DIY motoblock in the snow

Step-by-step manufacturing instructions

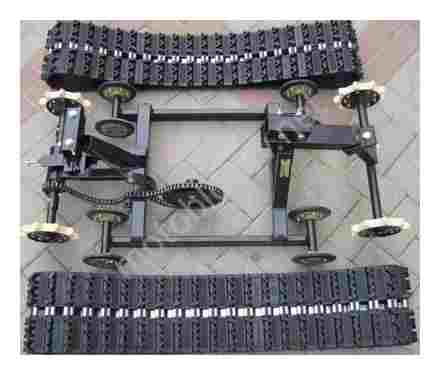

To make a caterpillar mechanism for a walk-behind tractor with your own hands, in addition to the materials used, you will need certain tools: a grinder, and sometimes a drill, a boot knife and a set of screwdrivers, bolts, nuts and wrenches, a welding machine, wire, chains and a sanding belt. Of course, drawings will also be necessary, which are easy to find on the Internet in the public domain.

If homemade tracks are made from car tires, then the first thing the tires are freed from the sides to the state of a running belt. a track for caterpillars. This is easier to do with a well-sharpened knife, for example, designed for working with boots. The adjustment process is lengthy, but it can be accelerated by periodically smearing the blade with soapy substance.

It is more convenient to cut the sides of the tires with an electric jigsaw, which has small teeth. At the next stage, the wrong side of the tire is also corrected: excess layers are removed from it. This should be done when the tape is too dense inside. Such a track attachment made of car parts turns out to be quite durable, since the tire is initially closed, which means that it will be more difficult to damage the tracks during operation. Unfortunately, the available tire width will not give the user the opportunity to use a large surface. However, some craftsmen solve this problem by using multiple tires.

The simplest track module can be made from a conveyor belt and sleeve-roller chains. First, depending on how powerful the engine is, the required thickness of the used belt is selected. This is followed by the processing of the edges, which can begin to shaggy and, because of this, fail earlier. For this, a fishing line is used with a pitch of ten millimeters. The finished edges are then sewn into a ring, with a special hinge, or simply along the end parts.

Despite some primitiveness of the mechanism, it will serve for a very long time. It is important to add that the thickness of the tape must exceed seven millimeters, otherwise the device will not be able to withstand the required loads. The optimal interval is considered to be from eight to ten millimeters.

The track module can be made from belts if they have a wedge-shaped profile. It is best to connect the parts with a lug, which is fixed on the straps with screws or rivets. Another common solution is to construct tracks from chains of equal size. Such a versatile part, as a rule, is abundant in any home workshop, so this method is also economical. To make caterpillars, you have to take a pair of equal chains and unclench their extreme links.

Now the two chains can be connected into one circuit, the links can be clamped back and for reliability everything can be welded. For greater strength, the chains can be fastened again with lugs, which, by the way, are also simply made from scrap materials. metal sheets of the required thickness. In general, this part can be not only steel, but wooden and even plastic. In the latter case, wood bars or plastic tubes are used as it. Which material will be most suitable can be determined depending on the purposes of using the walk-behind tractor.

In the case when the cargo expected for transportation does not differ in large weight, the lugs should be made plastic. The same applies to moving devices equipped with weak motors. When a walk-behind tractor is planned to be used as a tractor, and it has a rather powerful engine, preference should be given to steel parts.

Sometimes homemade caterpillars are reinforced with pipes, which are welded together. Parts in this case are made of metal and have a rectangular cross-section. In this case, it is recommended to remove the drive shafts from the “Oka”, and take the spline part from the “Buran”. The equipment must be equipped with brakes that are mounted on the front shafts. This addition allows you to get a device with maximum capabilities.

It is worth mentioning that in order to convert a conventional walk-behind tractor into a tracked one on the go, you first have to put two additional wheels on it, one on each side. The result should be a four-wheeled structure, on which the tracks are already put on. Some craftsmen prefer to make these additional wheels removable rather than weld on new mountings. This can be accomplished by attaching the wheels to the axle using a flexible or rigid transmission. It is impossible not to mention that it is not necessary to make the tracks yourself. no less economical solution would be to use parts from old equipment, for example, “Buran”.

Cleaning the snow MOTOBLOCK. I did not have time to make a rotary …

What can be done?

When choosing material for tracks, it is important to consider that it should not be excessively heavy. Since the walk-behind tractor itself does not have a powerful engine, it simply cannot cope with weighty material and, most likely, will break. The caterpillar mechanism, as a rule, is made of motorcycle tires, chains, pipes, belts, or a conveyor belt in combination with a sleeve-roller chain.

Most craftsmen create tracks from tires. these parts are easily converted to the desired design. It is necessary to choose tires for large trucks, taking into account the existing tread pattern and shape, because the correct pattern will improve grip. It is better if these are spare parts that previously belonged to tractors or other large-sized models.

A properly selected tread will be able to make good contact with wet ground, ice-covered and snow-covered surfaces. In addition to materials for the tracks, to design a full-fledged device, you will need a walk-behind tractor with a gearbox, as well as a pair of additional wheels. If necessary, an additional cart is attached to the walk-behind tractor and, if desired, even on skids to transport goods through deep snow.

How to make a walk-behind tractor on tracks with your own hands?

- Features and device

- What can be done?

- Step-by-step manufacturing instructions

- Recommendations for use

Features and device

Tracks for a walk-behind tractor greatly simplify both the transportation of cargo and the movement of the device itself. Due to the fact that the caterpillar mechanism covers a fairly large surface, the walk-behind tractor moves much more evenly, exerts less pressure on the surface and does not get stuck on difficult soils. The tiller on tracks is able to work even in bad weather, and in good weather it becomes even more maneuverable.

The maintenance and use of the tracked module does not cause any particular difficulties for the owners, and it is not difficult to do it yourself. It should be borne in mind that when the walk-behind tractor is equipped with a tracked module, its speed decreases. However, the device’s ability to navigate difficult terrain, transport goods and even clear snow from the area increases.

Motoblocks with tracked modules otherwise completely coincide with conventional walk-behind tractors. The engine must be four-stroke with the ability to lock the axles so that the device can turn without making a whole circle. There is also a requirement for water cooling to cope with high loads that cause the motor to overheat. This type is more effective than air. The clutch system, gearbox and gearbox for tracked mechanisms are presented in the traditional version. The walk-behind tractor is controlled on tracks with a handle.

When creating tracks on your own, it is important to understand that if you design them too high, the center of gravity of the walk-behind tractor will change, and it will begin to experience difficulties turning, and even tilt to one side or another. To prevent such a situation, the second driven axle will have to be made longer by a couple of centimeters. Also, with the help of the bushing, it will be possible to expand the wheelbase that already exists on the walk-behind tractor.

Recommendations for use

Using the tracks of the walk-behind tractor, it is necessary to constantly check how well the chain is tensioned, and also regularly oil the parts whose friction occurs when driving. In addition, it is recommended each time before use to check whether any damage and breaks have appeared on the chain. After the trip, a routine inspection should also be carried out in order to detect any damage or broken hooks in time. When using a walk-behind tractor, you should avoid driving over roots and stone massifs, as well as hemp, otherwise the track module will be torn very quickly.

For an overview of the all-terrain motoblock on tracks, see the following video.

How to make a snowmobile from a walk-behind tractor?

- What it is?

- Self-production

- Snowmobile from a walk-behind tractor on wheels

- Snowmobile from a walk-behind tractor on tracks

- Snowmobile from a walk-behind tractor on tires

- Safe driving advice

Snowmobile from a walk-behind tractor on tires

Another economical option for making a diesel snowmobile from a walk-behind tractor and tracks. Motonart on tires from the MTZ-80 or Belarus tractor can easily move on the snow. This design is equipped with two additional wheels and pieces of metal pipe. Consider the benefits of such a snowmobile:

- efficiency. cheap or used materials are used here: wheels from a VAZ car, a square tube, used tractor tires;

- the ability to make a car at home using a welding machine, grinder, drill, knife;

- high maneuverability of the resulting snowmobile, which has the ability to turn like a tank in one place;

- good cross-country ability in deep and viscous snow;

- active brake right or left track.

In order to make tracks, you need two tires from a tractor, used ones are quite suitable. Side parts are cut from each tire with an electric jigsaw or just a sharpened knife. The structure is made of a square tube and two additional wheels. It is required to securely fix the walk-behind tractor and the structure with wheels. Then the caterpillar obtained from the tire is sequentially pulled onto the front wheels, then onto the rear wheels. It turns out a diesel snowmobile on a caterpillar track, that is, on tires. In order to make it more comfortable, you can fit a small seat, which will not weigh down the structure. Otherwise, you will have to stand up to overcome the snowy expanses.

Fans of outdoor activities, hunting and fishing will appreciate the homemade snowmobile. The advantage of this incredible device will be high traffic at a low cost.

Snowmobile from a walk-behind tractor on tracks

Converting a tracked tiller into a snowmobile is a little more difficult, but possible. Using a walk-behind tractor motor, you can make a structure with great stability and maneuverability. For this, the frame and transmission are mounted. Make sure that the engine has enough power, you need a walk-behind tractor of at least 6 horsepower. To make a snow motonart with an engine, you need to use:

- reducer;

- fuel tank;

- steering;

- centrifugal clutch.

It is good if you have tracks from other snowmobile machines in your household stock. If not, then don’t give up. It is quite possible to assemble the caterpillars on your own, using improvised tools and materials.

Next, you need to decide on the location of the engine: front or rear. Try to keep the structure as light as possible and keep the ski soft. All this will make it possible to achieve high cross-country ability in deep snow. The principle is as follows: inside the caterpillar, when driving, 4 wheels roll along the conveyor belt. Special soil hooks are attached to the tracks to enhance traction. Caterpillars can be made at your discretion, but you should carefully consider the dimensions.

Wide or too long tracks will unnecessarily stress the engine. This, in turn, will complicate the handling of the snowmobile on tracks in the snow. A track that is too small will not be able to support the weight of the entire structure with the driver. It will become unstable and sink into loose and deep snow. For the manufacture of tracks, the simplest materials are used: plastic or plastic pipe of small diameter, wheels, bearings.

Workpieces with a length of 0.5 cm are made from the pipe, from which ground hooks are obtained. They are attached to the tape at the same distance from each other. Then they are bolted into the holes on the conveyor belt. The frame is made using square pipes or a channel. Use a tie rod without ball ends, as the steering and ski axes lie in the same plane.

On the front of the frame, bushings are attached to allow the skis to turn. They can be made from steel couplings with small diameter nipples and threads. Racks of skis and tie rods are welded to the pipes. To control the snowmobile, corners with a metal undercut are attached to the skis, which will allow you to move on ice or snow crust.

The weight of such a snowmobile is no more than 100 kg, and it is very simple to operate the vehicle. Since the power of the motor is low, the speed does not exceed 10-15 km / h, so no brakes are provided. The end of the movement occurs due to the reset of engine speed or the so-called engine braking.

What it is?

A snowmobile is a power-driven vehicle. The most famous are small-sized models equipped with track skis and controlled by the principle of motorcycle. However, in fact, there are many varieties of all-terrain vehicles on low-pressure pneumatics and caterpillar tracks, snowmobiles. Motoblocks are also divided into wheeled and tracked. You can make a snowmobile from a walk-behind tractor with your own hands with any chassis, only in this case, different methods and materials are used.

Snowmobile from a walk-behind tractor on wheels

To turn a walk-behind tractor on wheels into a snowmobile, you will need to take:

- an iron connecting structure-trailer;

- wheels for winter use, able to overcome snow obstacles.

A strict condition for the whole idea. the trailer must be rigidly coupled to the snowmobile frame. A metal channel about half a meter long must be welded parallel to the axis of the snowmobile. To do this, two holes are drilled at the edges of the channel. Hole clamps on the edges provide additional fastening and structural rigidity. They are attached to the axle of the snowmobile with bolts with a lock nut, using a cross welded to the structure.

This mount will act as a stopper that holds the trailer in place, preventing it from shifting at an angle. Such an element, although it reduces the ability to maneuver on the snowmobile, makes it more stable. Thus, a two-wheeled mechanism on one axle can be easily converted into a stable four-wheeled vehicle. At the same time, you will not need any diagrams and drawings, or additional costs.

A snow scooter with a motor will also require the correct selection of wheels. The easiest option is to purchase them in a retail network for a winter purpose, but it is not always advisable to look for easy ways. A more economical solution would be to make the wheels yourself. The budget option is to equip the snowmobile module with cameras designed for trucks. Deflated cameras are put on each wheel and fixed over the chain for driving on snow and ice. One is not enough, you need about five. An inflated chamber in a cache of chains will be an ellipse with a surface divided into segments like a daisy.

Another option for using ingenuity and saving the family budget is to use metal hoops over the cameras. They should be wide enough, twice as wide as the snowmobile wheels. The diameter of the hoop must match the inflated wheels of the walk-behind tractor and trailer. Several metal plates are welded on the inside of each hoop. The thickness of the plates must be made about 2-3 cm. After lowering the cameras, you should put hoops on the wheels of the snowmobile and pump them up again. The inflated chambers will squeeze as much as possible against the metal circles. Plates like dirt lugs help increase traction on snowy roads.

Self-production

Let’s consider step by step how to make different types of snowmobiles with your own hands.

Safe driving advice

Do not forget that any vehicle, even one made by yourself, requires attention and care. You cannot overestimate your capabilities and move in the dark or in bad weather conditions. If visibility is poor, you may not notice changes in the topography of the ground, holes, ditches covered with snow. The low stability of the snowmobile when hitting any obstacle (stones, stumps, metal objects) can lead to overturning, throw off the rider and / or press down with its mass, cause injury, or even death.

Care is required when overcoming slopes and when driving under any overhanging obstacles: sagging wires, stretch marks, fallen trees. The blow will hit the rider’s chest, so if there is a backrest, injury is inevitable. Be aware of possible road obstacles and take safety seriously.

How to make a snowmobile from a walk-behind tractor with your own hands, see the next video.

Manufacturing steps

The material for the cover must be folded together with the right side inward to cut two identical circles at once. An inflated chamber is placed on top. It is necessary to circle it along the outer diameter. The main thing is to make the calculation correctly, taking into account the allowance, about 15-20 cm.

Then on one circle it is necessary to cut out the middle. along the inner diameter of the chamber. This circle does not need to be thrown away, it will be used for the bottom. It is also necessary to cut a strip with a width of 15-20 cm and a length equal to the circumference of the cut circle.

Sew two circles on the outside. The seams must be strong. Treat them with synthetic tape. Sew on handles.

Sew a banner strip along the circumference of the cut-out “hole”. Since the fabric is dense, not every sewing machine will be able to sew it. You may need to sew by hand.

The bottom is sewn on at the last stage. The seam should not be continuous. You need to leave a gap in order to freely remove the deflated camera and put it back. At the same time, it is easier to shake out the snow from such a cheesecake. for these purposes, you can sew in a zipper or just pull it off with a cord.

DIY tubing is ready. It remains to pump up the camera. so that it is elastic, but not rigid, and you can ride down the hill. You can pump it up yourself at home using a compressor or in a tire fitting.

DIY materials for making tubing

For those who are willing to take the time to make a do-it-yourself ride, here are some tips on how to do tubing. You will need:

- car camera;

- material for the cover (PVC) and seat trim (raincoat, waterproof polyester);

- synthetic tape for finishing seams, handles and cable;

- special thick threads, needles and sewing equipment;

- time and patience.

The fabric for the cover can be purchased at sewing or specialized travel and sports outlets. The material must have a high density and be waterproof. The DIY Glossy Tubing Cover will not only look good, but it will also glide more easily on snowy surfaces, which will increase your riding speed.

To securely attach the handles and cable, as well as protect against damage and snow ingress, you will need to find special slings and dense synthetic tape. Parts need to be stitched with thick polyester threads, you can even reinforce them. The higher quality materials you choose, the longer your DIY tubing will last.

DIY cheesecakes for slide downhill

For this we need:

1. Tire from Zhiguli.

2. Piece of banner.

3. Nylon threads.

4. Needle.

Another DIY cheesecake for a slide

DIY tubing (“cheesecake”)

You will need:

- car camera with a radius of 13 cm. 1 piece.

- tent “Tarpaulin”. 90×150 cm

- thick Oxford fabric. 50×150 cm

- belt tape (sling). 250×3 cm

- lavsan threads 00. 1 piece.

- sewing machine needle 20. 1 piece.

- sewing machine universal

Manufacturing process:

- We measure the full girth of the inflated chamber (in our case, it is 170 cm).

- Divide the resulting figure in half and measure two circles with the same diameter on the tent material.

- In one of the circles, draw a circle with a diameter of 40 cm.You will get a ring, which will be the upper part.

- Cut out the ring and the bottom circle.

- We mark the attachment points of the handles and hinges.

- We make the inner part of the cover from Oxford fabric. When finished, it looks like a truncated cone.

- Draw two trapezoids with a base of 75 cm and a height of 25 cm.

- We put them together and sew along the side lines, leaving a gap of 2-3 cm for attaching the cord. You should get a detail that resembles a pipe.

- We fold it in half and along the upper border we make a seam for the cord, retreating 2 cm from the edge.

- We sew a cone into a ring of awning fabric.

- We make handles and a ring from the tape and sew.

- We close the seam with a belt tape and sew. The upper part is ready.

- Sew the upper part with the lower one so that the seam is inside.

- We turn out the cover and fill it with a deflated camera.

- We pump up the chamber with a pump. and the tubing is ready.

If you have any questions, watch this video tutorial on how to create a tubing:

We remind you about the main condition of any active games. safety. Talk with children about this topic, tell about important points.

- Inspect the track before skiing, make sure there are no deep holes and branches.

- You can only ride an inflatable sled while sitting.

- Do not overload the tubing, do not plant several children at the same time.

- Ensure that there is enough space underneath for braking.

- Avoid collisions, watch the movement on the hill.

- Do not tie the tubing to other vehicles: snow scooter, sled.

Instructions: do-it-yourself tubing for downhill skiing

What is the most fun and popular game for children in winter? Of course, downhill skiing! Children are looking forward to when the snow-white blanket will cover the slopes and hills and it will be possible to get their snow-scooters, sleds, ice-skids and other means for a fun and quick descent from the mountain.

Today we invite you to make a popular children’s transport for skiing with your own hands. a tubing that children will definitely like.

How to make a tubing for downhill skiing with your own hands?

Tubing is a special device for downhill skiing. In appearance, it resembles a cheesecake, for which he received the corresponding nickname. This is a great alternative to sledges and ice cakes. At the same time, tubing is not cheap. However, the budget model can be made with your own hands.

Iron tracks

The most reliable are metal tracks made of high quality iron. For this purpose, metal pipes or a profile cut into pieces of the required length are suitable. A profile metal pipe is cut according to the same principle as a plastic one and is attached to a conveyor belt with bolts.

However, metal tracks, despite their noticeable strength, also have their drawbacks: they are heavy compared to plastic and wooden ones, and can bend during use. To straighten the track, you need to remove it from the goose, and this is a laborious operation.

When choosing the material from which the track links will be made for your mini-all-terrain vehicle, you should evaluate the degree of load and operating conditions. To overcome the snowy expanses on a homemade snowmobile, light plastic or wooden tracks are perfect, and to use a walk-behind tractor as a mini-tractor, it is still better to make a caterpillar with metal grousers.

From conveyor belt

This method is the simplest, since it does not require a large number of special tools and auxiliary materials.

- When choosing a belt for a caterpillar, give preference to a strip with a thickness of at least 7 mm, because it has a fairly large load. Hitching with moving parts will be provided by a sleeve-roller chain.

- To give the tape strength and increase its operational life, it is recommended to sew along the edges of the tape with frequent stitches with a step of about 10 mm.

- It is also necessary to sew the tape along the ends in order to connect it into a ring of the required diameter, or use, for greater reliability, hinges resembling a piano canopy.

- Make sure that the additional wheelset that you install on the walk-behind tractor frame is the same diameter as the main wheels on the walk-behind tractor.

Homemade tracks for a walk-behind tractor with your own hands

To increase the throughput of the walk-behind tractor and use it as an all-terrain vehicle or snowmobile, you can equip it with tracks. They can be purchased ready-made, but they are expensive, and it is not always possible to find the right option for your walk-behind tractor. There are several ways how to make a caterpillar on a walk-behind tractor with your own hands.

Using our recommendations, you can easily turn your wheeled walk-behind tractor into a tracked all-terrain vehicle. At the same time, you will not need expensive materials and too much time.

Homemade track links

You can also make your own goose tracks from any suitable material. The main thing that needs to be taken into account is what kind of load you are going to give to your walk-behind tractor.

How to make a caterpillar for a walk-behind tractor with your own hands

If you wish, you can independently modify your walk-behind tractor, turning it into a tracked all-terrain vehicle or snowmobile. The main rule is that you should take into account what kind of work the tracks are intended for in order to choose the right material, because they must be not only durable, but also extremely light.

Having the materials at hand, having correctly calculated the length of the caterpillar, you can make it yourself using simple improvised means.

First of all, you need to equip your walk-behind tractor with an additional pair of wheels. For each side pair, a caterpillar track will be worn.

The length of each of the two goslings will be equal to the circumference of one wheel and the distance between the axles of each pair of wheels, multiplied by two.

Important: the wheels on the walk-behind tractor must be of the same diameter.

The material for homemade products can be:

- conventional conveyor belt and bush-roller chain;

- car tires;

- belts and chains.

So, let’s consider several options for making a goose yourself, depending on the material used.

Of belts and chains

In order to make a tracked all-terrain vehicle from a walk-behind tractor, you can use ordinary belts with a wedge-shaped profile. The connection of the belts to each other is carried out by grousers attached to them on rivets or screws. This gives us a belt track.

Снегоочиститель из мотоблока соими руками

To make a goose from chains (chain tracks), you need to take two pieces of the same chain of the required length.

- The end links of both segments are expanded in order to connect them into two closed rings.

- The unclenched links are clamped again, and then welded for strength.

- Sections are cut from steel of the required thickness, which will serve as lugs.

- The lugs are bolted at both ends to the links of both closed chains, thus forming a relief track on the walk-behind tractor.

From plastic pipes

You can use pieces of plastic pipe as tracks on a goose for a snowmobile. To do this, cut the plastic water pipe 0 into lengths equal to the track width. Use a circular saw to cut each piece lengthwise into two equal halves, or use a circular saw for wood.

The resulting tracks must be attached at regular intervals to the conveyor belt with furniture bolts with large hemispherical caps.

From wooden blocks

Sometimes, if the load on the goose is not very large, birch blocks can be used as tracks. They are not particularly durable for heavy loads, but they are lightweight, affordable, and a track with such tracks can be repaired at any convenient place.

A do-it-yourself snowmobile can be made according to one of the concepts

Classic design

With lead track and steering ski (s). The project, proven over the years, is the complexity of the manufacture of the caterpillar itself. The vehicle turns out to be universal, easily moves on any roads, including rough terrain. In some cases, homemade products are superior to many industrial designs.

Snowmobile

The easiest home-made snowmobile from the point of view of implementation. It is enough to put the cart on the support skis and install the traction screw on any suitable motor. In addition to some difficulties associated with the manufacturing technique of the lead screw, there are no more problems in the construction. The disadvantage is that this design moves only over a relatively flat surface. Another problem. with low engine power, it is difficult to move against the wind.

By donor type, or the use of different types of engine, homemade snowmobiles are divided into the following types:

- Using a motor from a chainsaw. Low power does not allow moving large weight on such a vehicle. Therefore, chainsaw snowmobiles are usually single-seated;

- Moped or motorcycle. The project is quite simple to manufacture. The engine is designed for a certain load, it remains only to remake the drive element and replace the front wheel with a ski;

- Snowmobile from a walk-behind tractor. The design is rather complicated, but in terms of reliability it is practically not inferior to the factory one. The engine is designed for continuous operation under load, the kit includes a gearbox, which expands the capabilities of the vehicle. In addition, the power plant can be removed for the summer season, and the walk-behind tractor can be used for its intended purpose;

- A do-it-yourself snowmobile based on a car or, using a motor from a car. A rather rare type of homemade products, professional equipment and complex engineering calculations are required for their manufacture. But snowmobiles made on the basis of a car are distinguished by high comfort, safety and reliability.

Consider several typical designs that have been tested and successfully put into operation:

On pneumatics

In fact, it is a mini-tractor with original wheels. Due to the large area of contact with the surface, it overcomes even loose snow. It is usually made from a motorcycle or walk-behind tractor.

Homemade snowmobiles. the implementation of creative ideas, or a means of transportation?

- A do-it-yourself snowmobile can be made according to one of the concepts

- On pneumatics

- Classic design

- Using the drive wheel

- Snowmobile

- Homemade snowmobile from a moped

- Snowmobile from a walk-behind tractor on pneumatics

Homemade snowmobiles last season. video review.

There are even models developed by folk craftsmen and then produced in small batches.

Homemade snowmobile from a moped

Actually, only the power plant and the steering wheel remain from the donor. All other parts are manufactured additionally, making the design completely unique.

The concept is as follows. a space frame (rear part) is manufactured, inside which the original propeller is located. The front end of the moped, together with the engine, is welded to the frame, closing the structure:

Two channels are welded to the upper crossbar of the standard frame, with the steering joint retained, passing into the lower part of the newly created frame. The gas tank remains in its usual place. If it is necessary to make long runs, you can install a larger tank, the dimensions of the snowmobile allow.

Instead of the front wheel hub, a ski hinge is installed. If desired, you can leave the shock absorbers (if they were provided by the design), however, when traveling on soft snow, this element of comfort is not required.

Cut out the motor pedestal from the moped frame, and weld it to the front spatial structure. It is advisable to convert the foot kick starter into a manual cable, like on a chainsaw. It will be inconvenient to start the engine with a foot launcher in winter shoes.

There was no place for a regular muffler, so a new one was made of stainless steel. It is located at the front of the frame, in front of the motor. The construction is primitive, but it does its job.

In addition, this arrangement has advantages. your legs are protected from the oncoming ice stream.

There may be questions about the blowing of the cylinder block. there is no such problem. Considering the ambient temperature during the season of use. everything is in order with cooling. Now let’s move on to the main body. the back of the space frame. It is made in the manner of a gymnastic “goat”, with an impressive seat and stable four legs.

There was a place for a traveling glove compartment under the seat. The soft part folds back on the door hinges, forming a cover.

The most original part of the structure is the propulsion unit. To reduce the cost of production, it was decided not to make a leading caterpillar, but to adapt the rowing blades, like in old steamboats.

The drive wheel is made of an automobile disc, with lugs welded across. An asterisk from the same moped is rigidly fixed to the axle. The whole structure is located on a pendulum suspension, from two profiles 40 mm wide.

The self-weight of the wheel is sufficient for confident grip on the snow surface, so no pressure devices are provided. In addition, if the paddle wheel hits a solid obstacle (stone or ice hummock), the mechanism will simply jump over it, without damaging the structure. The drum brake from the rear wheel of the moped is put on the same axle.

Homemade SNOW PLOW for MOTOCULTIVATOR

Using the drive wheel

In this case, the wheels are with grousers. This is how a paddle steamer works. The advantage of the design is the relative ease of manufacture. The disadvantage is insufficient adhesion to the propeller surface, slippage on difficult terrain is possible. Such models are quite good obtained from mopeds and motorcycles, giving a second life to “donors”.