

- California Residents

- Catalog Request

- Contact Us

- Dealers

- Gift Certificates

- Join Our Team

- OneTIME Tool Status Page

- Order Status

- Privacy Policy

- Returns/Repairs

- Shop By Brands

- Warranty

- Woodworking Resource Center / Blog

- Woodworking Shows

Eclub Signup

Join our FREE E-Club for news on our latest woodworking tools accessories as well as specials. Stay informed on new OneTIME Tools and more!

All Rights Reserved, ©2023