How to adjust the carburetor of a gasoline gasoline. Clogging of the adjusting cavity

A trimmer carburetor device for gasoline grass

Motokosa carburetor adjustment is a process that needs to be mastered for the full operation of a trimmer for grass. Trimmer for grass is a completely simple device that can break in only a few places and demand a mechanical repair or replacement of part. Adjustment of the carburetor device of the float.type motorcycles may require knowledge of certain subtleties. The nuances due to the model and the specifics of its functioning will ensure a clear mixing and supply regime of the fuel mixture.

CHAMPION BAS carburetor, how to adjust? This is just a trimmer for floating type grass. a common option designed to mix air and fuel in the proportions provided. The main problems arising during the operation of the motor are approximately similar to the problems that overtake the carburetor in the car:

- the motor can stall immediately after it managed to start. The reason is that gasoline is supplied in insufficient quantities. This is called “poor” fuel;

- Excessively fed gasoline leads to its incomplete combustion, excessive density of the mixture and uneconomous consumption.

Repair of the carburetor

Important! It is necessary to regulate the carburetor under different circumstances: a change in the temperature regime, octane fuel or type of oil, after winter or end of the run.in, load or spontaneous turning of the screws from strong vibration of the body. Some owners prefer to configure the module before each use to make sure of its correct work.

The main problems

Malfunctions of the carburetor Motokos or trimmer for grass, despite the relative simplicity of their elimination, sometimes require a long search by excluding. The main reasons are as follows:

The most repeating breakdown is wear, rupture of the membrane. As a result, its lavation. Fuel moves are not sealed at certain stages of the engine cycle. The reasons here are as follows:

- You have been working on a motorcycle or trimmer for too long without a break;

- Poor.quality fuel was seasoned;

- Wheelled gases fall into the pulse channel.

A deformed membrane is fraught with several bad consequences:

- not enough gasoline or oxygen in the created combustible mixture;

- the launch of the motor occurs after 10 or more unsuccessful attempts;

- the engine knocks, clats during operation, and t. D.;

- The working piston is deformed.

We offer to familiarize yourself with how many citric acid for a liter jar of cucumbers

The reasons for the clogging of the mesh filter are poor.quality fuel cleaning, damage to the hose and/or the injection head.

Wear of the contact edge of the lever. a consequence of not completely purified fuel, into which grains of sand or particles of clay, metal or other inclusions that are not soluble in liquid hydrocarbons fell. A problem with fuel injection appears, the motor does not function with interruptions without load.

The inlet needle breaks due to the presence of metal and stone particles in gasoline. As a result, the saddle of the intake needle tightly adjacent to it, the fuel mixture flows. In the combustible mixture created by the carburetor, there is too much air, which is why the motor can “sneeze” during operation. Finally, the needle can stop due to poor-quality gasoline, or the unit was idle for a long time.

Deposits may accumulate in the adjustment compartment. The needle does not completely cover the hole, and a lot of gasoline enters the fuel chamber. the motor pours it, perhaps floods the spark plugs. Because of this, the gasoline mixture contains an increased number of vapor of gasoline. The efficiency falls noticeably.

The membrane is often deformed (sometimes torn) due to continuous operation of motorcycles or trimmer for grass for several hours. If you abuse such a “shock” mode of operation, damage to the membrane occurs more often. New breakdowns will be sprinkled from a cornation of abundance:

- the piston will break;

- The number of attempts by the unsuccessful start of the engine will increase sharply;

- The fuel mixture will contain too little gasoline;

- Useful (thermal) power will drop sharply.

Sequeling of the adjusting lever. a consequence of the incorrect installation, random flexion. Contactive line will find an incorrect position. This will violate the additional injection of gasoline.

The damper has worn out

Throttle and air conditioning are unusable due to admission to the air flow of dust, metal particles, etc. D. Damaged shutters are similar to details subjected to streaming with sand. Due to wear of the damper, the efficiency of the motor decreases, breakdowns are detected. The piston and cylinder wear out.

In some cases, this filter is simply not suitable for your model motorcycles or trimmer for grass. In the end, the shaft of the motor will suffer. its pieces fall into the engine channels, which is why the piston will be broken.

The fact that the adjustment is too rough (it is not possible to accurately set the parameters) are to blame for the adjustment screws. The manufacturer Motokos or trimmer for grass can put excessively thick and hard springs. You can find others either in workshops where such equipment is repaired, or purchased from any dealer or official representative of the company who released the engine for your trimmer for grass or mechanical braid for grass.

The primer broke

Primer-a manual mini-pump for forced swinging fuel into a carburetor. For a successful start of the motor, it may be necessary to pump 20 ml of gasoline manually.

How is a gas mower carburetor?

The device of the carburetor is almost the same, both in famous German and Swedish motorcycle, and in Chinese.made tools. This node consists of such details:

- Membrane fuel pump;

- Adjustment system with atmospheric membrane;

- Idle system;

- A primer for pumping, which allows to facilitate the launch of the motor motorcycles;

- Elastic plate with two valves;

- Needle valve;

- Dosage system with a rotating rotor;

- Throwdoy damper.

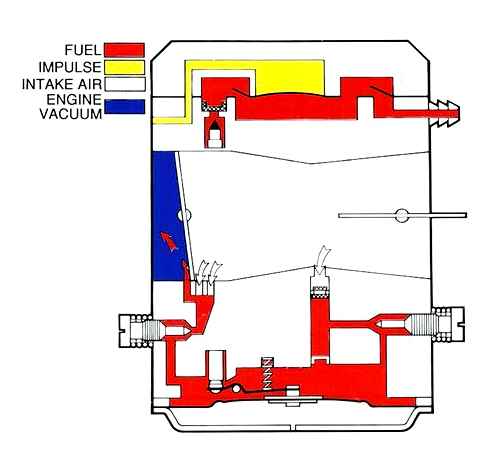

Carburetors of modern motorcycles work according to a certain principle. The diagram below shows the movement of air and the fuel mixture in the design of the carburetor.

At first, air through the throttle falls into the tube, after which it passes to the diffuser. the place of narrowing of the tube, where the air flow becomes especially intense. From the diffuser of the air enters the float chamber, where it is mixed with the fuel mixture. After that, the fuel enriched with air is absorbed by the pipeline and enters the motor cylinder.

Benzotrommer carburetor repair tips

Regardless of the manufacturer, there is a factory marriage of parts of the carburetor of the lawn mower. The adjustment vintana spring, the above setting method, may not give positive results with an excessively large number of turns at the spring supply spring and, as a result, the impossibility of optimal reduction in the level of gas supplied gasoline. To eliminate this, you can independently shorten the spring or, in accordance with the operating manual, purchase a new.

Many owners of a benzos when buying oil follow the recommendations for the preparation of the fuel mixture indicated there. Oil for a gasoline trimmetak here, often the information indicated on the bank by mixing gasoline with oil differs from the instructions in the passport of a trimmer for grass. As a result of this, a black fog can quickly form on the spark plug, which leads to a drop in power and an increase in fuel consumption. Therefore, when preparing a working mixture, the recommendations specified in the operation manual should be followed. In most cases, the proportion for the chopped ICE is 1:25. It is worth noting that many tool owners prefer to prepare fuel “by eye”, which will certainly lead to the rapid wear of the piston braid for grass in the case of a decrease in the portion of oil and the formation of soot on the spark plug with an increased amount of lubricant fluid.

Correctly performed tips for setting up the carburetor trimmer for grass will help to avoid not only overheating of the engine, increased fuel consumption, but also significantly increase the life of other parts and assemblies of the tool

Pay attention to the work of motorcycles in all modes and carry out regulated maintenance and repair of the tool on time.

Adjusting the gas mowing carburetor: the main points WAS Last Modified: June 25th, 2020 by administrator

The main problems and malfunctions of the carburetor.

The grid has only two problems with this element:

To determine the cause of the malfunction, unscrew the fuel filter lid to remove the mesh filter. If dirt just accumulated on it, the washing of gasoline or purging will help.

Be sure to install a new filter if there are any visible damage. There may also be damage to the fuel line (check this item during the repair).

The starter of the carburetor in most cases does not work due to blockages. For washing use acetone or the same gasoline.

Filling the parts of the carburetor clogged air is an acceptable and convenient repair practice.

Signs of unbalancing

Carburetor debugging is certainly done in the manufacture of the device. Texas 330 Lawn mowed Carburetor adjustment. Usually, the owners will find out about the need to adjust the supply of fuel with their own hands only after rather severe breakdowns, in the process of correcting which, the module was removed and, for example, was cleaned.

Signs of a malfunction in the settings are the following:

- It starts, but the engine stalls here. since the engine can only work when a certain amount of gasoline is submitted, with a very “poor” combustible, in other words, overlapping the supply channel, the motor will stop;

- A very large fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the consistency. In this case, there is a lot of fuel, on the contrary, and the mixture comes out extremely dense.

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor

Trimmer for STIHL FS 55 grass does not develop revolutions, stalls, we sort out the carburetor thank you for your views.

STIHL FS 55. Carburetor adjustment (idle)

Adjustment of the carburetor of the trimmer for the STIHL FS 55 grass in the video is executed in order to adjust the revolutions of the idle.

STIHL, Makita, Husqvarna and others tuned with adjusting screws. Sometimes a prerequisite for disruption of work is a violation of fixation-due to vibration or damage to a protective cap. You can find such a breakdown by just trying a bit to turn the screw: if the fixation is not hard, it is worth checking the setting.

Do.it.yourself carburetor adjustment

The setting of the module does not apply to the repair and the change of spare parts is not required. In this case, the karburetor’s remark is not useful.

- L. is regulated first, because it is responsible for the supply of fuel at low speeds;

- H. he is responsible for supplying gasoline at high speeds, also for fuel consumption and temperature;

- T. with it, the idle speed is debugged.

Adjust the Gas / Idle Mixture Screws on Your Edelbrock Carburetor

There are options, usually a carburetor of a Chinese lawn mower, when only one screw remains for debugging on the housing. for the idle option. Valve adjustment on a lawn mower. This does not mean that the module is adjusted by automatic. this means that even such a type of repair as debugging will be problematic. In the photo. adjusting the carburetor of the Chinese lawn mower.

- The module setup is carried out only with a heated engine: for this, the device is used to be included for 10 minutes. Carburetor adjustment Japanese trimmer for grass. Lawn mowing trimmer for grass ignition adjustment. If the mowing head is idle at idle, then they start debugging immediately: turn the screw T counts the clock until the rotation ends.

- Adjustment starts with a screw l. The screw turns on the right and to the left until it finds such a position in which the idle speed does not become the highest.

- Then the screw is turned on ¼ turn against the watch. This will be his working position.

- The idle stroke must be configured by turns against the sentry for the growth of speed numbers and the clock. to reduce. Its debugging consists in achieving such a regime in which a sufficient number of revolutions are performed before the rotation of the mowing head. Lawn mowers gasoline self.propelled speed adjustment. With all this, the engine should work stably at various positions.

- The position of the screw L is determined by the latter. at the highest revolutions the trimmer for grass should not work for more than 10 seconds. The throttle is revealed, the screw is cramped clockwork, very slowly, until a decrease in the number of revolutions is established by ear.

- Then also slowly the screw spins against the sentry until the time the motor starts to work with failures. After that, the screw is on the back of the time, until the engine again earned normally.

If there is a tanometer, and if the product is indicated in the product passport, coooreecration can be carried out more accurate, focusing not by ear, but on the testimony of the device.

6 Комментарии и мнения владельцев on recording adjustment and repair of the carburetor of the lawn mower

Please clarify. In the section adjustment p.5, screw l error? You should read the screw a? Thanks to.

Tell me the original position of the screws h l la

Do.it.yourself carburetor adjustment

Regardless of the model of the garden tool, adjusting the carburetor of the trimmer for grass requires careful preliminary preparation. The owner of the motorcycles will need to check the spark plug, air filter and the carburetor itself. In the case of pollution, all elements must be cleaned, or, if necessary, replace.

In the standard configuration of a trimmer for the grass, 3 adjusting bolt are provided. The first of them is marked with the letter L, and serves to configure the engine when it is working at low speeds. The second bolt. is marked with the letter H, and is necessary to adjust the internal combustion engine when it is at the highest speed. The third bolt can be marked with letters T or LA. with its help the operator can configure the engine operation at idle.

The process of configuring the carburetor Motokosa is as follows:

- First you need to carry out a number of actions with the adjusting bolt L. To do this, it should be turned clockwise until it stops. After this, the bolt L requires to turn half turnover in the opposite direction. This will make it possible to configure the optimal enrichment of the fuel mixture with oxygen during the operation of the motor at low speeds;

- Then you will need to adjust the operation of the internal combustion engine in idle mode. To do this, you need to turn the bolt T in different directions in turn until the mowing head or knife stops rotating;

- At the end, you will need to configure the level of fuel enrichment with oxygen when operating the engine at maximum speed. To do this, the bolt H will need to turn clockwise until it stops, and then return it to 1/2 turnover in the opposite direction.

Signs of unbalancing

Carburetor debugging is necessarily carried out in the manufacture of the device. As a rule, the owners will learn about the need to adjust the fuel supply with their own hands only after quite serious breakdowns, in the process of correcting which, the module was removed and, for example, cleaned.

Signs of failure in the settings are the following:

- starts up, but immediately stalls the engine. since the engine can only work when a certain amount of gasoline is supplied, with too “poor” fuel, that is, overlapping the supply channel, the motor will stop;

- too much fuel consumption, many exhaust gases. the result of incomplete combustion of the mixture. In this case, the fuel, on the contrary, is too much and the mixture is excessively dense.

Do.it.yourself carburetor adjustment

The setting of the module does not apply to the repair and the change of spare parts is not required. In this case, the armored complex of the carburetor of the lawn mower will not be needed.

- L. is regulated first, as it is responsible for supplying fuel at low speeds;

- H. he is responsible for supplying gasoline at high speeds, as well as for fuel consumption and temperature;

- T. with it, the idle speed is debugged.

There are options, as a rule, this is a carburetor of a Chinese lawn mower, when only one screw remains for debugging on the case. to configure idle. This does not mean that the module is configured automatically. this means that even such a type of repair as debugging will be difficult to carry out. In the photo. adjusting the carburetor of the Chinese lawn mower.

- The module tuning is carried out only with a heated engine: for this, the device is pre.included for 10 minutes. If the mowing head rotates at idle, then they begin to debugged immediately: turn the screw T counts the clock until the rotation stops.

- Adjustment starts with a screw l. The screw turns to the right and to the left until it finds such a position in which the idle speed does not become maximum.

- Then the screw is turned on ¼ turn against the watch. This will be his working position.

- The idle stroke must be configured by turns against the sentry to increase the number of revolutions and the clock. to reduce. Its debugging consists in achieving such a regime in which a sufficient number of revolutions are performed before the rotation of the mowing head. In this case, the engine should operate steadily at different positions.

- The position of the screw L is determined by the latter. at maximum speed the trimmer for grass should not work for more than 10 seconds. The throttle opens, the screw is closed clockwork, very slowly, until a decrease in the number of revolutions is established by ear.

- Then also slowly the screw rotates against the sentry until the engine starts to work with failures. After which the screw is on the time, until the engine again works normally.

If there is a tanometer, and if the product is indicated in the product passport, coooreecration can be carried out more accurate, focusing not by ear, but on the testimony of the device. Adjustment of the carburetor of the lawn mower in the video is carried out by ear.

It is no secret that the best and most effective way of repairing is a prevention of possible malfunctions. As already noted, one of the key points is how correctly the gasoline-oil mixture is prepared. Its components should be gasoline at least AI-92 and high-quality motor oil. The proportions, taking into account the mixture, are indicated in the manual of the manufacturer, which is included in the supply of any gasoline trimmer for grass. As a rule, oil to gasoline is added using an ordinary medical syringe. In a similar way it is easiest to observe the appropriate proportions.

Quite often, when problems with the launch of motorcycles arise, the owners of the tool try to carry out repairs with their own hands. In the presence of the necessary knowledge and skills, this approach will significantly reduce operational expenses. First of all, it is worth checking the fuel system and, in particular, the filtering element. If clogging is detected, the filter will be easiest to replace with a new. If an air filter has become source of problems, then you can get out of a difficult situation even in the process of work with minor time costs. The following actions will need to be performed:

- remove the filter element;

- Directly in working conditions, you can rinse the filter used by gasoline;

- When operating, braids for grass or at a summer cottage for cleaning use water and simple detergents;

- After washing, the part is carefully rinsed and dried;

- A completely dry filter should be lubricated with engine oil;

- excess lubricants are removed by compressing the filter element with the hands;

- The cleaned part is put in place and the plastic cover is attached with screws.

If the described actions did not provide a positive result, then the next step will be the clearance adjustment using the corresponding carburetor screw. Many publications and videos posted in the open spaces of the World Wide Web are devoted to this topic. When trying to solve the problems under consideration, you can take several steps.

The trimmer for the grass is placed on the side so that the “air” is from above. This will allow the fuel mixture to enter the lower part of the carburetor

Often, attempts to launch the internal combustion engine are successful if you pre.dismantle the mentioned part and literally send a couple of drops of gasoline directly to the carburetor itself. If, after all the described actions, the braid could not be brought into working condition, then the candle and, in particular, the presence of a spark should be paid attention to. In parallel, all fuel from the combustion chamber is completely removed. Often, the owners of the benzos are in situations where the fuel and air filters are clean, the candles are good, the fuel mixture is fresh and high.quality, but the internal combustion engine does not show signs of life

In such cases, experienced experts recommend using universal and proven many years of practice by launching. It is necessary to transfer the air damper to a closed position and pull the starter handle once. After the damper, the engine is opened and the engine is launched 2-3 times. In the vast majority of cases, the result is a positive.

The light of the ignition during the launch of the ICE of the Trimmer for the grass can be filled with fuel. Even with a high.quality mixture and the presence of a good spark, it is unlikely that you can get a device. The most effective exit will be to extract a candle and dry it. In parallel, you can check this spare part for performance, when identifying malfunctions, replace it. This procedure includes a number of simple steps, namely:

- drown out the device and wait for complete cooling of the power unit;

- turn off the wire;

- extract the candle itself;

- examine the dismantled part;

- make sure the presence of a gap (0.6 mm);

- screw a new, working candle and tighten it.

In practice, many repair work related to the fact that the braid for the grass has stopped starting and which sooner or later has to face the operation of a household lawn mower, it is quite possible to cope on its own. But with serious malfunctions, it will be most rational to contact a specialized service. However, the key factor in such cases will be the ratio of the cost of repair and the price of a new trimmer for the grass.

What to do if the engine does not start?

If the lawn mower fails is not possible, then the first thing is to check the presence of fuel in the tank and its quality. For refueling the tool, it is recommended to use high-quality gasoline purchased at gas stations, the brand of which should not be lower than the AI-92. Savings on cheap fuel can lead to a breakdown of the cylinder-piston group, for the repair of which a third of the cost of Motokosa itself can take

It is equally important and correctly preparing a fuel mixture of gasoline and oil. The proportional ratio of these components of the mixture is indicated by the manufacturer in the manual

Do not prepare the fuel mixture in large volumes, since during long storage its properties are lost. It is better to use a freshly prepared mixture.

When preparing the fuel mixture, pour the oil into gasoline using a medical syringe that allows you to accurately comply with the necessary proportion of the components

Fuel filter pollution in the tank may also prevent the operation of the lawn mower engine. Therefore, when problems with the launch of the motor, check the condition of the filter. If necessary, replace the filter. It is forbidden to leave the incoming pipe without a fuel filter.

The air filter also needs to be in the test. During contamination, the part is removed, in the field is washed in gasoline and put in place. In the country or at home, the filter can be washed in water using detergents. After that, the filter rinses, squeezes and dries. The dried filter is moistened with a small amount of oil used to prepare the fuel mixture. Excess oils are removed by compressing the filter with hands. Then the part is installed in place. The removed cover is placed back and fixed with screws.

The air filter washed in the fuel mixture, squeezed and dried, is installed in place in the plastic case and covered with a lid

How this procedure is done in more detail you can look at

If all of the above procedures are carried out, and the engine is not started, then adjust its revolutions at idle, twisting the carburetor screw

In the video posted at the beginning of the article, attention is paid to this issue

Specifications

With the technical characteristics and description of the Huter BS-52 chainsaw, it is best to get acquainted directly on the manufacturer’s website.

After unpacking the Huter saw, make sure that all components are available and carefully read the description of the motorcycle, the maintenance and operation of the product.

- Pull all the uninhabited screws, clamps and nuts, see the reliability of fasteners;

- Unscrew the nuts for fastening the protective cover and remove it;

- Put on the chain on the tire, make sure that the cutting edges are directed in the direction of the chain;

- Install the saw headset on the stilettos;

- Install the lid in place and fix it with the mounting nuts, without tightening them until it stops;

- The universal key adjust the chain so that it adjacent to the bus;

- Tighten the nuts to the stop. Check the correct tension of the chain. She should slide along the tire without extra sounds and jamming.

- Prepare the fuel mixture for running the engine in a ratio of 1/25.

- Put the saw on the ground, turn on the circuit brake and start the engine;

- Develop one fuel tank at idle, periodically bent the engine (for 20-30 seconds.).

- Prepare a fresh fuel mixture in a 1/40 proportion if another is not indicated in the oil used.

- Put on the saw in a sparing mode for 3-4 hours. Every 25-30 minutes stop the motor and let him cool.

Huter BS-52 chain tips for maintenance maintenance

- Inspect regularly and, if necessary, clean the lubricants not the bus;

- Clean dirt from the ribs of the engine, it can cause its overheating;

- After a certain time, turn the tire. this will lengthen its service life;

- Keep the air filter clean;

- Regularly check the condition of the spark plugs;

- Sharpically sharpen the chain;

- Follow the serviceability of the mechanical brake, lubricate its mechanical parts in time;

- Keep a saw in a dry, well.ventilated room.

REPAIR of the chainsaw

A chainsaw, a photograph of which you can find in an article, has a candle. When the tool breaks down, you first need to check this particular part of the mechanism. To do this, the wire is turned off, and the spark plug itself is unscrewed by the key. If it is covered with black carbon, this may indicate the use of low.quality oil. Sometimes black carbon is indicated by the incorrect calculation of the ratio of oil and gasoline and incorrect carburetor adjustment. The candle is washed, cleaned of sediments with a needle or awl, only after you wipe the electrodes with sandpaper.

If it is dry, then the fuel mixture is not included in the cylinder. The problem in this case is not in the ignition system, so the candle can be installed back.

If the candle was sprayed with fuel, an excess of the mixture can be explained by a violation of the rules of launching or improper adjustment of the carburetor. The spark plug should be wiped, turn off the fuel supply and turn on the starter so that you can remove excess fuel. After checking the combustion chamber, the candle can be installed in place, and the equipment can be restarted. Huter BS-45 chainsaw repair can always be carried out independently.

Setting up a carburetor of a lawn mower with three adjusting screws

Before starting work, you need to place the lawn mower on a flat stable surface. Remove the chain in the opposite direction. There are motorcycles with two and three adjusting screws. Two screws most often equip the tools produced in China. Consider the adjustment of the carburetor Motokos with three screws.

Setting up a carburetor of a lawn mower with three adjusting screws

Before proceeding with the adjustment of the carburetor of the lawn mower, you need to rinse the air filter. Cleaning is carried out with water with a detergent or soap, and if necessary, a new. Often in the poor work of the carburetor, scibberries are guilty. In order to prevent the filter, it is recommended to clean the filter after every 10 hours of operation of the tool. Do not forget to check the condition of the candle, if there is a dozen, you need to clean it. Candles are consumables and have their own resource. To ensure good operation of the engine of the lawn mower, candles periodically need to be changed. Next, we evaluate how well the carburetor is fixed to the cylinder-piston group. After the preparatory manipulations are completed, you need to start the motor. Let the engine work for 5-10 minutes. Then you need to identify how many adjusting screws on your tool.

There are the following adjusting screws on the gasoline trimmer:

Fuel supply adjustment

At first you need to slowly tighten the screw adjustment screw for the fuel mixture. You need to do this until the engine starts to stall or stalls. Following this, if the engine did not stop working, you need to turn the screw for a quarter of turnover, and if it stalled, then by half the turnover. Next, you should have a stalled engine. Then you need to open the throttle and see how the speed is gaining. Turn the screw for a quarter of turnover again. You need to scroll until the engine begins to confidently gain increased speeds during cuffing. This is the right time when the engine works most economically. There are times when adjusting this screw does not give anything. Often the reason is in the factory spring that is located on this screw. This does not happen to all the tools. And if the spring turned out to be defective, then replacing it will not be difficult. A suitable spring can be purchased at any construction store.

Cooper adjustment

Following the adjustment of the fuel supply, we are accepting for the adjustment of the idle. To do this, you need to adjust the corresponding screw so that the engine works slightly accelerated at small speeds. But it is necessary to trace, for the immobility of the reel with fishing line and knives. Before the start of their movement, several revolutions should remain in stock. The movement of the coil and knives can subsequently lead to the rapid wear of the clutch. Having noticed that the engine starts poorly, you need to increase the number of revolutions at idle. With an increase in revolutions, the fuel mixture is saturated with air, which leads to power loss.

The main signs of the proper idle work:

- Revolutions for a trimmer head;

- Uninterrupted operation of the engine even when the position changes (sharp rise or descent of the knife);

- Calm operation of the engine at a cold move;

- Lack of increased speed of hot engine.

Maximum speed adjustment

Further, for the full tuning of the carburetor of the lawn mower, it is necessary to adjust the maximum speed. It will not be superfluous to look into the instrument operating manual and see the maximum speed value. This amount will help to determine the tachometer most accurately. If such a device was not at hand, we set up by ear. Barely determining the maximum speed of revolutions by ear, we begin adjustment. A screw for limiting maximum revolutions will help in this matter. Control the engine operation at maximum speed. If necessary, reduce speed, weaken the fixing nut and unscrew the screw. If the turnover is too large, then you will need to screw the screw. These actions must be done in order to protect the engine from overheating. Scroll the screw until the clear even operation of the engine is established.

After the work done, if everything is done correctly, the stable work of the tool is provided.

Understand this by the following signs:

Husqvarna carburetor adjustment

Before adjusting Husqvarna, make maintenance of a trimmer for grass (wash the lawn mower and engine, replace the spark plug, eliminate minor defects).

Be sure to wash the foam element of the air filter. Wash the element in warm water with soap, then squeeze and dry (or replace it if it is old or damaged).

Note: If you adjust the Husqvarna carburetor with a dirty air filter, then after cleaning the air filter, the fuel mixture will become much poorer (which can lead to poor operation or even engine breakdown). Install a trimmer head with a cord of the maximum permissible diameter and standard length (to a cutting knife in additional protection) to create a load on the engine while adjusting the high speed of the Husqvarna carburetor. Get the lawn mower according to the leadership of Husqvarna and warm for 10 minutes (if at the same time the trimmer head rotates at idle speed, then the idle screw, t.e

Lower, it is necessary to turn counterclockwise until the rotation of the trimmer head stops)

Carefully turn both needles (right and left) in the middle position between fully twisted and completely screwed (do not cure the stopper!, This can lead to breakdown of the Husqvarna engine). Husqvarna carburetor adjusting screws for adjusting the carburetor: right, left and lower

Husqvarna carburetor adjusting screws for adjusting the carburetor: right, left and lower.

1) The right screw l. regulates the enrichment of a mixture of low revolutions (regulated first): Find the maximum idle speed, slowly turning the right screw to the right and left. Then turn this screw on ¼ turn counterclockwise. Note: from the Husqvarna plant, the right screw was completely unscrewed (at 0.5 turnover). Now he is looking at “11 hours”.2.

The adjustment of the idle speed is considered to be correct when:

- The cold engine is stable at idle.

- The hot engine has not highly high speed speeds.

- Before the rotation of the trimmer head, a sufficient supply of revolutions remains.

- The engine works steadily in any position (for example, with a sharp lowering knife).

Note: from the manufacturer (Husqvarna), the idle screw from the fully twisted, was twisted at 8 full revolutions and “2 hours” (now it remains). Husqvarna.2.recommended idle gas mowing engine. 2.900 rpm.3) Left screw h. regulates the enrichment of a mixture of high revolutions (is regulated last). It regulates maximum speed, engine power, temperature and fuel consumption.

Note: the Husqvarna engine should not operate at full speed for more than 10 seconds!

- Open completely the throttle (give full gas) and slowly turn the left screw clockwise until the speed of the Husqvarna engine is reduced (by ear).

- Then turn the left screw very slowly counterclockwise until the engine starts to work uneven.

- After that, turn the screw slowly back to a slight distance clockwise until the Husqvarna engine starts to work smoothly.

This is where the HUSQVARNA adjustment is completed.

Note: recommended by the highest possible speed of the Husqvarna engine. 11.500 rpm. The maximum output capacity of the Husqvarna 333R lawners engine is 1.6 kW (2.1 l.With.) at 8.400 rpm.

Note: on the new trimmer Husqvarna from the manufacturer (Husqvarna), the left screw was completely unscrewed (by 0.5 turnover) and blocked (bay) with solid plastic, which I drilled after the guarantee period. Now the left screw (like the right one) looks at 11 hours approximately.

We check the correct settings of the Husqvarna carburetor

The engine is quickly, evenly and confidently gaining momentum, and a little four at maximum speed, the T-35 trimmer head should not rotate at idle.

The principle of operation of the carburetor of the lawn mower

The throttle dashes determines the amount of air for supply, and the engine power directly depends on this.

Fuel is sucked into the carburetor system (its membrane). Then passes through the fitting in the carburetor. Next, the liquid moves through the intake and exhaust valve of the pump. Filtered with a net. The needle valve moves into the membrane chamber.

- Air supply to the tube with an air septum (damper). The partition regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and nozzle with narrowing. The chamber with a float regulates the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already low. Thanks to the pressure drop, fuel penetrates through the jetler.

- Air flow acceleration contributes to the transfer of fuel (gasoline) and its spray. As a result, the air-fuel mixture of the necessary proportion or density is formed.

- The air-fuel mixture penetrates the engine cylinder through the fuel tube.

The level of air density in the system depends on the area of the open air damper. The wider the damper is, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a benzocos. creating an optimal fuel mixture due to the correct air supply.

The main problems

Malfunctions of the carburetor Motokos or trimmer for grass, despite the relative simplicity of their elimination, sometimes require a long search by excluding. The main reasons are as follows:

Flamming fuel supercharger

The most repeating breakdown is wear, rupture of the membrane. As a result, its lavation. Fuel moves are not sealed at certain stages of the engine cycle. The reasons here are as follows:

- You have been working on a motorcycle or trimmer for too long without a break;

- Poor.quality fuel was seasoned;

- Wheelled gases fall into the pulse channel.

A deformed membrane is fraught with several bad consequences:

- not enough gasoline or oxygen in the created combustible mixture;

- the launch of the motor occurs after 10 or more unsuccessful attempts;

- the engine knocks, clats during operation, and t. D.;

- The working piston is deformed.

Ground of a mesh filter

The reasons for the clogging of the mesh filter are poor.quality fuel cleaning, damage to the hose and/or the injection head.

The failure of the adjustment lever

Wear of the contact edge of the lever. a consequence of not completely purified fuel, into which grains of sand or particles of clay, metal or other inclusions that are not soluble in liquid hydrocarbons fell. A problem with fuel injection appears, the motor does not function with interruptions without load.

The inlet needle is spoiled

The inlet needle breaks due to the presence of metal and stone particles in gasoline. As a result, the saddle of the intake needle tightly adjacent to it, the fuel mixture flows. In the combustible mixture created by the carburetor, there is too much air, which is why the motor can “sneeze” during operation. Finally, the needle can stop due to poor-quality gasoline, or the unit was idle for a long time.

Clogging the adjusting space

Deposits may accumulate in the adjustment compartment. The needle does not completely cover the hole, and a lot of gasoline enters the fuel chamber. the motor pours it, perhaps floods the spark plugs. Because of this, the gasoline mixture contains an increased number of vapor of gasoline. The efficiency falls noticeably.

The adjustment membrane is spoiled

The membrane is often deformed (sometimes torn) due to continuous operation of motorcycles or trimmer for grass for several hours. If you abuse such a “shock” mode of operation, damage to the membrane occurs more often. New breakdowns will be sprinkled from a cornation of abundance:

- the piston will break;

- The number of attempts by the unsuccessful start of the engine will increase sharply;

- The fuel mixture will contain too little gasoline;

- Useful (thermal) power will drop sharply.

The inlet regulatory lever sees

Sequeling of the adjusting lever. a consequence of the incorrect installation, random flexion. Contactive line will find an incorrect position. This will violate the additional injection of gasoline.

The damper has worn out

Throttle and air conditioning are unusable due to admission to the air flow of dust, metal particles, etc. D. Damaged shutters are similar to details subjected to streaming with sand. Due to wear of the damper, the efficiency of the motor decreases, breakdowns are detected. The piston and cylinder wear out.

In some cases, this filter is simply not suitable for your model motorcycles or trimmer for grass. In the end, the shaft of the motor will suffer. its pieces fall into the engine channels, which is why the piston will be broken.

The carburetor cannot be adjusted

The fact that the adjustment is too rough (it is not possible to accurately set the parameters) are to blame for the adjustment screws. The manufacturer Motokos or trimmer for grass can put excessively thick and hard springs. You can find others either in workshops where such equipment is repaired, or purchased from any dealer or official representative of the company who released the engine for your trimmer for grass or mechanical braid for grass.

The primer broke

Primer-a manual mini-pump for forced swinging fuel into a carburetor. For a successful start of the motor, it may be necessary to pump 20 ml of gasoline manually.

In what cases is it required to set the carburetor?

The stable work of the carburetor motorcosa largely depends on its correct setting.

The assembly adjustment is required in the following cases:

- After the run.in a new trimmer for the grass, when 4–5 full fuel tanks were spent during operation;

- with a frequent replacement by the operator of the brand used to refuel gasoline;

- as a result of a sharp change in the weather;

- due to long-term storage of a trimmer for grass;

- as a result of arbitrary twisting of the adjusting bolts, motorcycles caused by strong vibration of its motor;

- due to a sharp increase in the number of fuel trimmer consumed.

How to tune a carburator on a 1971 ford f100 302 small block

It will also be required to adjust the carburetor of the motorcycles in those cases when the soot quickly appears on the light of the instrument, as well as with a sharp increase in the volume of exhaust gases thrown out by the trimmer.

Elimination methods

The list of upcoming work with the engine may be as follows:

- replacement of the fuel pump;

- disassembly and flushing of the mesh filter;

- replacement of the adjusting lever;

- It is also necessary to clean the adjustment space;

- replacement of the membrane (or the entire block where this membrane is located);

- setting in intake, graduation and needle valves;

- replacement of the damper;

- cleaning the fuel channels and diffuser;

- replacement of springs of screws;

- Change of primer.

Not all these works can be completed. It often turns out that many of them have no need if a specific malfunction is immediately discovered.