How to check the ignition coil from the trimmer with a tester

How to check the integrity of the coil on small equipment?

On small vehicles, the procedure is much easier. As an example, consider the question of how to check the ignition coil of a scooter.

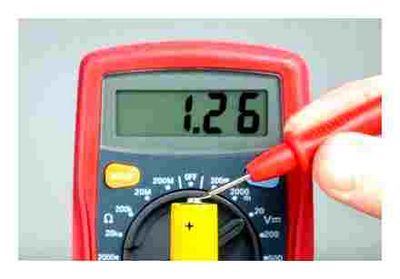

You will need a multimeter for detailed verification. When connecting the probes to the coil contacts on the multimeter, a resistance in the range of 0.5 to 5 ohms should be registered. With such indications, we can talk about the serviceability of the primary winding.

We check the secondary winding: we connect it in the same way as before, plus for plus, minus for high-voltage, while the resistance should be about 2-3 kOhm. With any deviation of this value, it becomes clear that the coil is out of order.

Checking the coil with a multimeter

How to check the ignition coil with a multimeter:

- Evaluate the primary winding first.

- On this winding, depending on the type of coil, the resistance can be in the range from 0.4 to 2 ohms.

- In the presence of a defect in the winding, the resistance will tend to infinity.

- If it is at a level below the threshold (0.4 Ohm), therefore, the turns are short in the coil.

- Then the secondary winding goes to check.

- We put a plus on the positive contact of the coil, and a minus. to the output of the high-voltage wire.

- We set the measurement on a multimeter up to 22 kOhm.

- With the tester’s readings tending to an infinite value, we conclude that there is a break.

- The normal operating resistance range ranges from 6 to 10 kΩ.

Thus, we have described another way of how to check the ignition coil.

detailed check

How to check if the ignition coil is working properly? After you have checked the coil for breakdowns visually and did not dare to pierce the body with a spark, proceed to more detailed search methods.

So how do you check the ignition coil and what is needed for this? To find a malfunction in the ignition system, you need to build a small circuit. You need to prepare the coil itself, a switch, a capacitor and some kind of battery (power source).

Now we collect the circuit:

- We connect one contact of the coil to the battery (to the primary winding).

- We interrupt the second contact through a capacitor and a switch (switched between the primary and secondary windings).

- The output from the secondary winding is connected to a switch and a capacitor. At this contact we make a gap (for the breakdown of the spark).

- You can insert a candle into the gap.

When the switch is closed, a spark must occur in the prepared contact break. Also, when checking, you need to inspect what color the spark will be. If it has a reddish tint, then this indicates a weak discharge. If such a syndrome can be traced, then the coil is hopelessly broken. It also indicates a breakdown between individual turns in the winding.

Thus, we can conclude that, before checking the serviceability of the ignition coil, you need to take a number of measures aimed at visually identifying a breakdown of the system.

General information

Ignition coils are widely used in engines with a carburetor and an injector. They can be produced in various variations: single, double, individual, multi-reel. Also, structurally, the coil can be made in various ways.

It is worth noting that an element such as an ignition coil is an ordinary transformer. It has two windings (primary and secondary) and a magnetic circuit (core). The secondary winding can consist of 5000-15000 turns of thin copper wire. The primary winding consists of 100-150 turns of thicker copper wire.

How to check the performance of the ignition coil?

If you have problems with the engine, namely with the ignition of the fuel, then in search of a malfunction, the gaze falls on the indicated element. How to check the ignition coil? The most common way to test this mechanism is the following sequence of actions:

- Unscrew the spark plug.

- Disconnect the high voltage wire.

- Now we take the wire to the side and insert a candle into it.

- We press it to the body of the car.

- We start the engine.

- In this case, a spark should break through on the car body.

- If there is no spark, then this indicates that the ignition coil has served its life, it must be replaced.

It is worth noting that it is not worth checking the coil in this way on some machines. So, for example, on a Honda, after such a check, the mechanism will immediately deteriorate.

How to check if the ignition coil is working? Before starting work, you should firmly make sure that it is she who affects the engine malfunction. Therefore, in order not to harm the car once again, a thorough inspection should be carried out.

Before checking the ignition coil for the supply of current from it, it is necessary to inspect its body for chips or breakdowns. After you get to the coil, determine if there is a breakdown on the body. To understand this, it is enough to inspect the adjacent walls to reveal burnt spots or black plaque. If such a fact takes place, then this indicates the presence of a breakdown. In this case, the coil should be replaced with a new one.

How to check the ignition coil with the device

The ignition coil is an integral part of the vehicle’s design. When it starts to work incorrectly or for some reason fails, then quite serious failures and problems appear in the operation of the power unit. Malfunctions in the ignition coil can cause the engine to stop or disrupt the rhythm of its operation. The element in question is part of the distributor. To exclude a breakdown of the ignition coil, it is necessary to check it according to the car diagnostic schedule.

Checking the ignition coil with a tester

There are many options for verifying this kind of mechanism. How to check the ignition coil with a tester? To carry out this procedure, you must take a device with the function of measuring the resistance of the circuit. All work is done quickly and easily.

- First, it is worth checking for the absence of a spark.

- The connector connected to the switch is connected to the coil.

- We connect the voltmeter to terminals 1 and 2.

- Turn on the ignition.

- The device should show a figure equal to the voltage on the battery.

- If there are digital discrepancies, then it is worth replacing the coil and rechecking.

How the ignition system works

To find out the main points due to which the coil fails, it is necessary to clarify the basic principles of the ignition system tied to the distributor. The distributor itself is nothing more than a distributor. A low-voltage discharge is applied to it, which is transferred to a large discharge on the winding. With the help of a breaker, the contact on the coil is opened; in fact, at this moment, it is fed through high-voltage wires to each cylinder.

In the cylinder, this discharge manifests itself in the form of a spark on the candle, due to which the fuel mixture is ignited. If the supply of current to the spark plug is carried out out of time or is not carried out at all, then the engine will stop working.

Methods for checking ignition coils

The ability to determine the cause of a breakdown of the ignition coil will always be useful and relevant for every car owner, because this unit is one of the most important in the design of an internal combustion engine.

A small malfunction in this part can cause unstable engine operation, and complete failure can cause engine failure.

Even taking into account the fact that ignition coils are quite reliable and rarely break, they still fail, and the following reasons can serve as the most common reasons for this:

- overheating, increased voltage or vibration can damage the insulation, which in turn leads to a short circuit in the coil winding;

- defective spark plugs or damaged high-voltage wires cause overloads in the coil, which can lead to winding breakage.

There are two ways to check the bobbin at home: the formation of a spark between the spark plugs and the car body, or using a coil tester (multimeter). At the first signs of unstable operation of a gasoline internal combustion engine, first of all, it is worth checking the ignition coil.

Despite the equal effectiveness of these two methods of checking the coil, the first one has recently been, not only undesirable, but also dangerous for both a person and a car. The spark created can cause serious injury or, in the worst case scenario, kill a person.

Also, this method can completely disable the ignition coil itself and all the electronics of the car (especially important for modern cars). Therefore, it is worth abandoning the “popular” method and resorting to checking the ignition coil with a tester.

How to check the ignition coil with a tester

Every car enthusiast knows that a malfunction of the ignition coil causes problems with starting a gasoline internal combustion engine. Carrying out computer diagnostics does not always help to identify a problem in the coil, since this method can only detect a misfire in any cylinder of the engine. Further check of the coil has to be done in the old fashioned way, manually.

The purpose of the ignition coil

The main task of ignition coils is to transform the low-voltage electrical current from a battery or generator into a high-voltage electrical impulse that generates a spark in the spark plugs.

Spark plugs can be divided into three types according to the type of electrical breakdown gap:

- one-petal;

- two-petal;

- three-petal.

The gap ranges from 0.4 to 1.1 mm, this distance depends on the technical characteristics of the motor. The average value of the power required to create an electrical impulse in air between two contacts is considered to be 6 kV per 1 mm of gap.

However, taking into account the voltage decrease at the limiting resistance in the high-voltage ignition wires, the pulse power should be 10-20 kV.

It is important to remember that spark plugs generate enough electrical discharge to cause serious injury or death.

For this, it is worth using special protective rubber gloves (standard protective gloves do not provide a sufficient degree of protection, since their breakdown voltage is only 6.3 kV).

Checking the coil with a multimeter

The multimeter is a versatile device for determining various characteristics of electricity. Such a device is quite widespread and is commercially available.

The following will give a detailed answer to the question: how to check the ignition coil with a multimeter. To do this, follow these steps:

- First you need to disconnect the “minus” on the car battery, unscrew the brackets a little, disconnect the coil wiring and clean its body. A visual inspection of the coil is also necessary at this stage. If cracks or other serious damage were found on its body, then it is necessary to completely replace the ignition coil. In this case, it is important to remember that the new coil must be selected in strict accordance with the technical characteristics: winding resistance, inductance and current of the primary winding, energy and duration of the spark.

- Next, the resistance of the primary winding is checked. To do this, the multimeter probes must be connected to the positive and negative terminals of the coil, and the tester must be configured to measure resistance. The coils of different cars have different resistance values, and you can find out this value in the instructions for the car. However, all ignition coils have a resistance in the 0.4-2 ohm range. If the multimeter, when measuring the resistance, showed a value that is included in this range, this will mean that the coil is working. If the display shows a value of 0 Ohm, these readings will mean that a short circuit has occurred in the winding, and with a value of infinity, an open circuit has occurred. Also, in order to check the integrity of the coil cables, it can be called.

- After checking the resistance of the primary winding, a similar check must be carried out for the secondary winding. For this, the probes of the multimeter are connected to the positive contact and to the high voltage wire. If the coil has a lamellar core, the resistance value will be in the range from 6 to 8 kOhm. For other types of ignition coils, this characteristic can exceed 15 kOhm.

- After determining the resistance of both windings, the obtained readings must be compared with the standard values for the tested coil.

Double coil testing is more difficult because the primary winding in such coils is connected to the connector. The dual coil circuit is different from the usual one and its knowledge is important when checking the primary winding. The secondary winding will ring without any problems, for this the multimeter must be connected to two high-voltage terminals.

Any ignition coil refers to ultra-precise and hypersensitive devices and any deviation of the actual readings from the norm can lead to serious malfunctions of the car during its further operation. Also, the inductance coil is the device that cannot be repaired and if it malfunctions, it must be replaced.

How to check the ignition coil

One of the most important elements of the ignition system of any gasoline engine is the coil. It is she who is considered the main unit of contact, contactless, as well as electronic ignition systems, playing the role of a kind of energy storage device intended for further distribution of the charge over the cylinders.

Methods for checking the ignition coil

Checking the ignition coil by the “old-fashioned” method can damage the electrician of a modern car

For proper self-checking of this car part, it is recommended to perform certain actions in stages. First of all, after removing the coil, you need to visually inspect it and make sure that there are no external signs of a short circuit: black dots indicating burnout, cracks, or other signs of breakdown.

In our country, for a long time, there were two equally popular ways of how to check the ignition coil for operability: by checking the spark between the car body and the spark plug or by measuring the resistance of the windings with a multimeter (tester). The use of the first method can be fatal not only for the coil, but also for the electronics of most modern cars, therefore, its use is strongly discouraged by manufacturers. It is safer to check this unit of the car with a measuring device.

Causes of coil malfunction

Partial damage to the ignition coil leads to unstable engine operation, and its complete breakdown makes it completely impossible to start the engine. That is why, when the engine is tripled, its power is lost, or other signs of fuzzy operation, one of the first steps should be to check the ignition coil. This element fails quite rarely, and the malfunction, as a rule, consists in the following:

- Insulation damage due to strong heat, vibration or high voltage, which in turn leads to a short circuit in the coil windings;

- Overloading caused by faulty high voltage wires or spark plugs can cause the coil winding to break.

Using a multimeter when checking a coil

In order to independently get a complete picture of the health of an element of the ignition system, you need to figure out how to check the ignition coil with a multimeter. This procedure should not cause any particular difficulties.

First, the primary winding is checked, to the positive and negative contacts of which the device is connected in the resistance measurement mode. Factory default values may vary slightly from manufacturer to manufacturer, but average resistance values should be between 0.4 and 2.0 ohms. If the device shows zero resistance, then a short circuit has occurred in the coil, if infinity, you need to look for an open circuit.

Checking the ignition coil with a tester

To check the secondary winding, a multimeter is connected to the positive terminal of the coil and the terminal from the high voltage wire. The resistance value of this winding for coils with a lamellar core is 6-8 kOhm, for other types. the parameter may exceed 15 kOhm.

It is possible to draw a conclusion about whether the obtained indicators are within the limits established for a particular model, it is possible only having an idea of its other technical characteristics: duration and energy of the spark discharge, spark discharge current and the value of the inductance of the primary winding.

Any malfunction of the ignition coil badly affects the efficiency of the car engine, and this can lead to a decrease in its durability. That is why its timely diagnosis and repair (or replacement) is necessary, if necessary.

Causes of malfunctions

There are several reasons due to which the ignition coil fails completely or partially. Among them:

- Mechanical damage. This can be trivial aging, due to which the destruction of insulation occurs. There is also the possibility of oil leaking through the seals, which gets on the insulation or coil body and destroys them. Repair in this case is hardly possible, so the best option would be a complete replacement of the unit.

- Damage to the contact connection. In warm weather, this may be due to moisture entering the engine compartment. For example, during heavy rain, driving through deep puddles, car wash. In winter, it is likely that the composition sprinkled on the road surface to combat icing is likely to hit the coil.

- Overheat. Individual coils are often subject to it. Overheating can significantly reduce the life of the ignition coils. Overheating is difficult to control, but try to use good quality coolant and ensure that the engine cooling system is working properly.

- Vibration. They are especially detrimental to individual ignition coils. Vibration usually comes from the cylinder head (cylinder head). To reduce the number and amplitude of vibrations, make sure that the engine runs in normal mode (without detonation and with serviceable airbags).

Ignition coils are fairly reliable and durable units, and their failure is most often associated with aging and / or insulation breakdown. Next, consider the methods for diagnosing coils.

The principle of operation of the ignition coil

As mentioned above, the ignition coil is a step-up voltage transformer that converts the resulting 12 V voltage into a voltage of several kilovolts. Structurally, the coil consists of two windings. primary and secondary (respectively, low and high voltage). However, depending on the type of coil, the windings and their locations differ.

Let’s start with the simplest common coil. There are 100.150 turns on the primary here. The winding is wound with insulated copper wire. Its ends are brought out to the coil body. The number of turns of the high voltage winding is 30.50 thousand (depending on the model). Naturally, the wire used here is of a much smaller diameter. The “minus” of the secondary winding is connected to the “minus” of the primary. And the “plus” is connected to the terminal on the lid. In this way, the resulting high voltage is diverted.

To increase the magnetic field, the windings are wound around a metal core. In some cases, to avoid overheating, the winding and core are filled with transformer oil (it not only cools the system, but also acts as an insulator).

Individual ignition coils are installed in electronic ignition systems. Therefore, their design is complicated. So, to cut off a significant current in the secondary winding, a diode is provided. Also, a feature of the individual coil is the fact that the resulting high voltage goes not to the distributor (as in classic systems), but directly to the spark plugs. This was made possible by a design that included an insulated body, rod and spring.

Another type of coil is two-lead. It supplies voltage to two cylinders at once. There are several varieties of them. As a rule, such coils are combined into one common unit, which is essentially a four-terminal ignition coil.

Regardless of the type of ignition coil, their main technical parameter, which should be guided by when diagnosing, is the resistance of the windings. In particular, the resistance of the primary winding is usually in the range of 0.5. 3.5 Ohm, and the secondary. 6.15 kOhm (these values may differ for different coils, so it is better to find reference information for the model that is used in your car). Measurements are made using traditional instruments. multimeters or ohmmeters. If the value obtained is very different from the indicated one, then there is a high probability that the coil is out of order.

You also need to be aware of the fact that each coil has different indicators:

- winding resistance;

- spark duration;

- spark energy;

- spark current;

- primary inductance.

Therefore, in order to understand how the coil readings correspond to the norm, it is necessary to clarify the technical characteristics of your individual coil. This is especially useful if the spark is missing, since the ignition coil is one of the first elements of the system to be checked.

Symptoms of malfunctions

There are several characteristic signs of a malfunctioning ignition coil. Among them:

- the motor begins to “triple”, and this problem is aggravated over time;

- in the cold, the motor “troit” until it warms up;

- interruptions in engine operation in wet weather;

- when the accelerator pedal is pressed sharply, there is a failure in the motor.

If the coil is faulty on cars with an ECU, the Check Engine icon is activated on the dashboard. However, the listed signs may also indicate other malfunctions, in particular, with spark plugs. But when at least one of them appears, you need to diagnose the ignition coil (s). When connecting a diagnostic scanner, it may show a P0363 code.

How to check the ignition coil

The ignition coil is designed to generate high voltage, which is then used by the spark plug. Therefore, its proper operation is necessary for the normal functioning of the ignition system. In fact, the coil is a small transformer, to the primary winding of which comes standard 12 V from the battery, and a voltage of several kV comes out. It is used in all ignition systems. contact, contactless and electronic. The reasons for coil failure are typical. As a rule, this is a wire break, insulation damage, mechanical deformation. Next, we will consider the symptoms of a malfunction and methods for diagnosing the ignition coil.

How to check the ignition coil

There are two main ways by which you can independently check the performance of the ignition coil. Let’s list them in order.

No sparking

If the magneto does not spark at all, the main cause is an open circuit in one of the transformer circuits (primary or secondary). The defective part must be replaced to fix the mower. If the primary circuit is shorted to ground, it can also cause no spark. You need to fix it to fix the problem.

On a note! Broken insulation of the high-voltage wire can also cause damage. You can correct the situation by replacing the wiring.

Disassembling magneto

Disassembling the magneto is very simple. First you need to remove this device from the engine and clean it, removing oil particles and dirt. Further, since the ignition timing machine is securely fastened, you need to unscrew the nut, and then remove the part and pull the key out of the groove. The cover is fixed with four screws; to remove it, you need to unscrew and remove the fasteners. Then you need to pull the magneto rotor out of the case, unscrew the pins holding the transformer, and get it out. And to collect the magneto, you need to follow the steps described above in reverse order.

Functional check

Before starting to diagnose magneto, you need to make sure that the problem is actually in this node. To do this, you need to check the entire chain and make sure that there are no other reasons for the breakage of the trimmer.

- First, you should carefully inspect the coil for cracks and other external defects on the case. Next, you need to examine all the elements and nodes that conduct current, and make sure that they are clean.

- The next step is to inspect the high voltage wires. They must be in good working order and securely attached to the contacts, free from rust and with intact insulation.

- The next step is to check the plug cap. As a result of careless actions, the user often tears it off the high-voltage wire, and then improvises and creates a homemade mount. You need to understand that any poor-quality connection in this place significantly reduces the power of the electric arc of the candle.

- Then you should make sure that the candle itself is in good order. Filling the mower with poor quality gasoline will significantly reduce the life of this part. In addition, it can be flooded or have a large carbon deposit that interferes with operation. Sometimes the candle even sticks and does not unscrew.

- Next, you need to inspect the circuit breaker. On trimmers and chainsaws made in China, it often breaks down.

After completing all these steps and excluding the listed nodes from the list of possible causes of failure, you should proceed to checking the coil. This can be done in several ways.

Replacing the magneto

Advice! Another good solution would be to provide an old ignition coil so the seller can pick up a new part.

To remove the magneto, you need to remove the plastic cover from the trimmer. This process is different on different lawnmower models. It is usually necessary to remove the bolts, but on some petrol trims it may be necessary to depress the latches. After that, access to the coil is opened. To remove the part, you need to unscrew the retaining fasteners and disconnect the wires.

When installing a new part, you need to correctly set the distance between the flywheel and the magneto. To do this, turn the flywheel upwards with the magnets, install the coil and secure it, but do not fully tighten the screws so that there is a small distance between the parts. Next, between the coil and the flywheel, you need to put a calendar, a business card or a A4 paper sheet folded in four, you can also use a plastic strip cut from a bottle. These tweaks will ensure adequate clearance between the flywheel and the magneto. A more competent solution would be to use a special template, but purchasing it for the sake of once is impractical. Next, you need to tighten the fasteners, remove the object between the parts, and, holding the magneto with your hands so that it does not spin, tighten the fixing screws tightly. After that, you should turn the flywheel and make sure that it does not catch the coil anywhere. Now you need to connect the wires and insert the candle into the cap, and then check the operation of the device.

Do-it-yourself troubleshooting

In order to repair the magneto with your own hands without the involvement of specialists, you need to know how to disassemble it, and how to change the breaker contacts to new ones.

Method 2

Magneto diagnostics using a multimeter is a solution that can be implemented on your own with such a measuring device. In this case, it is necessary to do the following.

- Switch on resistance mode on the Meter and set to 200 ohms to test the primary winding.

- Connect multimeter electrodes to magneto ground and output terminal. If the winding is intact, the resistance will vary from 0.4 to 2 ohms.

- Switch on the 20 kΩ tester to perform a secondary diagnosis. In this case, the first probe is connected to the “mass”, and the second is installed in the spark plug cap. Normal values are at least 4-6 com. If the circuit is damaged, then the tester will show infinity, and in case of a short circuit. zero.

The exact data on what the tester should read during the primary and secondary winding check can be found in the instructions for use of the trimmer.

Typical problems. causes

The faults that most often occur with magneto are typical for trimmers from different manufacturers. As a rule, this is a weak spark or its absence, as well as the presence of interruptions in this process.

Magneto. design and operating principle

The purpose of the ignition coil is to convert the rotational energy into a high-voltage discharge and form a spark that ignites the fuel mixture. In an internal combustion engine, this part is called a magneto, since in it an alternating current is generated from the rotation of a permanent magnetic rotor or an armature.

Magneto structurally consists of two windings: high and low voltage. A capacitor with breaker contacts is connected in parallel to the latter. Whereas the leads of the high voltage winding are connected to the candle and the body. Both of them are wound on a core, between the poles of which a rotating magnet is installed, magnetized longitudinally.

On a note! The whole structure looks like a large coil mounted on a U-shaped core.

Diagnosis of engine ignition systems: checking high-voltage wires

By themselves, high-voltage wires cannot burn out, since they have a large cross section. But their insulation can be damaged. This is due to the fact that it comes into contact with hot parts of the engine. Despite the heat resistance, over time it melts, and the current-carrying wire is exposed, closing to the motor case. Also, damaged areas can appear due to carelessness during engine maintenance. In both cases, when shorting to the body, a spark on the spark plugs will not be generated. Such diagnostics of the car ignition system is performed visually, since the damaged insulation is visible with the naked eye.

You should also pay attention to the terminals. If they are caked or oxidized, they must be cleaned as this is the reason for the lack of contact. The absence of damaged areas, as well as burnt terminals on the wires, means that the ignition coil has broken, checking it is the next stage of diagnostics. It is performed using a multimeter. a device available in every private garage. Even if he is not at hand, he should be with a neighbor, and therefore it will not be difficult to take him for a while.

Checking the ignition coil on a car

Every car owner should know how to check the bobbin (ignition coil). It is simple in design, but it does an important job. It is this device that creates the high voltage required by the candles to generate a spark. When the engine does not start or suddenly stalls, the ignition system components are checked first. Then the devices for feeding the combustible mixture are considered. Checking the car’s ignition system involves testing the candles for integrity, inspecting the wires and, in fact, checking the bobbin itself. Let’s consider each stage in detail.

Training

For those who do not know how to check the ignition coil with a multimeter, we will immediately make a reservation that the preparatory work consists in finding the device itself and the technical documentation attached to the car. The latter is necessary to find out the parameters of the resistance of the windings, because such devices differ depending on the make and model of the car. If such documentation is lost, you can find the necessary data using the Internet. It is necessary to find out the resistance limits at which the device operates normally.

How to check the ignition if there is a suspicion of candles

You can determine the absence of a spark by flooded candles. If they are in gasoline, then the fuel is not flammable. In this case, the ignition system is not checked with a tester, but a special device with a piezoelectric element is used. Using it, you can generate a spark between the electrodes of the candle. If it is missing, then the product is out of order. The presence of a spark, on the other hand, means that the device is working properly, and therefore the cause should be looked for in other areas. Breakage of candles in most cases consists in burning out the contact surface of the electrodes or soldering them together. This happens due to overheating, when the combustible mixture is assembled incorrectly or the engine cooling system does not work correctly.

Visual check

A visual check of the ignition coil on a car is performed to identify mechanical chips, cracks of various sizes or melted areas on the body. Such damage often occurs due to the fact that manufacturers generally make the case from ebonite, which is not resistant to mechanical and thermal stress. If such damage is not observed, then the cause of the breakdown must be looked for inside, for which it is enough to check the ignition coil with a tester, which we will consider below.

Checking the ignition coil with a multimeter

Now we have come to the most important thing, because we will consider how to test the main parts of the device, on which its performance depends. There is only one method to check the ignition coil, since most of the breakdowns consist in breaking the circuit between the internal windings. A low-voltage voltage of 12 volts is applied to one of them and, passing through the other, it rises to 30-40 thousand volts. And if we are talking about the integrity of the internal wiring circuit, then you need to know how to ring the ignition coil in order to determine its performance. Once again, we will make a reservation that the design of this device is quite simple, and in addition to a case with two windings, they have a contact group. The latter includes the main terminal, as well as input and output contacts. Nevertheless, despite the simple device, checking the ignition system with a multimeter is performed in three stages:

thorough visual inspection;

In the conditions of dealerships, these devices are checked at certified stands. But when solving a problem in your garage, you need to understand how to check the ignition coils with a multimeter. Let’s consider the process step by step.

Check

This device is located in the distributor, to disconnect the wires from it, you need to move the latch. After that, the contact group will become available for measurements. Next, you need to know how to check the ignition coil with a tester in order to avoid mistakes. In particular, the appropriate mode must be selected on the resistance meter. Further, the measuring wires must be applied so that one touches the body of the machine, and the other touches the output of the device. When the ignition coil is operating within normal limits, a tester test will show a voltage of 12 V. A value of zero indicates a problem in the electrical circuits of the distributor or the electronics of the power unit.

Further, checking the ignition coil with a tester consists in diagnosing the windings. You must connect one multimeter probe to the center terminal and the other to the input or output terminal. The secondary winding is considered serviceable with a resistance of 6-8 kOhm. This value is relevant for most of such devices installed on cars, but it is better to find out how to check the ignition coil and find out the optimal resistance of both windings in the technical passport of the car. This is due to the fact that for many models, the normal resistance is 13-15 kOhm. To find out the resistance of the primary winding, you must use the plus and minus devices to measure. A value of 0.5-2 ohms means that the winding is intact. If the numbers are different, then there is a break.

If you need ignition coil diagnostics, Kiev has several Oiler car services offering similar services. The foremen of each service station will quickly perform diagnostics and determine the operability of this device.

Checking the ignition coil with your own hands. the best ways

Date: 2017-05-16

This part in the car system plays an important role, since it is it that supplies the candles with direct current, which creates a spark that ignites the combustible mixture in the combustion chamber. If it is faulty, then the motorist needs to check the individual ignition coils. How to check the ignition coil with your own hands will be described below.

- Existing faults

- Troubleshooting Ways

- Spark testing

- Tester check

- Checking with a multimeter

- Oscilloscope check

Spark testing

How to ring the ignition coil this way. This method is used by motorists if they do not have special devices.

This requires two people. The first inspector will turn on the ignition at the right time, and the second will observe the presence of a spark.

The motorist must disconnect the armor-piercing (high-voltage) wire from the spark plug, and then unscrew the spark plug. Next, you need to take pliers with insulated handles, and take a candle with them, which should touch the metal surface of the power unit with the upper electrode.

A high-voltage wire must be put on the top of the candle, and the second person turns on the ignition, which closes the circuit, and, logically, an electric current flows to the candle, which creates a spark. It should be blue.

If there is no spark at all, or it is red, the coil is faulty, which does not supply current at all, or it is too weak.

Another way is this. It is necessary to wait until dark, then turn on the ignition and carefully look at the high-voltage wires, if sparks run through them, then the winding is broken. This indicates the serviceability of the ignition coil, but not the suitability of the wires themselves, which need to be replaced or insulated.

Existing faults

As mentioned above, these devices serve to supply electric current to the electrodes of the spark plugs, from which a spark is subsequently formed. It ignites the air / fuel mixture and the car moves.

If this part is in good working order, then the power unit is working properly, without any deviations, and there is no need to check the ignition coils. If malfunctions or problems are noticed (the engine is troit, black smoke appears in the exhaust pipe), then the spark of the candles does not appear at all, or its power is weak.

Malfunctions are as follows:

- the winding is damaged. this leads to the fact that the current in the circuit breaks through to the body of the part, therefore it does not create a spark in the combustion chamber;

- the circuit is broken or the coil is overloaded. this leads to the appearance of short circuits, violation of the insulating protective layer, and complete loss of spark.

PushMowerRepair.com. Testing a Victa Ignition Coil

If such malfunctions of the ignition coil occur, it means that they must be identified and repaired, or completely replaced.

Testing and replacing the ignition coil on a Stihl FS 80R string trimmer

Checking with a multimeter

Checking the ignition coil with a multimeter is also not very difficult. In essence, this device is the same as an electrical tester, but it differs in the presence of additional functions.

In fact, checking a given part with this electrical device is no different from a tester, so the method is the same as described above. Here, too, it is necessary to test the primary and secondary windings, which are on the coil.

With such a device, you can effectively check the ignition circuit for the Skoda Octavia.

Tester check

How to check the ignition coil with a tester. This device is also called a surge arrester. The essence of the check is as follows.

This device for testing (arrester) consists of a special case, to which two wires with clamps at the ends are connected. In the center of its body there is a screen on which there is a scale and an arrow, as well as a special relay, which is set to a certain resistance.

Before using the spark gap, you need to disconnect the ignition coil and wires from it.

Further, when visually inspecting it, you can see the presence of three side contacts, which represent the primary winding. The contact in the center does not participate in the verification. The arrester (its terminals) must be connected to the extreme left and right contacts, then set the required resistance and turn on.

The arrow on the screen will immediately show if the circuit is working normally, or if a short circuit occurs in it (this part is faulty).

Then you need to view the secondary winding. To do this, the arrester must be connected with one terminal to the extreme right or left side contact, and the second terminal to the central contact, which is located at the very top of the coil.

After that, the required resistance is set, and the device turns on, showing the resistance of the circuit. If there is a short circuit, then the secondary winding is faulty.

Now you need to decide what resistance the primary and secondary circuits should have. To do this, you need to take the technical documentation for the car, or specifically on the coil that is installed.

If there is no such documentation, then you need to use the following numbers:

- 0.7. 1.7 Ohm, this resistance is typical for the primary winding;

- 8-15 kOhm, these indicators are typical for the secondary winding.

Troubleshooting Ways

Naturally, it is possible to identify a malfunction if you come to a service station, but for this you have to spend a round sum of money, plus add the purchase of a new part to the costs. Therefore, in order to save money, it is best to check the modules and ignition coils at home.

There are several time-tested ways to do this:

- spark testing, this method is used if there are no special devices on hand;

- ringing out the entire electrical circuit;

- checking the ignition coil with a multimeter, a special electrical device;

- checking with a special electrical tester, this is a device for testing coils, based on diagnosing the resistance of an electrical circuit;

- checking the ignition coils with an oscilloscope, this is also a special electrical device with a monitor.

It is important to remember that before starting to check the coil, it is best to unscrew the plugs and check them for serviceability. If cracks are found on them, spalling of the protective case of the lower electrode, melting, then the reason is in them and it is not worth checking the ignition coil.

Now let’s look at all the ways how to check the performance of the ignition coil.

Oscilloscope check

How to check the health of the ignition coil using an oscilloscope. It is a complex electrical device that is used in various fields of electrical and electronic.

Ignition coils, check, therefore, occurs according to the following algorithm.

- The oscilloscope sensor is attached to the high voltage wire. It comes out of this part and leads to the spark plug. Then the device itself turns on and the motor starts.

- A waveform appears on the oscilloscope screen. This image, which shows the moment of accumulation of electricity in the primary circuit, then energy is supplied to the secondary circuit, after which the spark plug gap begins to break down, the spark burns and the current decays.

It is better to look at this process visually on the following diagram:

Of course, for those motorists who are poorly versed in this diagnosis, it is better not to resort to this method of checking, since, due to their inexperience, they will not be able to find out the reason for the poor performance of the candles.

This method is most often used at specialized service stations that carry out comprehensive diagnostics of the electrical wiring of the car.

Therefore, when giving recommendations to motorists about the ignition coil, how to test it for performance, it should be noted that the best ways at home are to ring it and the electrical circuit, as well as to use a multimeter or electrical tester.

It is important to remember that sometimes the cause of poor performance of the power unit can be wires, the winding of which is broken, and a spark breaks through them onto the body. Therefore, you also need to check them carefully.

Checking the ignition coils for operability and serviceability can take place at home, using special electrical devices, or by ringing high-voltage wires. The above are recommendations on how to do it correctly.