How to connect a screwdriver to a transformer. Pipping connectors of the power supply unit AT and ATX

How to make a network from a battery screwdriver

A screwdriver with a battery is useful in home economic activity, in construction, as well as when assembling a wide variety of structures, power tools. Its main advantage is the ability to perform work autonomously until the nutrition elements are discharged. For various reasons, it may be necessary to alte out a screwdriver for connecting to a 220 V network. Such a modification is relatively easy to carry out independently in various ways, for this you do not need special tools. Depending on the selected option, making changes will require different temporary and financial costs.

The battery screwdriver in power is worthily competes with network analogues, but only while charging its batteries is at a sufficient level. When the battery sits down, he needs recharging from the network. This factor is the first drawback of this power tool.

The second minus is considered limited number of reloading cycles. Over, the cheaper the battery block (battery), the faster its operational resource is exhausted. The acquisition of a new battery at a price is almost comparable to the purchase of a whole power tool. It also makes no sense to buy a new battery instead of the old, if the battery.Type screwdriver itself is outdated and is rarely used. It will be more practical to adapt the power tool for power from the network 220 V network.

Making changes will make it possible to further operate this tool with a minimum level of financial investments. The created alteration will have all Advantages of network devices:

- The need to perform periodic charging will disappear;

- The power of the power tool (torque) will not fall during operation;

- No need to worry about the proper storage of equipment during long.Term non.Working periods: it is enough to put it in a case in a dry place.

These advantages, as well as small expenses, compensate for the inconvenience related to the presence of the cord.

To make a network from the battery screwdriver, you need a power supply (BP), which can be placed in two ways: in the form of an external supply unit or mounted inside the old battery case.

For the practical implementation of any option, the following will be needed A set of tools and materials:

- Screwdrivers with different tips;

- Screwdrivers with different tips;

- Pliers;

- Kusachki;

- Solder with a set for soldering;

- Insulating tape;

- Wiring for jumpers taken, for example, from a multi.Core cable;

- Multimeter;

- Knife.

Features of a screwdriver device

Screwdriver and its main parts: 1. Cartridge; 2. Torque regulator; 3. Rotation switch; 4. Button for starting and stopping the electric motor; 5. A battery body; 6. Switch of rotation of the electric motor shaft; 7. Latch to hold the battery with a tool

Information to the products. The appearance of a conventional battery for the Rapid installation of threaded joints was facilitated by the appearance of compact cylindrical batteries. In 1982. The first sample was presented at the exhibition in Dresden (GDR). Then they looked at an interesting homemade and admired. The price was embarrassed. She reached 500 German brands (GDR). Then it was believed that not every user dare to buy this for permanent work.

Few people could assume that in 20 years the price of such a tool would be quite acceptable for production. Later they will be bought by home masters for mechanizing work in everyday life.

To remake the tool, it will have to disassemble it, so it is useful to know the internal device.

The internal device of the screwdriver: 1. Electric motor; 2. Button on, combined with reverse; 3. Battery block; 4. Gearbox; 5. Clutch of torque adjustment; 6. Cartridge

For disassembly, you need to unscrew the screws, with which the two halves of the case connect the product into a single whole. Will have to put the blade of the screwdriver in the end and open the halves. All installation is performed on the part in which the screws are injected.

When assembly, it is necessary to control the position of the protruding elements. Perhaps additional methods will be required to fix mobile parts.

Block: 2/6 | Summer characters: 1663Source: https: // metmastanki.RU/Peredlat-Kkumlyatornyy-Shurpovert-V-Setevoy

Power supply options for power supply

You can use the standard charger for this purpose. Here’s how to make a network from the battery screwdriver: you need to perform the following:

- From the housing of the charger, you need to remove the lid.

- In it you need to make a hole for the connected two.Wire wire.

- On the board you can see the terminals to which the battery battery used to be connected. They need to connect the veins of the cooked wire to redo the screwdriver for such work. In this case, it is necessary to take into account the polarity of the terminals. To determine it, you need to view the inscriptions on the board or on the device case.

- It is necessary to open the body of the screwdriver battery and extract all galvanic elements from it.

- It makes holes for the wire.

- The wires that were soldered to the terminals of the charger are connected in compliance with polarity to the output contacts of the battery.

- After the case is assembled, the tool can be used.

Although it is recommended to carry out the power to connect polarity, nevertheless, if you connect contacts in a different order, this will mean that here is how to redo the battery screwdriver on the network. The direction of rotation will change to the opposite. Most screwdrivers have the possibility of switching it, which makes it possible not to depend on the observance of polarity when switching.

Using charging from laptop

The charger from the laptop can be replaced for this tool, making only minor changes. He at the entrance receives an alternating current voltage from the 220V network, and at the output gives a constant current of 12V.

However, it will still be necessary to finalize the wires:

- The plug used for the laptop is not suitable for a screwdriver. Therefore, it will be necessary to cut the wire leaving the charge, and clean it.

- If necessary, you need to attach the cable of the desired length to it.

- The tool case needs to be disassembled.

- The cable is connected to those terminals from where the power supply is supplied to the screwdriver. In the tool case, you need to make a hole for it.

- Tool after it is collected, will be ready to work.

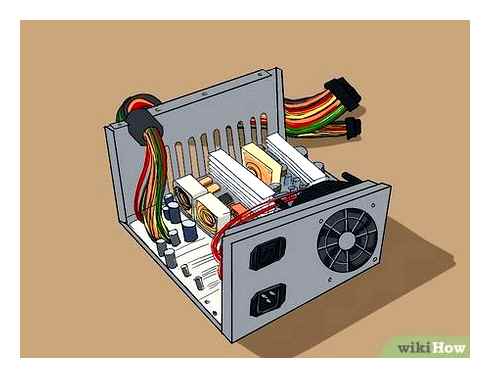

The power supply from the computer as the basis

You can make a power supply so that it uses a computer power supply. Here’s how to make a power supply for a screwdriver: for alteration in this way, you need to do the following:

- You need to find or purchase a power supply, the power of which will be at least 300 watts.

- The screwdriver case needs to be disassembled and the location of the wires for power power is found. They are connected to the veins of the cooked wires in advance.

- In the case, you need to make a hole for the output of the wires.

- To connect to the power supply, special connectors are required. One of them is soldered to the wires coming from the screwdriver, the other is already installed on the wire, which is connected to the computer power supply. This is necessary in order to power a screwdriver from the network

- Now we need to assemble the body of the screwdriver.

Now it remains to check how the tool works. To do this, you need to connect the power supply to the 220V outlet, and include a screwdriver in it.

Power from the charger of the car

You can redo this tool so as to receive food from a car battery. In this case, autonomy increases, since it will be possible to use a screwdriver in the immediate vicinity of the car.

In order to redo the voltage voltage of 220 V, you need:

- Disassemble the tool case. In this case, you can see the contacts to which the power should be connected.

- It is necessary to prepare the wires that are used in order to charge automobile batteries. They have Crocodile clamps on them. Other ends need to be carefully cleaned with a knife.

- The wires are attached to contacts to power a screwdriver. They can be attached by screeds or soldered. The last option will be more reliable.

- In the tool case, you need to make a hole for the wires.

- Now the hull of the screwdriver needs to be assembled.

To complete the work, you will need to connect the wire using clamps to the car battery.

Homemade power supply

Having made a power supply for a screwdriver with your own hands according to one of the schemes, it needs to be inserted with a case and connect with wires to the tool engine.

Network block built into the battery

One of the options for alteration of the screwdriver in the network is that the power supply, which converts an alternating current of 220V into a constant 12V, can be placed directly in the battery housing. To do this, you need to perform the following actions:

- It is necessary to disassemble the body of the nutrition element.

- The contents are removed from it.

- Previously, you need to purchase a power supply that has the characteristics necessary for the work of a screwdriver.

- It is necessary to extract the system fee from the purchased device and install it in the case, where there was previously a screwdriver of the screwdriver.

- The output wires join the battery contacts.

- For the input wires for which a voltage of 220V will arrive, you need to make a hole in the housing.

- Now the screwdriver needs to be assembled.

After the changes made, this tool can be used where there are electric sockets.

How to connect to a charger

Before solving the issue “whether it is possible to charge a screwdriver battery”, you need to remember that the charger unit supplies a low voltage, with a large length of the wire the voltage is lost, so the connection through a meter cord with section 2 will be rational.5 mm2 and more.

- Wires are attached to the contacts of the charger unit. Spoiled nutrients are removed from the nest.

- A groove is made in the case, a cable is passed through it. The entrance place is proposed to be compacted with elastic material so that there is no backlash and the wire holds reliably in place.

- Since the nest after removal of unusual elements was lost in gravity, it is recommended to restore the balance with the tab in the released space of any cargo, otherwise the brush will be very tired during operation, eventually harming the health of the joints, ligaments.

- The cable and the previously attached wires are connected together, the case is collected.

Connect a screwdriver directly to the charger

Connecting a screwdriver to a charger. How to make power supply units from energy.Saving light bulbs?

The main advantage of the battery screwdriver. Autonomy. True, auto.Accumulators remain our client after a couple of months, stop holding exercises. Because of this, using the inventory becomes more difficult for our client, because after several twisted self.Tapping screws, the battery is completely discharged.

Naturally, there is an option to simply purchase a new battery, but it almost always stands so much that you begin to think about the acquisition of a screwdriver. The best way out will be the alteration of one battery (usually there are several batteries in the kit) to the power supply unit. There will be a way to work both from the battery of the battery and the mains.

Preparatory stage

Before proceeding to alteration, you must first find network block Nutrition for a screwdriver. It is better that he can fit into the battery body.

Additionally, it should be removed from the body that it remains to make our client a filling, and measure his inner place, since the dimensions are different from the outside and from the inside.

Then you should study the marking as it is also called an annotation on the tool body to clarify the power voltage. Then you will have to calculate the current use of a screwdriver without the help of others, because the manufacturers do not indicate such a parameter. True, for this purpose you should know the power.

To avoid calculations, you can find a power supply without special devices. On the issue of acquisition, see not only at the current of the charger, and on the battery capacity. For example, if a container It is 1.2 ampere hours. And charging. 5.5, then the current current must be approximately between these numbers.

Untils, ahead of time before finding a suitable power supply, you must first record the next one:

How to build a PC, the last guide you’ll ever need!

The network power supply for a screwdriver is certainly owed reliable, comfortable, light and compact. Even in the matter of acquiring such a tool, you need to direct attention on the falling load characteristic. For which the overload design is intended specifically, it will help to avoid damage to the tool. It is also important to control the availability of parts and simplicity of the design.

It is better to suspend your own choice on a pulse power supply, since it is more compact and easier if transformer. However, Chinese models are often marked with very high features. Russian PSU is used. But their very small efficiency and impressive sizes have their very small.

It is recommended to find this device In amateur and flea markets. When buying it, immediately discuss the possibility of a return with the merchant. At home, be sure to check the operation of the power supply. For this purpose, connect it to the tool, and try to tighten several screws.

A way to remake a screwdriver

After buying and checking the power supply, it will have to disassemble it. Excellent if the case is fixed with self.Tapping screws, not glued. In the latter case, a hammer will come in handy, which is tapped around the entire perimeter of the seam. Difficulties should not appear. If the tasks all the same, then take the knife, and set it with the tip down, tick carefully on the handle. The case will probably begin to disperse.

Further, soldering from the fork Conclusions and cord are separated. In the area where the battery was battery, you need to place the contents of the case. Later, a cord is removed through the hole here to perform work from the network and is soldered to the power supply. His exit joins the terminals, observing the polarity with all this. It remains only to assemble the case and connect the power supply to the screwdriver for testing.

By the way, if the battery body does not coincide in the dimensions with the power supply, then you will have to integrate a suitable nest in the device handle.

So that the voltage does not go to the battery at one time, you should connect the unit parallel to supplying outputs and put in the rupture of the plus wire the diode of the desired power. You need to install it minus towards the motor.

The use of a car battery

He will be a good candidate for connecting a screwdriver, especially when construction is carried out far from the electronic network. Enough turn off the clamps from the tool and connect their batter. Naturally, it should not be used in this mode for a long period.

Creating a transformer coil

There is another way to modernize the device in the network device. It consists in the manufacture of a portable power supply. A flexible cable is connected to the screwdriver, on the other side of which there is a fork.

True, you will have to do a very very power supply or use a ready.Made transformer that is equipped with a rectifier. At least some, the main thing is that its properties coincide with the parameters of the tool.

It will be difficult for an inexperienced person to do at home Transformer coils. There is an option to just make a mistake in the number of turns and the choice of wire dialect, you should not do this. There are many unnecessary modern technology, in the design in which the desired transformer is already required of course. You just need to choose a suitable one and make a rectifier here.

Semiconductor diodes are used to solder the rectifier bridge. Fundamentally, so that their characteristics coincide with the device.

Another method for remaking screwdrivers

What to do if it is necessary to carry out repair and construction of work on the roof or street? In this situation, the battery should be changed to a more powerful. Batteries are suitable from at least some old technique. For example, they use a lithium battery in a laptop outstanding their own term for 2200 amperes.

Homemade power supply

When working with the soldering iron, you need to check the connection of the battery elements to the network and a home.Made unit, if there is a connection, it is necessary to de.Energize all power sources for safe operation.

The performance of work on the alteration takes place step by step, to get the result, you will need a little experience when soldering and installing boards:

- Disassembly and dismantling of the body of the old battery;

- In accordance with the scheme, install the elements on the mounting fee, plunge contacts and connections.

- After soldering, check the output voltage with a multimeter.

- Collect a fee for the battery housing.

- Connect the corresponding wires to the outputs of the low voltage of the tool.

- Check the work by connecting the converted device to the network.

How to connect a screwdriver from a screwdriver of a screwdriver Urkomp.Ru

Standard circuit of chargers for screwdrivers for 18 volts

All screwdrivers work from batteries. The average battery capacity is 12 mAh. And for the opportunity, he was always in good condition, a constant recharge is needed. For this purpose, you need a charger characteristic of each type of battery. But they are very different in their own way.

Currently released models for 12–18 in. It should also be noted that domestic manufacturers use various components for charger different models. To deal with this, you need to familiarize yourself with the typical scheme of these chargers.

Standard electric circuit charger

The basis of the standard scheme is A three.Channel type chip.

Four transistors are attached to this version on the microcircuit, very different in capacity and high.Frequency capacitors (pulsed or transitional).

For stabilization of current, thyristors or tetrods of open type are used. Current conductivity is regulated by dipole filters. This electronic circuit simply cooles with network overloads.

Principal scheme

The purpose of power tools immediately about making our daily work to the least painful and routine. In home life, a non.Replaced assistant in the repair or disassembly (assembly) of furniture and other household items is a screwdriver.

Autonomous nutrition Shuruzerte makes it more mobile and comfortable in the process of applying. The charger is a power source for any battery power tool, including screwdriver.

As an example, we will get acquainted with the device and the principle scheme.

For the principle schemes of charger devices of screwdrivers by 18 V, they are used transitional transistors several capacitors and a tetrod with a diode bridge.

Frequency stabilization is produced by a mesh trigger. 18.4 mKa conductivity of charging currents of charging. From time to time, to improve conductivity, they use chromatic resistors.

Capacitance of capacitors, in this case, is not suitable above 15 pf.

The design of the battery device for screwdriver

The “banks” of the battery are enclosed in the corps, which has four contacts, including two power plus and minus for discharge/charge.

Upper control contact Included through the termistor (thermal sensor), which protects the battery from overheating at the time of charging. With strong heating, it limits as it is also called disconnects the charge current.

Service contact is cut through a resistor by 9 kOhm, which smooths out a charge of all parts of complex charging stations, alas, they are usually used for industrial devices.

Standard and personal properties of the Electskol charger

- Charger devices of the Interskol brand use transitors with high conductivity. Their largest current load reaches 6 A, in new models and above.

In the standard charging device of the screws “Interskol”, a two.Channel microcircuit, 3 PF condensers, pulsed transistors and tetrods of open type are used. The current of the current is achieved by 6 μA, with the average energy intensity of the battery 12 mAh.

Workshop salary

How to finalize the block charger device of a screwdriver. Charge board: or this: how.

Elements of the power supply

The battery is the most expensive part of the screwdriver and is approximately 70% of the entire price tool.

By his readiness, it will have to be spent on the acquisition of an actually new screwdriver. If there are certain abilities and knowledge, it is possible without the help of others to correct the breakdown.

For this purpose, certain knowledge of the features and structure of the battery or charger is necessary for this purpose.

“Banks” are: lithium. Ion, nickel. Cadmium and nickel. Metal. Hydride. The first species voltage is 3.6 V, others have voltage. 1.5 V.

Battery malfunction It is determined by the multimeter. He will determine which of the “cans” failed.

Battery repairs on their own

When repairing a screw of screwdriver, you need to know its design and accurately find a breakdown place and a malfunction itself. If at least one element fails, the whole chain will lose its performance. The presence of a “donor”, which in which our client remains in order, as the new “banks” call him to solve this case.

A multimeter or lamp for 12 V will give a hint, what specific element is faulty. For this purpose, you need to put the battery to the working option of it charging. After that, disassemble the body and Determine the voltage all parts of the chain. If the voltage of the “cans” is below the nominal, then it is necessary to mark them with a marker.

Then collect the battery and let it work while his power falls. After a while, disassemble again and measure the voltage of the marked “cans”. Their voltage subsidence is more noticeable. If the difference is 0.5 V and above, and the element works, then it reads its imminent failure. Such elements need to be replaced.

Using a 12 V lamp, you can find faulty chain elements. For this purpose, you need to connect plus plus and minus on lamp 12 V to the contacts for the contacts.

The load made by the lamp will be Discharged the battery. Then measure the sections of the chain and determine the faulty links.

Repair (recovery in other words of the shift) is carried out by 2 methods.

- The faulty element is cut and the new. This applies to lithium. Ion batteries. Because it is forbidden to return their work.

- Nickel. Cadmium and Nickel. Metal. Hydrid elements of course to return, if there is an electrolyte that has lost the volume. For this purpose, they are stitched with voltage, also enhanced current, which helps to eliminate the effect of memory and increases the capacity of the element. Although it is impossible to remove the disadvantage one hundred percent. Maybe after a couple of weeks the malfunction will return. Another best option would be to change the failed parts.

Fault prevention

The batteries are made of several elements folded together, which come into a malfunction not at the same time, but in parts. To determine the broken part of the battery, it is necessary to fully charge it and let it work out at full power until discharge. Then, disassemble and measure the voltage of each individual element.

The parts on which the voltage will be absent or inferior to other elements must be completely replaced. Repair is carried out using a soldering tool. All elements of the battery are soldered by the same wired strip that parts were connected initially.

Tips for use

Experts of changing screwdrivers, who easily cope with the task, advise beginners to follow certain rules:

- A network screwdriver is able to function for several hours in a row, so let him five.Minute breaks to protect against overload.

- The wire must be attached to the elbow to prevent interference during operation.

- The power supply should be systematically cleaned from dust and dirt.

- The battery (new) is provided by grounding.

- Not recommended to use a large number of extension cords.

- Do not use a screwdriver in high.Rise work (starting from two meters and above).

Following these tips will help save the tool in working condition and extend its life.

Redistering scheme for a 220 screwdriver

When the screwdriver of the screwdriver finally became unusable, and it is not possible to replace the battery, the most optimal and budget solution remains. To convert it to the 220 volt network. Yuri Onishchenko examined which power supply is needed, what to connect and other points with the alteration. All the necessary radio components can be purchased cheap in this Chinese store.

The best option for feeding a screwdriver on the battery from the network

What is available to remake a screwdriver in our case? Food block for 15 volts, 6 amperes. There is also a computer BP, slightly converted, conclusions are drawn, but there are no changes in the diagram.

Power supply unit. Lamp power 12 volts, 50 watts. There is a charger for automobile batteries with a current regulator.

It will be used as a power source and as a separate ammeter.

Masters buy inventions in the best Chinese online store.

So, let’s get down. Let’s start connecting directly from the power supply. The conclusions are already connected. 12 volts, idle. 3 amperes. Maximum ratchet. As you can see on the device, the current reaches 8 amperes.

Try the BP laptop for fifteen volts, six amperes. Idle current 4 amperes. In rattles mode maximum current 9 amperes, voltage 14 volts. It turns out that the 6-ampers power supply copes with this task.

Electronics for home.Made people in a Chinese store.

The line of computer unit came. He calmly withstands the load.

A screwdriver connected to a 90 watt transformer easily copes with the screwing of large screws and drilling any materials.

After watching this video, it becomes clear that finding a power source for a screwdriver, which has become unusable, is not problematic. Finding a computer unit will not be difficult. An even more convenient option is a block from a laptop for 6 or more amperes.

It is advisable to find a device with a current of more than 10 volts, since 6-voltage will from time to time go into defense.

There are two screwdrivers at work, they were purchased and, with everyday use, the batteries lost the container and it is already useless to charge them, they sit down very quickly. They tried to remove the battery to reanimate, it did not work and had to make a power source and work on it in the workshop. So, we check how the screwdriver will show itself when working from a network with a computer power supply.

The block from the old computer was taken as a basis. It is 220 volts. Brought the wire with the connector to insert into the screwdriver. The convenience is that the device has a switch and indicator. Power supply is enough. 2.5 meters wire.

We test in the work. It screws the screws very well, drills holes.

It took about 1.5 hours to alte out the block. The test showed that the power supply is enough to screw screws into the pine tree, chipboard. Let’s try to drill a hole. How you are convinced, everything works. There are no overloads, smoke, etc.P.

How they redid the screwdriver for 12 volts in the network

To make such a device, almost any computer source has a generator on the TL494 chip. She has an analogue. This is the K 7500 chip.

A suitable block was found, his generator was made on the TL494 chip. But before starting to alteration, you need to make sure whether the working unit is. To do this, you need a 12.Volt bulb and a wire jumper. Each block has such connectors. The red wire is 5 volts, two black wires are minus wires, and the yellow wire is plus 12 volts.

We connect a car light to the 12th voltage line. This will be a kind of load and an indicator that says that the device is working.

There is another connector. We need a green wire and black. We need to close them to turn on the block and make sure that it is working. We will do this with a wire jumper. Connect 220 volts and close the green and black wires. As you can see, the fan spun, the bulb caught fire. This suggests that the unit is working and it can be redone.

We will analyze the diagram and redo the connection of the TL494 chip, as shown in the scheme in the journal article Radio, 2009, No. 1, p. 38. “Computer power supply. Charger.”This magazine can be easily downloaded on the Internet.

We do not need the whole scheme, but we need a knot responsible for connecting the microcircuit. Alteration in our case should be done in the same way as in this part of the scheme.

We make to remove all the protection from the block and allow the generator operation so that the unit works immediately and does not turn off when loading.

This is not enough for us to work with a screwdriver, we need to raise the voltage to 16 volts for a power supply. At the output in the circuit there is an electrolytic filter capacitor to 16 volts.

It needs to be soldered and the capacitor is 25 volts, since we will raise the voltage to 16 volts and the previously installed capacitor will not withstand.

In the circuit of the power supply, there may be a resistor to other parameters, but you should put a resistor by 3 kilooms. It is also necessary to replace the section of the circuit in the block, which goes on the 12 volts line.

Next, we connect the multimeter with the operating block to the line and with the help of a variable resistor we increase the voltage to 16 volts. After that, the alteration can be considered almost finished.

The wire must be soldered to the 12 volt line, you can display indicators, switches.

And I have a dead professional hitchi. I tried to write off my native charge directly. It is Smart, bastard, does not want! The loader does not see the load of the proper charge, and is cut off.

I had to put dead native batteries at the exit to the buffer. Result. I work endlessly from the network, then 5 minutes on dead cumulators. Not very mobile, but for free.

Scheme for 220 in

It’s not so difficult to do. First of all, you need to find out the voltage and current of the tool and choose the desired mode. Looking for in search of the characteristics of your brand of a screwdriver and we get the necessary information. Now we buy a lowering transformer or take it from the old electronics and collect a simple scheme.

DIY screwdriver power supply

Home »Boar of the Board» Nutrition of a screwdriver from the network with your own hands

Screwdriver refers to the most commonly used tools of tools.

This device is in demand for the performance of electrical and construction work, as well as for the assembly of furniture and other items, the design of which provides for the presence of threaded joints.

The battery screwdriver has advantages such as compactness and mobility. Nevertheless, many owners of this tool are often interested in how to redo the battery screwdriver in the network.

What is it connected with? When applying it, one has to deal with such a disadvantage as a low energy intensity, forcing the battery to charge every 40 minutes of intensive operation.

On the other hand, with a rare use of the device, spontaneous discharge of the battery leads to its breakdown due to the destruction of the constituent elements.

It is impossible to repair the battery into disrepair, difficulties can arise with the acquisition of a new one: often, components of the manufacturer are realized by components, and the cost of a new battery is slightly inferior to the price of a new screwdriver.

What advantages will a change of food type provide

Household screwdriver with a failed battery can be transferred to network power to some changes to its design. This will not require significant expenditure of funds, time and effort. At the same time, the advantages of this transformation of the tool are obvious:

- The need for regular charging the battery will disappear, and with it forced breaks in work, since the duration of this procedure is 3 hours or more.

- The unchanging value of the current force, which does not decrease as a result of the gradual discharge of the battery, will ensure the constancy of torque.

- If there is no need to use the tool, its prolonged simple will not lead to a deterioration in technical parameters.

The only disadvantage when working with a network screwdriver is dependence on the availability of a power grid.

Preparatory stage

Before starting work, you should prepare all the necessary materials. They are all inexpensive and on sale. Some structural elements, such as a battery or power supply, can be taken from old, no longer used devices.

Component Scavenger: ATX Power Supply

Before remeding the battery screwdriver in the network, make sure:

- Charger and battery (from the screwdriver itself);

- Soft multi.Lifetime cable;

- Soldering iron;

- Acids;

- Solder;

- Islands.

Selection of power supply

The power supply provides a transformation of alternating current, the voltage of which is 220 volts. Screwdrivers consume direct current with a nominal value of 9-19 V, so the connection to the network is performed using an electronic transformer, for this purpose it is better to use the products of TOSHIBRA and Feron brands.

The transformers of these brands are reliable in operation, quite compact, light, do not complicate the movement of the tool.

The design of the devices has 2 input and output wires, they allow for power to power halogen lamps and other types of electricity consumers with a voltage of 12 V.

Design features of electronic transformers

Increased scattering inductance provides a falling characteristic, additional galvanic denouement increases the safety of the power supply. A change in the number of turns of the primary winding can be adjusted to the output voltage, adjusting it to a certain type of screwdriver.

Thanks to the execution of the secondary winding from the middle point, it is possible to use not a diode bridge, but a two.Sulfur rectifier equipped with only 2 diodes instead of 4. This will reduce power loss by 2 times.

Capacitors C1 and C2 smooth out low.Frequency and high.Frequency pulsations, HL1 LED can be used to check the operation of the unit. The resistor R1 limits the value of the charger supplied by the capacitor, the load resistors R2. R7 provide the launch of the power supply unit.

Connection of the cable to the terminals of the charger and battery

Alteration of the battery screwdriver on the network requires the creation of a strong connection of the wire with the contacts of charging and the battery.

When performing an operation on a charger, a cable with terminals is usually connected using soldering, but it can be replaced by using Crocodile clamps like.

Before starting work, the surface of the soldered parts is treated with acid. You can also use a special solder.

When connecting a cable to the battery terminals, it is not recommended to use clamps. During operation, such fastening will be separated. The only reliable exit is to swing the ends of copper core to contacts.

It is most convenient to use the battery of the screwdriver itself. Previously, it is disassembled to delete the exhaust nutrition elements.

It is advisable to protect the skin of the hands and respiratory tract from the hit of harmful substances contained in the old filling of the battery.

Entering and fixing the cable in the battery housing

Then you need to clean the tool. The screwdriver at the location of the spent elements is treated with a rag moistened with a weak alkaline solution, then with ordinary water. To drain the case, it is wiped with a clean flap. After the moisture is completely evaporated, the ends of the cable are soldered to the contacts located on the inner wall in compliance with the polarity.

If it is broken, there will be a change in the direction of rotation of the screwdriver, and hence the position of the button switching reverse. To enter the wire into the battery housing, the hole is drilled in it. On the inside of the wall of the device, the cable is fixed using island and isolation removed from the wire of a larger diameter.

To prevent pulling and the wiring, the insulating shell is put on it and fixed on the surface with several layers of insulating tape. To exclude the displacement of the center of gravity, it is necessary to compensate for the change in the mass of the handle of the device with the addition of a counterweight. As it you can use a piece of pressed rubber.

Other methods of feeding

Block inside

The solution to the problem “Is it possible to connect a screwdriver through a charger” can be an alternative option for writing a screwdriver. Installing a power supply unit in the devastated body of the tool supply unit.

Before starting actions, it is necessary to prevent overheating of the block, for which holes are arranged in advance in advance, which will provide air movement, removal of heat. The time of continuous work with a screwdriver with such an improvement is advisable to reduce to 15 minutes.

A finished block is purchased, it is selected by the size of the case, technical indicators. The impulse version of the module is most suitable for use, it is small, light. The use of domestic production modules of the time of the last century is not recommended. They have large volumes with a small efficiency of efficiency.

Unsuitable nutrition elements are removed from the bed, a power supply is laid in their place. Contacts are noted, the case is closed. A collected hybrid gadget is ready to work from the network.

- The wires can be lengthened for convenience.

- It is necessary to monitor the quality of the assembly: the design should not be able to touch metal elements, otherwise the short circuit is not avoided. It is best to leave some place between the transformer and the board, which will positively affect cooling.

- If any parts of the structure are very hot, it is possible to install excessive heat of the modules, or the device of ventilation grooves.

On your own

For users with special knowledge, skills, the problem will not turn out to be difficult “whether it is possible to power a screwdriver from a charger without special means”, t.To. Assembling a nutrient unit is possible with its own hands. Instead of spoiled elements, the power module collected according to the scheme is inserted into the case. The outgoing voltage is measured, the wires are transferred, the case is locked.

Tip: the scheme may require an additional load, provide it with the inclusion in the 15W light bulb, which will also provide backlight.

The computer module is also suitable

Another solution to the problem of writing a screwdriver is to install it to the computer power supply. This option is applicable to such modules that are equipped with a mechanical switching lever. The positive aspect is that the block is cooled by the cooler, is protected from exaggerations of the load built.In special system.

Such an assembly is arranged only with the use of power modules at 300-350 W and an current of 12 volts, at least 16 A. For tools with a voltage of more than 14 volts, this recording option does not work.

The user may wish to hide an unaesthetic block into a beautiful case, then it is recommended not to forget to arrange ventilation in it.

Car charger

In search of a solution to the question “Can I connect a screwdriver to a charger”, you can stop by charging by a car ak block. The modules with manually adjustable current, voltage are applicable. The connection is absolutely not complicated. It is enough to connect the input channels of the tool motor with contacts of the car charger.

General recommendations

All of the listed methods include one stage that unites them. Disassembling the body of the supply module. If the skeleton is fixed on the bolts, then this is not a difficulty, fastening on the gap requires careful opening of the seam by tapping the gap with a hammer, deepening the knife into it.

During installation, observe the direction of the voltage. It should not be supplied to the battery. Therefore, the module is mounted in parallel to supplying contacts, a diode illuminator for a certain power is built into the plus line.

Resume: to the question “can a screwdriver work from a charger” have a positive answer, and several solutions, however, caution, some scientific knowledge and dexterity are required.

Power supply options for power supply

There are several options for converting a screwdriver to work from the mains. The task is to write down the device electric motor using an intermediate source.

We use charging from the laptop

You can make a power supply 12 V for a screwdriver with your own hands without even having technical knowledge. It only follows Find an unnecessary charger from a laptop, which has technical characteristics similar to parameters for feeding screwdriver. The main thing is that the output voltage corresponds to the desired (12-14 volts).

To achieve a given goal, you must first disassemble the battery and remove faulty elements from there. Then the such manipulations follow:

- Take a charger from a laptop.

- Cut out the output connector, expose and carry out the end of the ends of the wires.

- Save the cleaned wires to the inlet wires of the battery.

- Isolate the rations to avoid short circuit.

- We make a hole in the housing so as not to squeeze the wire, and we assemble the structure.

Basic. A power supply from a computer

For the manufacture of such a device, you will need a block from a personal computer of format a. T. Finding it is easy, this is an old model of a supply device, which is easy to buy in any radio component market. It is important to know, that you can use a 300-350 watts with a current in a power circuit 12 in at least 16 A.

It is the block format blocks that correspond to such parameters. The power button is located on the housing of this device, which is very convenient when working. The cooling fan is installed inside and the protection circuit from overloads is mounted.

The procedure for the reconstruction of the block:

- Remove the lid of the case b. P. Inside we will see a fee with many wires going to connectors, as well as a fan.

- The next step is to turn off the protection against turning on. We find a green wire on a square large connector.

- We connect this wire with black from the same connector. You can make a jumper from another piece of wire, or you can just cut it briefly and leave in the case.

Then, in the output beam, we find a smaller connector (Molex) and make the following operations with it:

- We leave the black and yellow wires, and cut the other two briefly.

- For the convenience of location of the BP, when working, we solder to the black and yellow wires extension cord.

- The second end of the extension cord is attached to the contacts of the empty battery compartment. You need to do this by soldering, you can make a good twist, while it is necessary to strictly observe the polarity.

- We make a hole in the case so as not to squeeze the wire when assembling. The device is ready.

Power from the charger of the car

Having charging for a car battery, it is quite easy to make a screw for power supply. To make alteration, you just need Combine power terminals output of the charger with power engine power.

If there is a charge for charging with a smooth adjustment of the output voltage, then it can be used as an 18 volt power supply unit for a screwdriver.

Autonomous diet of a screwdriver

Manual tools can also be done in a building where there is no electricity. In such cases, the device is connected to the car accumulator or to any other power device suitable for parameters for the work of a screwdriver.

To connect a car battery, you need to take wires with crocodile clamps, expose one end and solder directly to the contacts of the tool electric motor. The second end is attached to the terminal terminals in compliance with polarity.

The principle of connecting a portable battery is similar to a car device. Only at the ends of the wires are copper clamping terminals suitable for fastening.

The electric tool is much longer than the battery. Therefore, you should not throw screwdriver if the nutrition elements have worked out their resource. A business man will be able to convert his power tool for food from the network, thereby extending his life.

Options for the power source

Any screwdriver requires much less voltage than a regular outlet issues. Therefore, for recharge, you will definitely need a special converter, at the output of which the necessary voltage will be obtained. All power sources are divided into two large groups: impulse and transformer. Consider each of them separately.

Impulse

The principle of operation of pulsed systems is that the voltage is first straightened, and then converted into a special pulse signal. At the same time, it is important to achieve stable voltage. A transformer winding or resistors can help this.

Impulse power sources are quite effective and can be used in different conditions. Over, they have a high level of protection against short circuit and similar effects. However, the pulsed systems clearly lose the transformer. In addition, such blocks are very moody to the input voltage. If it is below the installed, then the element may simply not work.

Transformer

Common power supplies that have proven their reliability and effectiveness in many areas. The device consists of a lowering transformer and rectifier through which a low voltage passes. Rectifiers can be different, depending on the number of diodes used.

Such elements are easy to manufacture, cheap and reliable. Therefore, it is often it is for them that they prefer. They provide stable voltage without interference with a high maximum power. But there are several disadvantages. The main drawback is cumbersome, with much smaller efficiency than in impulse sources. This fact requires to select a power supply for a screwdriver with power than the tool is necessary. Since part of the capacities will go to side processes.

Assembly of a serviceable battery of two that lost the capacity

Of the two faulty devices, one can collect one suitable for operation.

850W computer power supply. How does it work (with schematics)

Important! Having connected the power supply unit to the defective battery case, the second repaired will provide mobility when performing small volumes of work.

Search for faulty elements

The battery is assembled from individual elements. They do not fail at the same time, but even one faulty element worsens the work of the whole battery.

To determine the parts that have lost the capacity, it is necessary:

- Charge the battery;

- Work to loss of power;

- Disassemble the battery;

- Measure the voltage on each element separately.

Batteries on which the voltage will be noticeably smaller than others or at all, it is necessary to replace.

Battery repair

After determining and removing faulty parts, a device suitable for further operation is collected from the remaining ones. The connection is carried out by soldering, with wires with a cross section of 1.5 mm² or a strip similar to the one to which the details were connected earlier.

With insufficient amounts of working elements, we buy the missing or redo the tool for a network power 220 volts.

Knowing how to redo the battery screwdriver in network with your own hands will help save money and not purchase a new device.