Drilling passage holes in concrete. Stages of drilling

Diamond drilling

Diamond drilling technology makes it possible to quickly obtain the required number of even and exact holes in various building materials of high hardness. Most often, holes are created in concrete, brick, stone, reinforced concrete. Sometimes there is a need to drill holes in other materials, such as granite, marble, ceramics.

In the professional sphere, often diamond drilling technology can be called diamond drilling technology.

The creation of holes is required for many types of work, which include the installation of ventilation systems, laying communications, heating and gas supply systems, installation of air conditioners, as well as for a very wide list of other works.

The process of diamond drilling is quite difficult and has a number of nuances and subtleties. Diamond technique requires a very careful and correct attitude, so any mistake can cost not only breakdowns of expensive equipment, but also damage to the construction structure. In order to have complete confidence that the result will be as high quality as possible, it is better to contact professionals.

Our company has been providing services for professional diamond drilling for many years and has a staff of highly qualified specialists. We use only high.quality equipment that allows optimizing and speeding the workflow as much as possible. Turning to us, you can be sure of 100%quality and observance of the agreed terms.

Among the advantages of diamond drilling, one can note the high speed of work, the lack of vibration, which can affect the appearance of cracks, the absence of chips and high accuracy of holes, the possibility of drilling structures with a high degree of reinforcement. Among other things, diamond drilling will not cause inconvenience to people living in neighboring apartments, as it is low.haired.

When preparing for the work, first of all, it is necessary to draw up a drawing of the future hole and determine its center and diameter. After the openings parameters are precisely determined, the bed is attached to the wall (a special guide stand), and a diamond crown of the required diameter is attached to the drilling system engine. Then the engine is installed on the bed. The system is provided to the system, which is necessary to cool the crown and neutralize dust and work begins.

The water supply process can be complicated when there is no water supply at the facility. In such cases, special tanks are used to supply water. Particular difficulty arises when it is necessary to drill at negative air temperatures, t.to. Water may freeze. In this case, non.freezing fluid is used, but the minus of this method is that it significantly increases the cost of drilling. If there is source of running water at the facility, then such a problem will not arise.

In some rare cases, drilling is used without water supply, the so.called “dry drilling”. This method is used when the use of water in the room is undesirable due to the availability of repair. Dry drilling is possible when it is necessary to drill concrete with a large number of pores, or brick and other soft materials. In such cases, the crown heats up slightly and does not require additional cooling. The disadvantage of this method is a huge amount of dust.

One of the most important elements of diamond drilling is not only a high.quality drill system, but also a reliable drilling crown, which serves as a tool for drilling. The crown has a corps on which special segments with high ms of industrial diamonds are attacked, it is precisely due to them that the drilling occurs. When the segments are shy, it is necessary to attack new. The slower the segments grows, the higher the resource of the crown, and, accordingly, its quality.

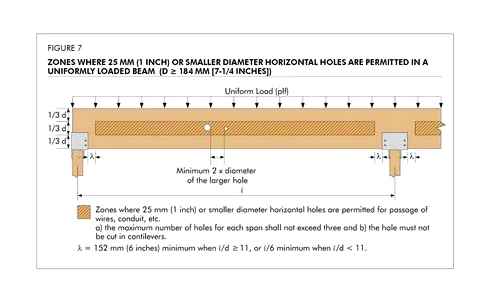

The length and width of the hole directly depends on the diameter and length of the crown body. The longer the crown, the more deep the hole can be drilled, and the larger the diameter of the case, the wider the hole will be. Worms have a variety of diameters, from very small (25 mm), to very large (600 mm). Each drill installation in terms of its technical parameters is designed to use crowns of certain diameters, therefore, to create holes with a significant difference in width, various drilling systems will be needed.

The standard length of the diamond crown is 450 mm, but in certain cases it can have other values. To create holes of very large depths, special extensions of the crowns are used.

Diamond drilling is carried out not only in under construction facilities, but also in residential buildings. It is also common in the arrangement of urban infrastructure objects: granite embankments, various structures, etc.D. Diamond drilling is used in a huge number of spheres and areas. Such a service is quite expensive, since good equipment and equipment cost a lot. But the technology of drilling holes with the help of crowns is able to save a huge amount of time from the contractor who has chosen just this method of work, and the terms, as you know, play an important role not only for the image of the performer of the work, but also for its profit.

Holes created using a diamond crown do not need further processing, t.to them are the most even as possible. Crings easily undergo reinforcement, so there are no obstacles for quick and high.quality drilling.

Diamond drilling holes for sockets

The creation of holes for sockets is carried out using special crowns, which are called “sockets”. “Participants” can have various diameters, which allows you to drill the hole required in width. To create holes for sockets, the contours are also applied first, and then drilling is carried out.

Granite drilling is a separate complex technology that has a number of nuances. Granite is a low.amatery material with high hardness and strength, therefore, the supply of water when working with granite is carried out limitedly, so as not to wash out the abrasive. Another important point is that the rack should not be fixed with anchors to the surface, the drilling of granite is performed manually.

It is worth paying special attention to the fact that when drilling granite, the engine works at high speeds, the crown heats up greatly due to high friction, which can lead to equipment breakdown. Such work can only be entrusted to professionals with extensive experience who know all the subtleties of this process.

PRICE

Diamond drilling

Masterfully drill a hole in concrete, monolith, reinforced concrete, FBS blocks and brick

Additionally, we will produce a water collection, we will take out the garbage.

During finishing repair, we use dry drilling technology without dust.

It is possible to drill walls without fixing. manual installation and telescopic stand.

A drill hole “into the ceiling”. Vertically from the bottom up.

The Almaz Best team produces diamond drilling of the openings of the software and the plug of commissioning of technical life support networks. plumbing, ventilation and electric power systems; water treatment, heating, septic tanks, air conditioners, and other needs. We have been operating since 2007. We have a park of European equipment in the required quantity. We give warranty obligations under the Civil Code.

How not to spoil the finished repair, performing diamond drilling?

Drilling holes in the walls and floors with diamond crowns refers to capital work, during which a significant amount of suspension is formed from the water and processed material of cement, ceramics, sand. The suspension falls on the diamond crown and receives a rotational movement, sprinkling in the work area (no further than 1 meter), after several hours the water evaporates and it remains only to collect a solid powder substance with a spatula and a vacuum cleaner, or wipe it with a damp cloth.

When operating the premises, it is often required to connect new communications, there are many reasons for this-you need to make a hole for supply and exhaust ventilation, the object was connected to gas supply, and it is necessary to make a neat input of the pipes into the house, the transfer of plumbing equipment, etc. Do not worry on this issue, diamond drilling holes will not spoil your finished repair.

Having in its arsenal a special drainage adaptation of CEDIMA, connected to the professional “Moastons”, we will collect 98 % of the resulting suspension. Why only 98 percent of dirt gather? The answer is quite simple. Pure drilling walls made of reinforced concrete looks technologically like this:

A crown is put on the mounted installation of diamond drilling to make the holes of the required diameter, and the system for removing the liquid is attached to the wall with a vacuum or a clamping mechanism. Turn on the vacuum cleaner and installation. The process of drilling the hole in the wall begins. Consider the options for the appearance of a certain amount of moisture in the room during drilling the hole in the wall:

1) Passing the reinforcement is the first underwater stone. The diamond crown begins to vibrate a little, the direction of vibration parallel to the crown (the operator feels the return), at the time of this micro.returns, the drips are sprayed, while the bulk of the liquid goes into the water collection device. You can deal with drops by fixing a rubber bandage on the seaple, tightly fitting a crown, but rubber begins to melt from a long drilling of the reinforcing ligament and then the floor is no longer water, but a droplets of a sticky rubber.

2) a rough surface of the wall, or having grooves. Due to loose contact, small subterations are possible.

3) leakage under the wallpaper. Wallpaper having air s can also cause subteces.

What can cause smudges when diamond drilling of holes in a brick wall occurs. It would seem that the brick has a lower density than concrete and drilling rate of brick walls is not comparable to drilling reinforced concrete. That’s right, but when it comes to finishing drilling holes, unpleasant surprises can be wait:

1) Diamond drilling holes in a brick wall price, which is lower than working with monolithic concrete as usual, the only difference is that the seams between the rows are not tight and the leak can be observed a meter from the drilling point.

2) hollow brick, more resembles a system of communicating vessels. where the water is pouring there and who will come out and whether it will come out? In this case, we try to limit the supply of water to the drilling zone.

Force-major circumstances of the final diamond drilling include the disconnecting of electricity when working with a vacuum water collection ring-it just falls down!

We also did not mention that from all the compounds of the drilling installation, diving occurs, because the water is supplied under pressure, and the compounds are collapsible and not tight.

Offshore Deep Water Drilling Process |Cementing & Casing Explained

We are ready to perform diamond drilling in the room with repair and guaranteed to collect. 98 percent of the waste fluid. It is possible to completely eliminate water to the surface when drilling concrete, you can only carry out a number of additional insulating works, which will significantly affect the cost of diamond drilling. After all, hardly anyone to agree to pay for the safety of wallpaper exceeding their value.

Optimal work in rooms with decoration is when finishing the drilling of holes is possible, but only 98 % of the liquid is assembled.

You can order diamond drilling in a room with a finished repair by phone 985 260-08-00

Where the diamond drilling of holes is used

Now it’s hard to imagine modern construction without the use of diamond drilling. Here are some works related to diamond drilling:

- Drilling holes for ventilation

- Installation of supply and exhaust devices and valves in t.h. Imatiators (for example Tion, nod)

- Drilling holes for laying sewage

- Drilling holes in the overlap for heating risers, water supply

- Round and square openings for ventilation boxes

- Drilling reinforced concrete for the cooling/air conditioning system

- Drilling in the foundation

- The device of various niches in the floor

- In road construction

- Installation of anchors

- Punching openings in concrete walls and floors

- Punch (drill) the hole in the foundation for the sewer, and t.D.

With the help of diamond drilling crowns, you can get not only round holes, but also any other shape alternately making holes around the perimeter. However, for the installation of rectangular openings, disk diamond cutting is more often used. Diamond cutting of openings allows you to reduce the cost and deadline for the manufacture of the opening. If there is no possibility of cutting the opening of the disk, group drilling of the perimeter of a rectangular hole is performed. The price of the drilling group of holes is lower than drilling piece holes, t.to. Do not constantly transfer equipment.

Diamond drilling holes

Diamond drilling holes in concrete, foundation, walls and ceilings! Diameter from 50 to 452 mm. Low prices. There is a solution to SRO. We work and the hovering of excessive noise, dust and shock vibrations for a long time by builders have mastered the technology of diamond drilling holes in reinforced concrete, as well as on brick surfaces and other materials. It is from the above materials that the walls and ceilings are most often built in the premises, and the high accuracy of the methodology avoids the gap between them during the work of the work.

The scope of diamond drilling technology

| 42, 52, 62 | fifteen | twenty |

| 72 | eighteen | thirty |

| 82. 102 | twenty | thirty |

| 112. 122 | twenty | thirty |

| 132. 142 | 25 | 35 |

| 152. 162 | thirty | 40 |

| 182 | 40 | 55 |

| 202 | 40 | 55 |

| 225 | 45 | 60 |

| 250 | fifty | 65 |

| 275 | 60 | 80 |

| 300 | 60 | 80 |

| 325 | 65 | 90 |

| 350 | 70 | 95 |

| 400 | 90 | 125 |

| 450 | 100 | 135 |

- Minimum order. 10,000

- The minimum cost of the hole. 600

- Work by the chipper. 3000 / hour

- Discounts for construction organizations. up to 15%

- The departure of the brigade for a small concrete ring. The price is contractual

To drill concrete, a tool with diamond spraying is used. It is used for drilling concrete surfaces, for example, on roads, often a tool with diamond spraying is used in work on laying home communications. electrical wiring, ventilation and air conditioning systems, fire extinguishing and other things.

Very often there is a need for creating, even for a inhabited room, additional doorways or simply. niches in the wall, for built.in pantries or cabinets. And in this case, also, a diamond tool will come to the rescue. Technological holes when using it can be made in both vertical and horizontal directions.

It is also recommended for dismantling work that is carried out during the reconstruction of the premises. It can be vertical columns or horizontal beams. a diamond tool will provide the maximum quality and safety of the process carried out.

The manufacture of the opening by drilling is slightly different from traditional cutting. The openings are cut in the form of a cylinder, as a result of which the holes are created overlapping, around the perimeter.

Drilling is used where an anxure machine is ineffective. In most cases, when working in rooms, water is used. She washes and cools the working mechanisms. The method is called. hydrochlving. For increased efficiency, a water collection ring, cumulative moisture and an industrial vacuum cleaner, sucking it, is used. Thus, dust is besieged, which contributes to cleanliness on the object.

Diamond drilling

Diamond drilling/drilling holes is a modern, quick and safe way to produce holes in the wall or foundation without harming the building itself and supporting structures. In this case, the resulting openings or holes do not require additional processing or grinding, and diamond equipment working without vibrations eliminates the possibility of cracks or chips.

| Drilling of openings | |

| Concrete, railway: cost 1cm, (with VAT 20%) | Brick: cost 1 cm, (with VAT 20%) |

| from 40.00 | from 30.00 |

| The hole in concrete | |

| Hole diameter, mm | Concrete, railway.1m.P, (with VAT 20%) |

| 16-36 | Contractive |

| 40 | 2500.00 |

| 50, 60 | 2600.00 |

| 80 | 2700.00 |

| 100 | 2900.00 |

| 120 | 3400.00 |

| 130 | 3600.00 |

| 150 | 4100.00 |

| 160 | 4100.00 |

| 180 | 4800.00 |

| 200 | 5300.00 |

| 225 | 5800.00 |

| 250 | 6700.00 |

| 270 | 7600.00 |

| 300 | 9000.00 |

| 350 | 11000.00 |

| 400 | 14000.00 |

| The hole in the wall | ||

| Hole diameter, mm | Concrete, railway: cost 1 m.P, (with VAT 20%) | Brick: cost 1 m.P, (with VAT 20%) |

| 16-36 | Contractive | Contractive |

| 40 | 2500.00 | 2000.00 |

| 50.60 | 2600.00 | 2000.00 |

| 80 | 2700.00 | 2000.00 |

| 100 | 2900.00 | 2200.00 |

| 120 | 3400.00 | 2500.00 |

| 130 | 3600.00 | 2700.00 |

| 150 | 4100.00 | 3000.00 |

| 160 | 4100.00 | 3000.00 |

| 180 | 4800.00 | 3600.00 |

| 200 | 5300.00 | 4000.00 |

| 225 | 5800.00 | 4300.00 |

| 250 | 6700.00 | 5700.00 |

| 270 | 7600.00 | 6500.00 |

| 300 | 9000.00 | 7300.00 |

| 350 | 11000.00 | 9800.00 |

| 400 | 14000.00 | 13000.00 |

| Drilling of a brick wall | |

| Hole diameter, mm | Brick: cost 1 m.P, (with VAT 20%) |

| 16-36 | Contractive |

| 40 | 2000.00 |

| 50, 60 | 2000.00 |

| 80 | 2000.00 |

| 100 | 2200.00 |

| 120 | 2500.00 |

| 130 | 2700.00 |

| 150 | 3000.00 |

| 160 | 3000.00 |

| 180 | 3600.00 |

| 200 | 4000.00 |

| 225 | 4300.00 |

| 250 | 5700.00 |

| 270 | 6500.00 |

| 300 | 7300.00 |

| 350 | 9800.00 |

| 400 | 13000.00 |

| Diamond drilling holes | ||

| Hole diameter, mm | Concrete, railway: cost 1 m.P, (with VAT 20%) | Brick: cost 1 m.P, (with VAT 20%) |

| 16-36 | Contractive | Contractive |

| 40 | 2500.00 | 2000.00 |

| 50, 60 | 2600.00 | 2000.00 |

| 80 | 2700.00 | 2000.00 |

| 100 | 2900.00 | 2200.00 |

| 120 | 3400.00 | 2500.00 |

| 130 | 3600.00 | 2700.00 |

| 150 | 4100.00 | 3000.00 |

| 160 | 4100.00 | 3000.00 |

| 180 | 4800.00 | 3600.00 |

| 200 | 5300.00 | 4000.00 |

| 225 | 5800.00 | 4300.00 |

| 250 | 6700.00 | 5700.00 |

| 270 | 7600.00 | 6500.00 |

| 300 | 9000.00 | 7300.00 |

| 350 | 11000.00 | 9800.00 |

| 400 | 14000.00 | 13000.00 |

| Drilling concrete | |

| Hole diameter, mm | Concrete, railway: cost 1 m.P, (with VAT 20%) |

| 16-36 | Contractive |

| 40 | 2500.00 |

| 50, 60 | 2600.00 |

| 80 | 2700.00 |

| 100 | 2900.00 |

| 120 | 3400.00 |

| 130 | 3600.00 |

| 150 | 4100.00 |

| 160 | 4100.00 |

| 180 | 4800.00 |

| 200 | 5300.00 |

| 225 | 5800.00 |

| 250 | 6700.00 |

| 270 | 7600.00 |

| 300 | 9000.00 |

| 350 | 11000.00 |

| 400 | 14000.00 |

Performing work with the peorator, it is important to take into account certain rules. When drilling concrete, experts recommend using a coolant or special lubricant. Before starting work with a long drill, it is advisable to work with a shorter drill. Often the concrete surface has a loose structure, so in order to prevent its scattering, processing is recommended in the “drilling” mode. At the end of the work, the tail of the drill should be cleaned of dust, for this it is wiped dry with a soft cloth and lubricated with machine oil or solidol.

To extend the life of the infantry, they need to be used according to the instructions provided by the manufacturer. In addition, regardless of the volume of work, you should take small breaks for cooling the body. If the gearbox is overheated, then the device will quickly fail. You can not lower the device for cooling into the water. The increased pressure on the processed concrete is not allowed, this will help increase the power of the device, but can lead to a quick breakdown of nozzles.

Review of tools

For processing surfaces made of concrete, an electric drive is used.

There is equipment with additional shock impact, which allows to obtain holes of the correct geometric shape in solid materials. Installations for diamond drilling are characterized by increased weight and dimensions, the equipment is used by construction or repair teams.

If the user needs to perform single channels, and there is no electric tool in stock, then he needs to know how to make a hole in the concrete wall without a penetrator. For drilling, a steel rod or a segment of a pipe of a suitable diameter, having a teeth at the end, are used.

A hammer is struck on the rod, and then the impromptu tool is rotated by 1/3 turnover. The procedure takes a lot of time, the quality of the edges of the hole is low.

Peorator

Drilling the hole in concrete is carried out by a shock drill or a pedorator, the tool allows you to drill channels up to 500 mm deep. The disadvantages of the use of equipment are increased noise during operation and the risk of wall destruction due to vibration loads.

An additional minus is the formation of a large volume of dust, the professional tool provides for the installation of a sleeve for a vacuum cleaner hose.

Ordinary drill or electric screwdriver

Making a hole in the wall of concrete with a manual or standard electric tool is almost impossible. The equipment allows you to perform channels of small diameter in soft material, when you try to drill the concrete base, the drill is stupid or breaks down.

To facilitate the drilling process, a chisel or punch, which is broken by solid inclusions in concrete, are used. It will not be possible to drill concrete ceilings or walls without a penetrator.

Diamond drilling

For cutting holes in concrete reinforced with metal reinforcement, a diamond crown installed in special equipment is used. The tool provides water supply to the working area, which cools the crown and washes the formed dust. Installation allows you to perform a hole of a large diameter, there is no damage and chip on the edge of the channel.

Features of drilling drill

When using a drill, it is important to choose equipment and a drill with the necessary technical parameters. It is recommended to use an electric device with a speed regulator and an additional shock mode.

The use of the side handle accelerates the drilling and reduces the load on the operator, the drilling depth regulator will not be superfluous.

Drill device and installation of a drill

The DRALE design uses a collector electric motor engine. The engine design provides for a speed controller displayed on the power button. To reduce the speed and increase the torque, a gearbox is used, a tool with a 2-speed box is found.

A fist cartridge is mounted on the output shaft of the gearbox, a cartridge with a latch is used in the peorators. The peorater gearbox is equipped with a separate unit that ensures the formation of the progressive and revolutionary movement of the drill.

Before drilling a concrete surface, it is necessary to fix the drill. The tool is placed in the cartridge, the fists provide the alignment of the drill and the axis of the cartridge. The drill is placed inside the cartridge over the entire length of the shank, lengthening the working part of the tool due to extending the shank from the cartridge is prohibited. To tighten the cartridge, the key is used (it is included in the drill set).

Selection of power

To perform holes in concrete surfaces, a tool with a capacity of at least 600 W is required. The speed of rotation is selected depending on the diameter of the drill and the characteristics of the processed material. The employee independently selects momentum, reducing the release of dust into the air and reducing the likelihood of refusing the wall fragments when drilling a hole.

Errors when working with a drill

The main errors in the operation of an electric drill:

- It is forbidden to hold the equipment when working for the cartridge. Protective gloves and clothing should not sag and have dangling elements, since there is a danger of winding the material on a rotating drill.

- You should not direct the tool at an angle or apply an excessive effort, since the employee can fall from a stepladder or stairs and get injuries.

Increasing the length of the cut during drilling holes at an angle

| Slope angle in degrees | Increase the thickness of the wall by |

| up to 5 | 0 |

| ten | 2% |

| fifteen | four% |

| twenty | 6% |

| 25 | ten% |

| thirty | 16% |

| 35 | 22% |

| 40 | 31% |

| 45 | 41% |

| The cost of work is increased in accordance with an increase in drilling. |

Drilling holes at an altitude of more than 3 meters is possible only when the customer is provided or the cost is specified separately.

The opening of 30 cm by the reinforced concrete plate is carried out by drilling holes with diamond crowns around the perimeter.

Diamond drilling holes in concrete with water collection without a vacuum cleaner. It is used where there is no finishing, but you can not pour water.

Video drilling holes in concrete with a water collection ring.

Finished hole in the concrete wall after drilling with water collection.

The remaining cores with reinforcement and plate after diamond drilling of concrete.

The minimum distance to the opposite wall with diamond drilling holes 115 cm.

It is possible to make the opening at a minimum distance to the opposite wall of 80 cm (contract cost).

Diamond drilling of the technological hole.

Forgot to make the perfume? No problem. Understanding in the foundation with diamond drill. You can make a hole in the foundation for the fiction at any time

Drilling holes for fraud with a diameter of 12 cm. In the strip foundation.

Diamond drilling holes as close as possible to the wall without water collection

Small square and rectangular holes in the floors and walls are cut out with a manual diamond tool or drilled around the perimeter.

Manufacturing of the technological hole in the ceiling

Cutting rectangular “holes” under the hatch

Rectangular ventilation hole in the ceiling

Diamond drilling holes with crowns around the perimeter is more expensive than diamond cutting with discs by an average of 20-30%. But cutting with disks of small holes (40×40, 50×50, 60×60, 70×70) is possible only in walls up to 24 cm with access on both sides. In the photo, a rectangular hole of 24 cm. monolithic wall size 60×70 cm.

Below photography of the manufacturing of a window opening by diamond drilling around the perimeter in a monolithic wall 30 cm. Holes drill over each other.

Drilling a hole in the photographs

At a distance of 32-42 cm from the center of the future hole, a hole for an anchor (or a through hole for a hairpin) is drilled, a fastener bolt is mounted in it.

We fasten the bed under a given hole. You can start drilling a hole.

13.375 Casing Run and Cement

We drill a hole, water under pressure is supplied from the tank.

Finished hole and anchor in the wall (or a through hole under the hairpin).

ATTENTION! We have no other sites, But on many sites, the theme of which are: redevelopment of apartments, diamond cutting, strengthening openings, cutting concrete and drilling holes. Pictures posted by the company Slop Service, as well as information from the Slom-Servis website.ru.

Diamond drilling holes in brick

The formation of door and window openings in brick residential buildings and non.residential buildings using unstressed diamond cutting technology is our profile. Diamond installation operators can quickly and efficiently perform partial or complete dismantling of floors, carrying walls, interior partitions in compliance with safety precautions.

Successful competent operation of professional equipment with branded components makes it possible:

Cut multilayer brickwork without dynamic effects on the material, preventing the destruction of nearby structures;

Minimize dust formation in the process of dismantling manipulations (powerful industrial vacuum cleaners and the use of water to bind dust- a guarantee of purity and interior safety in good condition);

Carry out urgent orders in a short time, without reducing the level of quality and accuracy of the cut;

Comply with warranty obligations, fully realizing the needs of the client.

List of key phases of diamond drilling holes in the brick:

Stage of measurements and applying the final marking;

The main stage of drilling technological holes;

Extraction and removal of dismantled brick blocks;

Installation of a pre.calculated and developed strengthening project (Channel and corners).

In the presence of a wide arsenal of working equipment, from manual cutters to powerful cable cars for sawing thick walls. The use of fault.resistant diamond discs and foreign production equipment allows you to implement large volumes of complex dismantling in the shortest possible time and with a high.quality guarantee.

Use the specialized services of the company MSCMMONATION. a transparent pricing policy and excellent service we guarantee!

Drilling holes in reinforced concrete

Home repair, restoration and capital construction, ordinary household needs. the need to drill the structure of the structure arises very often. Due to the complicated patency of the super-strength structure of reinforced concrete, you can not do without professional, powerful equipment.

Qualified executors comply with all technological aspects of the dismantling procedure and guarantee 100% safety during the drilling of holes in reinforced concrete.

Identification of functioning wiring, pipes and cables in the walls to ensure the possibility of their further operation;

Marking for the exact hit of the crown into a given place of the wall structure;

Smooth launch of the tool and compliance with the optimal drilling mode in order to prevent premature failure;

Ensuring uninterrupted supply of coolant to preserve the working resource of the crown and exclude the dustiness of the room;

Removal of extracted reinforced concrete fragments and cleaning the territory.

To form wide technological holes with even edges for laying engineering communications, we recommend using the services of relevant experts MSCMMONATION.

The operator acts according to a clearly worked out scheme. this contributes to:

Preservation of the bearing capacity of wall structures;

The operational implementation of the tasks, without exceeding the budget specified in the estimate;

Compliance with the maximum level of security at the facility;

Implementation of original planning solutions.

Before cutting a niche in a concrete wall or dismantle part of the supporting structure, think about the possible consequences. It is better to responsibly approach this issue and enlist the support of professionals MSCMMONATION.