Heat Resistant Glass Cutting Furnace

Organization of cutting

If you have chosen the option of cutting glass to the desired size with your own hands, the possibility of performing this action depends on its structure. If it is not hardened, it can be cut with a special glass cutter or a grinder and a segmented diamond disc. Consider an alternative cutting option with a grinder:

- Take a grinder and a segmented diamond disc for stone processing (it is better to use the smallest diameter for ease of use), you also need water or oil;

- Determine the exact dimensions of the intended glass, draw lines on it along which you will cut for convenience;

- Begin cutting gently without using strong pressure movements;

How to choose heat-resistant glass for your oven?

For a large number of people, having a real stove in the house is an integral part of the comfort. However, when organizing such pleasure in your home, it is important not to forget about safety and select the right heat-resistant glass for the oven.

- What it is?

- Refractory, heat-resistant and heat-resistant. what’s the difference?

- How to choose the right glass?

- How to distinguish a fake when buying?

- Stamps

- Glass work

- Organization of cutting

- Do-it-yourself installation in the oven

- Output

It must be durable and able to withstand high temperatures to prevent unpleasant flame situations from sparks emitted from the oven. Also, it will not block your view of the beautiful view of a burning fire.

How to distinguish a fake when buying?

Nowadays, a huge number of companies are trying to sell tempered glass for a furnace, attributing to it the properties of heat-resistant, but in fact it does not have these properties and cannot be used in fireplaces and stoves, because it is produced using a different technology.

In order not to get hooked by such companies:

Do-it-yourself installation in the oven

When installing on your own, you should follow all safety rules and take into account the following nuances:

- Do not exceed these expansion factors and use the correct frame material. To do this, you can lay a fire-resistant cord between the glass and the base of the mount;

- The pressure of the installed parts on the glass surface must be the same at all attachment points;

- The fixing of heat-resistant glass to the furnace frame must be done very carefully, the use of heat-resistant hermetic means is prohibited;

- To exclude the possibility of uneven overheating of the furnace, the glass must not be allowed to be in direct contact with the furnace frame and fixing elements.

to the content

How to choose the right glass?

Glass work

If you have already decided on the choice of glass suitable for your furnace, ensure that it is properly cared for for a longer life. Heat-resistant glass plays a protective role, the temperature inside the oven reaches very high marks, so that soot residues can remain there. To clean them properly without damaging the glass, follow the tips below:

- To avoid damaging the glass polish with hard sand particles, do not use abrasive cleaners that contain them. Perform cleaning with special products to avoid the consequences of scratches;

- It is not recommended to clean when the glass is still hot after use. This can injure its protective layer.

to the content

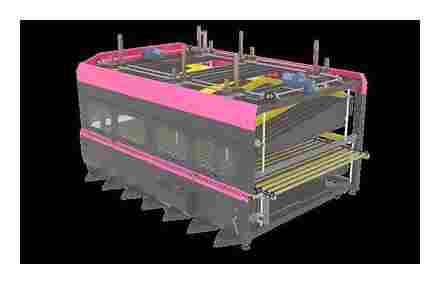

Flat & Bending Glass Tempering Furnace

What it is?

Heat Resistant Oven Glass is an incredible advance in the development of glass production methods. Due to its composition and high quality production method, it possesses:

- good sound insulation. muffles the internal noise in the oven;

- excellent durability. it is almost impossible to scratch or break it;

- high thermal stability. does not lose its durability during sudden changes in temperature;

- decent appearance. reliably observing the furnace flame through it does not cause any discomfort;

- long term of use;

- guaranteed safety. sparks from the fire in the stove will not be able to enter the room.

how to cut tempered glass easily. (pls skip 1st min as zoon in too much.)

- It can be single-layer and multi-layer, on which the number of degrees maintained by it depends: the more the number of layers. the higher the possible temperature gap (up to 1000 ° C);

- Thickness 4 or 5 mm, in some cases it can be thicker;

- For a longer period of use, you can apply the maximum thrust mode;

- It can be different in appearance: transparent, colored, embossed, with a pattern.

to the content

Refractory, heat-resistant and heat-resistant. what’s the difference?

When choosing glass for a fireplace or stove, special attention should be paid to its strength, because your safety first of all depends on this. It must be heat resistant. resistant to sudden changes in temperature and able not to deteriorate from sharp hot collisions.

An ordinary glass product, when in contact with a flame, heats up to 500 ° C in half an hour, while heat-resistant, when interacting with fire, during the same time can heat up to about 70 ° C.

The essence refractoriness glass is in safety first of all. it prevents sparks from entering the room from the stove, and also prevents ash and soot from entering the room. Its temperature resistance is approximately 700 ° C.

Heat resistant glass is a unique type that includes both high heat resistance and high-quality fire resistance. Quartz glass is the most heat-resistant, able to withstand oven temperatures up to 1000 ° C.

Refractory Glass Properties and Applications

Glass is one of the most demanded materials in construction. As the main part of the window, it lets in sunlight while maintaining a comfortable indoor environment. It is used for glazing facades, decorative elements, dishes and even furniture are created from it.

In addition to classic window glass, the industry offers materials that are similar in appearance, but with much higher characteristics. One of the striking examples of such products is fireproof glass.

Scope of application

Heat-resistant glass grades are widely used in enterprises, the production process of which is associated with high temperatures. The use of transparent material with good heat-resistant characteristics makes it possible to ensure the continuous operation of units and assemblies, while guaranteeing the safety of the operating personnel. Installing fireproof glass in doors and partitions separating production facilities significantly reduces the likelihood of a fire occurring and spreading.

This material is indispensable in everyday life, where there is a high temperature, and it is impractical to use metal. A prime example is glass fireplace doors. This comfortable, beautiful and functional fireplace will perfectly complement the interior of a residential building, it will also create an atmosphere of warmth and comfort. The fireproof glass door is beautiful and practical. It will not become an obstacle to heat radiation, while protecting the room from smoke and soot.

Fireproof glass can be found in the kitchen, among other things: kitchen apron, transparent doors for ovens and microwave ovens. Such solutions allow you to control the cooking process without having to open the door. Separately, you can recall the hobs of gas stoves, they allow you to evenly distribute the heating, thereby contributing to energy savings.

High temperature resistant glass is also used for making glassware. Transparent kitchen utensils are great for both open fire and oven cooking. over, transparent dishes can be used in the microwave. An additional plus. the glass surface is easy to clean.

Varieties

The very concept of “refractory glass” includes a wide range of materials that differ in production technology and purpose. Distinguish between glass, which protects against high temperatures, and glass, which does not interfere with heat exchange, but protects the room from combustion products and prevents the spread of fire. The first is used in fire-fighting systems, the second in heating systems, for the manufacture of hobs, dishes.

There are three main types of fireproof glass:

- reinforced;

- hardened;

- compositional.

Reinforced fire-resistant glass withstands the stresses associated with temperature changes due to the presence of a metal mesh inside. Such a solution allows providing the product with a sufficiently high heat resistance, but noticeably limits the scope of its application due to its low transparency. These materials are widely used in fire protection systems.

Tempered glass production technology includes the procedure of repeated heating and cooling of the material (tempering). Both single-layer glass and multi-layer glass units are on sale. In double-glazed windows, the space between the sheets is filled with a special transparent multicomponent gel. These solutions are quite affordable in terms of price, while they have good consumer characteristics.

Composite heat-resistant glass should be noted separately. In a general sense, this is not glass, but glass ceramics. The material has practically zero coefficient of thermal expansion, which allows products from it to withstand extremely high temperatures.

Manufacturing features

The production of refractory glass is a complex technological process that includes constant control at every stage. The production technology varies, it depends on the type and purpose of the material.

Borosilicates are used for the manufacture of inexpensive, but sufficiently high-quality types of refractory glass. Quartz glass is more expensive. The components are mixed, melted, rolled. The obtained sheet material goes through a cycle of specific production processes, consisting of chemical treatment, hardening, followed by high-temperature polishing. All this is designed to provide the proper level of heat resistance and give the glass an attractive look.

Fireproof glasses undergo mandatory temperature tests, according to the results of which a certificate for products is issued.

Fireproof glass in ovens and fireplaces

Fireplaces and open stoves are increasingly being installed in country houses and even in apartments. An open fire decorates a room, but it can also cause a fire. You can’t do without refractory glass. It is an excellent fire protection material. Transparent doors are created from it that do not let the flame into the room, but not only, modern design solutions allow you not to be limited to small glasses, you can easily create a unique transparent fireplace.

Wood Stove Glass VS Tempered Glass. What should I use?

Regardless of the size of the door or the scope of the project, installing fireproof glass in the metal frame of a stove or fireplace requires careful attention to detail. There are a number of recommendations that must be followed in the process. When determining the linear dimensions of structural elements, it is necessary to take into account the difference in thermal expansion of materials. There must be a gap between the frame and the glass, in which the refractory cord is placed. When installing the glass, it is necessary to ensure uniform pressure on it from all sides. In no case should you seal the joints, this can cause cracks.

Main characteristics

There are several indicators that determine the properties of fire resistant glass. They help to determine whether the material is suitable for use for certain purposes, whether it complies with fire regulations.

Thermal expansion coefficient. This is a value that characterizes the degree of change in the linear dimensions of a substance when its temperature changes.

Heat resistance. This value determines the maximum temperature at which the material retains its properties. Ordinary tempered refractory glass used in everyday life is guaranteed to cope with temperatures of 500-550 degrees. Short-term heating up to 760 (for single-layer) and 1000 (for multi-layer glasses) degrees is allowed.

Material thickness. The industry offers fireproof glass in various thicknesses. For household needs, a material with a thickness of 4-5 mm is used.

The service life of refractory glass directly depends on the operating conditions. To ensure the maximum service life of borosilicate glass used in fireplace doors, it is advisable not to raise the flame temperature above 500-550 degrees, in this mode it will last several thousand hours. With an increase in temperature, this indicator decreases markedly.

Fire protection glass marking

Most of the information regarding the characteristics of fire protection glass can be found from its markings. The letters of the Latin alphabet are used for designation:

- E. resistant to destruction;

- I. has a high resistance to heating up to a critical temperature;

- W. retains heat, does not let heat into the adjacent room.

The manufacturer guarantees the preservation of the declared characteristics for a certain period of time. The time in minutes is indicated after the lettering. For a better understanding, you can consider examples:

- EIW 60. the product retains resistance to destruction, resistance to heat and retains heat for 60 minutes.

- EI 60. resistant to destruction, prevents heating for 60 minutes.

- EI 30. resistant to destruction, prevents heating for 30 minutes.

The characteristics and test methods of fire-resistant fire-resistant glasses are regulated by GOST-33000-2014.