How to configure the ignition on the chainsaw. The device and principle of operation of the gaspile ignition system

Installation of the ignition on the chainsaw

If at one fine moment the chainsaws suddenly did not start and this is not the only such case, it means that the ignition of the chainsaw will be adjusted for more than ever by the way. It must be produced in the following sequence:

Wabled candles are always dry. Having discovered that the candle is quite wet, it is worth switching your attention to the carburetor, the problems of which can lead to the bay of the candle part and prevent sparking. The presence of a dark plaque is a signal that there are problems in the cylinder.Piston elements of the motor. If the previous point of the audit did not give visible results, the next step needs to be checked if there is a spark

To do this, it is necessary to move the cable coming from the candle to the cylinder. At the time of a small gap between these parts, a spark is necessarily distinguished. In the absence of a spark, we proceed to checking the voltage. Its absence can mean only one thing. The integrity of the wire has been violated. If the high.Voltage cable is serviceable, it is worth redeeming the angle of installation of the ignition, because its non.Compliance can cause the spark either “hurries”, appearing too early, or “deeds”, not having time to light the fuel. After all, all leading experts FOCUS on the fact that the adjusted gap between the flywheel and the ignition coil is the basis of the timely formation of the spark, and as a result. The trouble.Free start of the motor and uninterrupted operation. Another option, which must be taken into account by checking and correcting all previous points, is a candle itself, which could be worn out and demand a replacement for a new. A benign spark from a new working candle looks like a zipper. If it is dull, it is worth studying in detail the quality of the spark.

For this, the high.Voltage wire is connected directly to the candle. Then the starter is launched with jerking movements. Based on the results of observations, we can conclude whether to change the candle or not.

The main problems and malfunctions of the carburetor.

Mesh filter. Only two obstacles often arise with this element:

In order to find out the cause of the breakdown, unscrew the fuel filter lid to remove the strainer. If dirt simply accumulates on it, then rinsing with gasoline or purging will help.

If there is a visible damage to the strain, you must definitely install a new. Fuel supply pipes can also be damaged (during repair, they practice checking this element).

Carburetor starter in most cases does not work as a carcass. For washing, use acetone or the same gasoline.

Blowing parts of a carburetor with clogging compressed air is acceptable and convenient repair practice.

The housing of the throttle, the location of the parts of the carburetor, the intake or output pipeline, all these parts are subject to depressurization. Perhaps you can check the problem area in a simple way with soap foam.

Structural components

All gasoline two.Stroke engines have a similar principle of operation, and therefore the ignition system in them has a typical structure and device.

The ignition device of the chainsaw:

- Magneto: a device that converts the mechanical energy into an electrical energy, provides a current pulse to the lighting of the fuel of the chainsaw;

- Spend of the ignition: designed to ignite the fuel-air mixture through the category that occurs between the electrodes;

- Electric cable;

- Engine shutdown button.

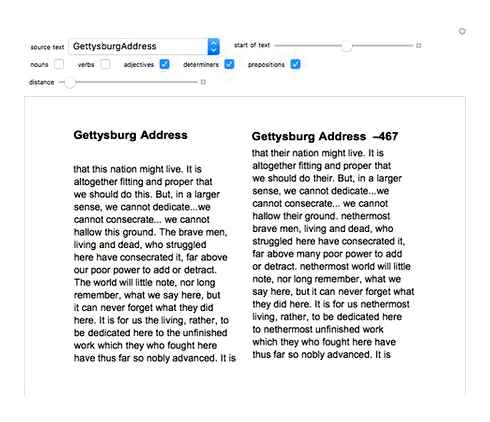

Candles are spark, arc, incandescent and catalytic. In the devices of the chainsaws, spark candles for 2-stroke engines are used. The schematic scheme of the chainsaw is shown in the image.

The Chainsaw Guy Shop Talk Vintage McCullough Ignition Repair

Causes of problems

Когда бензопила не запускается с первого раза, рекомендуется осмотреть провода, которые связны с катушкой. So you can find:

Important! Damage to internal isolation during examination cannot be identified.

If everything is in order with the initial assessment of the coil, you need to look for the cause of the breakdown in the toggle switch (you need to disconnect the module from the wires). Do not know how to check the ignition on the chainsaw? To start:

- Assess the state of the electrode (it can fail due to wear), check the integrity of the insulator from ceramics;

- Examine the removable valve, which should fit tightly (not in all models it is removed);

- Brown plaque on ceramics of the winding indicates a walking spark;

- Looking for a crack in a candle (sometimes a cap is cracking).

Как отключить брандмауэр Windows 11.Как выключить брандмауэр.Отключение брандмауэра

Carefully inspect the coil for the presence of traces of fuel. The candle should be dry (the traces of deposits should have a light color). If you find excess fuel, then the problem may be in the carburetor, which, supplying a large amount of gasoline, floods the candle. In addition, plaque may indicate a change in the geometry of such components of a chainsaw as a piston and cylinder.

A thorough check

If the preliminary assessment of the state of the coil did not give results, you need to carry out a thorough diagnosis.

- Experts recommend taking the multimeter and check the level of resistance of the coil. Learn the optimal indicators of your model (this information is in the instructions for the chainsaw). Keep in mind that sometimes the “call” ends with the “chain rupture” indication, you should not panic, since semiconductor parts are used in many saws. A positive result of the audit indicates the presence of a malfunction.

- Checking the serviceability of an electrical circuit. The cable is leaning against the gap between the cylinder and the reel. In the absence of a spark of breakdown, we can conclude that the malfunction of the high.Voltage cable, damage to internal isolation.

- Verification of the presence of a spark (a special device is also used). The testing device is placed between the output of the coil and the flask flag (this place is called the rupture of the chain). Pay attention to the data displayed on the measuring device screen, compare them with optimal for your chainsaw. This method of verification can be allowed in “home” not all, since special equipment is expensive.

- Performing homemade ignition. This test involves the use of a candle. It is taken out and leaning against the cylinder body, while starting the starter. Follow the spark. The method is not the most reliable due to the non-standard speed of rotation of the flywheel (since the position of the candle is unnatural), but many masters actively use it.

In the field, when the above methods of ignition testing are not available, resort to this method.

- For the method, you will need a clove without a hat, which is placed close to the cylinder. 7 millimeters from it. Keep care so as not to damage the part.

- Pull the starter and follow the spark. If it appears and will be bright, there is no malfunctions.

The method is useful if there is no electronic nodes. In addition, you will have to adhere to such rules.

- Do not unscrew the candle completely so as not to accelerate the rotation of the flywheel. This will negatively affect the engine work.

- The candle is placed so that the distance between it and the cylinder is no less than that recommended taking into account the compression model of saw and dielectric properties of the used fuel mixture (on average placed at a distance of 7 millimeters).

The ignition angle angle

Mechanical device and factory installation of Magneto ensure the coincidence of the time of the candle discharge with the optimal position of the moving piston. For four.Stroke gasoline engines, the passage of the spark should occur even before the piston arrives at the upper dead point. This is due to the fact that the process of complete fire of the fuel mixture takes a certain time. The speed of the engine parts is comparable with the speed of ignition of fuel, so the piston from the moment the spark is up to the moment with burning gases of extremely high pressure manages to go some path.

For each engine, there is an angle of ignition ahead. It is equal to the turn of the crank in degrees from the moment of breakdown in the interelectrode space of the spark plug until the piston is in the upper dead point. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

STIHL MS 361 IGNITION MODULE REPAIR “MUST SEE FOR ALL STIHL OWNERS”

In what cases is the ignition setting is required? There are main symptoms of a system failure:

In these cases, you should not rush to contact the service center. Try to adjust the ignition on your own first.

Block: 3/4 | Summer characters: 1545Source: http: // tehnika.Expert/Dlya-Sada/Benzopila/Vystavit-Zazhiganie.HTML

How to set a ignition on a chainsaw?

Install the ignition on a household chainsaw is definitely required if the garden tool does not start. The control of the ignition of the chainsaws will improve the normal joint operation of the factory engine and other work mechanisms of the chainsaw.

Before adjusting the ignition on the chainsaw, you need to carefully examine the candle. It should not be completely dry or abundantly flooded with oil. If a thick layer of soil has formed on the candle used, then it will need to be cleaned and dried.

Next, you need to correctly set the gap between the flywheel and the ignition coil on the chainsaw:

- First you need to remove the left side cover of the protective plastic case;

- A coil and a flywheel are located under it. Near the flywheel there are 2 screws that are responsible for the offset of the element. The simultaneous turning of both screws counterclockwise will help to slightly push the flywheel from the ignition coil;

- As soon as the element is shifted, to the side of the coil, you need to motionly attach the template. A gasket with a thickness of 0.2 mm. The thickness of the template is directly proportional to the necessary gap between the flywheel and the coil ;;

- Further, without violating the position of the template, it will be necessary to start screwing the screws along the clock of the clock. This must be done until the flywheel is close to the template.

After setting up the gap, the system will need to be checked by a multimeter. At the same time, the indications on the device correspond to the instructions in the operating instructions.

Shtil 180 gap between the coil and the magnet

The ropper of the Shtil MS 180 is considered one of the most reliable among the models of its segment. But the technique is a technique, and sometimes there are malfunctions, to eliminate which it may be required to repair the STIHL MS 180.

Read more about the repair of nodes, you will find out by reading the article.

Is it possible to repair a saw with your own hands?

This is the very first question that arises before the owner of the chainsaw of Shtil 180, which for some reason ceased to function normally. To answer which will definitely not work. It will be correct to say: it is possible, but is it necessary? Of course, it is more expensive to repair the chainsaws in the service center than to try to fix the problems with your own hands, but using the services of specialists, you will receive guarantees and confidence that the chainsaws will be correctly configured and adjusted. In general, the choice is yours.

Another small nuance regarding the choice of repair independently or not is that for the diagnosis of a chainsaw and its further disassembly and repair, it is necessary to have some specific tools and certain knowledge of the construction of the saw. Otherwise, you will not even be able to unscrew and remove the flywheel without damaging.

Conducting independent repair of the saw, very often break off aluminum fan blades located on the flywheel. This is because during disassembly they do not use a special stopper of the crankshaft, but try to fix by installing a screwdriver between the saw case and the flaps of the flywheel, which leads to sad consequences. The flywheel nut has a serious tightening moment, and the blades are fragile and are not able to withstand such efforts.

Timely diagnosis is one of the chances of salvation of details

As practice shows, the problem is easier to eliminate even at the stage of its development than when the technique has already completely refused to work. For this, it is necessary to carry out inspection of all parts and nodes in time, not only visual. Its worthy replacement is a hardware method that is popular lately.

Testers were able to combine different devices for measuring voltage, resistance and current strength.

But before checking the ignition coil of the chainsaws with a multimeter, it is worthwhile to read the instruction to the chainsaw in detail to own the original information regarding its normal technical parameters, which will compare the values obtained on the tester.

The sequence of verification is as follows:

- Check the primary winding (zero resistance means problem with the coil, and “و”. The rupture of the wire);

- The secondary winding is examined by connecting the scanner to the high.Voltage wire and contact with the sign “”.

As you can see, the ignition system is considered one of the most capricious in any technique working on gasoline, but everyone can understand it.

Installation on new chainsaws of electrical chips that regulate this process without human participation allows you to avoid many points. However, they are practically not amenable to repair, like an ignition on more obsolete models.