How To Build A Racing Lawn Mower? (Step-By-Step Guide). Race lawn mower engine

How to Build A Racing Lawn Mower

Are you a lawn mower enthusiast who is looking to build a racing mower? Maybe you like alternative sports and want to take part in a lawn mower race? If you answered yes to either of these questions then this article will give you some information and advice about building your first racing lawn mower.

Finding Parts

Building a racing mower is kind of like making a small car. The first step in this process is to find enough parts to make your mower. You can do this by taking apart your existing mower, asking friends and neighbours if they have an old mower they no longer need or searching garage sales and scrap yards. You may also like to look on eBay or other auction sites for specific parts. Finding the parts is often the hardest part, once you have everything you need building it is actually quite straight forward.

The main parts you will need are as follows:

- An Engine

- Transmission ( right angle gearbox)

- Centrifugal clutch

- sprockets

- Front axle and spindles

- Rear axle and axle hangers

- A steering wheel

- Brake system

- Chain

- Electrical components

- Wheels, tires, and hubs

- Gas lever

- High endurance engine component

Building the Frame

In order for you to be able to sit on your mower and ride it, often at a high speed you will need to create a large, bulky frame. You can do this by adapting the existing frame and welding it together, use other scrap metal to make it sturdier and add a seat. It’s also important to reinforce the frame as racing will take place on dirt roads and your lawn mower has no suspension.

Steering system

The next step is to create a great steering system, remember if you want to be in with a chance of winning you will need to be able to steer accurately even at higher speeds. Create a direct steering system as this will give you an easier time when driving.

Install internal components

The next step is to install the lawn mowers internal components. Start with the RAGB (transmission). The brakes can be added next. There are a number of different brakes available on the market. These will be either mechanical or hydraulic. In the case of racing lawn mowers, hydraulic brakes usually work best. They are also easier to install as you will be able to route the brake lines to wherever you want them.

The mower deck can then be welded to the frame and the battery stored underneath this as well as the electrical system.

The next step is to make a casing or tank, known in the lawn mower racing world as a puke tank to hold the engine. This will stop the lawn mower spilling oil all over the track.

A seat can be added to the mower for comfort and safety. You can use the type of seating common in schools but cut the legs off. Alternatively you could weld a seat from pieces of scrap metal. If you want your seat to be more comfortable, cover it with pieces of foam from an old car seat.

The last step before putting everything back together is to make your mower look great. Paint the frame in a bright, eye catching colour. You can then assemble it, choose wheels that are large and have deep treads, so that you can use it off road.

Racing mowers are used in national events where competitors race against each other. You can research lawn mower racing events on the internet in order to find out where to race once you have successfully built your racing lawn mower.

How To Build A Racing Lawn Mower? (Step-By-Step Guide)

Ernest Hemingway, a famous sportsman mentions auto racing as the only real sport and calls the others as games. Do you think so and plan to build a racing car that makes you a real sportsperson?

I know you have a great desire to have an aracing car. But you know building a racing car is too expensive and needs more skill to do that.

Will your dream end here then? No way. Think of the alternative way. Yes, you can turn your lawn mower or lawn dethatching machine into a racing mower!

From 1968, people have been practicing this and joining a world-class lawn mower racing competition. You can even take the lawn mowers engine and use it for simple racing, such as building a Go Kart.

Now, the fact is, do you know how to build a racing lawn mower? If your answer is even no, nothing to worry about.

We are here to give you the proper guidelines. Trust me, you can do this at home by yourself.

So, why delay? Let’s start the journey of fulfilling your dream.

The Process To Build A Racing Lawn Mower

Are you ready for building a racing lawn mower? Not at all. You know before starting any work you need some equipment that is needed to complete the task.

When you are planning to build a racing lawn mower, first you have to gather all the tools. Let’s see what tools and materials you will need to build a racing lawn mower and making your lawn mower faster.

- Engine

- Engine set up component

- Centrifugal clutch

- Hydraulic brake system

- A steering wheel

- Front and rear axle

- Chain

- Transmission

- Front and rear wheels

- Fuel tank

- Electrical equipment

- Hand gloves

- Googles

- Tire Sealant

I think you are ready now. Let’s get started.

Step #1: Building a Strong Frame

We will first look at building a frame. Usually, lawn mowers always have a built-in frame. But when you build a lawnmower for racing purposes, the frame needs to be stronger to take the high-speed load.

The existing frame of the lawn mower can’t be able to take the load. So, add additional metal pieces with the existing frame to make it stronger. Weld the additional metals with the mainframe of the mower.

The shape of the frame depends mainly on the shape of the wheels you want to use. But there is no need to keep too much distance between the mower and the ground. If you place it 4 feet above the ground, you can easily drive the mower.

Step #2: Setting up the Steering System

If you want to win the race, you need a strong steering system. Set up a direct steering system. Connect the steering wheel with the front wheels. Direct steering will help you to drive the mower easily.

Step #3: Install the Internal Components

Now, it’s time to set up the internal components.

- At first, install the transmission with the mower.

- After that, set up the hydraulic brake. You know there are two types of brake found in the market. One is mechanical and the other is the hydraulic brake. Hydraulic brakes are more suitable for the racing mower. You can easily install it rather than the mechanical brake.

- Now, weld the mower deck with the mainframe of the mower. Wait a while so that the mower deck clings tightly to the frame.

- Install the battery under the deck and complete the electrical connection.

- Install the puke tank now. It is developed to carry the engine. It is also able to fend oil leakage in the time of racing.

- You need a seat to drive the racing mower. It should be comfortable for your easy driving. Usually, people use school seats but without legs. If you are a people who love comfort, then you can use any one of the old car foam wrapped seats.

- After setting the seat, it’s time to install the engine. We recommend you to use 12 horsepower (HP) Briggs and Stratton engine. This is the most used engine for the racing mower and really inexpensive. Try to purchase the updated version of the engine. Place the engine in the engine shroud.

- Place the battery underneath the seat and connect the battery with the engine.

- Attach a chain between the engine and the rear wheel. It will help you to drive the mower easily.

- Now, get ready to give your mower a new look. It’s time for painting the mower. Before painting, clean up the mower as it gets dirty after welding. Light and the eye-catching colors are always suggested.

- After painting, install the front wheel to give the mower the final look. Check all the connections and internal components carefully.

Done! Now your lawn mower is ready to reign on the racing track.

Final Verdict:

If you are a racing lover person but don’t have enough skills to build a racing car, you can build a racing mower to fulfill your desire. And you know building a racing lawn mower is not a much difficult task.

I hope following the above-mentioned process has helped you to understand how to build a racing lawnmower. But keep in mind, if you don’t have enough confidence and skills about that, don’t try this at home.

A faulty electrical connection or a simple mistake can bring a big disaster. So only try it when you are enough confident. And don’t forget to take essential safety measures.

How to Create a Go Kart with a Lawnmower Engine

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 52 people, some anonymous, worked to edit and improve it over time.

There are 9 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 674,846 times.

Though go-karts traditionally use horizontal mount engines, with a little modification, you can install a vertical shaft lawnmower engine to be the driving force behind your homemade racing machine. Taste again the speed, freedom, and exhilaration of the open road when you convert your lawnmower engine into the go-kart you’ve always wanted.

Removing a Lawn Mower Engine

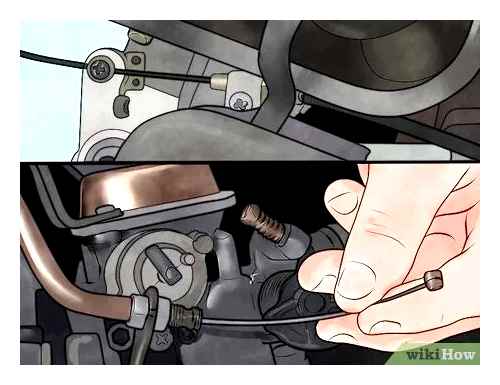

Drain the gas. Loosen the fuel hose clamp before you start draining your fuel. You can do so by tracing the route of the fuel hose from the engine to the base of the gas tank. Notice where the hose attaches to your lawn mowers carburetor. [2] X Research source Using your pliers, squeeze the clamp loose and slide it upwards on the hose. Now you can detach the hose and drain your fuel into a bucket.

Locate the throttle linkage. You can usually find the throttle linkage beneath the carburetor. There will be a cable that should connect to the throttle, and by removing the screw that holds the cable in place, you can easily remove the throttle linkage. [3] X Research source

Find the starter. This part is on the side of the engine and will have the shape of a small can. [4] X Research source Electric-start lawn mowers will have a red battery cabled attached. Use a wrench to unfasten the cable from the starter.

Remove necessary nuts and bolts. At the base of your mower engine is the mower house, which is where the engine is seated normally. Using your wrench on the bolt and another to hold still the nut below the mower house, unscrew the bolts holding your engine in place.

Take off the drive belt. You will find the drive belt on pulley on the crankshaft beneath the engine. Incline the engine slightly forward and pull the drive belt from its pulley. [5] X Research source

Remove the engine. Taking the engine firmly with both hands, lift the engine from the mower house and place it carefully off to the side in a safe place.

Preparing to Install

Pick a suitable go-kart frame. You will want one that can support both your vertical shaft engine and lawnmower gearbox comfortably. Your gearbox should will need to have non-trans axle set-up.

- Most frames have a width that varies between 1/3 and 2/3’s the wheelbase of your go-kart, with wider models giving better stability. [8] X Research source

Assembling the Frame

Put in a floor. A 16 gauge sheet metal piece should be sufficient for the floor of your kart. Using your plans from earlier, drill holes in the sheet for the fastening bolts for your seat.

Weld a brace for your seat. You should brace both outer sides of the go kart frame with flat, 3/16″ gauge steel. This is where you will install the bench for your seat.

Assembling the Steering Column, Tabs, and Spindle Brackets

Cut and install you steering column. You should cut a section of 3/4″ x 11 gauge tubing and weld it to your steering tabs. Insert an additional 1″ spacer loosely by the shaft near the steering hoop, grinding the shaft slightly near the hoop if too tight. Drill a three hole pattern with the holes equidistant from the center of the washer at the end of your shaft.

Racing mower build

Add resting tabs for brake and throttle. These 2″ long 3/8″ diameter tabs keep your pedals in their resting and full forward positions. The closest tab to the center of the frame should be fixed a max of 1/2″ after the crosswise piece your to which your steering column is attached. The second tab should be installed 1 3/8″ after the first tab.

Attach spindle brackets. You will weld these to the front axle of your go-kart. The spindle should have a 1″ clearance above the front axle.

Give yourself a foot rest. Use a 3/8″ rod in a vise to bend it with a hammer into the shape of your passenger footrest if applicable. This will keep your feet from resting on tie rods.

Don’t forget your brake Band stud. This stud will serve as the pivot for your brake Band. Weld a 3/8″ round bar to the frame 1 1/2″ after your axle.

Assembling Motor Mount, Brake Rod, and Accessories

- The motor mount should be welded as the final step to building your kart.

- Your mount should be able to hold your lawn mower engine in the horizontal position.

Attach the throttle cable guide tab. About 4″ away from the middle of the throttle pedal bolt hole, weld this tab to your kart on a 45 degree angle.

Put in the brake rod guide tab. Take your brake rod and insert it through the tab, bending it to adjust it to the brake Band. Next, take the tab with the rod inserted and weld it to the kart.

Bend your brake rod into shape. Bend this 1/4″ round rod so that it angles to meet your brake pedal assembly. Cut the length of your brake rod as needed, and weld eyelets to the rod with a return spring installed brake pedal.

Give yourself a seat. Many go-kart kits do not bolt seats directly to the kart. If this is the case for you, use a simple frame and bolt this into the seat braces. Your seat should be cut at a 37.5 degree angle for a 105 degree incline for your backrest.

Weld motor mount and attach accessory parts. Having finished with the body of your go-kart, you can now weld the mount to your frame. Upon completing your weld, you can add tires, seat padding, and all other necessary hardware to your vehicle.

Installing the Vertical Motor and Gearbox

Bolt down both motor and gearbox to the mount. The location of your motor is not as important as that of the gearbox. [9] X Research source To properly install your gearbox, align it with the gear on the rear axle, and then bolt it into place.

Change the sprocket size for the gearbox. A sprocket is a gear toothed wheel inside your gearbox that controls the gear ratio for your transmission, which is another name for the gearbox. Your target gear will be about 16 teeth.

Attach a throttle cable to throttle linkage on carburetor. Now you can clean off any residual oil from your kart, but do so with care. Always allow for sufficient time for the materials you are working on to cool, like the engine or solder, before using a cleaner.

Community QA

Speed mostly depends on three factors, engine RPM, tire size, and gear ratio. So that question is not easily answered. Most 5-7 HP yard go-karts go 17-35 mph, with 25 mph being common. 8-13 HP go-karts with torque converters and large tires top out at around 40 mph. Race karts can go much faster as they use modified or two stroke engines that rev higher, so you could see speeds of 50-60 mph in those. Enduro and high end race karts can go much much faster.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

As long as the engine is from a decent brand (and therefore good quality), it won’t explode out of nowhere. You’d really need to damage it to make it explode.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Lawn Mower Racing ~ The Worlds CHEAPEST Motorsport

This is Lawn Mower Racing — a bunch of maniacs get together in a field to do some of the craziest racing you’ve ever seen on 50mph lawn mowers.

For some reason, UK based YouTube channel Driven Media are giving it a go!

The trio at Driven Media recently took three cheap cars to a track day, so the obvious next step was to take on the world of motorsport.

Motorsport is EXPENSIVE — A season of Formula 2 would cost you about two million dollars a year. A year of GT racing would cost you around 450K.

Lawn Mower racing, on the other hand costs LESS! You can sport a full season for just a couple grand, and that includes the mower!

So to give Lawn Mower Racing a go, the guys are going to do some practice on the fastest class of lawnmowers before doing a 20 minute race with 35 mowers on track — they’ve been thrown well and truly in the deep end…

Lawn Mower Racing

The guys head to Dorking, a market town in Surrey in South East England for the final round in the British Lawnmower Racing Championship…

What if the 1952 Chevrolet Deluxe Sport Coupe was Built Today?

SketchMonkey brings the 1952 Chevrolet Deluxe Sport Coupe into the modern world — Keeping the charm of the 1950s with design cues from today. […]

Reversing Gears ~ Rescuing One’s Own Derelict 1967 Pontiac GTO

Kerry Pierno has manufactured for himself a story of vehicular misfortune but is reversing gears by reviving his 1967 Pontiac GTO. […]

Danny Trejo and his 1965 Buick Riviera on Jay Leno’s Garage

Jay Leno checks out Danny Trejo’s interesting car collection and the two go cruising in Danny’s 1965 Buick Riviera. […]

Race Mower Stg 1 Ep 1

Rider Mower

Riding mowers racing began in the 1960s as a form of novelty. Since that time they have grown into a serious form of low-cost racing.

Rider Mowers typically used for racing have the cutting blades removed, the CG height lowered and the transmission geared up to give speeds of approximately 45 mph (72 km/h). To keep the racing low-cost, entry-level classes retain many stock components while most open classes allow customization of the powertrain and chassis.

Racing is generally held on small dirt tracks to keep the racing competitive and close. Racing takes place in the Americas, Europe and Australia.

Design and Construction

Race Car Models of This Type

There are numerous models of stock mowers that qualify for racing or as a donor for a customized machine.

Knowledge Level

Rider mower racing does not permit extensive modifications in the entry-level classes, so a basic working knowledge of handling is useful. As you develop your mower into more of a purpose-built racing machine, it will be helpful to have a working knowledge of powertrain and chassis, as most modifications will center around these areas. In addition to a small engine repair manual, it will be useful to have resources around customizing the transaxles.

Design Challenges

Weight Distribution: The rider mower’s weight is relatively well distributed front/rear with it being a front engine/rear drive short wheelbase machine.

For racing purposes, the lower the CG (Center of gravity) the better, but there are limits to seat height as well as chassis and mower deck ground clearance.

Suspension: There is generally no suspension allowed on rider mower racers. Tires provide the absorption of bumps and their types and pressures are usually regulated. Rear axle and front wheel brakes are worth consideration. Brakes other than that provided by a transaxle are required in the top classes.

Widths of the machines are regulated, but using the maximum allowed width will generally give the best handling. The exception perhaps is in situations where there is very little grip (such as a slick wet surface). In this case, narrower tires and track width could be helpful in getting corner “bite”.

Throttle, brake and clutch controls are critical to smooth operation of the mower. The most natural configuration for you is the one to build. Some designs use a hand throttle attached the steering wheel, while others use traditional “car-like” pedal arrangements. In the case where a hydraulic disc brake is used, there will need to be separate clutch actuation because many rider mowers combine the brake and clutch into one pedal.

Chassis: Depending on the class, modifications may be made to the chassis and body work. Modifications might include strengthening a weak chassis, altering CG if allowed, changing the wheelbase if allowed, and welding the front suspension as a fixed beam.

Powertrain: Using aftermarket filters and racing exhaust may be a consideration if permitted by the regulations. Modifications must be made to stock transaxle gearing for higher speeds to be reached. Most transaxles have a limit to the input RPM, and so adjusting the gearing inside the transaxle enables output speeds to be increased. In top classes the powertrain regulation is open so far more flexibility is available in final drive configuration (ie. Centrifugal clutches, Chain drive, live axle)

Safety: Consideration should be given to securing critical fasteners with locking mechanisms (Castellated nuts, safety wire, cotter pins, etc.) to prevent failures of brakes, loss of wheels, or drivetrain components. A spring-loaded “throttle close” system should be included to close the throttle in case of a control cable failure. An ignition kill switch should also be included to quickly kill the motor in an emergency.

If you intend to race under a sanctioning body, always read and understand the regulations of your chosen racing class before designing or building any race vehicle.

Design Resources

Download our free race car design aids to assist you designing your race vehicle.

Construction Challenges

Having sufficient space around your mower for the build is important, as a cramped workshop can be difficult to work in.

The tools to modify the chassis (ie. welder, metal working) can add considerably to the cost of your project if you don’t already have a workshop, but borrowing or renting items is also an option.

Build Costs

Donor mowers can be had used for low prices, provided the state of the engine and transmission is still good. Because of the limited size and power, most parts are OEM or fairly low cost to fabricate.

Build Effort

Due to the unique nature of each rider mower brand and model line, modifications will usually require OEM/off-the-shelf part replacements. Customizing beyond that will require metal working or creative part scrounging.

Racing Cost

Very, very low. Tire replacement, except in the case of damage is infrequent.

Transportation and Support Equipment

Can be loaded into the back of a pickup truck or onto a small trailer. Support equipment can be carried in the transport vehicle.