From which the pneumons of pneumons are made of. Specifications:

Homemade rotor blade according to the drawings JT-5

Nikolai. We and Zhenya had these effects on the rotors with remote loads. After discussions together with Vert. Zhenya decided to place the load in such a way that. in flight, the load twisted the blade on positive angles.

The oldest participant

Which, in theispe, is strange, because here they say that this effect should be achieved; D And the world is fighting with it. Maybe they must tell them, to the rest of the world? ; D

The oldest participant

fine. This is for each rotor in its own way: there were 550 grams in the gymopopter, we are from 1.2 to 2.1 kg was tried in Rusovskoy pasta. But the sportcopter has flexible blade. Soft, and Rusovsky pasta oak. The Rotor has a renewed rotor. Probably, they also do not know what they are doing. ; D

The principle of operation of the pneumatic gaykort

The pneumatic nutrition is connected through the fitting to the air compressor, the pressure of which should not exceed the value specified in the instructions for the operation of the device. When pressing the trigger, compressed air entering the rotor’s shoulder blades leads it into a rotational movement. Through the frame and hammers, the rotor rotation is transmitted to the stop and the nut or the bolt is turned away or wrapped in their seat. If a lot of effort is required to rotate the nut, then the emphasis does not rotate, and the hammer, turning, deviate back and gathered with an emphasis. During the next turnover, hammers gain inertia and, approaching the hook, hit the stop in the direction of rotation. Blows are repeated until the nut begins to turn. Thus, stressed gaykovitors allows you to quickly and easily unscrew and tighten tight bolts and nuts. Due to the small weight (not more than 2.6 kg), the tool can be kept with one hand.

Switching the air flow channels to the rotor blades, you can change the direction of its rotation, which allows you to use the Gaikovyrt, both for twisting and to unscrew the bolts and nuts. The reverse direction of rotation is achieved by a simple turn of the switch handle to the desired position.

How to choose a gaykovita pneumatic?

When choosing a tool, you should pay attention to the following indicators:

The presence of a shock mechanism

Not all nuts have a shock mechanism, there are simple devices with uniform rotation of the rotor. Shock devices create a pulsed rotating effect on the unscrewed bolt, which allows you to effectively tear it off from the “accused” place. The mechanism gives a significant increase in labor productivity at time for one fixed part no longer than 5 seconds. Such tools are widely used in automobile, volulcanization centers, agricultural machinery, aviation-technical bases and railway depots.

The presence of a reverse mechanism allows the use of a gaykowert not only for dismantling, but also in the assembly of structural units and assemblies. A shit of threaded joints allows you to achieve the required density without large physical efforts from the side of the operator. After the use of the shock nuts, it is no longer required to carry out a control tightening of fasteners. A set of replaceable heads of different sizes is attached to the tool. durable nozzles made of fecal steel are black. Compared to ordinary white heads, they last longer and better withstand the shock load.

Pneumatic nuts with a shock mechanism are more used to tighten large sizes of fasteners, and unstressed nuts are more efficient to use where an accurate tightening of fasteners with a strictly defined effort is required. If they have to tighten large bolts and nuts (24mm or more), then after the gaykovrta they still need to be pulled by hand.

Rotor rotation speed.

This parameter may have a value of up to 8000 rpm. Large speeds allow you to increase the speed of the tool and the power of the tool, but at the same time you need to be more caution, as you can tear the threads in small nuts and bolts. The rotor speed can be adjusted with a small change in the pressure in the compressor. At the same time, you should not get involved in large speeds, since at the same time the tightening control of fastening is deteriorated.

Torque.

Parameter depending on the power. A short tightening moment leads to rapid weakening of fasteners when exposed to variable loads on them. Too strong a tightening moment causes an overvoltage in the thread, leading to its rapid destruction under load. Therefore, you should select a tool with the desired value of the delaying moment.

Greenhouse “productive”. Delicious vegetables in any weather!

Greenhouse “productive”. a real find for many gardeners. A lot of problems that used to seem to be a real disaster, now they are solved very simply. The base of the greenhouse is the AGROFLEX covering material and durable polypropylene arcs. Covering material imitates a tropical microclimate, withstands a layer of snow and does not damage the seedlings. It can be used for several seasons. The design is convenient and practical, and most importantly, it is easy to install, supports the optimum temperature in a greenhouse, which is so necessary for constant growth of products, also protects against harmful insects, winds, rains and other manifestations of nature.

This gaykowert is designed for professional use. Its maximum torque is 5000 nm

The range of twisting puffs in tools of different manufacturers is 30-3000 nm. Shock pneumatic nuts are characterized by the value of the working moment from 300 to 2200nm. If the tool is needed to tighten large.sized fasteners, then you should choose more powerful nuts with a high value of the created point of rotation. For tire centers, where the installation and removal of wheels is installed, a tool with a working moment of at least 100nm is required. In auto.assembly workshops, where different units requires different values of tightening moments, nuts with an adjustable rotating moment are used.

Spindle size.

To work with fasteners with a thread with a diameter of up to 25mm, which are maximally in cars, you should choose a half.inch spindle. If you need to tighten larger bolts with a threaded diameter of 25 to 32 mm, then you need an inch spindle, and for a thread up to 50mm a spindle with a diameter of one and a half inches. The above 4 characteristics of the tool are interconnected. The higher the speed of the gaykovrt, the greater the delaying moment it creates, therefore, it is designed for the larger fasteners and has a larger spindle diameter.

Compressor compatibility.

In order for the tool to work effectively and fail ahead of schedule, it is necessary to ensure its compatibility with the source of air pressure. This property is characterized by two parameters. working air pressure and its flow. An ideal condition for the efficient operation of the pneumatic nuture is an option when the compressor pressure exceeds the working pressure of the tool by 2 bar, and the productivity is 1.2-1.3 times more than the necessary air consumption. Subject to these conditions, the tools of the tool and the compliance of its declared characteristics are ensured by the real indicators.

For example, we acquired a pneumatic gaykovita with a working pressure of 6ATM. and air flow 7.5l/s. Then for the operation of the tool you need a compressor that creates a pressure of 8 atm. with a performance of at least 9l/s. Attention should be paid to the quality of the supplied air. It should meet the requirements that are determined in the instrumentation instructions for humidity and oil maintenance.

To ensure the necessary quality of air in compressors, filters and lubricators are used. Without this, the Gaikovyrt will fail much previously specified in the passport of the service life. Therefore, you need to keep in mind that when choosing a powerful tool, you may have to buy a stronger and productive compressor for it.

The manufacturer of the tool.

Manufacturers of modern gaykovrts equip their products with many auxiliary pens and switches, which serve to change various characteristics of the tool, for example, revolutions and delaying moment. However, the complication of the tool can lead to a decrease in its reliability. Therefore, when choosing a gaykovrt with various “bells and bellsways” you need to focus on those manufacturers who have already established themselves as manufacturers of reliable equipment. Chinese goods are especially attractive to their multifunctionality, however, in terms of reliability, they do not inspire trust, many functions cease to function within a few weeks of use.

The main characteristics of the pneumatic stories

As we mentioned above, a compressor needs a compressor for the work of a pneumatic control, we will not consider this in this article. We will talk about the main characteristics of the actual pneumatic nuts, which must be taken into account when choosing. Well, we talked about compressors in a separate article where this issue was analyzed in great detail. But let’s move on to the case and figure out what characteristics are most important in terms of choice.

Torque

In general, it is this parameter that many consider to be the main and not without reason, because it is he who to a greater extent indicates the possibilities of a gaykort. It is not worth taking with a margin, since excessive torque is also not needed. Measure it in Newton meters (NM or just NM). In many ways, here you need to push back from the diameter of fasteners, for example, if it is up to 18 millimeters, then there is enough gaykowert up to 700-750 nm. If the fastener diameter is 25-27 millimeters, then this is already about 1300-1500. In principle, here you can simply look for specific tasks, for example, “car discs”, etc.D. and decide which indicator is right for you. Excessive torque is not very good, since this is how you can simply tear the thread and damage the fasteners.

Tightening adjustment

There are not all models, but if this function is, then it is very useful. It regulates the amount of air supplied, which directly affects the capabilities. Simply put, this makes the tool much more universal, because in this way it can be configured for specific tasks. For example, you can work with a small fastener and eliminate the risk of damage it.

Type of shock mechanism

Although all the pneumatic gaywo verses are made according to one principle, and their device seems to be that the shock mechanism can be different. And the difference between different types is quite large, therefore, when choosing a pneumatic gaykowert at this moment, you definitely need to pay close attention. Manufacturers always indicate the type of shock mechanism, but below we will briefly talk about them.

Rocking Dog. A simple simple strike mechanism, which is considered one of the most unpretentious. He has a small mass of a small mass, so the shank can reach a very large number of revolutions per minute. One blow takes place in one spindle revolution.

Pin-Yess. Here one turn is equal to one blow. Pneumanogycorte with this type of shock mechanism are very well suited not only for difficult, but also for long.term work.

Pin.less Rocking Dog. A kind of hybrid of previous options, which is clearly visible from its name. There are no pins in its design, which increases its reliability. It is believed that this type is best suited for working with fasteners of large diameters.

Twin Hummer. This is a double hammer clip that can provide a very high torque. Among all types of shock mechanisms, this is the most universal. For this reason, the most common is, in most modern pneumatic nuts, it is Twin Hummer that is used.

Connection to the compressor

Connection to the compressor (or to the air line) is also what you need to pay attention to. In fact, this parameter is extremely important, because there should be nominal values here. If something is wrong in this part, then this can lead to a breakdown. Here it is worth looking first of all at the type of connection, there are two types. The first is Rapid, which fully justifies its name: you can connect or turn off the hose very quickly. The second connection is a threaded. reliable, but here to turn off or connect much longer. In principle, both options have a place to be, but the first is much more convenient when mobility is important.

It is very important to comply with the working pressure of the pneumons and actual. Reduction of pressure leads to a decrease in tool performance. We said that we won’t write about the choice of the compressor, but we will give universal advice: it makes sense to buy one, the performance of which is slightly higher than necessary for the pneumatic gaykoVERT. At least 15-20%, and preferably a third. Not only pressure should correspond, but also air consumption. This parameter is also necessarily indicated by manufacturers.

additional characteristics

It is also worth telling about some other moments that can be important, in any case, choosing a pneumatic control, you need to know them. It makes no sense to talk about them for a long time, so it’s briefly here, a list.

The size of the cartridge. The shank usually has a square shape (this is the most common option, others are much less common), and the planting size of half to one inch. When choosing a pneumon carberty, this is not particularly important, but when choosing equipment about this, you should definitely not forget.

The number of revolutions. For the pneumatic control, this is not a key indicator, except for the larger number of revolutions, the lower the torque. Well, for the gaywovers in general, the main indicator is precisely torque, and the number of revolutions is secondary and relevant only for some work.

The weight. In any case, he will be attached to the possibilities of the tool. Particularly powerful pneumons, with a high torque, cannot be easy. Most of the mass falls on the shock knot. Sometimes it happens that models of approximately the same characteristics have different mass, so here it is worth seeing if it is relevant. Still, work all day with an instrument weighing 2 kilograms or 3.5. very big difference.

Reverse. Implies the rotation of the shank in the opposite direction, regulated by a separate switch. The function allows you to not only tighten, but also spin the fasteners. This function is on almost all models for very rare exceptions.

Review of the best models

Well, now let’s move on to the very review of the most successful models among pneumatic gayworts. This is not quite a rating, we just chose the most successful models in different price categories.

Zubble MG-320

The most inexpensive model on our list, but quite suitable for solving many problems. Maximum torque up to 320 nm, rotation frequency up to 7000 speed, pressure. 6 atm. The diameter of the cartridge ½ inch. Yes, this model is not suitable for solving complex tasks and work with great fasteners, but it was created for other purposes. It is light (2.1 kg) and a fairly compact tool that is convenient to use. In addition, it is very reliable, the case is made of aluminum, the shock mechanism is characterized by increased reliability, which is said, including user reviews. The shock pneumatic gaykort Zubble MG-320 will be very useful in a car workshop, with assembly or analysis with various structures, as well as in furniture production. Of course, this is also the weakest model on our list, but you need to understand what tasks it was created.

DIY pneumatic gaykovert repair

Details: Pneumatic Gaikovert repair with your own hands from a real master for Olenord.com.

- The principle of operation of the pneumogakovert

- Types of faults

- Parsing of the pneumatic gaykort

- Repair of a pneumatic gaykoVERT

- Lubrication for pneumons

- Conclusion

Pneumatic Gaykowert is an indispensable tool for working with threaded connections. It is widely used in car services and numerous construction work. Excellently tightens the nuts and weakens tight compounds.

The design of the pneumatic ovvert is quite simple, but there are many parts incomprehensible at first glance. Often, the details of the mechanism have sufficient strength for a long service life and fail only because of wear or increased loads. Most of these problems can be identified at home without the need to contact specialists. About how to determine the place of breakdown and eliminate the malfunction, we will tell in this article.

To understand the reason for the breakdown of the tool, you should understand how it is arranged (since the mechanism here is very simple). The pneumatic gaykoVert consists of a fitting, to which the air hose from the compressor joins. The start button is followed, which directs the air flow into the cylinder with the rotor and the lop, promoted by high pressure. The motor transfers rotational movements to the emphasis, where nozzles are installed to tighten the nuts. If the gaykovert is shocking, then between the emphasis and the rotor, the shock mechanism is located.

For greater clarity and understanding of the Gaykowert device, below are the photo and video of the tool in parsing.

Breakdown or problems in the work of the Gaikrovert can be caused by wear, damage or severe pollution of its mechanism. There are many faults of malfunctions, below we will give the most common of them.

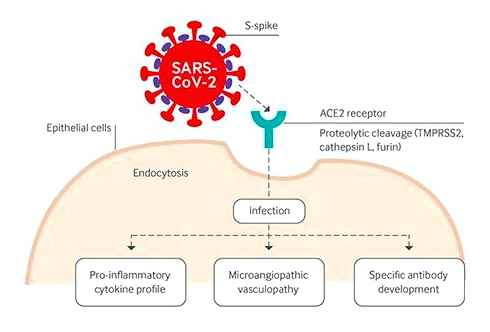

COVID-19: The Pneumonia Vaccine & Coronavirus

- Low power even at maximum speed and at high pressure.

- Speed or reverse mode do not work.

- The tool is warming up

- The cartridge does not rotate

- Increased noise and vibration

The reasons for such malfunctions can be the following details: bearings, rotor blades, valve, springs, shock fists, sealing gaskets and speed regulator. Depending on the level of damage to the part, it can be fixed or replaced. Let’s look at how you can return your Gaykowert Living Sound.

Typically, this process does not cause much difficulties due to the simplicity of the design of the tool and the minimum number of unscrewed elements. The first thing to do to get to the “insides” is to unscrew the hexagon several bolts on the back cover. After unscrewing, remove the cover with the gasket and the speed regulator. Having gained access to the main mechanism, carefully remove it from the body, be sure to remember the sequence of parts. If you are afraid to confuse the details when collecting, remove the disassembly in the photo or video.

After taking out all the details, the first thing we have to do is evaluate their appearance. Details must be lubricated, without rust and oxidation. Next, we must view the mechanism for chips. If the details are damaged, they must be replaced. You can read the name of the details of the pneumatic gayworm on the image above.

If your instrument for many years and before a malfunction has not been used for a long time, then perhaps the cause of the breakdown is cut in banal corrosion and rust, formed on the mechanism over a long time of the inaction of the tool. The solution to this problem may be elementary cleaning of parts with subsequent grease. Even if this method does not return the performance to your tool in order to work in the future, it should not be dirty and without lubrication.

The tool may not function or work incorrectly even with a clean, lubricated mechanism. In this case, the cause of the malfunction lies clearly in the breakdown or wear of a certain part. Here you should carefully examine each complete set for chips, cracks or scuffs. Close attention should be paid to the bearings and blades of the rotor, since these parts are most prone to mechanical damage.

You should also carefully examine the cylinder block and make sure that the rotor blades fit tightly to its walls. This happens when the Gaikovert works for a long time without oil, as a result of which the power of rotation falls significantly. If there is a clear backlash, you have 2 options for repairing a pneumatic ovation: installing a new block or grinding of an old. Grinding is required to be carried out on the machine for a perfectly flat surface.

The service life of any mechanical tool largely depends on the quality of the lubrication of its parts. The easier the mechanism will work, the less wear will occur. If you want Gaikovert to serve you with faith and truth for more than one year, follow the elementary rules for servicing the tool.

To add oil to the gayword mechanism, you do not need to disassemble it. It is enough to add about 8-10 drops of lubricant to the tool pipe where the air hose is installed, then start and let it work for 30 seconds at idle so that the oil is distributed faster through the details. This procedure should be repeated every 3-4 hours with continuous operation, as well as before cleaning the tool for storage.

If you use the tool constantly, actions for gravy oil every 4 hours can turn into routine. To eliminate unnecessary distracting factors from your workflow, install the oilfield for a gaykort (lubricator), which will serve the oil gradually during operation. This method is more convenient and provides constant lubrication of parts, just do not forget to add oil into the lubricant itself.

Many articles have been written about the pneumatic tool, about its advantages, device, features of operation. As a rule, the information presented in them is limited to general information and recommendations. In this article, we will try to tell in detail about the features of the preparation of the air line and the main errors made by users.

So you have acquired a pneumatic tool. What needs to be done so that the tool serves for a long time and operates according to the characteristics declared by the manufacturer, and what should not be done in any case?

Types of pneumons and features of the device

Before disassembling the basic design features of the pneumatic gaykowert, it should be noted that it is divided into two types:

- unstressed pneumatic security vehicle. used when working with fastener elements of simple shapes that do not require special professional skills and efforts. Such a tool allows you to carry out work with maximum efficiency and lack of risk of breaking the nut from the thread;

- shock pneumons. applied for more significant and large volumes of work. For example, with rusticated and “cloudy” bolts. It is the shock mechanism that often involves a conveyor nature. during construction, in factories or other large.scale works, as well as in domestic conditions.

Today, due to technical modifications, many models of such equipment are distinguished. In this case, the device of the pneumatic stroke remains practically unchanged and has a fairly simple design. The main components of the pneumatic stories include:

- Shock system. can consist of cam clutch, fist, pusher, roller and spring mechanisms, pins and flywheel with a roller;

- Pneumatic type engine. most often in the tools are placed engine.type rotational.type engines installed in the case;

- The reverse node. together with the starting mechanism is located in the instrument handle;

- The starting part is located in the handle;

- Equipment housing

Some modern models of the pneumatic storage are additionally equipped with a handle placed in two and more different positions in relation to the corps part. This small addition can ensure more comfortable operation of the tool during operation.

Characteristics of pneumatic nuts

From the characteristics of the pneumatic stroke, it should be noted the connecting size of the head, the maximum size of the nut/bolt, developed by torque, engine speed and minute consumption of compressed air.

Most of the gaywortes are equipped with a spindle with a square for end heads. The size of the square corresponds to the standard row: 3/8, 1/2, 3/4, 1 and 1½ inches. Structurally, squares do not differ from similar devices on manual keys. At the same time, the maximum fastener with which the tool can work lies about the same limits (the maximum permissible fastener size is 1.1-1.5 times larger than the connecting square).

The torque developed by the tool depends on the power (as well as on the connecting square, the higher the torque. the greater the size of the square). In small gaycroverts (with a square of 3/8 inch), the maximum torque lies in the range of 70-120 N m. In a medium.power tool (squares 1/2 and 3/4 inches), torque can vary from 200 to 1500 N m. And in the most powerful gaykovers, this indicator can reach 2500-5500 N m.

With the engine speed, the situation is opposite: in powerful tools, it barely exceeds 3000-4000 rpm, in average it can reach 6000-6500 rpm, and in small ones-up to 10,000-12500 rpm.

Air consumption in instruments of various types of even one power can differ significantly-from 65-70 l/min, to 850-1100 l/min. On average, the gykowert requires 200-500 liters of air per minute.

The characteristics presented here will help make the right choice of tool.

Where the pneumatic shock gaykortes are used?

First of all, these are large enterprises, namely assembly workshops. Where there are a lot of installation and dismantling works associated with threaded connections. There all the gaybover are connected to a powerful pneumatic line. In workshops that are engaged in tiremontal operations or similar operations associated with the tightening and promotion of threaded joints. For example, these are car services that are engaged in the collapse of the convergence of the chassis of the car, operations related to car suspension repair.

In domestic conditions, most likely, it is irrational to use the shock pneumatic gaykort. Although there are situations when without this tool it is impossible to promote a nut or bolt. But if you approach from the point of view of the cost of acquiring the entire set of equipment, then the compressor will cost a lot of money, and not the Gaikovert itself.

Pneumatic Gaykowert’s operation tips

To extend the service life of a pneumatic tool, it is recommended to listen to some tips from professional masters.

- Do not allow the instrument to fall.

- It is necessary to ensure that the pneumatic tool is outside the zone where a car can run into it.

- To increase the tightening power, do not allow pressure exceeding in the system. This leads to the rapid wear of the unit.

- You should not hold the Gaikover for a long time under load, since this mode of operation will quickly disable the stress mechanism out of order. If the “encouraged” nut or bolt does not turn away for 5 seconds, then the unit should be stopped, and replace it with a more powerful. It is also recommended to use penetrating fluids for problem bolts, which are in the arsenal of any car owner: gasoline, antifreeze, kerosene, diesel fuel, brake fluid. It is most correct to apply a special fluid to a threaded connection, for example, WD-40.

If you follow these simple recommendations, then your tool will become an effective assistant in performing labor.intensive operations, will last a long time and justify the funds invested in it.

Pneumatic shock gaykoVERT. device and features

The pneumatic shock gaykoVert belongs to the category of tools designed to work with threaded connections. In contrast to the gaycroverts that work on an electronic drive, the formation of a spark at one time of work is absolutely excluded in pneumatics, therefore there is an option to work with such an inventory if there is an inflated fire threat.

Assencing machine hose

Specialized technology is cleaning cesspools by means of such a device as a hose for an assenced machine, it is also necessary for work in reservoirs and washing of sand. On modern farms and lands, this is a rather important tool, since you can use it as a addition to moving feed and grain for livestock. With the help of a sleeve for Assencing machines, you can free cesspools from sewage, feces, contaminated water, chemicals and other things. Its features are in the possibility of use at different temperatures, resistance to impacts due to the spiral placed inside the PVC, as well as environmental friendliness.

Senior residents in Manila administered with flu, pneumonia vaccines

The service life of any mechanical tool largely depends on the quality of the lubrication of its parts. The easier the mechanism will work, the less wear will occur. If you want Gaikovert to serve you with faith and truth for more than one year, follow the elementary rules for servicing the tool. To add oil to the gayword mechanism, you do not need to disassemble it. It is enough to add about 8-10 drops of lubricant to the tool pipe where the air hose is installed, then start and let it work for 30 seconds at idle so that the oil is distributed faster through the details. This procedure should be repeated every 3-4 hours with continuous operation, as well as before cleaning the tool for storage.

If you use the tool constantly, actions for gravy oil every 4 hours can turn into routine. To eliminate unnecessary distracting factors from your workflow, install the oilfield for a gaykort (lubricator), which will serve the oil gradually during operation. This method is more convenient and provides constant lubrication of parts, just do not forget to add oil into the lubricant itself.

In addition to the main mechanism of the rotor, there are elements in the Gaikovert that require a consistent, non.conductive lubricant. Such elements include bearings, couplings and hammers. For this procedure, the tool will need to be disassembled to get to the desired parts. Fortunately, one lubricant is enough for 50-60 hours of continuous work.

We use the pneumatic stroke correctly!

Before work:

Check the condition of the air system hoses. Drain the condensate from the Jeeneen-Separate filter. The air line from the lubricator to the tool must be blown to the pressure of the air so that inside the highway is clean and dry. The presence of moisture and dust in the pneumatic massacre leads to the formation of corrosion on the details of the Gaikrovert, worsens the work and power characteristics, and, as a result, to the failure of the pistol.

Check the air pressure in the air line from the compressor to the tank tool. For maximum tool performance, it is necessary to maintain constant working pressure 6.3 bar. To adjust the pressure, use separate regulators or moisture separators with a regulator or a single air preparation unit.

Use the correct sizes of connections, hoses and fittings to ensure the maximum productivity of the tool.

For convenience and safety of work, use quick.detachable compounds. Check them. Make sure they are well connected and do not let out air (do not “poison”).

Use lubricants and lubricators to prevent premature wear of the tool and the appearance of rust. Before connecting the pistol with the hose, drop 4-5 drops of machine oil (!not very thick) in the inlet air valve.

Use personal protective equipment: glasses (mask), headphones, gloves.

Use only those end heads that are recommended for use with a gaykort.

When connecting threaded fittings directly with the tool, use liquid sealant, for example, permatex. Do not use Teflon tape.

The workplace must be provided by ventilation.

During work:

- Install the desired direction of rotation (F. right, r. left) using the switch;

- Set the desired value of speed (moment of rotation) using the regulator in shares from the maximum value (“1”. the smallest);

- During operation, take a stable position;

- Long.term and strong vibration causes numbness and is harmful to health. Take breaks in work;

- The trigger allows you to turn on/off the mechanism and does not have a fixed on position. It should be noted that after you release the trigger, the rotation of the mechanism will be carried out for a few more seconds;

- If the gaykovert at maximum power cannot unscrew the threaded connection within 5 seconds, then apply penetrating grease, for example, Valera or WD-40, and try again. If the connection is not unscrewed, then use a more powerful model;

- The gaykowert can cause return and lead to injury if the fasteners are twisted too much. In such cases, use a hand tool.

After work:

- Do not throw the tool. For safety reasons, only after a complete stop of rotation, place the tool on a horizontal surface or hang on a hook;

- It is necessary to block the pressure in the highway, remove the equipment, disconnect the tool from the air line.

The principle of operation of the pneumogakovert

To understand the reason for the breakdown of the tool, you should understand how it is arranged (since the mechanism here is very simple). The pneumatic gaykoVert consists of a fitting, to which the air hose from the compressor joins. The start button is followed, which directs the air flow into the cylinder with the rotor and the lop, promoted by high pressure. The motor transfers rotational movements to the emphasis, where nozzles are installed to tighten the nuts. If the gaykovert is shocking, then between the emphasis and the rotor, the shock mechanism is located.

For greater clarity and understanding of the Gaykowert device, below are the photo and video of the tool in parsing.

Types of faults

Breakdown or problems in the work of the Gaikrovert can be caused by wear, damage or severe pollution of its mechanism. There are many faults of malfunctions, below we will give the most common of them.

- Low power even at maximum speed and at high pressure.

- Speed or reverse mode do not work.

- The tool is warming up

- The cartridge does not rotate

- Increased noise and vibration

The reasons for such malfunctions can be the following details: bearings, rotor blades, valve, springs, shock fists, sealing gaskets and speed regulator. Depending on the level of damage to the part, it can be fixed or replaced. Let’s look at how you can return your Gaykowert Living Sound.

Diameters

Below is also a table of the selection of the hose depending on its diameter and the purpose of the pneumatic tool.

| Inner diameter of the hose | Maximum throughput | Application |

| 6 mm | 1000 l/min | spray.sprayers, purge pistols |

| 8 mm | 2000 l/min | pneumatic tool |

| 10 mm | more | Industrial pneumolines |

Various compressors pump different air pressure, on which the performance of a particular type of work directly depends. In order to avoid improper operation and subsequent breakdowns, it is first of all to determine the throughput of the hose with which the air tool will be attached to the compressor. Manufacturers indicate the size of the dimeters on the product, but it is the internal that is a priority for determining the throughput of the hose. The principle is simple: the larger the inner diameter, the greater the throughput.

From all of the above, it follows in order to choose the right air hose to take into account many factors. Each of these facts is important and, depending on the choice, can facilitate the work with pneumatic design.

Repair of a pneumatic gaykoVERT

Be sure to inspect the tool inside. All elements must be lubricated, not to have corrosion, or oxidation, as well as chips. Damaged parts should be replaced with new.

If the Gaykowert for many years, or it has not turned on for a long time, the cause of the breakdown can be the most banal. corrosion of parts. In this case, they must be cleaned and lubricated.

If these actions have not returned the tool to work, the reason for the wear of details. Inspect each element, paying special attention to bearings and rotor’s lobe. Such elements fail the first. Rotor’s lop should fit tightly against the walls.

All elements for replacement can be bought in specialized stores or workshops. You can install them yourself. After replacement, be sure to lubricate all components, this will improve the work of the tool.