DIY Birdhouse Using Leftover Siding. Hardie board hole saw

DIY Birdhouse Using Leftover Siding

Congrats, your siding project is finished, and your exterior is looking brand new! But you are stuck with some extra panels of siding and wondering, “What should I do with my leftover siding?” The answer is simple: a DIY birdhouse to match your exterior! Even if you don’t think you are a handy craftsman, a birdhouse is a perfect project to make you feel like a pro.

Part 1: Supplies

Before you start your DIY birdhouse, you will want to gather all supplies needed. You don’t want to be halfway through and realize you didn’t get the right nails or don’t have the correct drill bit size!

In this project, we used: – Leftover 6″ trim in Terra Bronze – Touch-up paint in Terra Bronze – Hand saw or compound Miter Saw (ask a friend or neighbor!) – Tape measure – Pencil – 7/32″ 1/4″ drill bits – Electric drill – 2″ screws – 3″ galvanized finish nails – Hammer – 1 ½” hole saw

Part 2: Measuring Cutting Down Leftover Siding

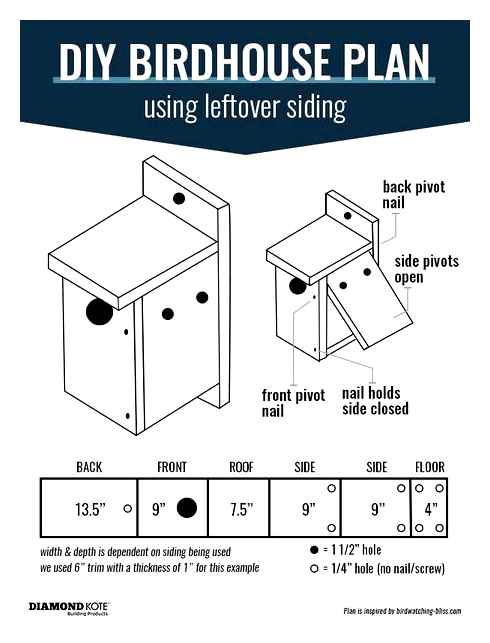

Look over your birdhouse plan and begin to measure and mark the various lengths needed for the birdhouse. We cut out all of the required pieces for the birdhouse from one piece of leftover trim with a Miter Saw. Once all pieces are cut to size, lay them out to double-check you have enough of the various sizes needed before moving on. Note: the bottom part you may need to cut shorter/longer than the instructions based on the thickness of your siding as the side pieces will go around the bottom piece. Our trim is 1″ thick, so we adjusted our measurement to accommodate.

You will end up with one 13.5″ piece, three 9″ pieces, one 7.5″ piece, and one 4″ piece.

Part 3: Pre-Drill Holes

Before you begin, set up the unassembled pieces into the birdhouse to ensure everything is aligning correctly. On the front panel, mark where you will need to screw that piece into the side and bottom pieces.

First, let’s make the ¼” holes used for airflow inside the birdhouse to prevent it from getting too warm for the bird and her eggs during the summer. These holes can be about 1″ from the edge. When the airflow holes are complete, drill the hole on the back piece. This hole is for hanging or mounting your birdhouse. feel free to skip this hole, adjust its position, or add more depending on how you would like yours to be displayed. We drilled ours 2″ from the top and directly in the middle of the 13.5″ piece.

Next, change out the drill bit to the 7/32″ bit to pre-drill holes in your cut-out pieces for the 2″ screws; this will prevent the siding from splitting if you were to drill in the screw without a hole.

Once the 1 ¼” holes are finished, you will need to measure where the entrance hole will be. Start by measuring 2 ½” from the top and then find the horizontal halfway spot (ours was 3″) and mark where you will need to drill the hole. Using the 1 ½” hole saw attachment, begin to push it through the wood slowly. Take your time with this step to help avoid splitting the siding or creating rough edges. You may need to use a small piece of sandpaper to smooth it out to make it safer for birds to enter and exit.

Before the final assembly, we used our touch-up paint in Terra Bronze to give the Diamond Kote finish you love!

Part 4: Assemble

Time for the moment of truth: assembly! Start screwing the side pieces using your pre-drilled holes to the large back piece. we recommend doing this at the edge of a table to help the drill have more clearance when in use. Continue by adding the bottom, front, and roof of the birdhouse. Do not attach one of the side pieces, as you will use nails to create a hinge (this will allow you to clean out old nests easily).

On the back, you will screw the roof of the birdhouse into the back siding panel. Using the 7/32″ drill bit, pre-drill holes, and then screw in the screws.

For the last side panel, you will be using nails to attach. Note: you do not want the bottom nail to go all the way in, so you can easily slide out as it makes a stopper for the hinged panel.

Show It Off!

Whew, the hard work is over, and now it’s time to show off your brand-new birdhouse. This birdhouse is perfect for hanging in your favorite tree, or you can mount it to a backyard shed or fence; either way, you are about to make a bird very happy.

If you want to post all about it on Instagram, make sure to tag us and use #dkbirdhouse so we can “ooh and ahh” in the Комментарии и мнения владельцев.

Fiber Cement Siding Repair FAQs QA on how to repair fiber cement siding

FAQs about how to repair damaged, loose, broken, bubbling, or peeling fiber cement siding on buildings.

This article series describes repair procedures for cosmetic or functional siding issues that may arise such as loose siding, wind-damaged siding, siding paint or coating failures, and siding gaps, especially gaps at fiber cement siding butt joints where lap siding is installed.

Our page top photo shows loose and improperly installed fiber cement siding on a New York home.

We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

QA on Repair Fiber Cement Siding

Recent questions answers about repairing or patching fiber cement siding posted originally at SIDING, FIBER CEMENT BOARD REPAIRS

Question: how to repair bubbles holes on the HardieBoard Siding on my home

I have a hardy board at each corner of our front porch. Looks like a 1×6 by 8 long. Both pieces have numerous bubbles opening up and showing open holes on the face and the sides. House is 10 yrs old. What would be the best patch / repair treatment? Thank you

Reply:

Discussing their HardieZone HZ10 siding Hardie says:

Repair or Patching Fiber Cement Board Siding

Dents, chips, cracks and other minor surface damage in James Hardie siding and trim products can be filled with cementitious patching compound. Refer to manufacturer recommendations for products that are compatible with fiber cement.

For small areas of damage you can use a sealant/caulk (preferably one designed for cement repairs) but then you will have to paint those areas of repair to match the original color.

OPINION: Clean out the area of damage, removing loose material but trying not to gouge into the boards. For larger areas I prefer to use a cement (or “cementious”) patching compound, sold in plastic tubs or in tubes that can be used in a caulking gun.

If your boards include a pattern such as a wood grain, small areas of repair can be tooled to match the surrounding lines with a putty knife; for larger areas of repair some owners have tried making a clay impression of nearby surfaces to press into the patch.

Hardie sells touch-up paint that can match the color of your HardyBoard siding.

Boards that are actually broken away will need to be cut out and replaced.

Here is what James Hardie says about repairs to their siding product:

James Hardie [JH] does not approve use of JH approved color matched caulk, other caulking materials or cementitious patching compounds to touch up nail heads, nail holes, dents, chips, cracks or other minor surface blemishes on JH products with ColorPlus Technology.

James Hardie routinely receives inquiries from consumers and builders regarding the use of paint as touch-up on ColorPlus products. These inquiries sometimes include requests that James Hardie provide warranty coverage to remediate problems associated with paints, and other non-approved materials as touch-ups.

James Hardie’s warranty provides coverage for defects in materials and workmanship on ColorPlus products and its Touchup only. It does not warrant, in any respect, the appearance or performance of any third party coatings or finishes, including paint, used as touch-up and third party touch-up paints used on ColorPlus products Touch-Up Notice to Contractors and Consumers

-

Best Practices – Installation Guide, Siding and Trim Products [PDF] (Version 8.3. May 2016) for HardiePlank HardieShingle HardiePanel HardieTrim HardieSoffit retrieved 2017/04/04, origial source: https://www.jameshardie.com/d2w/best-practices/intro-tools-hz10-us-en.pdfSee “Repair Patching” p. 27Excerpt:

On 2017-02-07 by (mod) re: did previous siding repairs lead to a loose board?

Possibly, Annette Bill, one would need to take a closer look at the repair. Indeed to remove and replace a lower siding board one needs to cut the nails through the lower end of the board above.

On 2017-02-07 15:55:45.392788 by Annette Bill

Before we purchased our home, we noticed loose siding on the lower side of our home and asked the Seller to have repaired. Now 8 months later, siding at the top of the same side of the house has fallen off. Does this mean that the earlier repair loosened the upper piece?

On 2016-11-09 18:57:58.792317 by mod) re: gluing house wrap?

Comment: trying to glue to house-wrap may not give secure results if the board simply pulls away the house wrap too.

Did you tape down the siding temporarily to allow the adhesive to bond?

I encountered the same issue as described above with siding ends on the gable popping out. I used polyurethane construction adhesive to hold it down. Seems to work like a charm and looks much better than face nailing. Criticisms?

On 2016-11-01 15:47:32.080839 by Anonymous re: I’d use stainless ring-shanked siding nails or color-coated ring-shank siding nails that are as close as possible to the siding color.

To fasten down any board type siding without removing and replacing (working from bottom-up) you’ll want to follow the manufacturer’s face-nailing recommendations such as are used at trim where nails are not covered by the next siding course.

Typically I’d use stainless ring-shanked siding nails or color-coated ring-shank siding nails that are as close as possible to the siding color. Nail the head flush-tight but not recessed into the siding to minimize damage.

My James Hardie Board siding came loose during a high wind storm. It is in the middle of the wall. How can I refasten it down. It is top nailed.

On 2016-09-17 13:04:49.461095 by mod) re: how do I repair damage to a fiber cement wall?

Felix, you need to remove either the entire panel that was damaged and then replace it, or you may, taking dust control and personal protection measures, set a carbide-blade circular saw to cut just through the depth of the panel, not into building framing, snap a chalk line or use a strait edge to mark the area of damage to be cut out. taking care to cut the sides to end at the middle of wall framing studs.

With the cut section removed (nail removal is discussed in the article above) you’ll need to custom cut and fit a replacement panel of matching fiber cement panel board.

Along the upper edge of the fiber cement panel use Z-flashing to prevent leaks into the wall cavity.Seal the panel sides to the studs with exterior-rateed sealant-caulk when you set the panel in place.If necessary, pre-drill nailing holes at the panel edges to avoid breaking it in that location.

On 2016-09-17 12:11:27.369725 by Felix Cruz

I have a vertically installed fiber cement exterior wall. Hit by a riding mower a section, just above ground, cracked and a piece broke off. At another location, likewise just above ground, another hit and the section cracked showing pieces still clinging to the wall.

Yes using a masonry blade set to cut through siding but not into the metal flashing BUT you’re creating a horrible dusty mess; even if your newer siding doesn’t contain asbestos its dust may be harmful to breathe including containing silica and I don’t know what else.

Why are we contemplating this cut? Siding bottom contacting a poorly-drained surface damaging siding?

Let’s be sure the flashing extends a couple of inches above the cut line before making the cut.And let’s see that the saw you’re using can fit into the space and cut where you want to cut, using a guide to give a straight cut.

And let’s wear appropriate protective gear: eyes, respirator, gloves;

And perhaps use a vacuum or HEPA vac for dust control.

A 6 year old house has the fiber cement siding abutting the flashing. This goes all around the house. Can we take a saw and cut a 1/4″ out of the bottom plank?

On 2016-07-01 20:39:54.616560 by mod) re: corner trim board failures

We need to know more accurately what the corner trim board product actually was. so that you can match it accurately, Charlene. Do you know who installed your siding to ask?

Also I’ve not seen foam-based trim used at corners for cement board lap siding installations; but there are some polyurethane foam trim products widely sold.

On 2016-07-01 18:10:01.046766 by Charlene Bielakowski

I have a home with the cement board was applied. The siding is okay in most spots except for the garage which I noted the Комментарии и мнения владельцев to repair it. However, the problem we have is with the corners which are a Styrofoam board and the likes of a nasty squirrel.

The squirrel has chewed the corners and I need to figure out what to replace it with. can anyone tell me what can be used that will not be chewed by this squirrel?

Be very very careful who does your install. My entire house is a wreck due to a contractor who said he knew what he was doing and did not. Now I have a rear of and replace situation.

On 2016-05-30 22:22:41.936614 by mod) re: replacing Hardieplank boards close to the ground

Yeah it’s tricky. If you pry a rigid material it’ll break. But often you can use a thin flat prybar blade driven up between the planks at the nail location to cut the nails.

I have a few hardiplank boards about 5′ above the ground that have holes (thanks to my son’s hockey pucks). I need to replace those. The boards are face nailed. How do I remove them when they are above and below boards they have been nailed to? Thanks.

On 2016-04-18 14:44:15.302627 by mod) re: using adhesive on fiber cement siding repairs?

Loctite’s “Power Grab” construction adhesive is not likely to perform well in an effort to glue loose fiber cement siding boards, because those boards, in a normal installation, are nailed to building sheathing and framing that have first been covered with housewrap.

You’d be gluing the boards to housewrap, not to the structure. Once glued to housewrap, whatever forces are causing a fiber cement board to move, buckle, or respond even to changes in temperature and moisture, are being restrained by the glue against the housewrap fabric. But the housewrap itself is being restrained just by some staples. Hardly much resistance there.

understand the underlying cause of loose siding, as knowing the cause may dictate the solution

be sure that any open butt joints are back-flashed

be sure that required clearance gaps and sealant were used at vertical abutments such as at window trim, door trim, and building corners

then consider adding fasteners where needed, choosing a fastener recommended by the manufacturer.

I’m considering options for securing loose hardiplank on our home built in 2006. It seems that one option would be to use exterior grade “power grab”. I’m wondering, though. would that prevent any seasonal movement of the hardiplank and possibly cause cracking of the siding? Thanks for any help you can give me.

On 2016-04-13 18:47:44.996022 by mod) re: using metal flashing under cracks and gaps in fiber cement siding boards

I would certainly use metal flashing behind cracks across a fiber-cement siding board, just as should have been done at end-butt-joints between boards on long walls. That’s what assures that there won’t be leaks behind the siding. The sealant is a cosmetic addition that might improve the look if you keep the sealant only in the cracks rather than blobbing it on the board surfaces.

Thanks danjoefriedman, I can get the flashing way up there. I was planning on it not to be visible but if it is unsightly I will not use it. I guess it may push the board out a bit even if it can’t be seen. I like the idea of color matched sealant. I will take my stuff back and look into that. Thankfully I know the color! Thanks a lot.

On 2016-04-12 22:37:49.964102 by mod) re: keeping water out of a fiber cement wall

Ward: your flashing repair will keep water out of the wall provided you get that back-flashing all the way up to beneath the bottom of the next-higher boards. It may not look beautiful.

Your sealing repair using thin-set cement is not likely to wear as well as a more flexible color-matched sealant.

My cracks are from the kids kicking a soccer or basketball at the house. About three areas with cracks. Luckily I’ve stopped that practice!

I plan to slip sheet metal flashing up behind cracks, use a straw to get a dab of No Nails on each side of the cracks to prevent board flex at the cracks, to massage silicone into the crack to make as waterproof as possible, to then trowel some thin set concrete over the cracks to hide them and then to sand and paint the existing color. Am I on the right track! Any expert advice would be appreciated. Ward

On 2015-12-31 22:36:31.468266 by mod) re: who is responsible for construction defects in a new home?

Steve I should have added that regarding your assumption that the builder of a spec home is not responsible for construction defects, that depends in part on where you live. For example New York and some other states have a New Home Warranty Law. It would raise an orange flag: someone has done non-standard work on nailing siding. we may not know why. When I see any work that does not follow industry or manufacturer recommended practices it makes me worry not just about what was wrong at the point I’m examining, but what other DIY work was done by someone at the property: Im on alert for other possible snafus.

Document what you did and why. that may help resolve questions.

Question: fix for bowed fiber cement siding

(Dec 11, 2014) ran23 said:The cement fiber siding (approx 13 yrs old, Pacific NorthWest), one piece is bowed out in the center. NO water damage or insect, or leaks present. Can I screw it back down? this is up toward gable highth.

Reply:

Press gently on the siding. If it flattens into plavpce yo can try through screwing it to a stud or to,the building sheathing f the sharp earthing is plywood. Don’t let the screw head cut nor break the siding as will happenif the siding is warped or significantly bent. You may need to Pre drill a pilot hole. Older fiber cement siding may contain asbestos so confirm its age and type before drilling or cutting.

Question: chalky fiber cement siding joints

(Oct 13, 2015) Tim said:Have a new home built and the contractor used cement board lap siding in a clay color. In certain light some of the joints look chalky colored 4-6″. I first thought it might be a joint where it was cut and painted but after talking to the installer he said they were factory edges. Not sure if builder is going to want to paint the boards that are affected or replace.The home is only 1 month old. What’s your opinion of what I should allow them to do. It’s not James Hardie but whatever was cheap. Odd that all the affected boards and joints are in the same area.

Reply:

Tim I don’t quite understand the issue; you can find an email at our page bottom CONTACT link if you want to send some photos.

Question: buckling siding, missing back flashing, improper fasteners: how to repair my fiber cement siding

(Dec 16, 2015) Steve said:First, thanks for the wealth of knowledge on these concerns with fiber cement products in one location. My questions/Комментарии и мнения владельцев revolve around the use of fasteners and butt joint maintenance on an existing home under 3 years of age.

Regarding dealing with improper fastener and back flashing installation as the source of both loose planks and buckling, although it is not the recommended installation practice, would it be advisable to ensure the proper securing of the boards to studs by face nailing the entire home with the appropriate fasteners to ensure the proper fastening and unify the nail procedure to aid the weathering of the certainteed boards over it’s remaining life span?

This is especially a relevant question as to properly securing siding repairs (cracked/damaged boards), as blind nailing is not an option without removing boards to access the repairs, only face nailing. Additionally, with those repairs using face nailing, can the fasteners penetrate the boards in multiple locations (ie, every 16″ on center the length of the board repair).

With butt joint treatment, if the proper caulk is used (allowing for expansion and paint-ability) is the only concern involved with using this as an after the fact/poor installation without sheet flashing solution to preventing water infiltration concerned with aesthetics (ie care with application to only the joint and potential shiny finish)?

The fiber cement boards are certainteed, installed on a home in the southeast, displaying these characteristics on all faces of the home.

Reply:

I understand the reasoning. Since a lot is at stake, let’s ask CertainTeed for an opinion. Or did you try that?

Also see Pin Back Nailing Repairs in the fiber cement siding repair article above.

(Dec 17, 2015) Steve said:The warranty rep from the company visually inspected because of the cracked boards and info I saw online about other potential issues being possible.

The Certainteed rep opinion was improper nailing and types of nails were present on 2 sides of the home, with the inspection not going all the way to the top of the second story (all this was visible from within step ladder reach). Securing the boards was advised, but I can not seem to be able to obtain online through the link on this site the installation/repair best practices from certainteed, as they have gone on to become allura). Boards were installed 2012 on a spec new construction. The replacement of the cracked boards therefore has to be through another company.

Trying to move soon with a job relocation and would rather not have to swallow a full blown install, but I also don’t want to raise concerns as to over nailing for our region or introduce exterior ventilation issues with the home. (Open-cell spray foam, with unvented attic building envelope, mechanically vented)

Also, with flashing, the boards end at a brick veneer water line architectural feature (the bottom 18″-24″ of the homes in the neighborhood have this design element).

There is a L-shaped flashing run located behind the bottom of the fiber cement run and at the top of the of the brick that extends out about 1″ to 1.5″, but not all the way out-and-over the brick course. Should this flashing element be caulked between the union of the flashing and the brick? (there are weep holes present).

If I were to attempt repair the cracked boards and secure them with a face nail using roofing nails, and attempt to secure the remaining loose boards that were improperly fastened with the same face nailing process, would it be necessary/beneficial to use the metal hacksaw method to eliminate the blind nailing that is in place and then rely on the face nail repair at the appropriate fastening schedule and spacing so that the boards are not secured by both methods potentially limiting their ability to adjust to the seasons?

Steve, sorry you had trouble with the Certainteed link. let me check it out.

I agree that you’ve got the right questions in mind.

Steve I forced “off” our citations section so that you can see the original link for the Certainteed instructions.

[5] Certainteed Weatherboard fiber cement siding and trim products. see certainteed.com/ or see certainteed.com/resources/sidingandtrimspecsheet.pdf

[5a] “CertainTeed WeatherBoards Fiber Cement Siding Installation Manual”, CertainTeed Corporation, 2012, CertainTeed Corporation, PO Box 880, Valley Forge PA 19482, Professional Help Line: 800-233-8990, Consumer Help Line: 800-782-8777, Website: Certainteed.com www.certainteed.com/resources/fc017.pdf retrieved 4/11/2013, [copy on file as Certainteed_Fiber_Cement_Siding_Install_fc017.pdf ]

[5b] “Certainteed WeatherBoards Fiber Cement Siding Best Practices for Effective Job Site Management”, CertainTeed Corporation, retrieved 4/15/13 original source: www.certainteed.com Copy on file as Certainteed_FC_Handling Brochure-Contractor_FC063.pdf

Steve I want to add that roofing nails will look horrible and be visible from afar; I’d look at other fasteners, maybe stainless steel ring-shank nails driven carefully; It’d be nice if the manufacturer would comment as they’re the authority.

Thanks for all of the advice. The roofing nails as a solution was something I thought I had read as a method of fastening in a face nailing situation because of the wider head. Definitely will look at ring-shank option, was already leaning towards stainless steel from other input I have uncovered. Trying to get in touch with the manufacturer once the holidays ease up, and continue to gather info to see if this is going to be something I can handle or if we need to hire someone.

From the standpoint of an inspector, how concerned would you be looking at a property that you saw the face nailing as long as the correct fastners were used? What if it was only done in spot areas, versus if I were to go around the entire home to face nail the boards insuring they were in fact secured?

Again, thank you for your input and taking the time to answer and compile this resource.

It would raise an orange flag: someone has done non-standard work on nailing siding. we may not know why. When I see any work that does not follow industry or manufacturer recommended practices it makes me worry not just about what was wrong at the point I’m examining, but what other DIY work was done by someone at the property: Im on alert for other possible snafus.

Document what you did and why. that may help resolve questions.

I should have added that regarding your assumption that the builder of a spec home is not responsible for construction defects, that depends in part on where you live. For example New York and some other states have a New Home Warranty Law.

How to Build A Birdhouse: Use Scrap Fence Board Ends

Continue reading at SIDING, FIBER CEMENT BOARD REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Recommnded Articles

- SIDING, FIBER CEMENT

- CERTAINTEED WeatherBoards /li>

- CHINESE fiber cement siding

- FIBER CEMENT SIDING PAINTS

- FIBER CEMENT SHINGLE CUTTING TOOLS

- FIBER CEMENT SHINGLE REPAIRS

- JAMES HARDIEPLANK FC SIDING

- NICHIHA FIBER CEMENT SIDING FIELD REPORT

- SIDING CLEARANCE TO GROUND

- SIDING FIBER CEMENT COEFFICIENTS of EXPANSION

- SIDING, FIBER CEMENT CURL / LIFT DEFECTS

- SIDING, FIBER CEMENT DEFECTS. home

- SIDING, FIBER CEMENT DEFECT DIAGNOSTIC QUESTIONS

- SIDING, FIBER CEMENT GAP CAULK SPECS

- SIDING, FIBER CEMENT GAPS

- SIDING, FIBER CEMENT GAP CURES

- SIDING, FIBER CEMENT IDENTIFICATION

- SIDING, FIBER CEMENT MAINTENANCE

- SIDING, FIBER CEMENT MOISTURE ABSORPTION

- SIDING, FIBER CEMENT MOISTURE LEVELS

- SIDING, FIBER CEMENT REMOVAL

- SIDING, FIBER CEMENT BOARD REPAIRS

Suggested citation for this web page

SIDING, FIBER CEMENT REPAIR FAQs at Inspect A pedia.com. online encyclopedia of building environmental inspection, testing, diagnosis, repair, problem prevention advice.

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Комментарии и мнения владельцев box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many Комментарии и мнения владельцев, and therefore images, as you like. You will not receive a notification when a response to your question has been posted. Please bookmark this page to make it easy for you to check back for our response. Our Comment Box is provided by Countable Web Productions countable.ca

Books Articles on Building Environmental Inspection, Testing, Diagnosis, Repair

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The Home Reference Book illustrations from The Illustrated Home. Carson Dunlop Associates’ provides extensive home inspection education and report writing material.

The ILLUSTRATED HOME illustrates construction details and building components, a reference for owners inspectors. Special Offer : For a 5% discount on any number of copies of the Illustrated Home purchased as a single order Enter INSPECTAILL in the order payment page “Promo/Redemption” space.

TECHNICAL REFERENCE GUIDE to manufacturer’s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon Associates Special Offer : Carson Dunlop Associates offers InspectAPedia readers in the U.S.A. a 5% discount on any number of copies of the Technical Reference Guide purchased as a single order. Just enter INSPECTATRG in the order payment page “Promo/Redemption” space.

Or choose the The HOME REFERENCE eBook for PCs, Macs, Kindle, iPad, iPhone, or Android Smart Phones. Special Offer: For a 5% discount on any number of copies of the Home Reference eBook purchased as a single order. Enter INSPECTAEHRB in the order payment page “Promo/Redemption” space.

Building inspection education report writing systems from Carson, Dunlop Associates Ltd

COMMERCIAL BUILDING INSPECTION COURSES. protocol ASTM Standard E 2018-08 for Property Condition Assessments

HOME INSPECTION EDUCATION COURSES (USA) including home study live classes at eleven colleges universities.

HOME INSPECTION EDUCATION: HOME STUDY COURSES. ASHI@Home Training 10-course program. Special Offer : Carson Dunlop Associates offers InspectAPedia readers in the U.S.A. a 5% discount on these courses: Enter INSPECTAHITP in the order payment page “Promo/Redemption” space. InspectAPedia.com editor Daniel Friedman is a contributing author.

How To Cut Through Stucco – Everything You Need To Know

There are a few different ways to cut through stucco and some work better than others and are better for certain circumstances too.

Knowing what the different tools, blades, etc. will help you get a better understanding of what to expect and how to cut through all kinds of plaster effectively.

What About The Dust?

The Dust Factor: An important thing to remember when cutting stucco is the fact that it will create a lot of dust. This can be controlled using a couple of different methods, some working better than others, some more convenient and so on.

Using A Wet/Dry Vac As You Cut: You can use a simple wet/dry vac when you are saw cutting stucco to help suck up a lot of the dust that comes with cutting any type of cement-based material. The picture shows the nozzle of a wet/dry vac close to the grinder to catch the dust.

This will never completely eliminate the need for protection like respirators but it does a pretty good job at catching a lot of the dust, probably eliminating somewhere around 70 to 80% of the “visual dust”.

Your filter must be clean for this to work though so keep that in mind. If you have a dirty filter, all it seems to do is divert the dust going in one side of the vacuum and coming out of the opposite hole.

Helpful Tip: Try to hold the end of the hose where the majority of the dust is coming out to pick up the greatest amount possible.

You will want to hold it off to the side of the “dust stream” and not directly in front of it (because of flying particles) so a more powerful vacuum is recommended to add more suction.

Special Attachments: They have special dust collection systems that you can attach to just about any wet/dry shop vac and it will do a very good job of separating out the dust, which will save your vacuum in the long run.

A lot of these will require a longer hose which usually is not included but has to be bought separately and typically comes in 20 feet increments.

The other part of these dust collection systems is the actual dust separator that is connected to the vacuum that collects all of the dust before it enters your vacuum.

If you plan on doing a lot of cutting this will save your filter and help cut down on the amount of time it would take to clean out your filter constantly.

Special Vacuums And Dust Collection Systems: They make HEPA filtration type vacuums that can eliminate nearly all of the harmful dust particles that pass through the filter.

There are two main types of these vacuums out there and one has a standard HEPA filter and the other has a special HEPA filter that can actually filter out harmful material such as asbestos,silica, chromium and so on.

The major difference between these two types of vacuums is the price and it is pretty significant if you plan on getting a true HEPA filter vacuum that can eliminate a lot of the harmful particles in the air.

A standard one will do the job just as good, providing that the majority of the dust is sucked up through the vacuum nozzle.

Using A Grinder And A Diamond Blade:

These work extremely well and are much lighter in weight than a circular saw is. These are very versatile and is the go to tool if you are looking to cut out any sort of stucco.

A 4.5 inch grinder is more common and easier to find blades for too, so a nice tip.

These can be a little tough and jerky at times to hold on to, even with the side handle attached so it can be hard for some people who have limited strength in their wrists.

The Blades: These are some of the toughest blades, compared to all of the others in the lineup, excluding the circular saw but are far less than a 7.25 inch blade too.

These are hard to find at some stores and the selection is usually weak so I would recommend looking online for them.

Using A Circular Saw With A Diamond Blade:

A circular saw with a diamond blade attached is also a great tool to have for cutting stucco. It is larger than a grinder but also has a depth gauge, which comes in nice for cutting the stucco out.

The handles are also a big advantage and lets the user have a more comfortable grip on the saw.

It is a lot heavier compared to an angle grinder, so you will get wore out a bit quicker and be more susceptible to cramping if you use the saw for extended periods of time.

The dust also has a streamlined pattern to it, which makes sucking it up a lot easier and more controlled, at the same time.

The Blades: These are typically just like what you would see from an angle grinder but larger in size, to accommodate the larger tool.

The most common saws are 7 1/4″ circular saws and the blades seem to be less expensive than a saw that uses a 6″ blade (supply and demand, I suppose).

Using A Jigsaw With A Diamond Blade:

This is a helpful tool for detail work but is NOT recommended for cutting large amounts of stucco. It will not hold up to the task long and is slow when cutting, compared to a standard (circular shaped) diamond blade used in a circular saw or angle grinder.

If you have to cut out a square or rectangular shape out of interior or exterior plaster, then you would make the initial cuts with a smaller grinder or mini saw and then finish off the corners with one of these (jigsaw).

It will help to have someone constantly spraying off the blade while you use it to help keep it cooler during the cutting process and to wash away some of that debris that gets built up on the blade.

Will A Reciprocating Saw A Diamond Blade Work?

A reciprocating saw blade will work the same way a jigsaw blade would and is recommended for more detail type work than it is for massive amounts of stucco cutting.

The same problem exists with the blade, it just doesn’t last long enough to do any real damage to large amounts of stucco. There are two different types of blades (shown below) and these are a diamond grit blade and a carbide tipped blade.

The blade will also get caked with cement dust which makes it cut a lot less effectively and doesn’t really take all that long to get like that.

So my final word on reciprocating saw blades for stucco is to only use them as much as you have to, where a circular type blade would not work as well which is usually detailed type cutting applications.

Diamond Reciprocating Saw Blade For Stucco

Carbide Tipped Reciprocating Saw Blade For Stucco

A Hole Saw Will Also Work On Stucco.

A hole saw blade will cut only one type of hole in the wall and as you can tell from the picture on the right these are circular holes.

These are probably one of the easier types of tools to use and are simply attached to a drill and the diamond grit on the hole saw a bit eats through the stucco quite well. They make these in just about any size you need.

These can come in so many different sizes which is helpful for many different things such as plumbing fixtures coming through the wall, dryer vents, exhaust vents and so on.

If you have a round hole that needs to be cut in your stucco exterior then these hole saw bits are the only way to go and make the job a lot easier and a lot more efficient.

How About An Oscillating Multi Tool?

Oscillating multi tools can also be helpful for cutting holes in wall, equipped with the correct blade, that is. These usually use a carbide blade that will do a decent job at cutting through stucco.

This is also a tool for more of the detailed type cuts and typically don’t last that long but from my experience they do last longer than jigsaw or reciprocating saw blades do. I know a lot of electricians that like using these tools for cutting out electrical boxes.

If you do plan on using in oscillating tool with a carbide blade, then I would recommend getting a few just in case they wear out quickly.

A quality carbide blade should last a little while and keep in mind that the better quality blades usually cost more, in general.

Below, are two different diamond blades that you will typically find for a multitool, the carbide blade looks a little different and has teeth on it (not pictured).

Will A Mini Saw Work On Stucco?

These mini circular saws actually work pretty well on stucco and have the equivalent power that an angle grinder would.

The advantage to using a mini circular saw is the fact that you have a depth guide to use and the position of the trigger is a little bit more comfortable on the hand.

You will need a diamond blade to go with these though, which is not that big of a deal considering you would need a diamond blade for a standard circular saw or an angle grinder anyways.

Most of these mini circular saws will use a 4.5″ blade, which is the same size as some angle grinders, so a pretty standard blade so to speak and easy to find online.

FAQ’s Related To Cutting Stucco:

How Long Will A Blade Last? This depends again, on the type of blade you actually end up using. I have cut several hundred linear feet using a diamond blade (wheel).

A carbide blade is going to be more commonly found on an oscillating multitool and a reciprocating saw and has a tendency to only last a few feet, in my experience anyways.

There are many more determining factors that go into how long a blade will actually last in these things are related to the amount of force you use, the amount of heat that builds up while cutting, the quality of the blade and materials that it is made of (price of the blade) and other variables like that.

The best advice I would have is to go with a diamond blade, if possible and get a moderately priced one and stay away from the cheaper ones.

What Is The Best Way To Cut Through Stucco? If you are simply cutting through stucco to remove it from the wall then a circular type blade (diamond) is by far the best tool you can use, hands-down.

If you are looking to cut finer detail type things then you may want to use an oscillating tool, a reciprocating saw or a jigsaw (in that order) to get a more precise cut.

How Much Dust Does Cutting Stucco Make? If you are using a circular diamond blade type of cutting tool it is going to create a ton of dust, which is come parable to the amount of smoke a small fire pit would make.

That is quite a bit of dust! You really want to take extra precautionary measures to make sure you have adequate ventilation and have the proper tools to combat the best especially if you are sensitive to airborne particles.

Using a reciprocating saw, oscillating multitool or a jigsaw will create far less dust in the cutting process than a circular saw or angle grinder would.

It is significantly less but is still present and the same precautionary measures should be taken.

Lenox Bi-metal Plumber Hole Saws. 3/4-in Dia. Speed Slotted

This item is not currently available for immediate purchase, but can be ordered by visiting the selected store.

EAB. How To Install A Vent In Hardie Plank or Wood Using A Carbide Tipped Hole Saw

You may also like

Rated 5 out of 5 by Dollarbilly from Best I Have Ever Used For Glass My wife uses glass wall blocks for craft projects and she requires a hole be drilled in the edge of the block. I have used Kobalt 1/2″ spade-shaped drill bits and I get about a half dozen holes from each bit before it becomes noticeably dull. Have used this 3/4″ hole saw for at least twenty holes in 1/4″ thick glass and it still works fine. You get a clean hole and a plug of glass instead of chips and dust. I drill the blocks in the kitchen sink under a trickle of cold water. It would be nice if the saw came with a pilot drill; however, just starting the saw at a 45 degree angle to cut a pilot slot works fine. This saw costs a little more than bits I have used in the past, but it’s definitely worth it!

Rated 5 out of 5 by FarmKid from Cut Holes For Grab Bars In Shower Tile Wall After looking around on-line, I knew that I needed a diamond tipped bit to do this job. I went to Lowes and found the Lenox bit and decided to try it out. The Associate reminded me that slow rpm and frequent water cooling were the keys to long life of the bit. I cut four holes in ceramic tile, two of them near the edge of the tile, in about 20 minutes, without any cracks. The cuts had very smooth edges. Maybe I was being conservative, but I only went 30-45 seconds between stopping and cooling the bit with a spray bottle. I have to say this was the most expensive drill bit I have ever purchased but the project was a textbook example and went perfect.

Rated 5 out of 5 by KEG from Worked very well OK I had tried first a carbide tipped drill, I guess my tile is porcelain, it took me two hours to drill two holes, I had 8 to do. When I started the third one, I guess the bit was already too dull, it really wouldn’t do anymore. I then tried a special drill bit manufactured by the firm that makes the fasteners I had bought, WingIt. It was spear shaped. After 20 minutes it had drilled(scratched)a hole 1/8 deep, I am sure it would work fine for plain non-porcelain tile. I decided after research on the internet to try this. Wow I just drilled five holes in about a hour, this includes installing the grab bars in my tub. Each hole took perhaps 2 minutes. Before using I would suggest watching a video on YouTube in using this hole saw, if you start the hole at a 45 degree angle, you will not have issues with it jumping around like another person mentioned in his review.

Rated 5 out of 5 by Ben86 from Just what I needed. I had tiled my entire bathroom floor when I began to wonder how I would reattach my water lines. through the floor. I tried some concrete bits and one of those spade bits for drilling through tile and after about 30 minutes of drilling, I had one hole that wasn’t big enough for my pipes. I used this hole saw and had two holes through the tile within 2 minutes. Like the first reviewer said, it definitely needs to be started at an angle but makes a fine hole quickly. I used a sponge and squeezed water out on the hole while drilling, then used the same sponge to soak up the water.

Rated 5 out of 5 by dave from ceramic hole saw [This review was collected as part of a promotion.] was struggling putting drain holes in my wife’s flower pots.went to lowe’s and bought a lenox diamond hole saw.what a difference.in no time at all the pots had their drain holes.I highly recommend this item.

Rated 5 out of 5 by Jake from Lenox is worth the money [This review was collected as part of a promotion.] I have used Lenox bits and have had no problem. I use this 3/4” to put holes in bottles for Christmas lights to be stuffed into.

Rated 5 out of 5 by MalikWick from It does the job I used this saw to go through the kitchen sink, which is Porcelain and cast iron. I just kept the cut area wet while drilling and it worked like a charm.

Rated 5 out of 5 by StupidJasper from Does the job well Used it to drill holes in marble for shower grab bars without a problem.

- Lenox Bi-metal Plumber Hole Saws. 3/4-in Dia. Speed Slotted Reviews. page 2

- y_2023, m_5, d_24, h_22

- bvseo_bulk, prod_bvrr, vn_bulk_3.0.35

- cp_1, bvpage1

- co_hasreviews, tv_0, tr_24

- loc_en_CA, sid_79915177, prod, sort_[SortEntry(order=RELEVANCE, direction=DESCENDING)]

- clientName_rona

- bvseo_sdk, java_sdk, bvseo-4.0.0

- LOCAL, getContent, 2ms

- REVIEWS, PRODUCT

Total Tools. Low Price Guarantee Policy (Terms Conditions)

At Total Tools we offer Low Prices, every day, guaranteed. We will not be beaten!

We check our daily against our competitors to ensure you can shop online or instore with the confidence you are buying at the very best price, every day.

Should you find a lower advertised price for the identically stocked product elsewhere, we will happily match the price. [Subject to Terms Conditions – see below for details]

At times have moved in the market, and our in store and online price for printed catalogue items may be lower. Check online or instore for the latest price.

How to Price Match

Simply visit a Total Tools Store or contact our online team with evidence of a cheaper price (print out or website link). We will verify the price, and then immediately match any current advertised price (Terms Conditions apply).

Terms Conditions

For eligibility, the following terms and conditions need to be met;

- Product must be identical (same brand, colour, model #)

- Product must be currently advertised in print or electronic media (Including newspaper, catalogue, radio, television advertising or online)

- Product must be in stock at the competitor

- The competitors price of the product must be inclusive of delivery fees, taxes and charges

- The competitors price is lower than our price on the day the price guarantee is requested (day of purchase)

- The competitors price excludes finance, installation, bundling, rebates, cash back, coupon offers, loyalty rewards or free bonus goods.

- The competitor is located in Australia

- Trade/commercial quotes and/or large volume/bulk purchases

- Products for sale via auction, stock liquidations, fire sale, sale or clearance (including eBay)

- Blemished, seconds, refurbished, damaged or ex demonstration stock

- Advertising errors where competitor has published a rectification notice

- Products distributed by unauthorised dealers / parallel importers

- Special event, club or membership offers, third party promotions or not available to the general public

- Special order products

Total Tools reserve the right to terminate or amend the price guarantee policy at any time without notice.

For Further Information

Further information may be obtained in-store at any of our stores nationwide or online at www.totaltools.com.au/priceguarantee. For the most effiicent response please use the contact us page, or alternatively email onlinesupport@totaltools.com.au.

GET TO WORK NOW, PAY LATER Click to see your options

Love tools? Start earning points to redeem rewards on your next purchase Log in or Sign Up to redeem today!

Pickup In Store

If you don’t want to pay for delivery or need to ASAP, you can pick it up in store. Just bear in mind not all stores will have everything in stock. You’ll be able to see if they do during the checkout process.

Free Delivery

Most products are included in free delivery, however some are excluded as follows:

- Orders and/or items under 99.

- Orders and/or items that are deemed bulky, large or heavy.

- Clearance items.

- Orders that include or items that are classed as dangerous goods.

- Remote areas are excluded from free delivery and you will either be charged delivery at checkout or may be contacted prior to delivery to confirm delivery charges if necessary.

- Interstate deliveries.

Total Tools reserve the right to change or withdraw free delivery at any time.

Estimated Delivery Timeframes

If you opted to collect in store you will receive an email to inform you when your goods are ready for collection.

If you opted for delivery, you will receive an email when the goods have been despatched to the couriers with details so you can track our order.

We aim to despatch all orders within 1-2 business days. In the unusual event of a delay to the despatch of your order you will be contacted at the earliest opportunity. Once the order has been despatched the estimated delivery time is as follows:

- Metro (Excludes Hobart Metro) 1-2 business days

- Hobart Metro 3-4 business days

- Regional Areas 3-4 business days

- Remote Areas 6-9 business days

Please note that these delivery timeframes are estimates and are not guaranteed.

Returns

Changed your mind? No worries. You just need to get the product back to the store it was shipped from (this is on your receipt) within 30 days, unused and in its original packaging and we’ll give you a refund (excluding delivery costs). You can read our full returns exchanges policy here (special order items are excluded from this returns policy).

Total Tools. Low Price Guarantee Policy (Terms Conditions)

At Total Tools we offer Low Prices, every day, guaranteed. We will not be beaten!

We check our daily against our competitors to ensure you can shop online or instore with the confidence you are buying at the very best price, every day.

Should you find a lower advertised price for the identically stocked product elsewhere, we will happily match the price. [Subject to Terms Conditions – see below for details]

At times have moved in the market, and our in store and online price for printed catalogue items may be lower. Check online or instore for the latest price.

How to Price Match

Simply fill in price match form available on every product page or visit a Total Tools Store. We will verify the price, and then immediately match any current advertised price (Terms Conditions apply).

Terms Conditions

For eligibility, the following terms and conditions need to be met;

- Product must be identical (same brand, colour, model #)

- Product must be currently advertised in print or electronic media (Including newspaper, catalogue, radio, television advertising or online)

- Product must be in stock at the competitor

- The competitors price of the product must be inclusive of delivery fees, taxes and charges

- The competitors price is lower than our price on the day the price guarantee is requested (day of purchase)

- The competitors price excludes finance, installation, bundling, rebates, cash back, coupon offers, loyalty rewards or free bonus goods.

- The competitor is located in Australia

- Trade/commercial quotes and/or large volume/bulk purchases

- Products for sale via auction, stock liquidations, fire sale, sale or clearance (including eBay, Amazon)

- Blemished, seconds, refurbished, damaged or ex demonstration stock

- Advertising errors where competitor has published a rectification notice

- Special event, club or membership offers, third party promotions or not available to the general public

- Special order products

Total Tools reserve the right to terminate or amend the price guarantee policy at any time without notice.